Composite ablation-resistant plate structure

A plate structure, ablation-resistant technology, applied in the direction of coupling devices, electrical components, circuits, etc., can solve the problems of high manufacturing cost of thermosetting molds, difficult to ensure structural size tolerance, high cost of parts, etc., to achieve good versatility and popularization and application Value, guaranteed flame ablation resistance, reduced processing difficulty and cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solution of the present invention is further described below in conjunction with the accompanying drawings, but the scope of protection is not limited to the description.

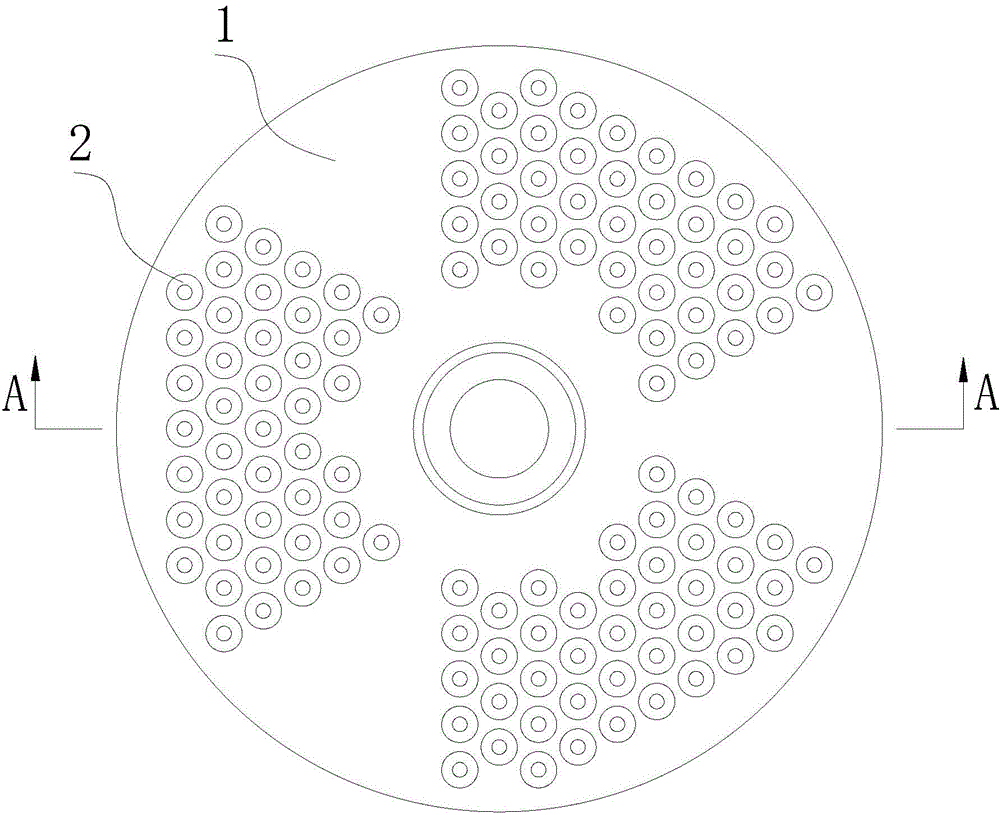

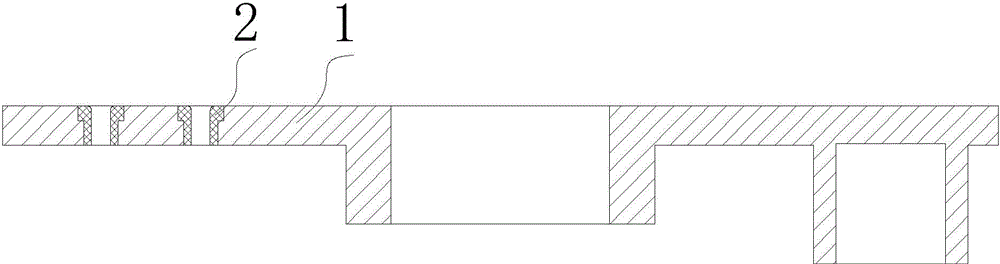

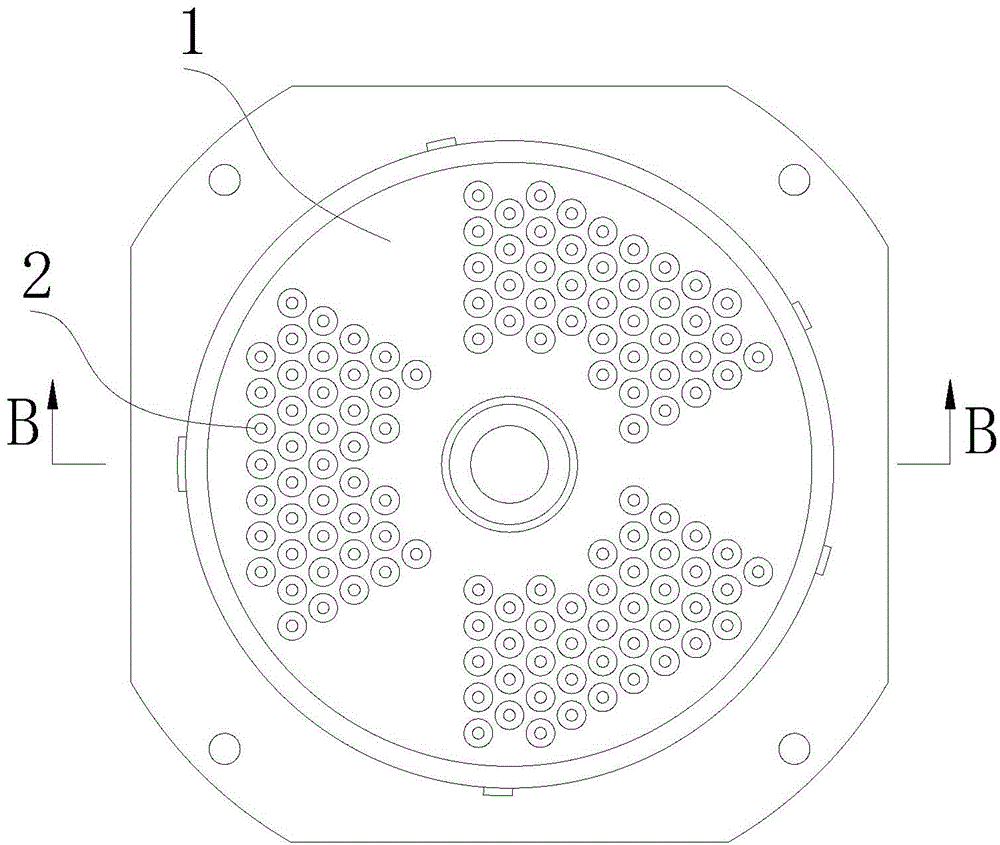

[0021] Such as figure 1 , figure 2 As shown, the structure of a composite ablation-resistant plate according to the present invention is mainly composed of a substrate 1 and a plurality of insulating sleeves 2. The substrate 1 is provided with a plurality of casing holes, and the insulating casing 2 is fixedly installed in the casing holes. . This technical solution replaces the traditional single material structure by using the combined structure of the substrate 1 and the insulating sleeve 2, thereby overcoming the shortcomings of processing the ablation-resistant plate with high-temperature-resistant plastic or ceramic materials alone, and ensuring the flame resistance of the ablation-resistant plate The ablation performance ensures the insulation performance between the holes of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com