High-speed reciprocating two-way servo wire tightening mechanism

A wire-tightening, high-speed technology, applied in electric processing equipment, metal processing equipment, electrode manufacturing, etc., can solve the problems of molybdenum wire tension, inability to correct and stabilize tension, accumulated error in molybdenum wire length, etc. Frequency real-time detection of intelligent two-way servo tight wire, good promotion and application value, and overcome the effect of different tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

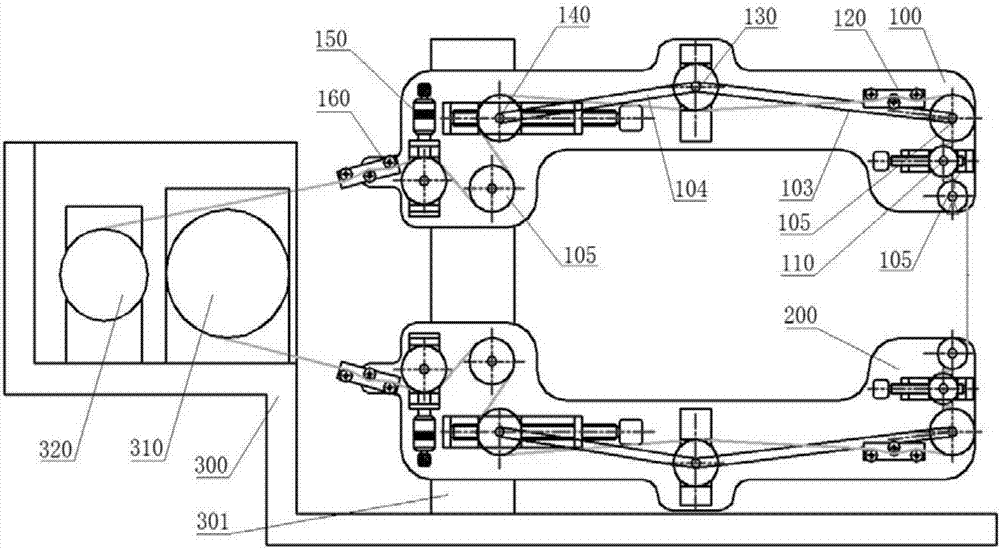

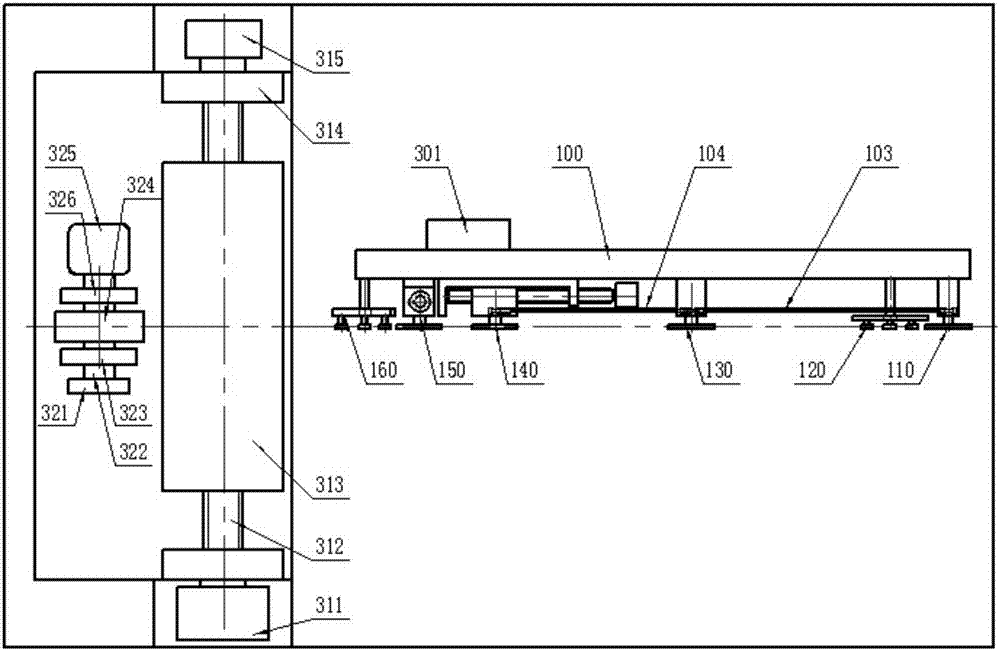

[0038] combine figure 1 , the present invention proposes a high-speed reciprocating two-way servo wire tightening mechanism, including a wire feeding mechanism 320, a wire drum mechanism 310, and a wire discharging mechanism arranged on the wire cutting machine bed 300 in sequence, and the wire discharging mechanism includes two groups of the same plane The link combination mechanism set in mirror image, the two sets of link combination mechanisms are respectively fixed on the upper and lower wire arms, the wire arm is fixed on the machine bed 300 through the bracket 301, the end of the wire arm is threaded with the bracket 301 and can be mounted on the bracket 301 moves up and down.

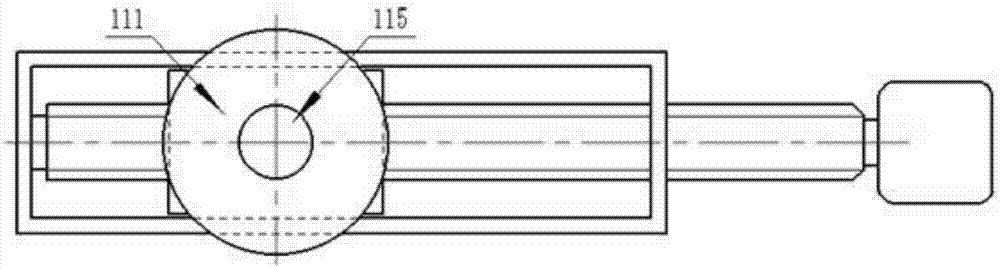

[0039] The connecting rod combination mechanism includes a manual wire tightening mechanism, an automatic wire tightening mechanism, a sliding mechanism and several fixed guide wheels for changing the direction of wire discharge arranged in the same plane for the electrode wire to pass through. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com