Blast furnace gas, coke oven gas and converter gas mixing control method and system

A technology for coke oven gas and converter gas, which is applied in control/regulation systems, non-electric variable control, and simultaneous control of multiple variables, etc. The effect of less intervention, ensuring stable supply, and liberating labor productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

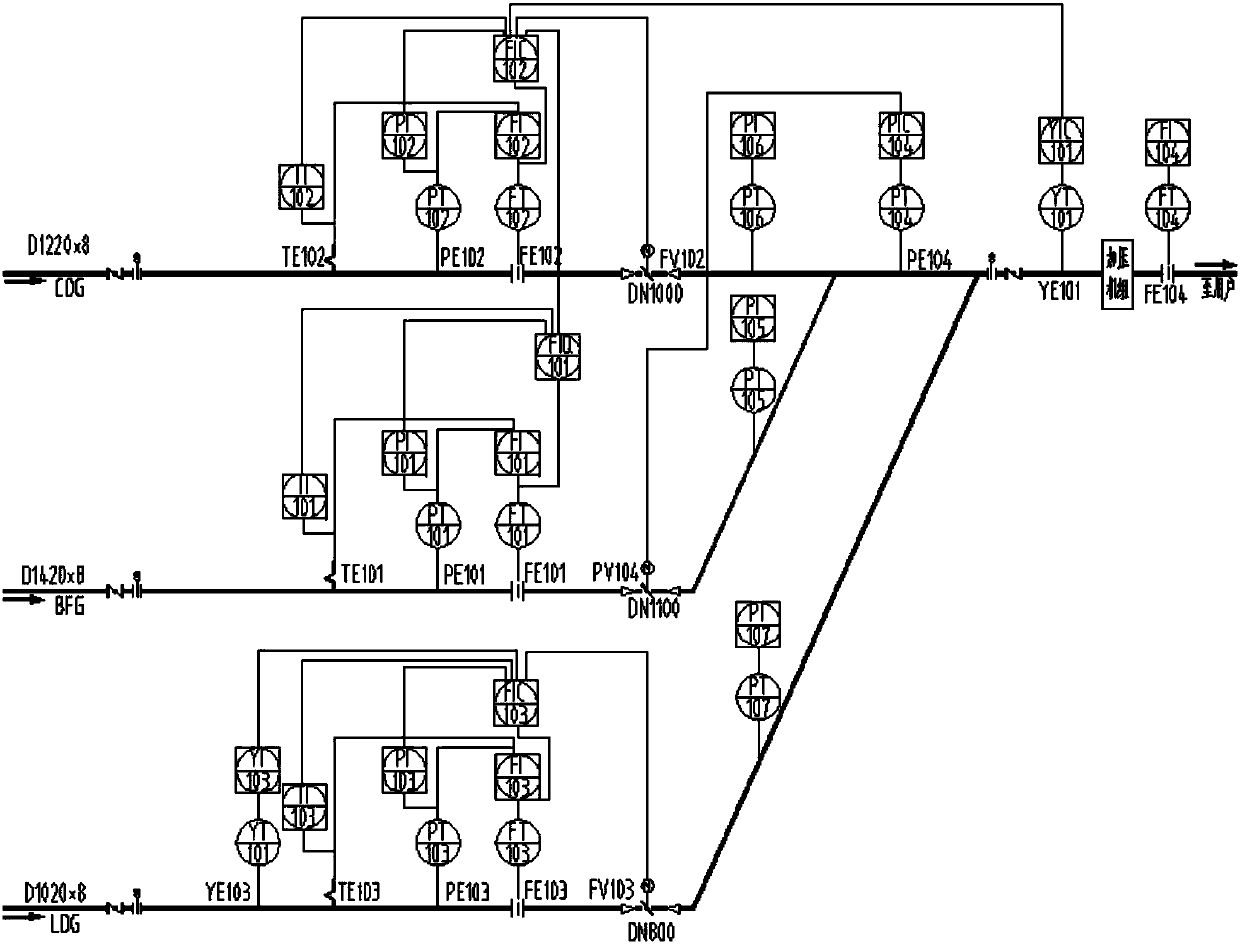

[0040] figure 1 From top to bottom, there are coke oven gas branch pipes, blast furnace gas branch pipes, and converter gas branch pipes. Each branch pipe is equipped with a regulating valve. The regulating valve PV104 on the blast furnace gas branch pipe is used to stabilize the gas pressure after mixing. When the total flow of users after the pressurizer suddenly becomes larger or smaller, the setting value of the gas pressure before the pressurizer, that is, after mixing, will be fine-tuned (automatically increased or decreased) on the original basis. , adjust the valve opening on the blast furnace gas branch pipe in time to partially eliminate the impact of the user's total flow mutation on the gas mixing pressure. The regulating valve FV103 on the branch pipe of the converter gas is used to adjust the flow of the converter gas. The fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com