Special-shaped electronic component terminal shaping device

A technology for electronic components and shaping devices, applied in electrical components, electrical components, etc., can solve the problem of high cost of industrial robots, and achieve the effects of reducing labor costs, production costs, and resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

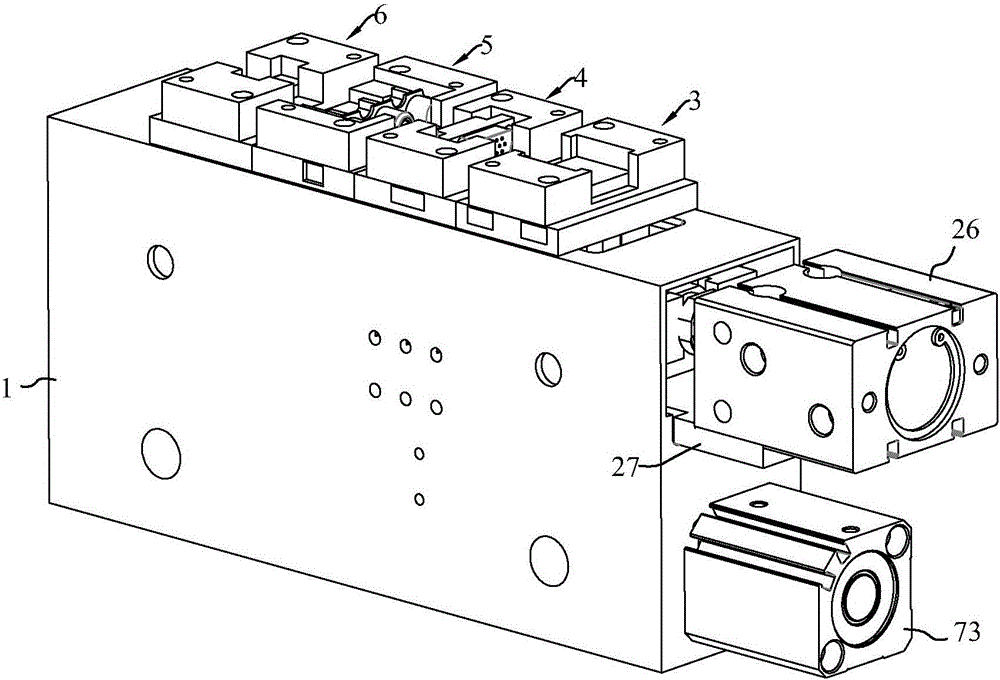

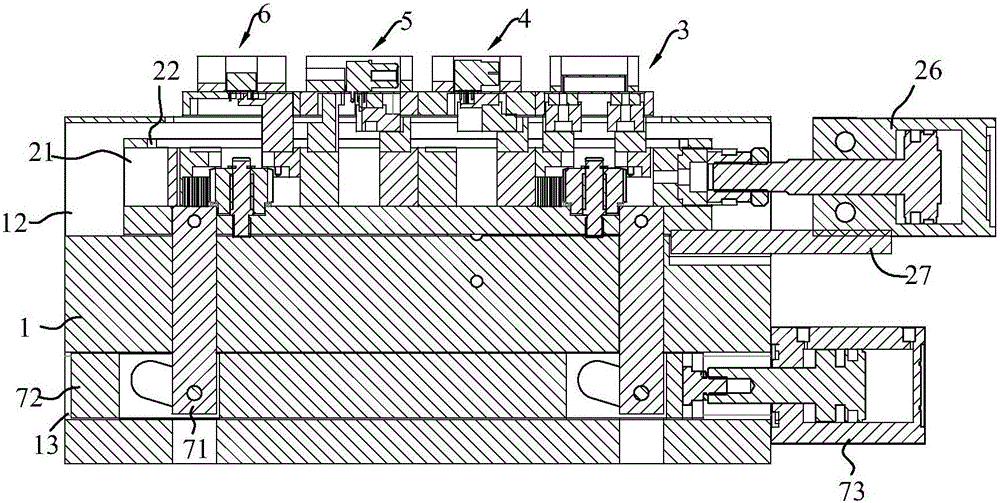

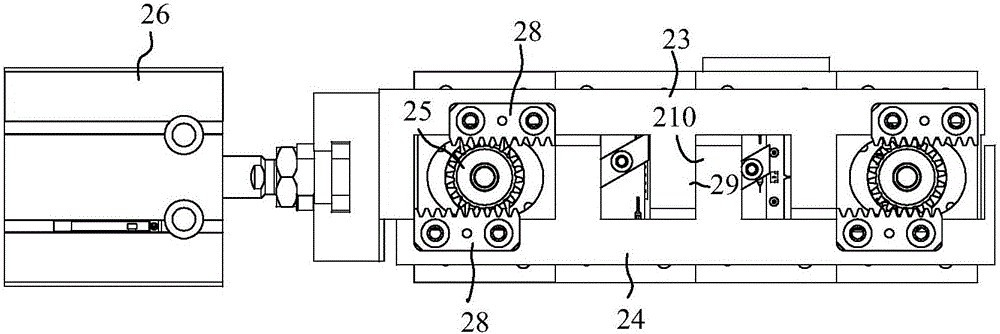

[0027] refer to Figure 1 to Figure 9 , which shows the specific structure of the preferred embodiment of the present invention. The structural characteristics of each element of the present invention will be described in detail below, and if there is a description of the direction (up, down, left, right, front and back), it is based on figure 2 The shown structure is a reference description, but the actual use direction of the present invention is not limited thereto.

[0028] see figure 1 , figure 2 , the present invention provides a terminal shaping device for special-shaped electronic components, including a shaping body 1 and a component placement plate and a shaping mechanism arranged on the shaping body 1, and the component placement plate is provided with a The limit groove, the component placement plate is provided with a placement seat 11 for fixing electronic components, and the placement seat 11 is provided with a component placement slot and an anti-loosening...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com