Corrugated pipe threading device

A threading device and corrugated tube technology, which is applied in the direction of electrical components, cable/conductor manufacturing, cable laying equipment, etc., can solve the problems of low threading efficiency, high labor intensity, and difficulty in manual threading of cables, so as to improve threading efficiency and compatibility Good performance, reduce the effect of manual labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

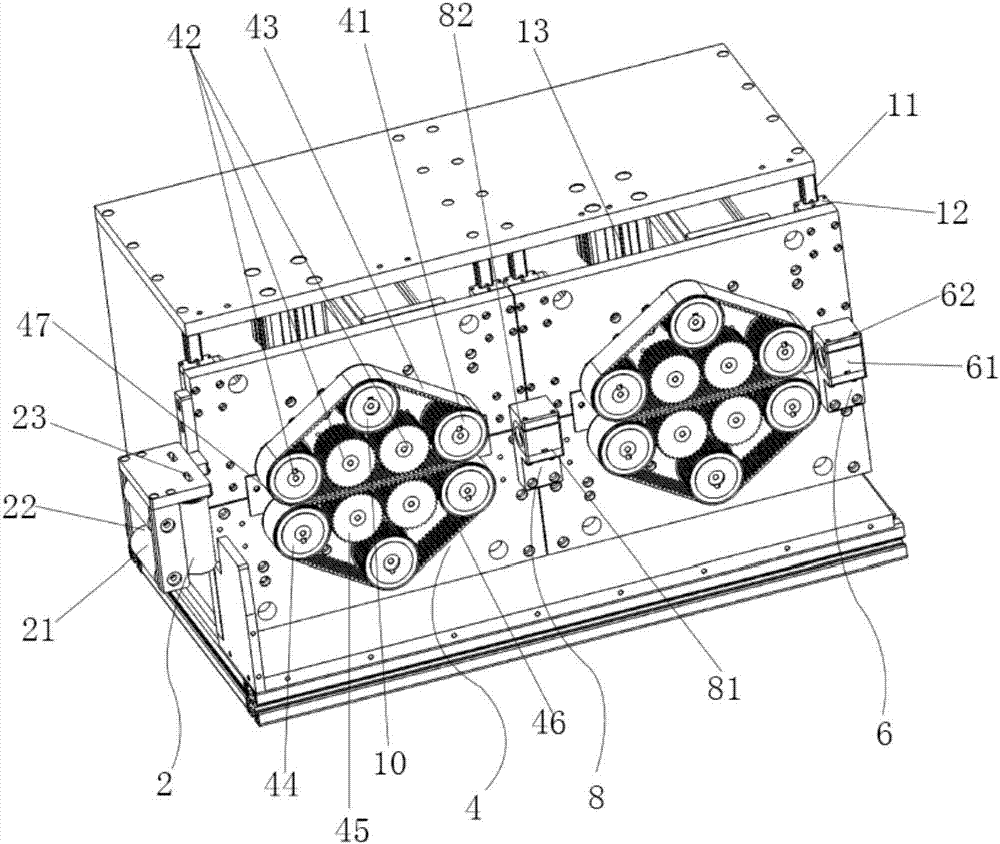

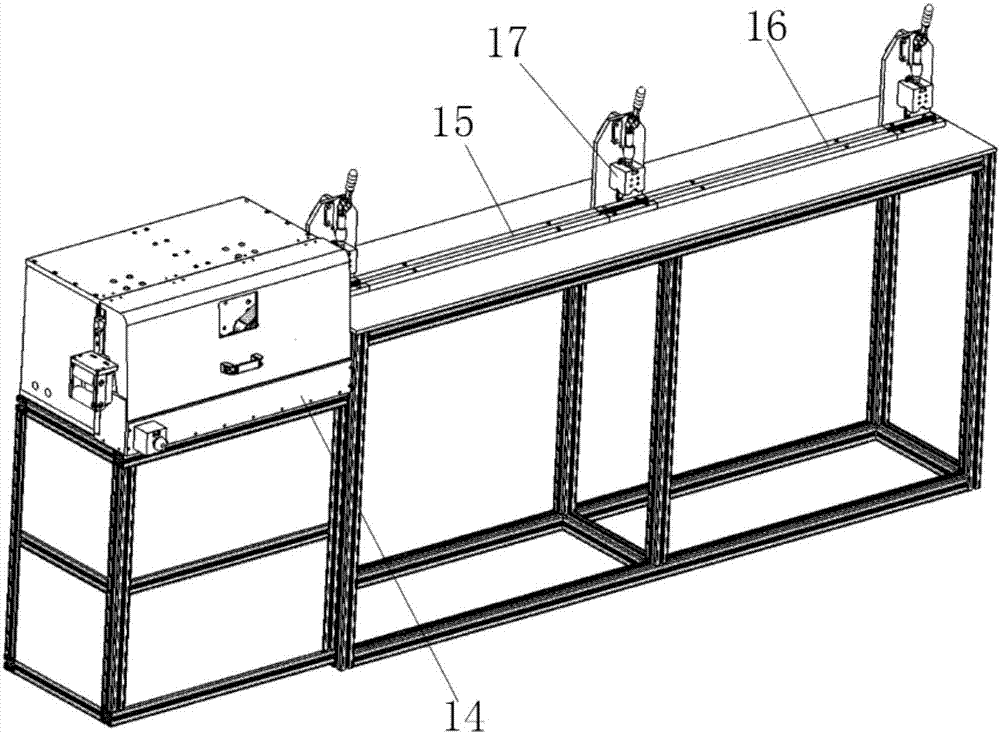

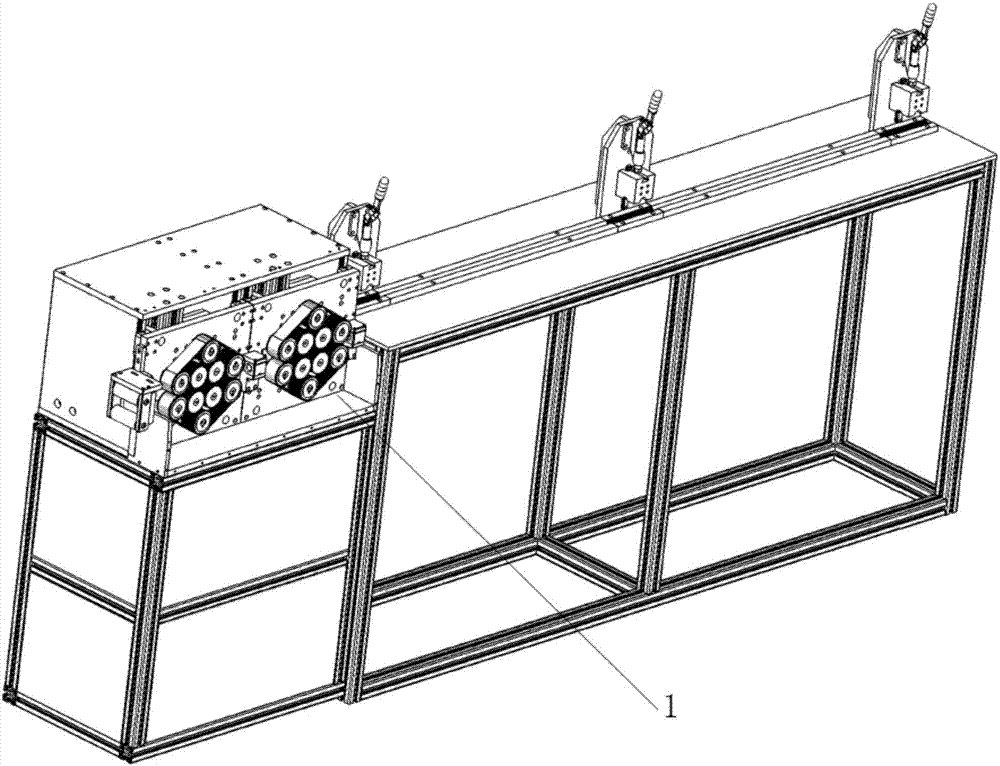

[0036] Such as figure 1 , 3 As shown, a corrugated pipe threading device is disclosed in this embodiment, which is used to automatically thread the cable axially into the corrugated pipe 15, replacing the current manual threading, and producing and obtaining the wire harness, which includes a machine 1, a cable The input guiding mechanism 2, the cable pulling mechanism 4 and the cable output guiding mechanism 6, the above-mentioned cable input guiding mechanism 2, the cable pulling mechanism 4 and the cable output guiding mechanism 6 are all arranged on the machine table 1 The above and the three are arranged in sequence along the moving direction of the cable. Driven by the cable traction mechanism 4, the cable is input from the cable input guide mechanism 2, and the output axially penetrates from the cable output guide mechanism 6. In the bellows, the cable input guide mechanism 2, the cable traction mechanism 4 and the cable output guide mechanism 6 are coordinated by the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com