Patents

Literature

299results about "Needle-threading devices" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

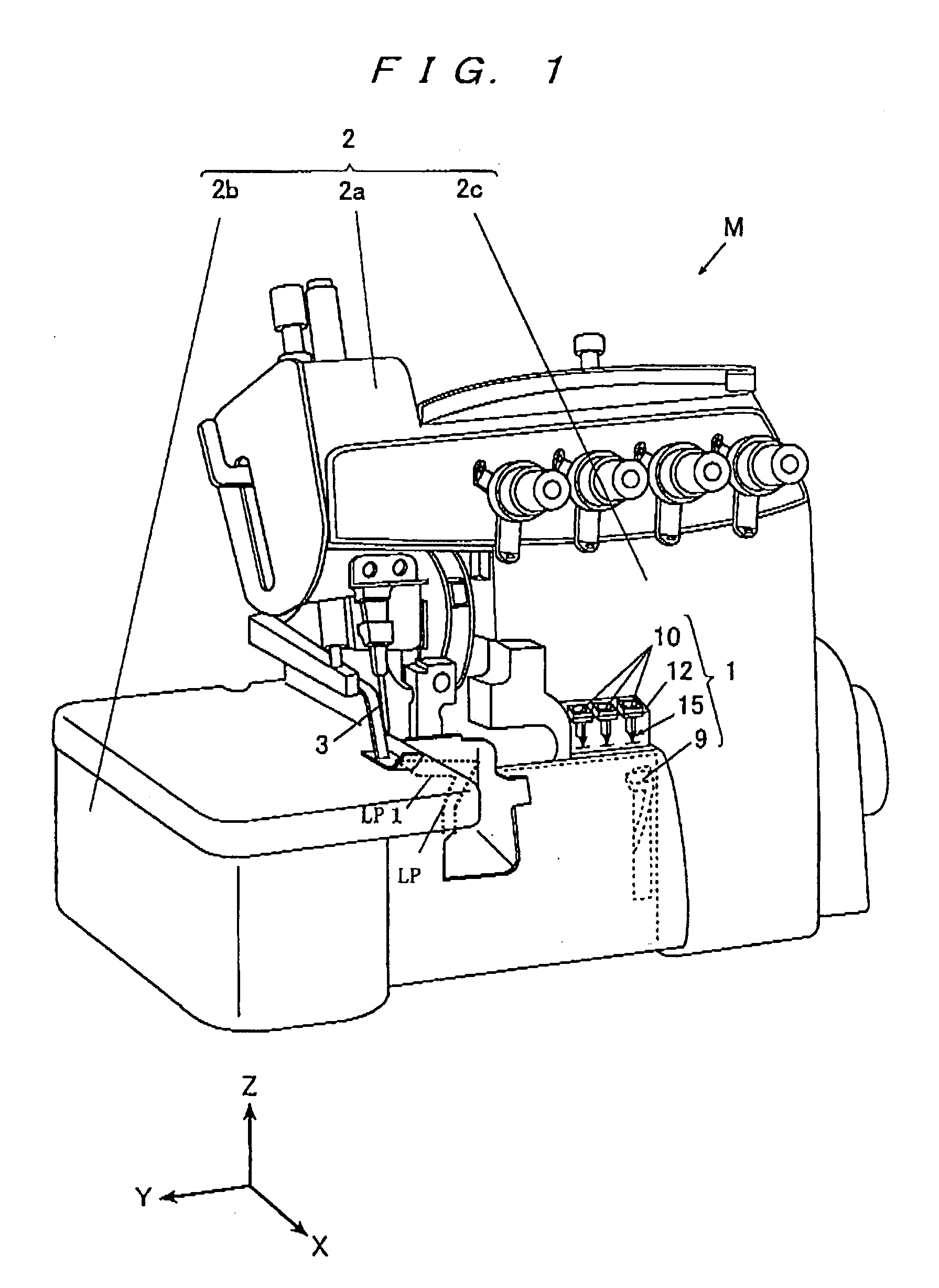

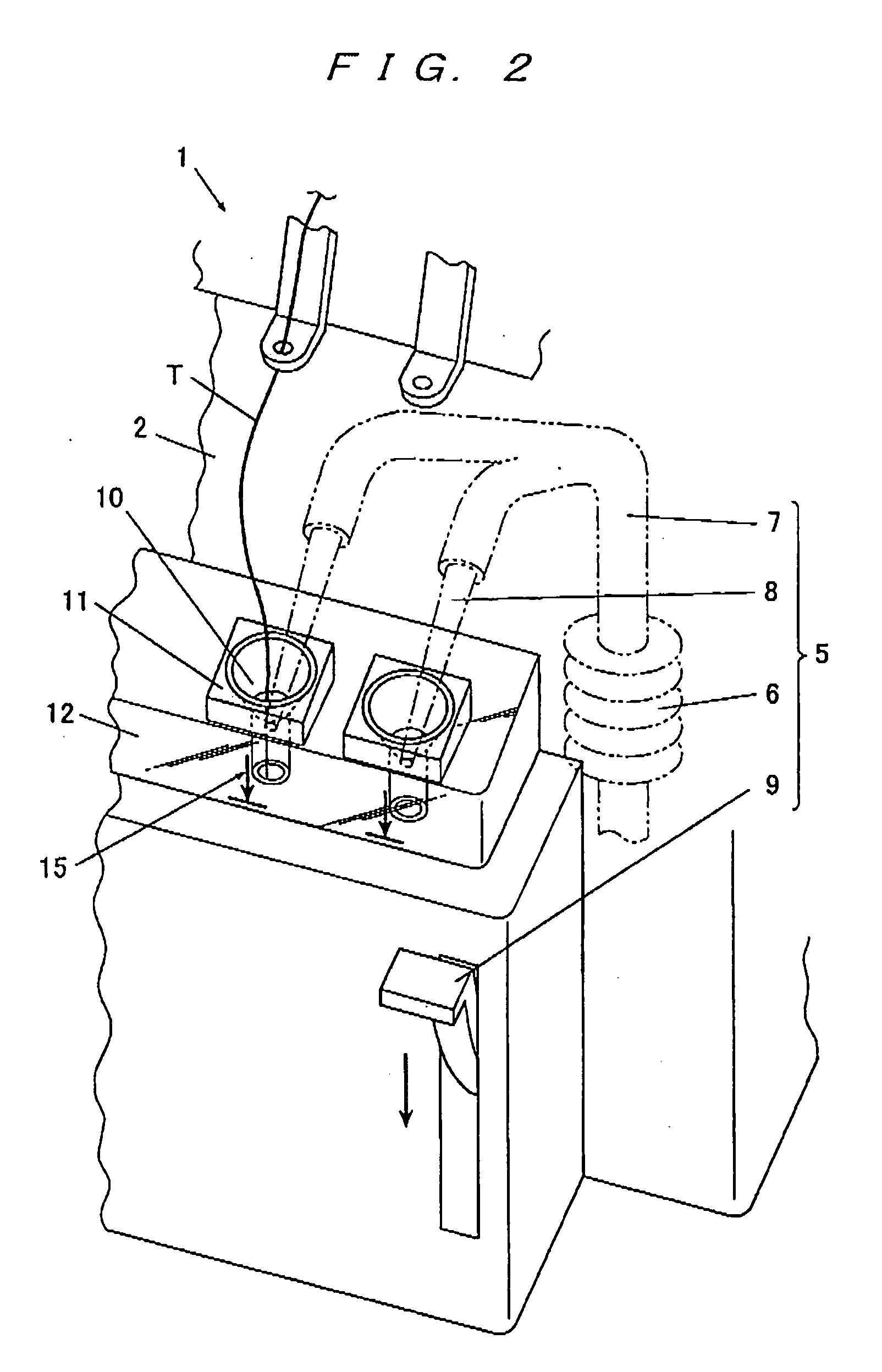

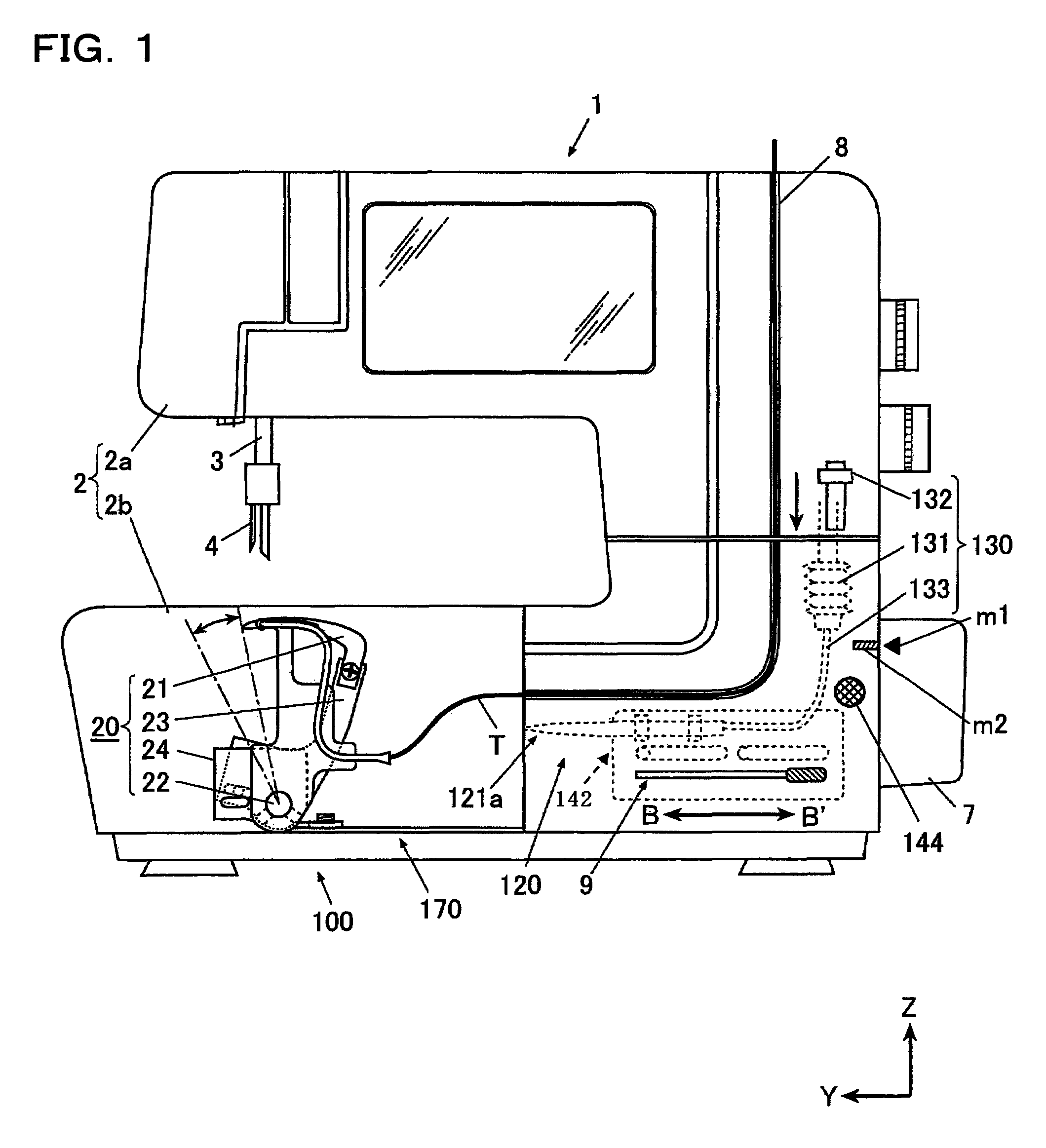

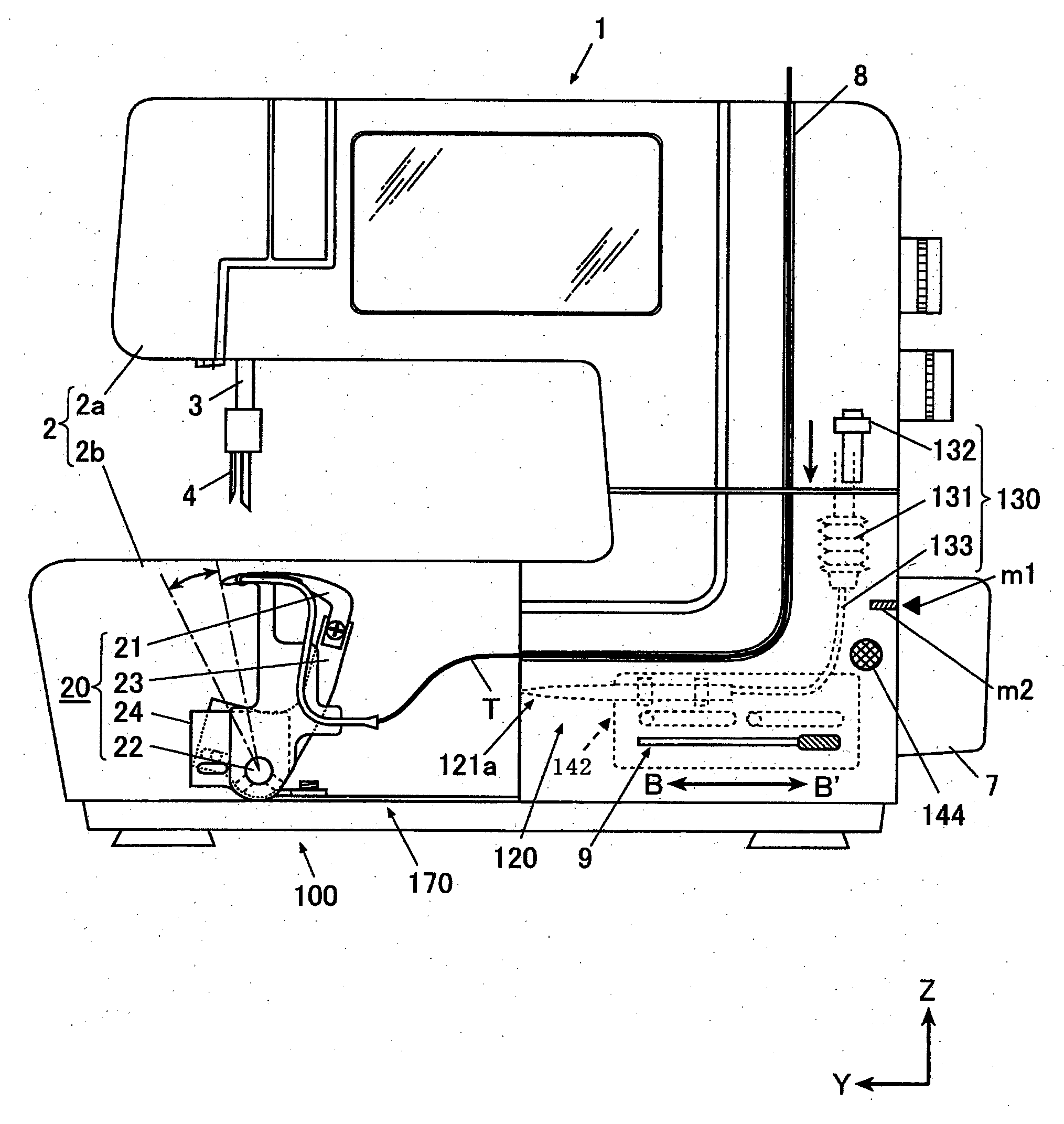

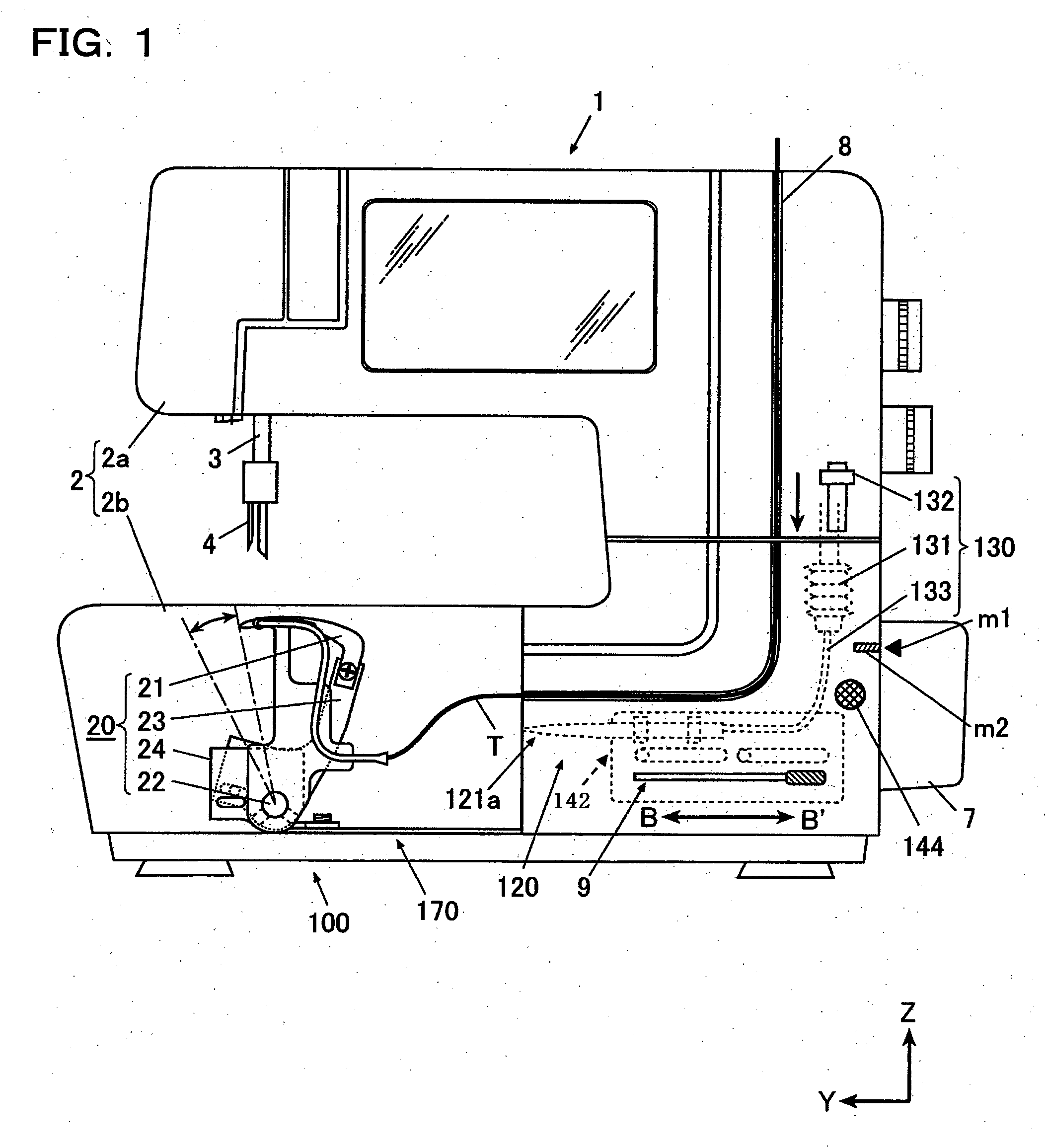

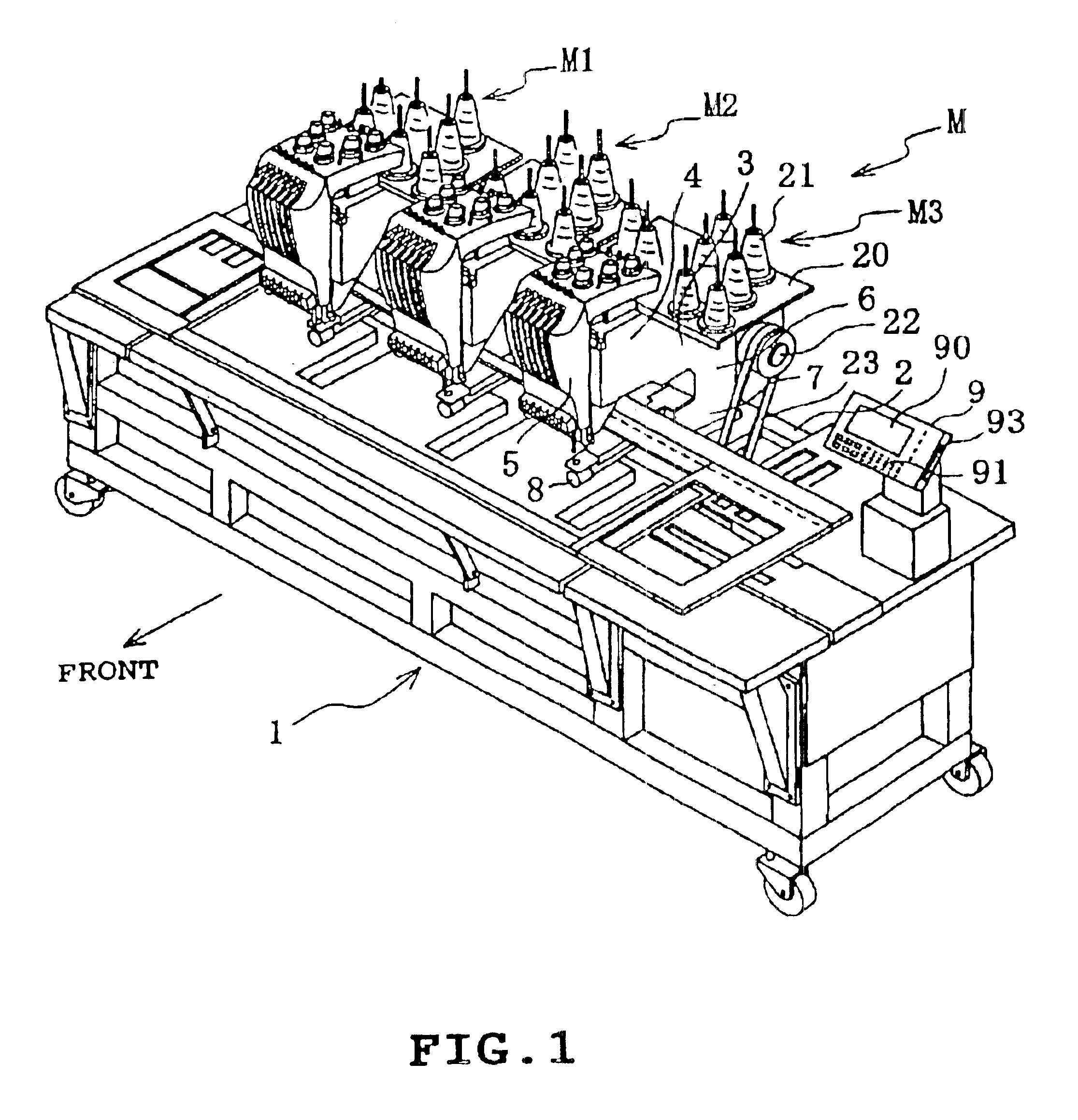

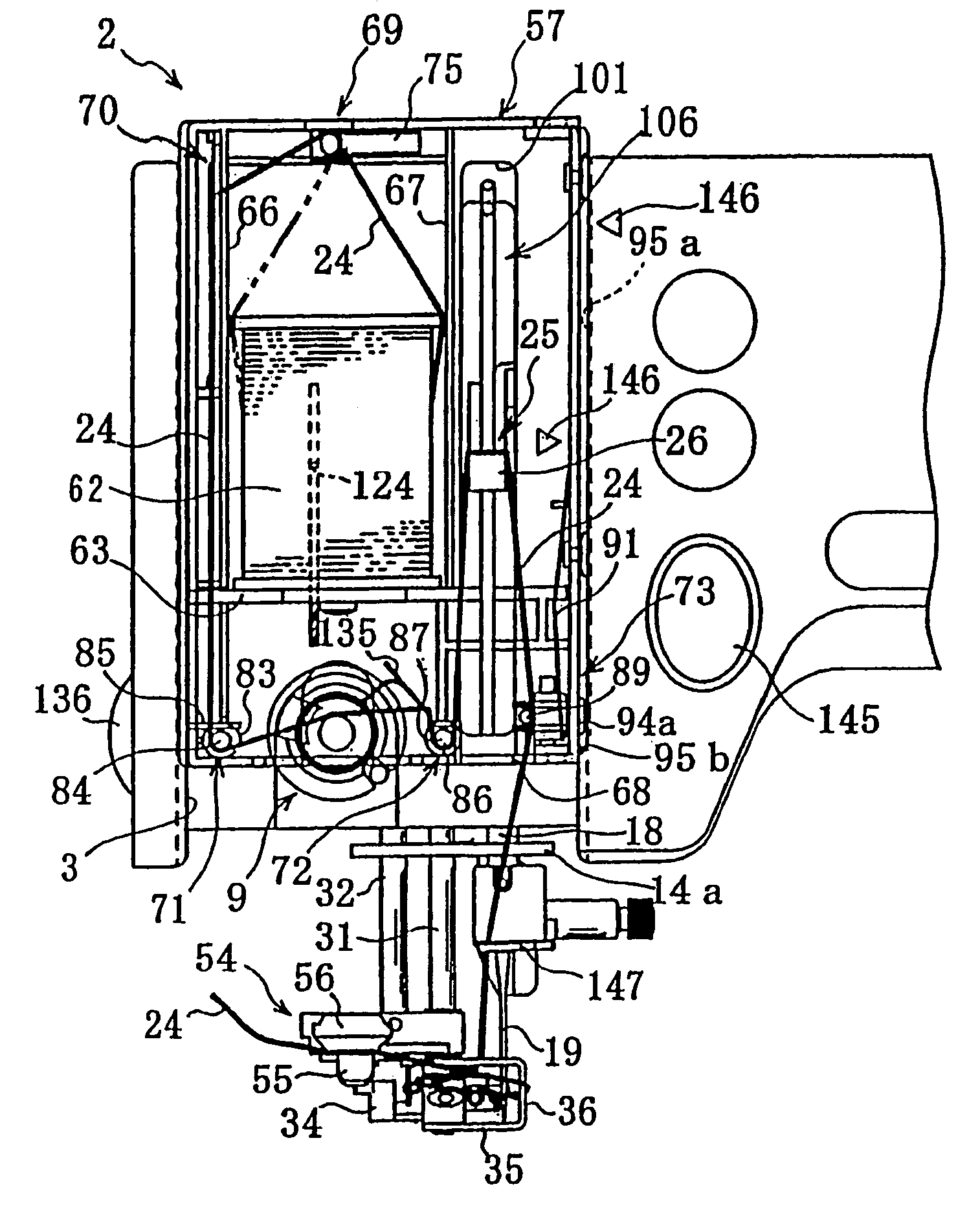

Gas Carrying Threading Device of Sewing Machine

ActiveUS20120210922A1Easy to handleEasy to operateThread-break detectorsNeedle-threading devicesTransmitted powerDrive shaft

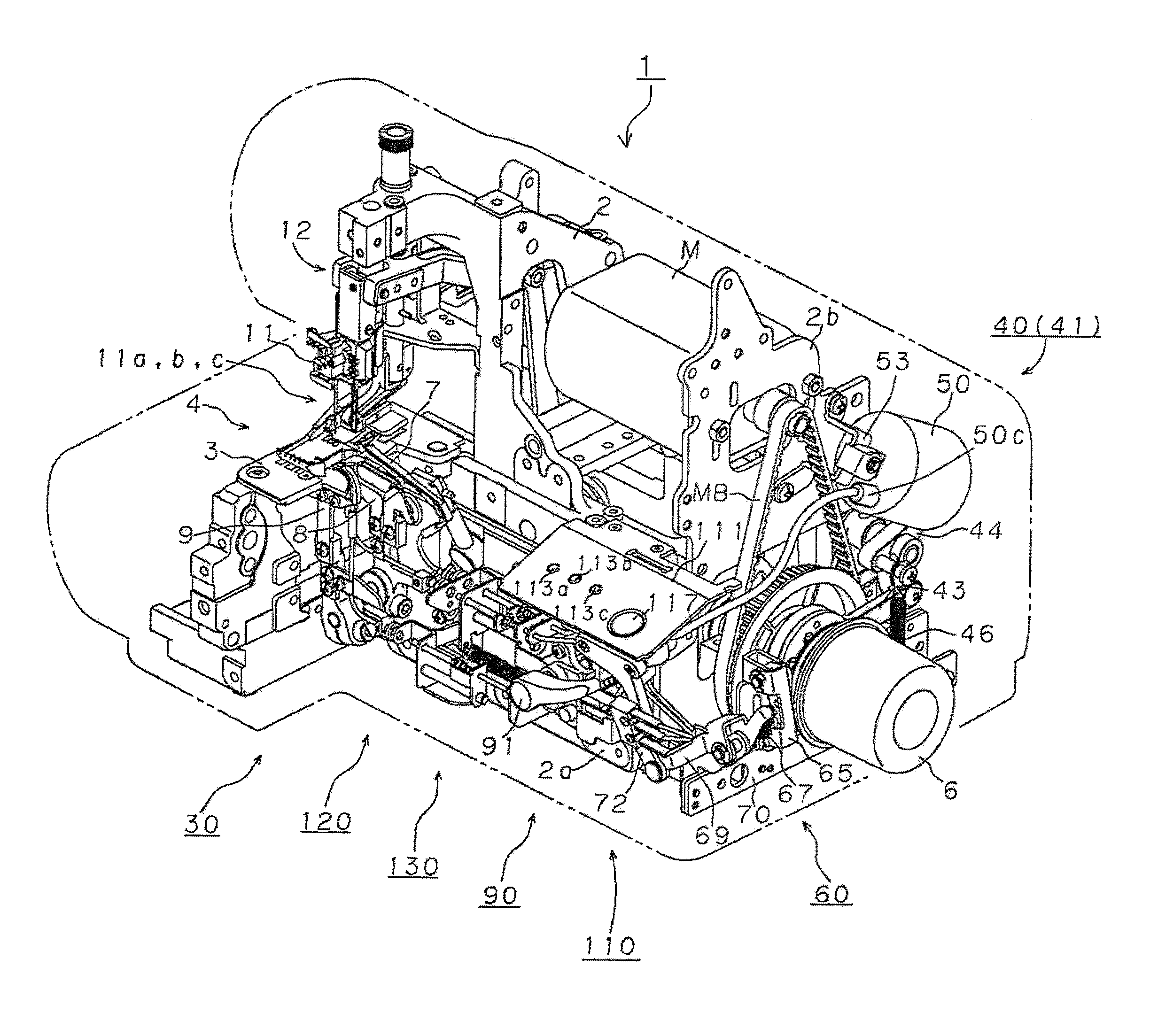

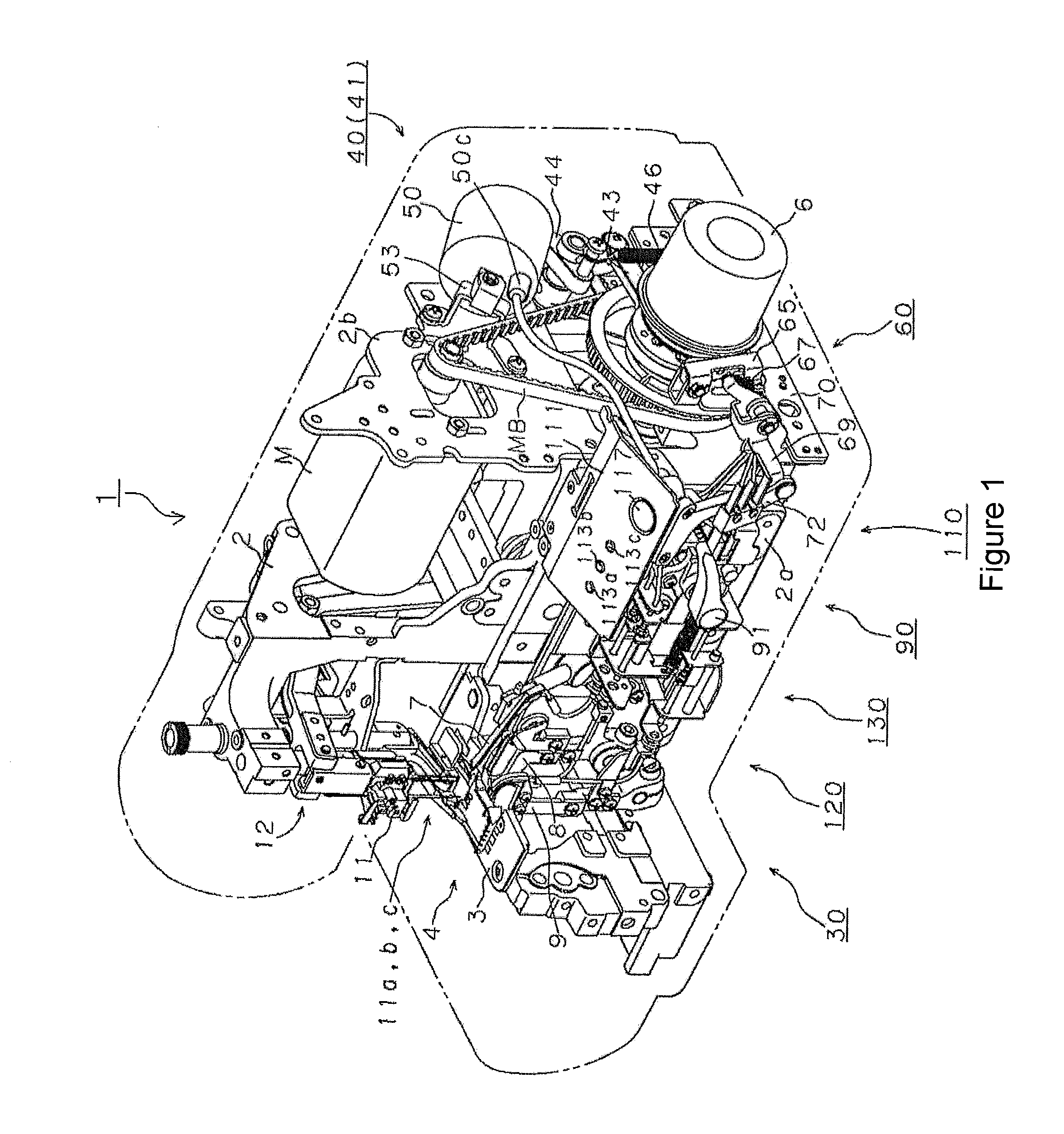

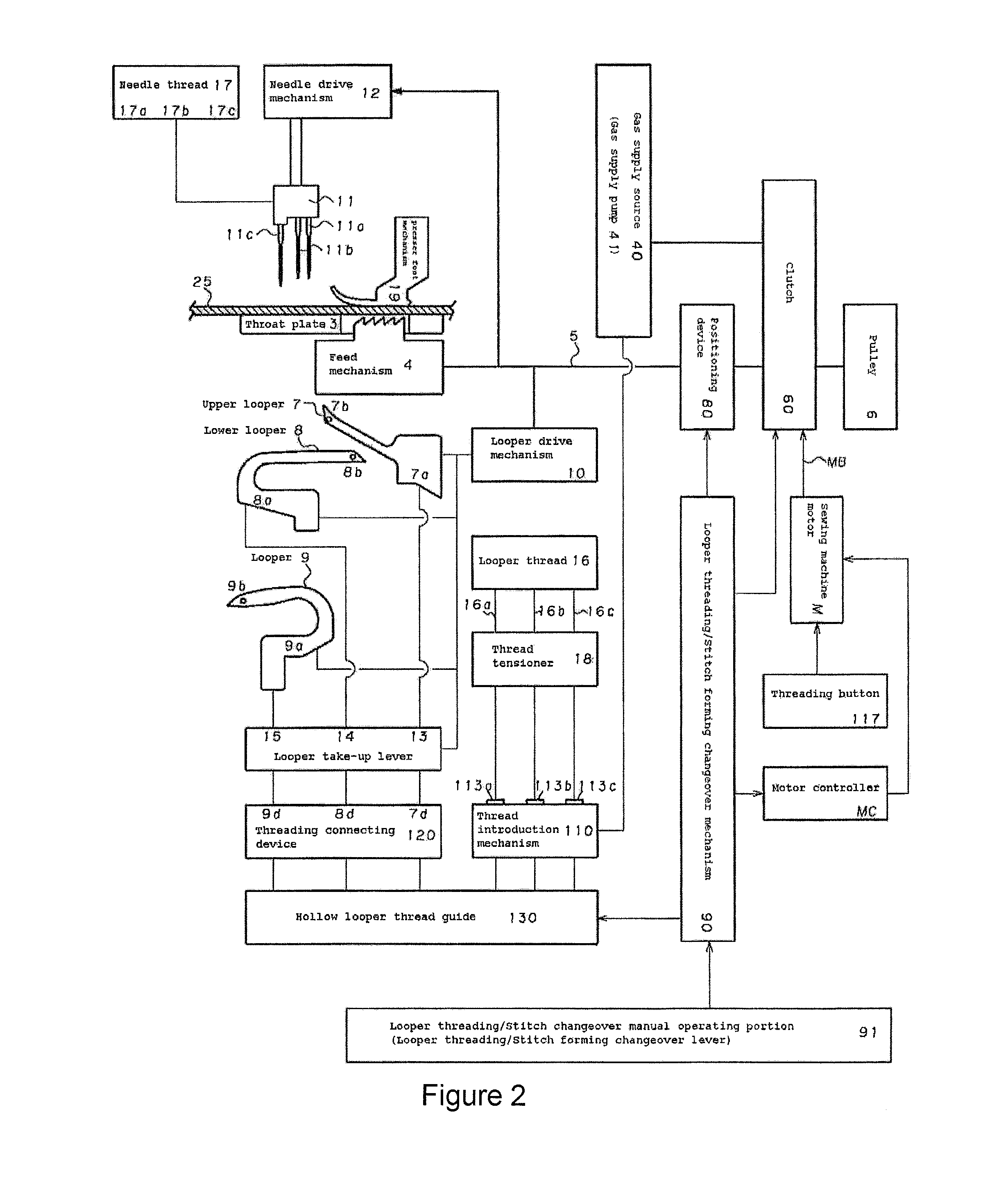

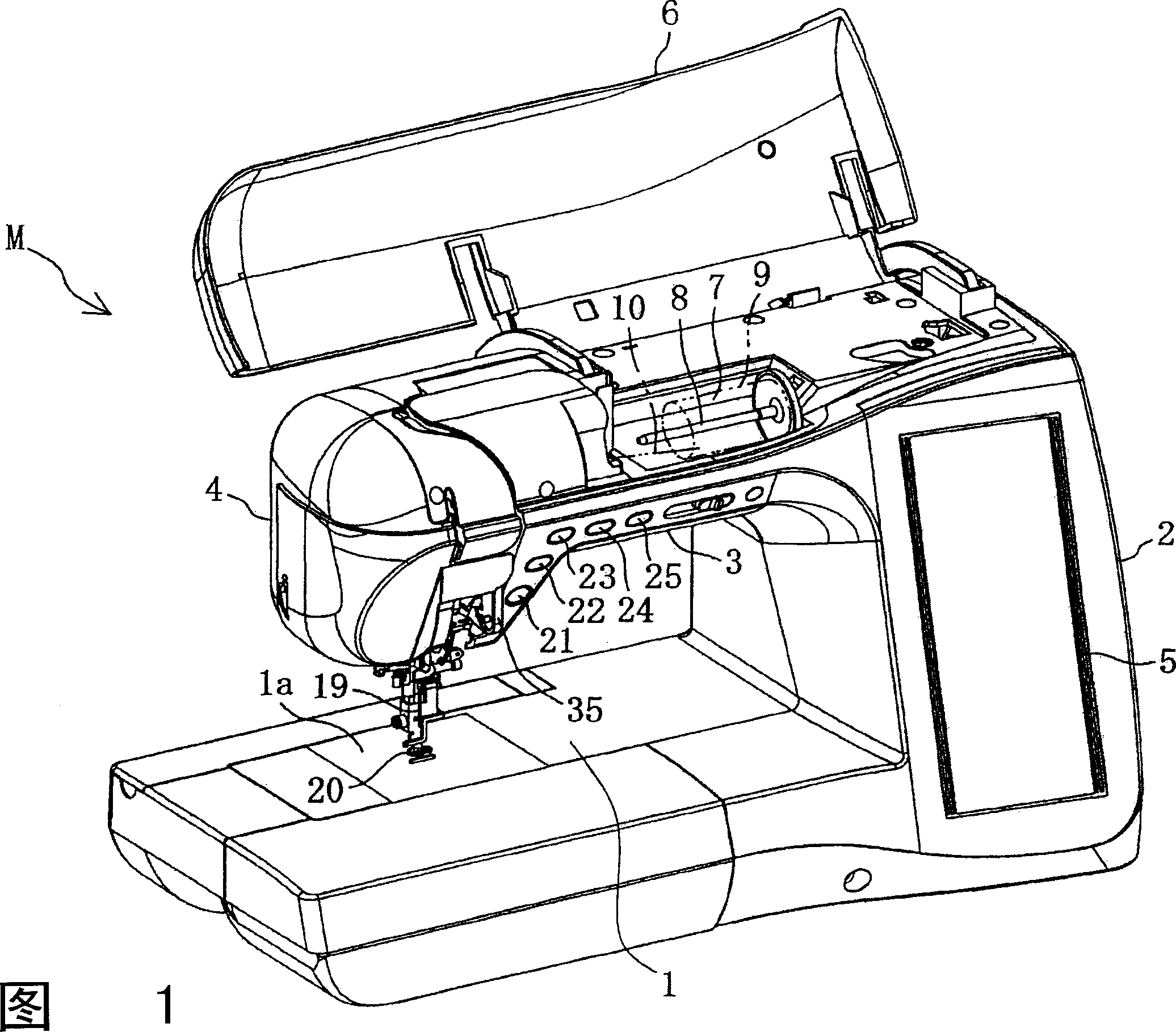

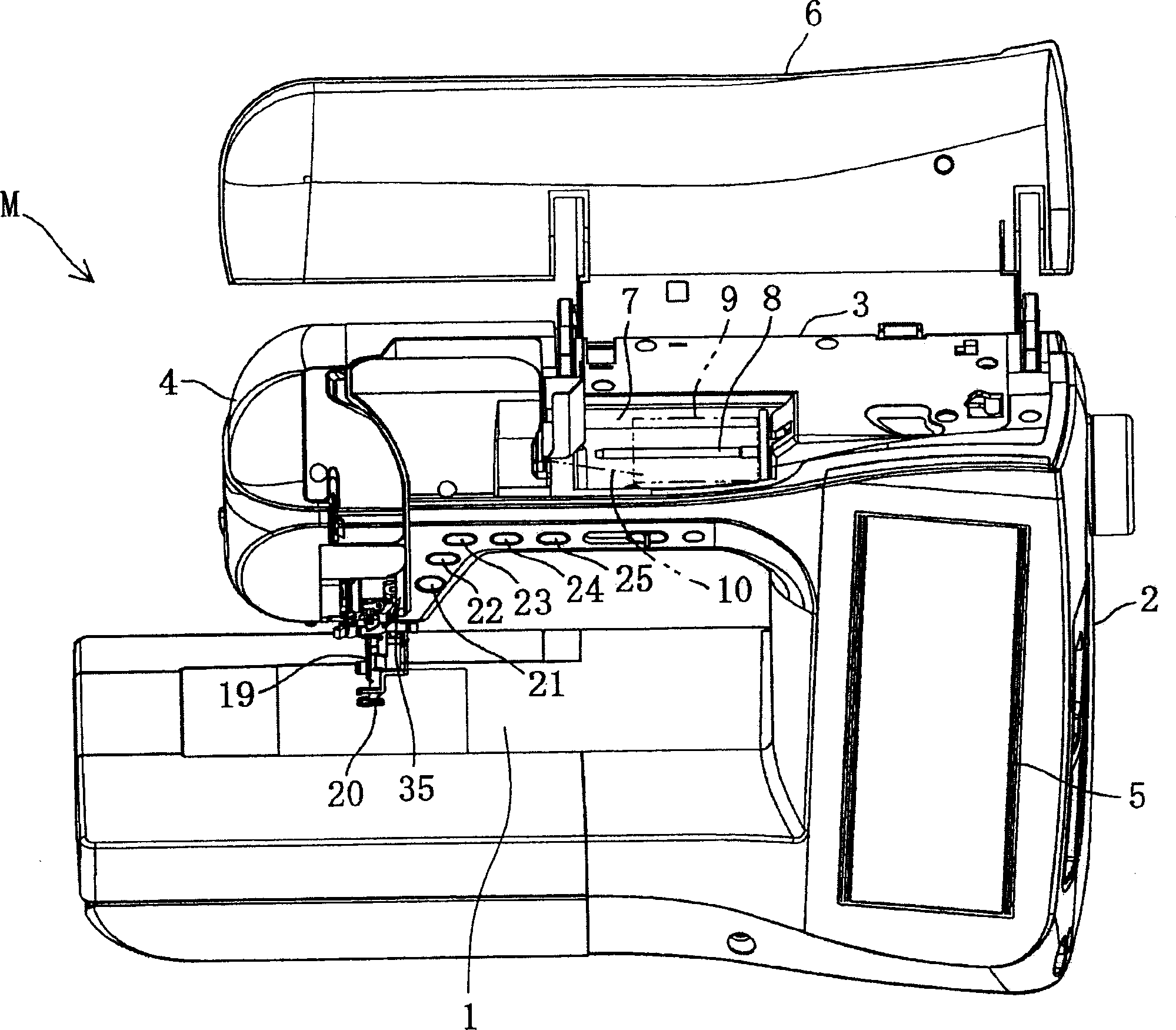

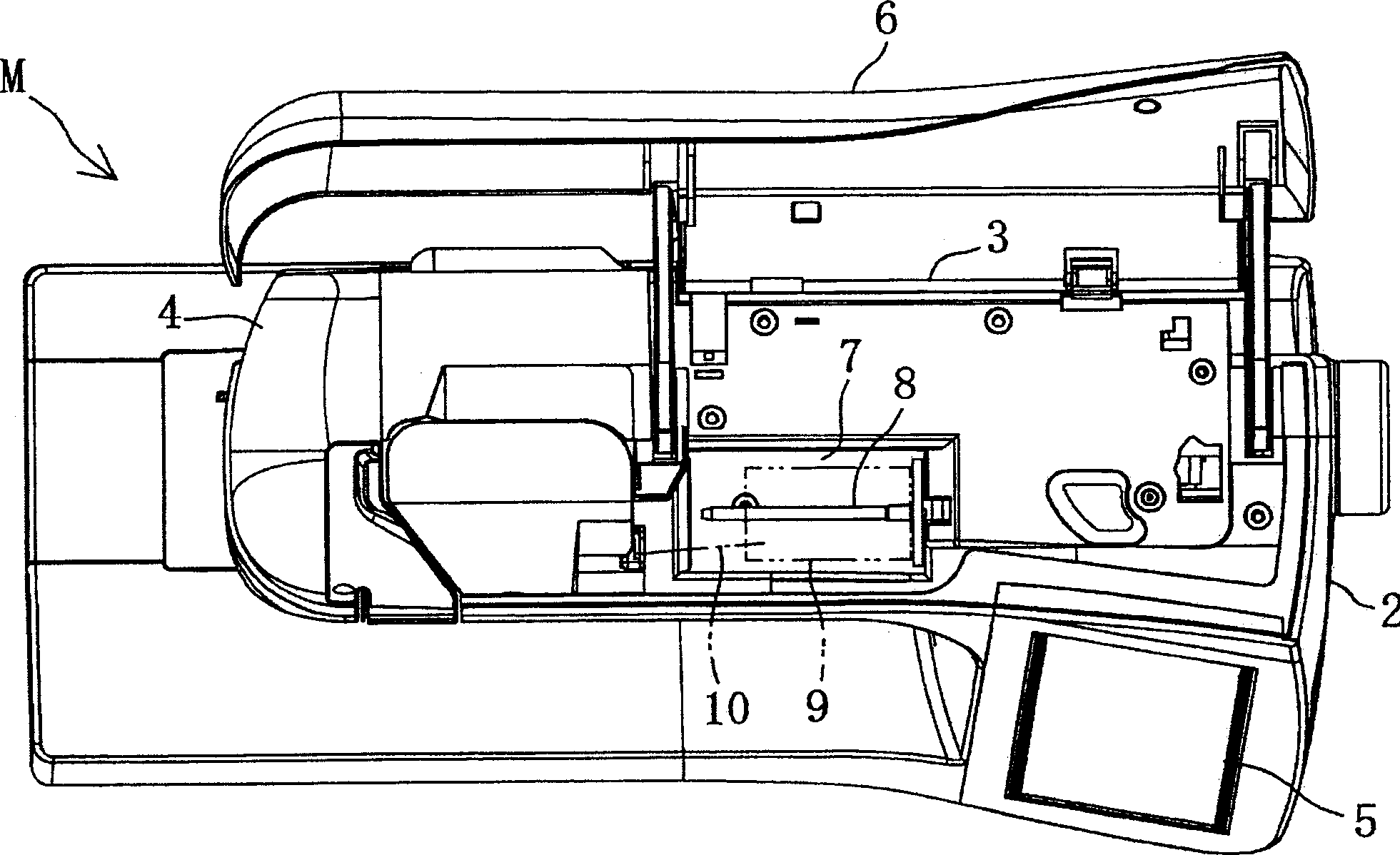

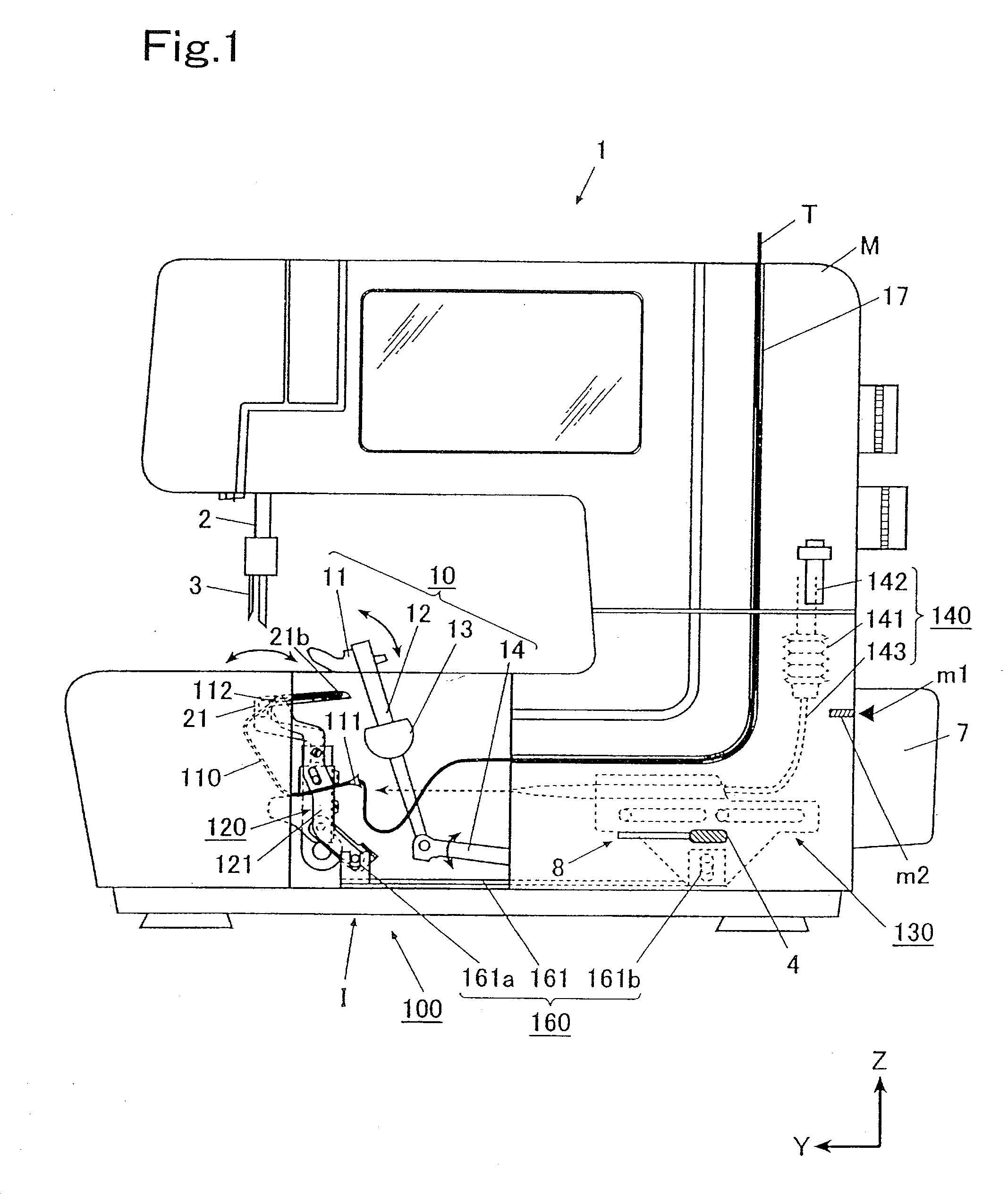

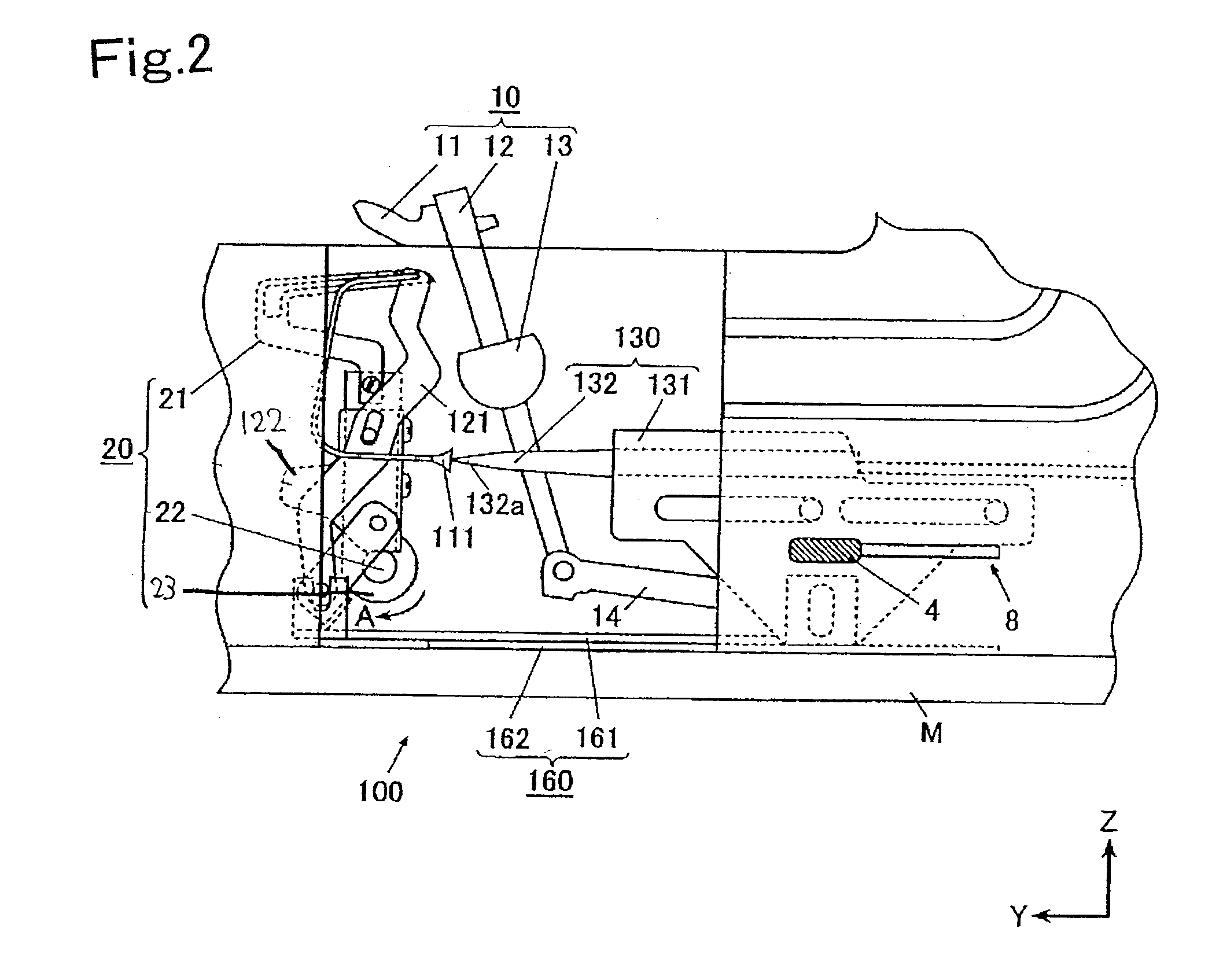

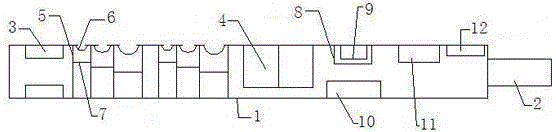

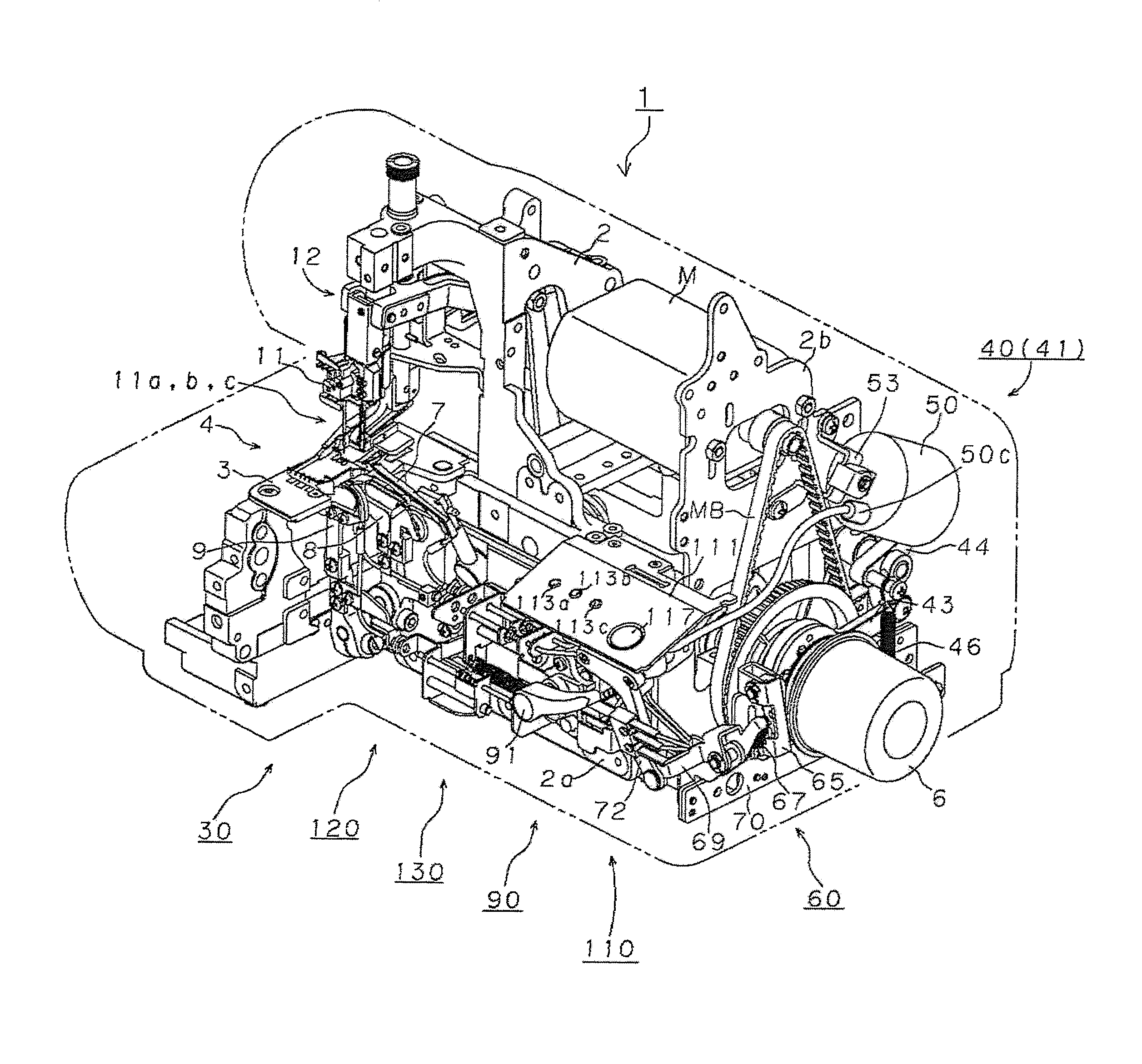

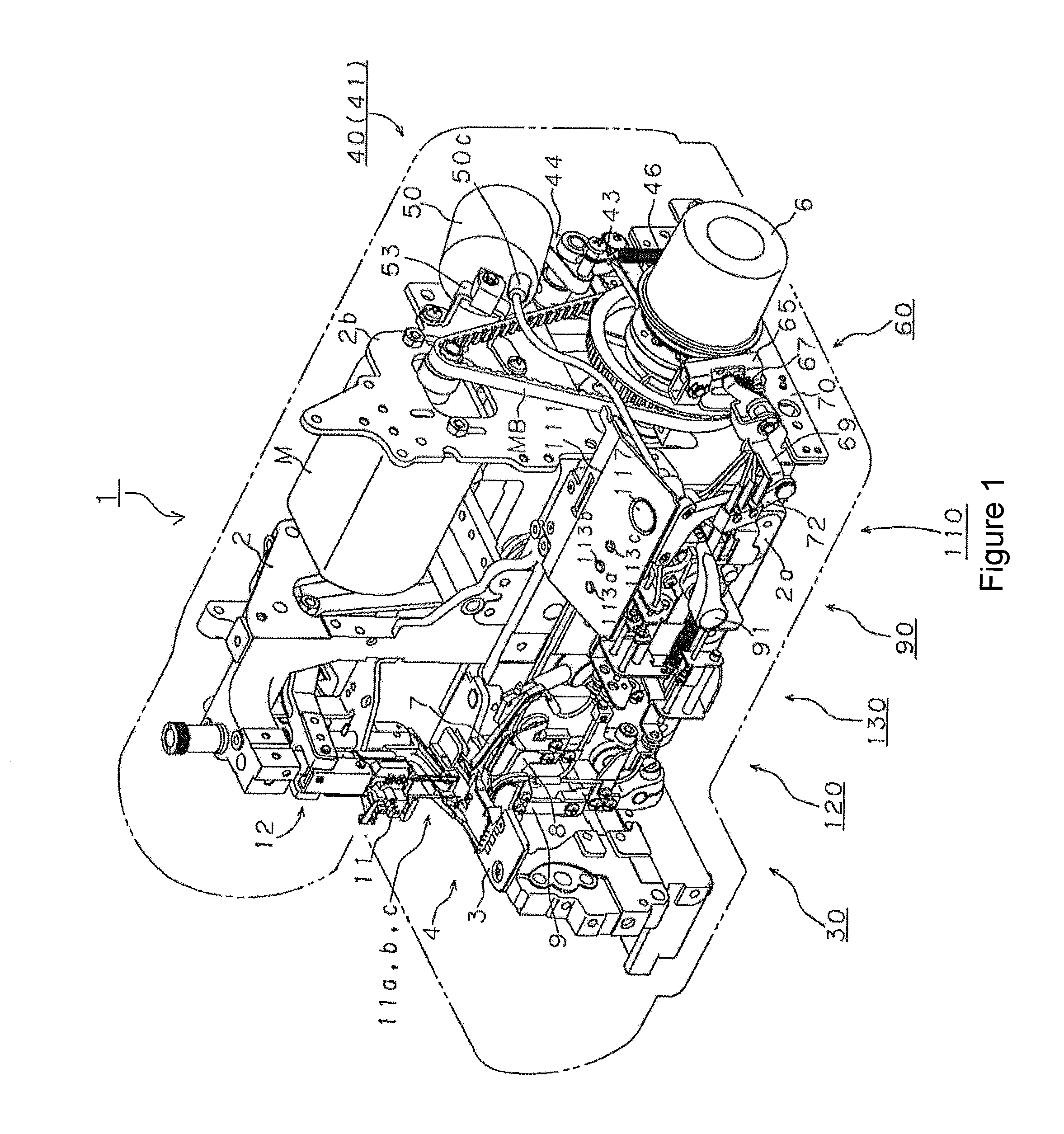

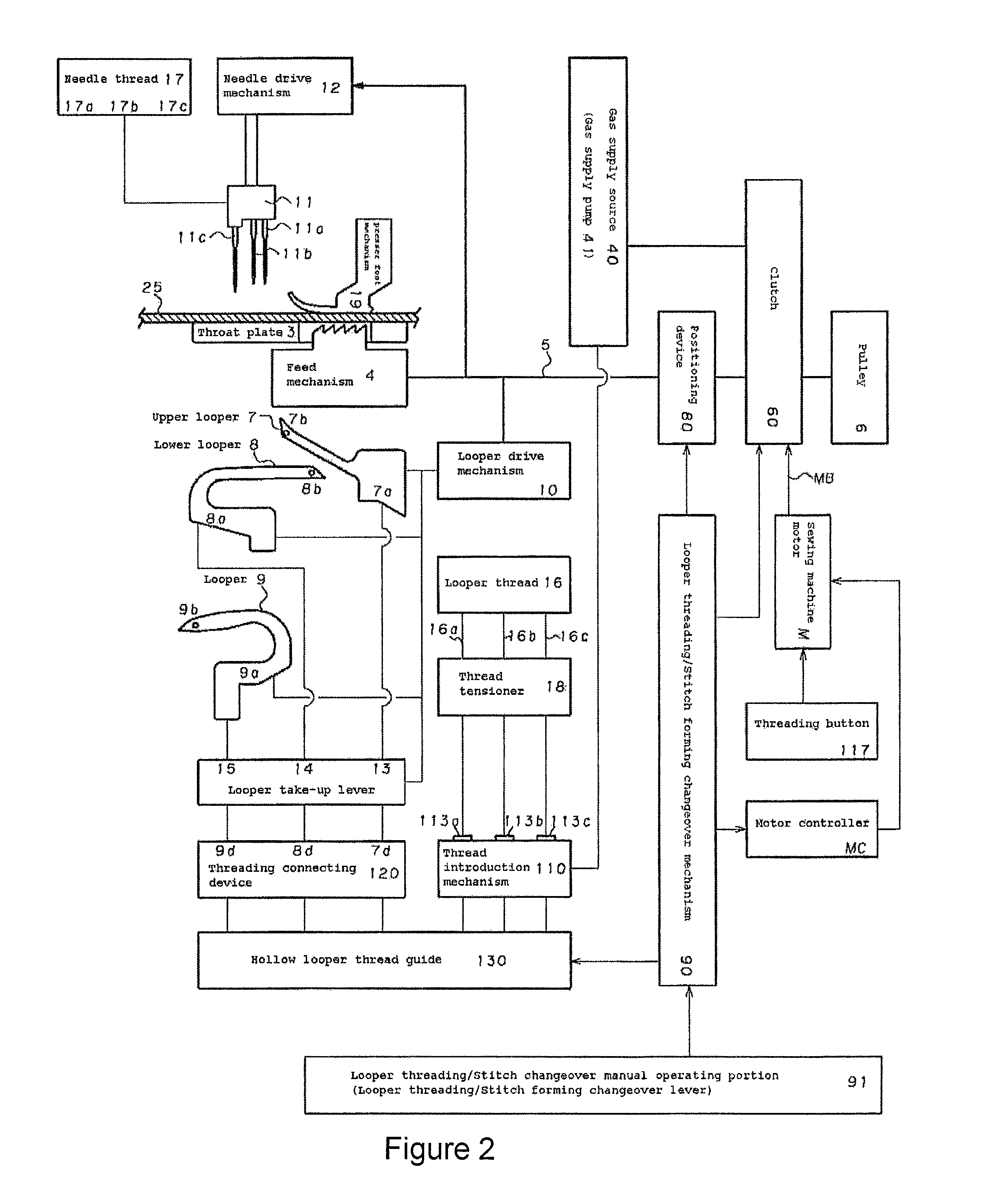

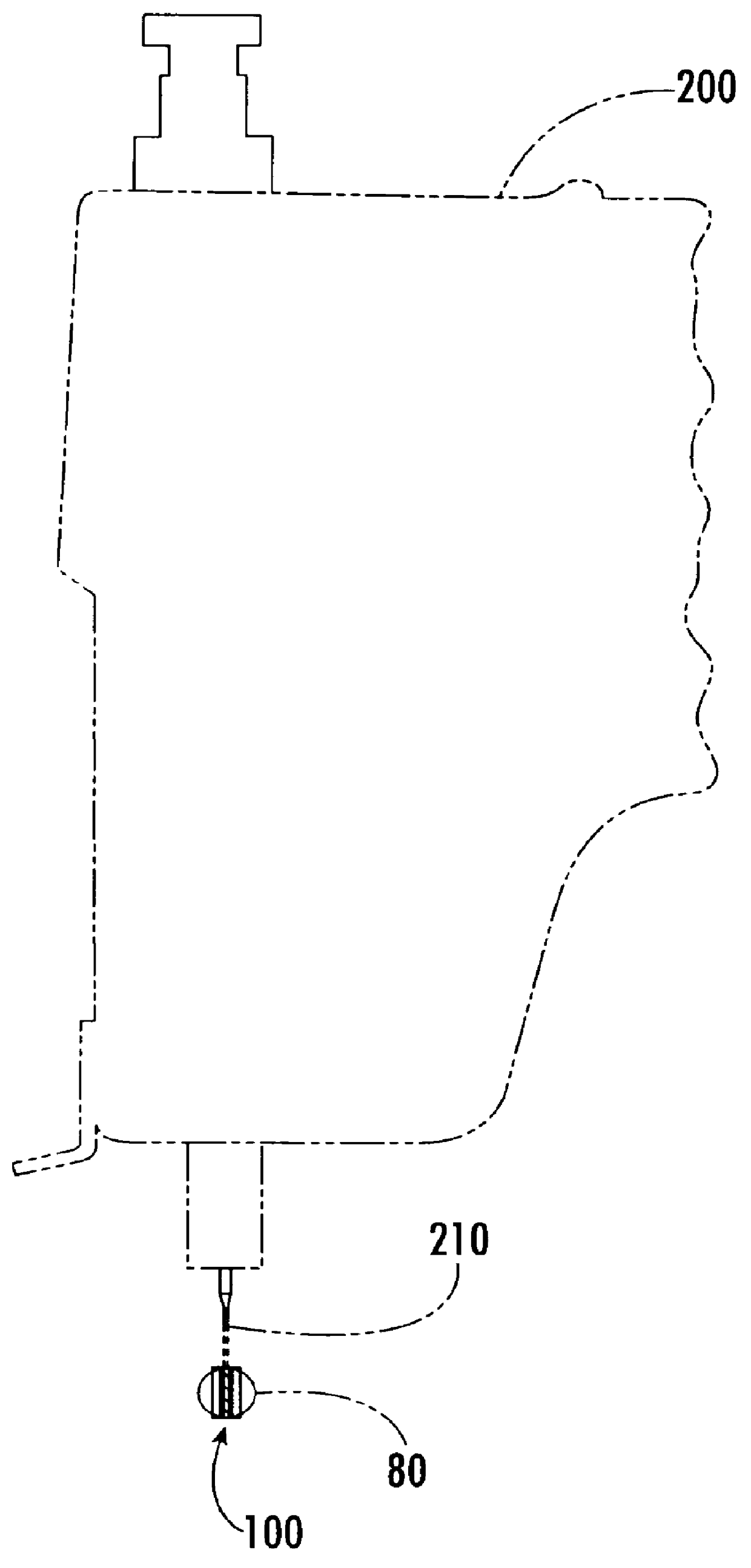

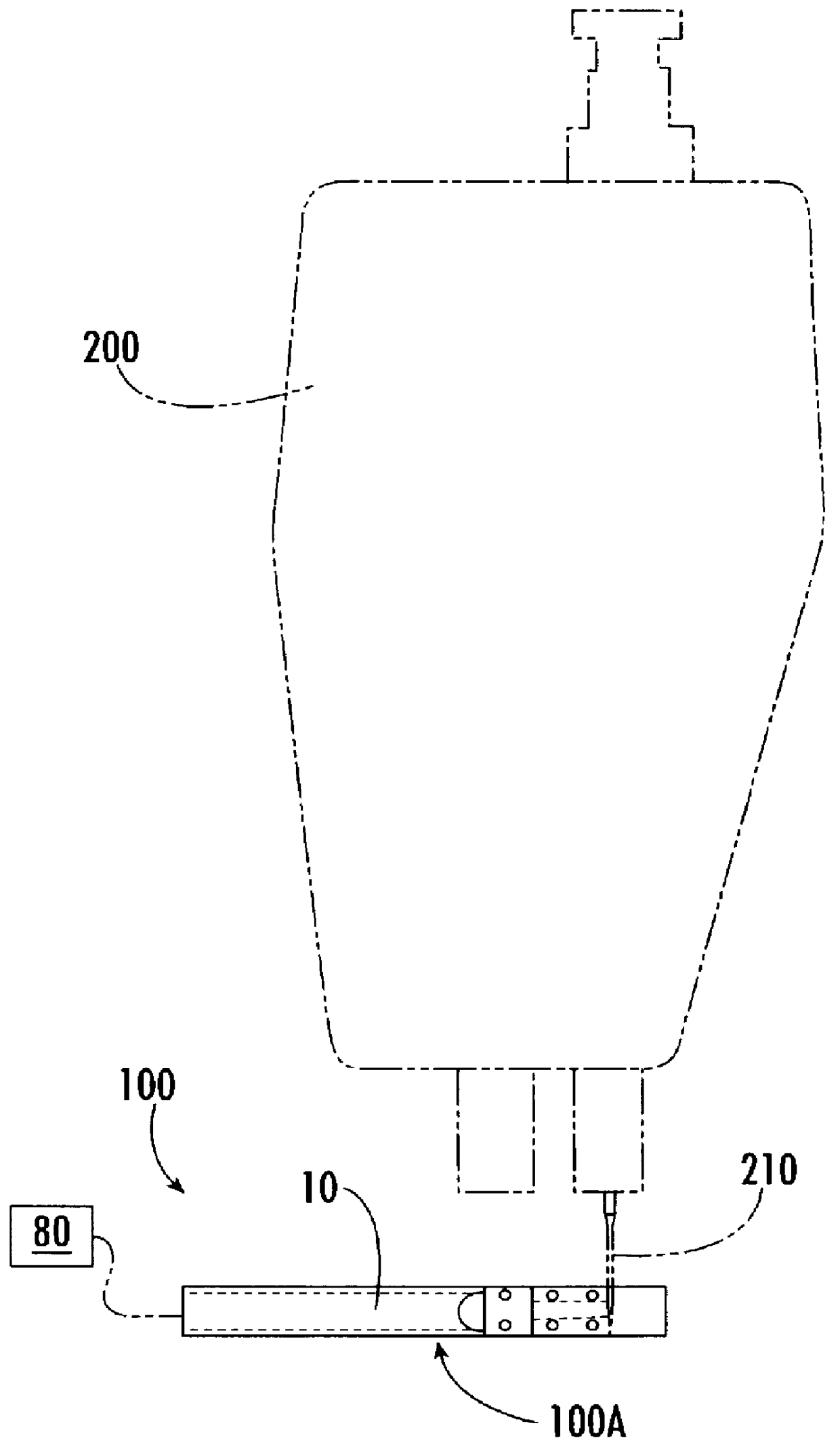

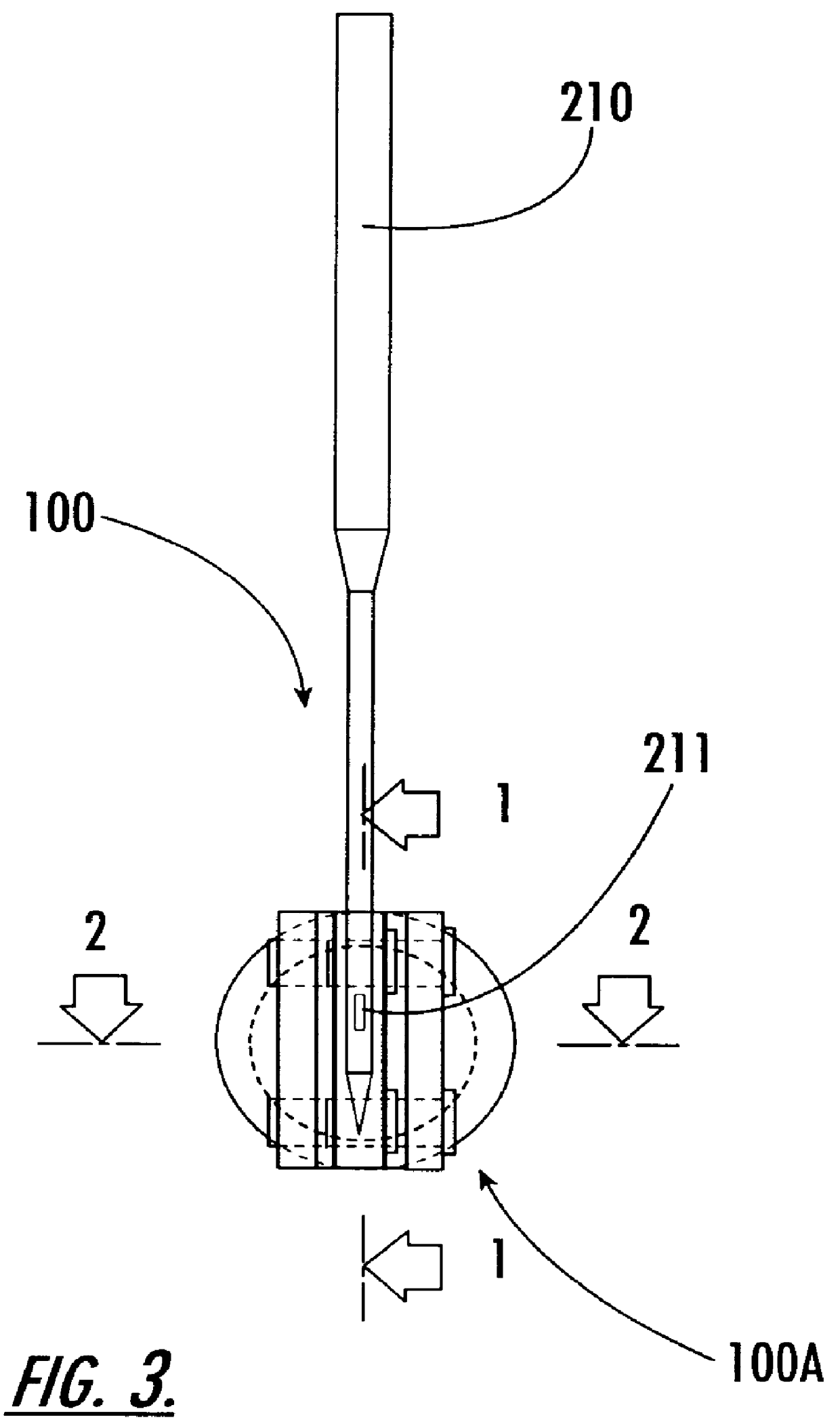

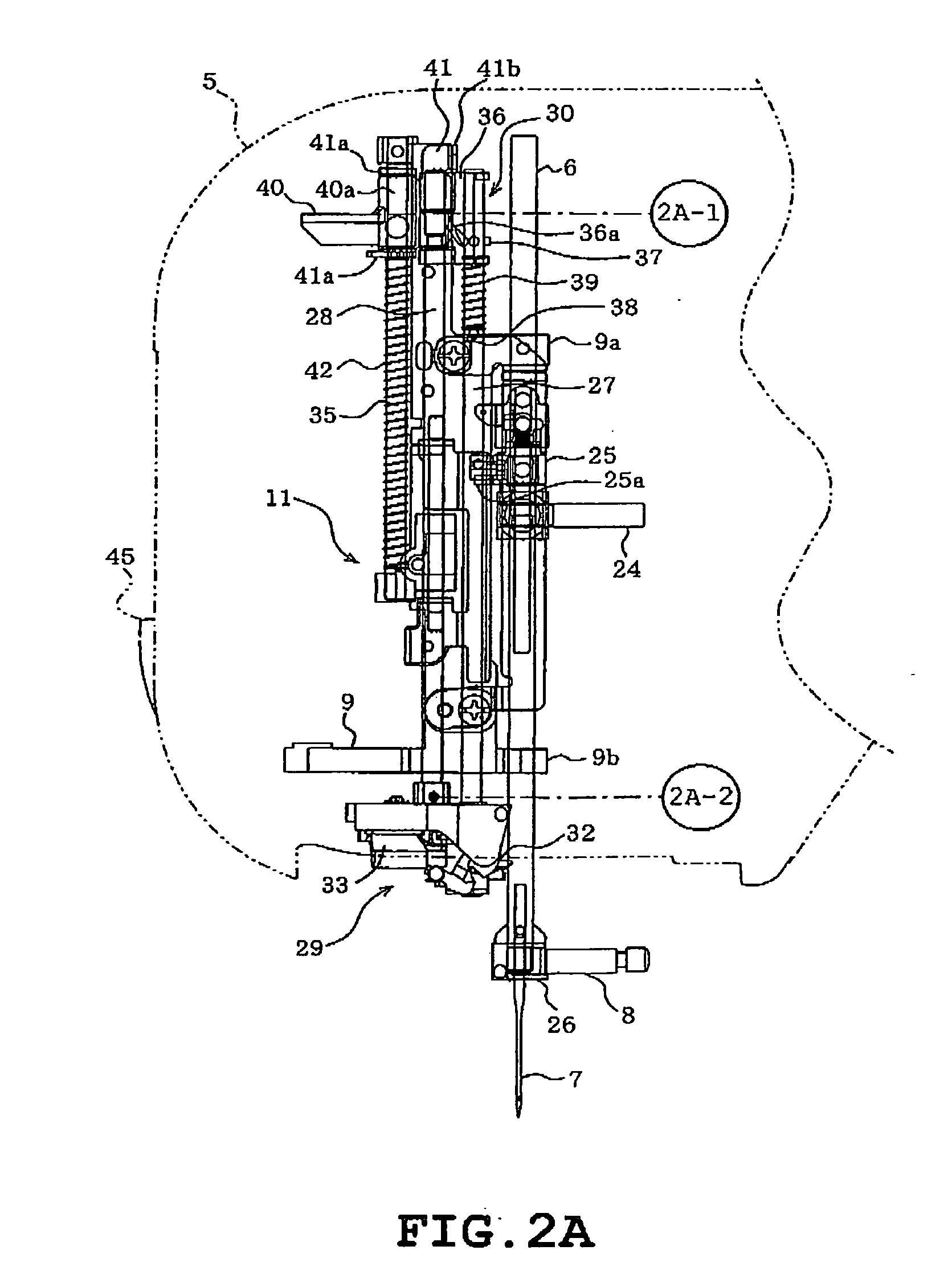

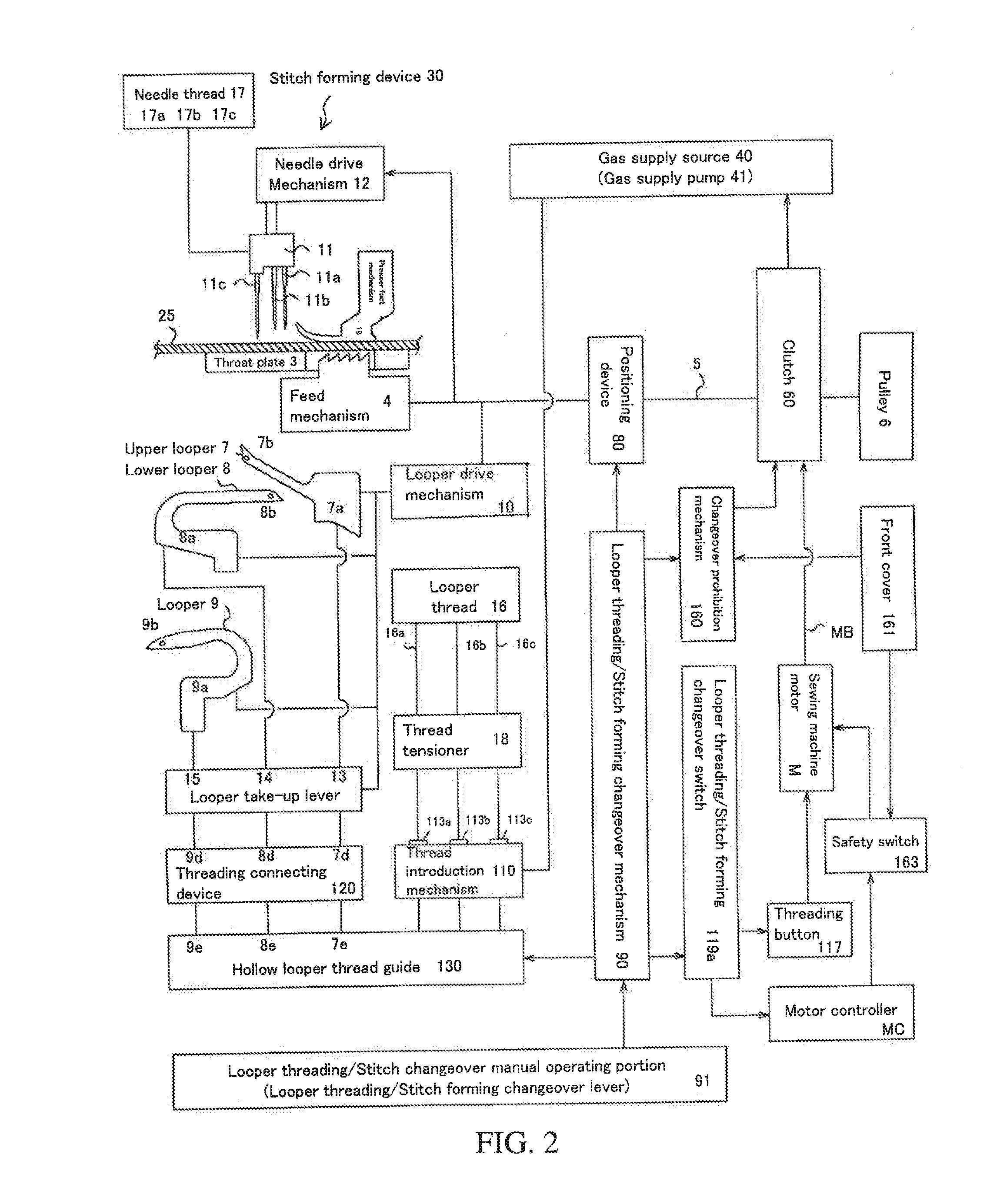

Pressurized gas for carrying looper thread by gas is generated by gas supply pump operated by changing over a sewing-machine motor, which drives stitch forming device, looper threading is performed through loopers by one-touch operation. Gas carrying threading device of sewing machine, comprising: looper thread introduction mechanism inserts looper thread guided to loopers; hollow looper thread guide extends from looper thread introduction mechanism to looper thread inlets and has looper thread guide outlets; gas supply pump for performing looper threading by carrying looper thread by gas from looper thread introduction area through hollow looper thread guide to looper thread loop-taker point outlets; clutch for transmitting power from sewing machine motor M to drive shaft which drives stitch forming device including loopers at time of stitch formation or to gas supply pump at time of looper threading.

Owner:SUZUKI MFG CO LTD

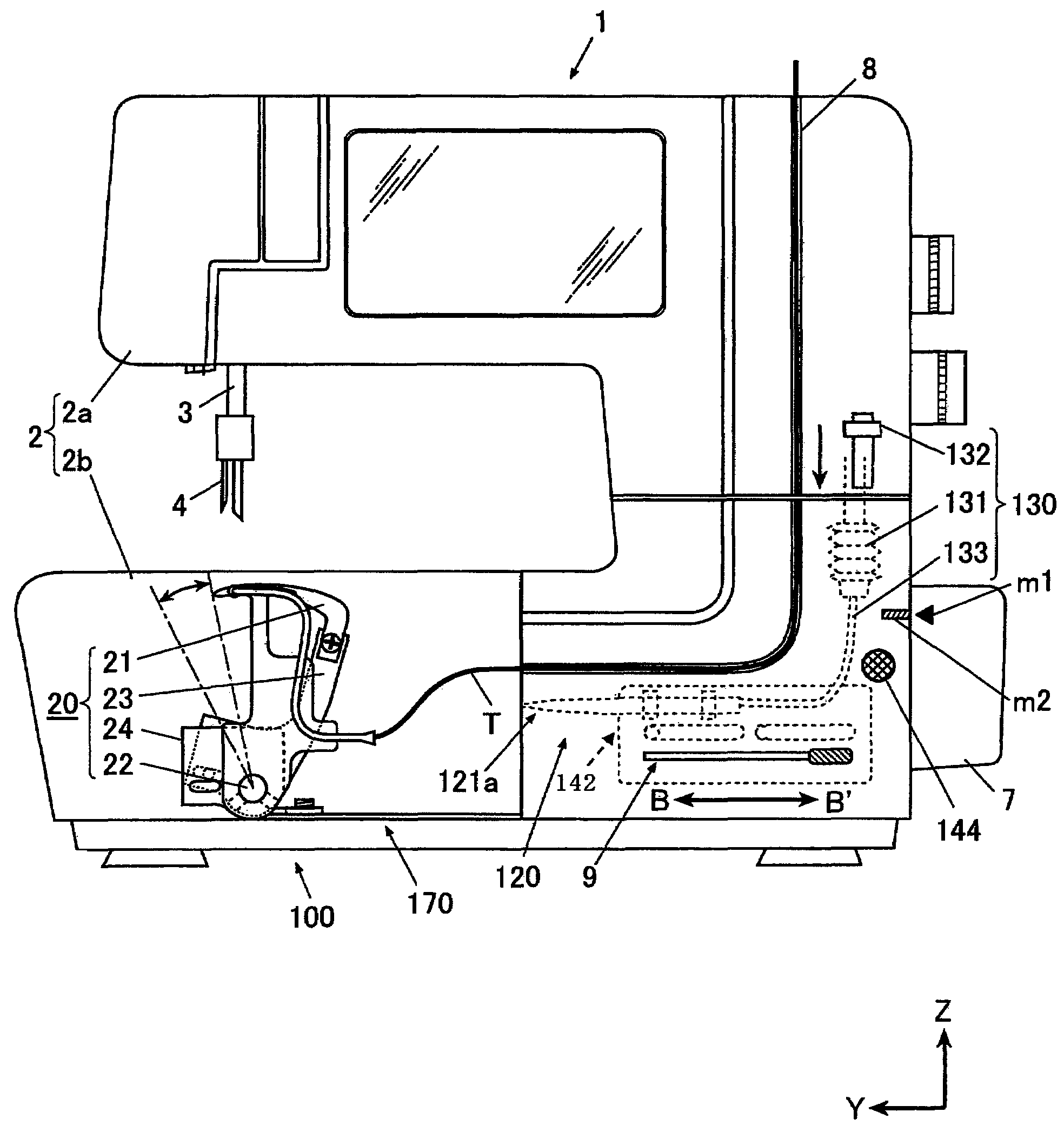

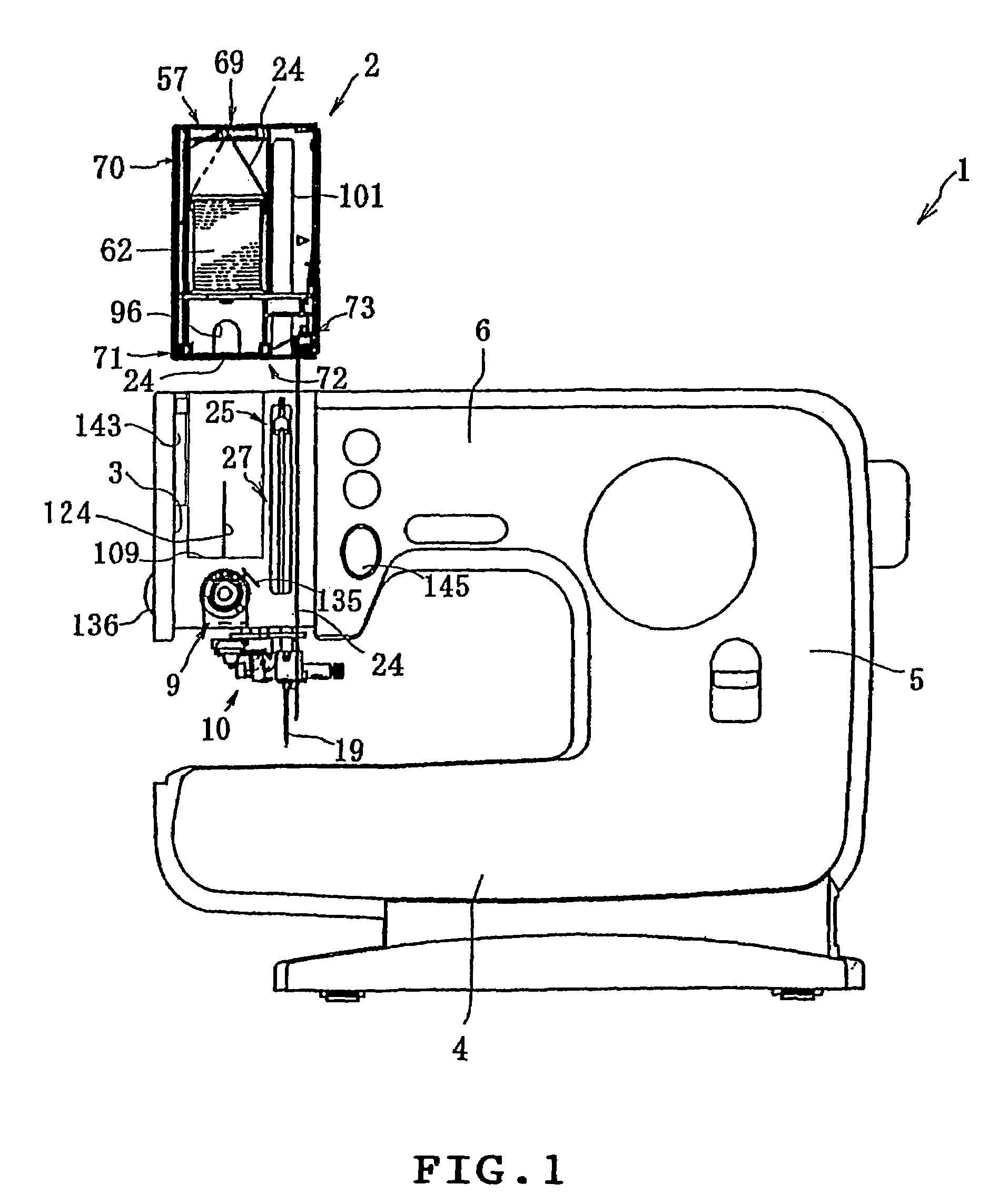

Threading device of sewing machine

InactiveUS20080257241A1Easily and visually recognizeReduce stepsFilament handlingLightening equipmentEngineeringScrew thread

A threading device of a sewing machine includes a thread inserting base formed with a thread path hole having a thread inserting port opened toward an outer side of a sewing machine frame, and further formed with an air path hole which joins the thread path hole in the vicinity of the thread inserting port, an air supply device coupled to the air path hole to supply compressed air, and illuminating means provided on the sewing machine frame to irradiate a joining portion of the thread path hole and the air path hole. The thread inserting base includes a transparent member through which at least the joining portion of the thread path hole and the air path hole can be visually recognized.

Owner:JUKI CORP

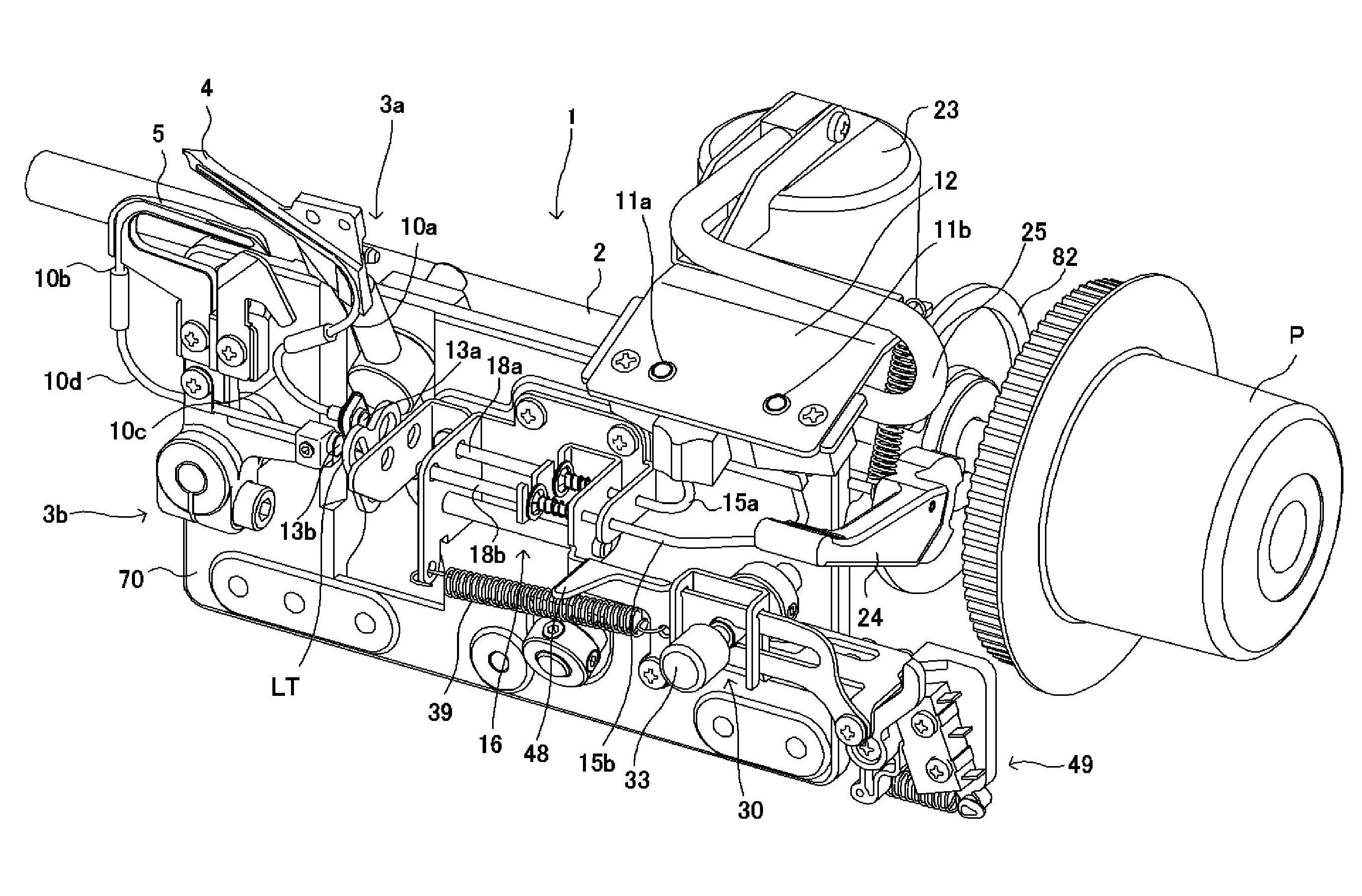

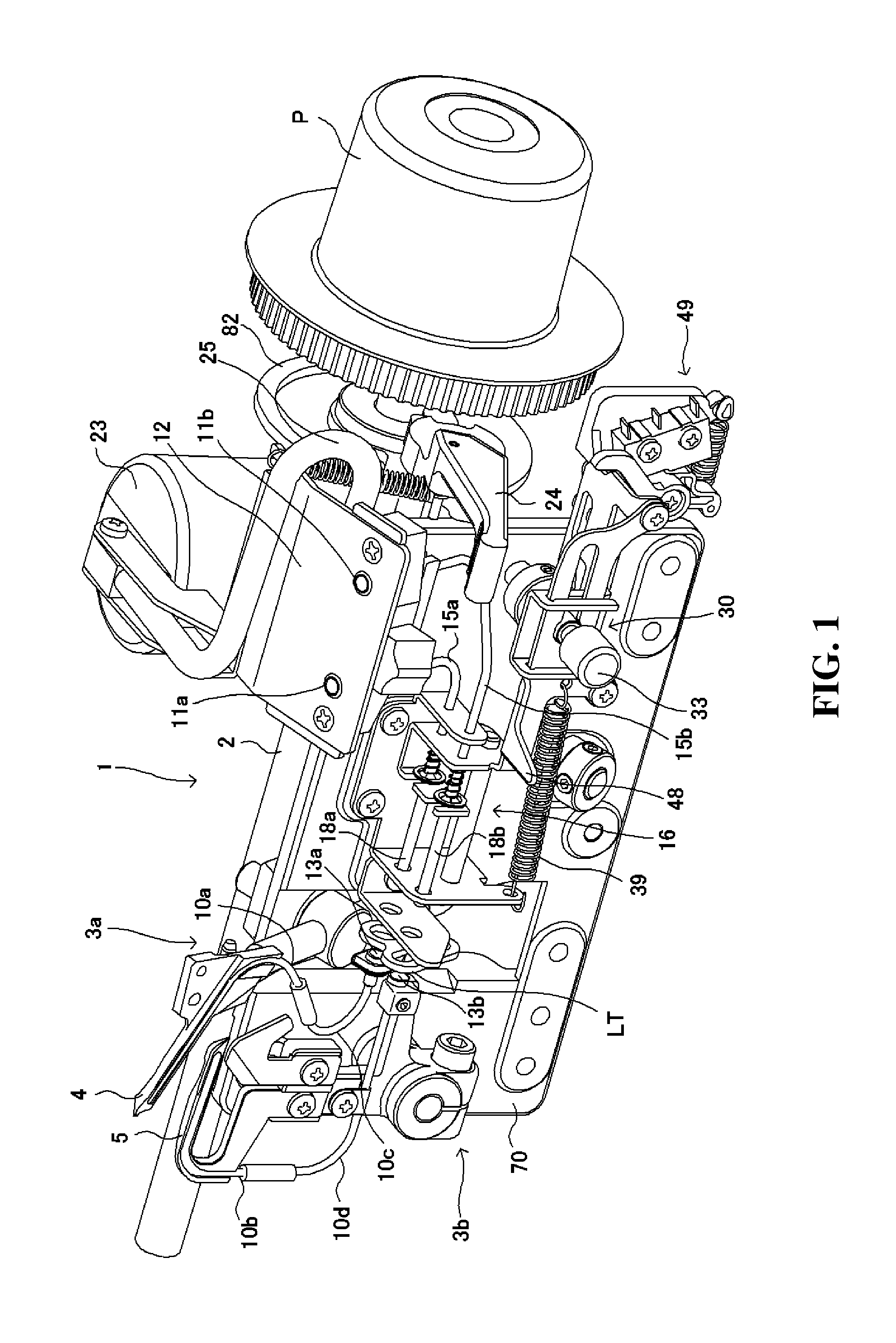

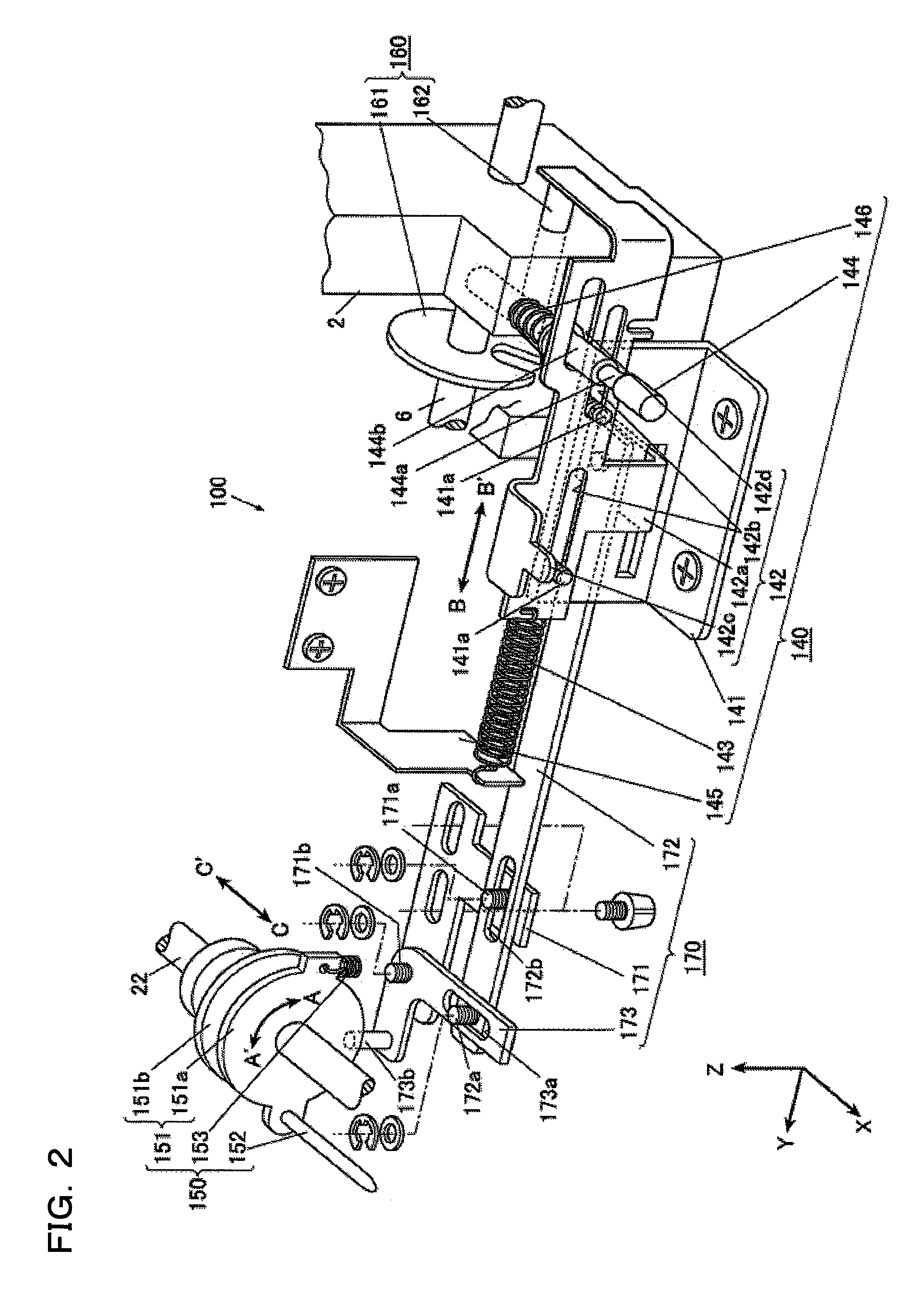

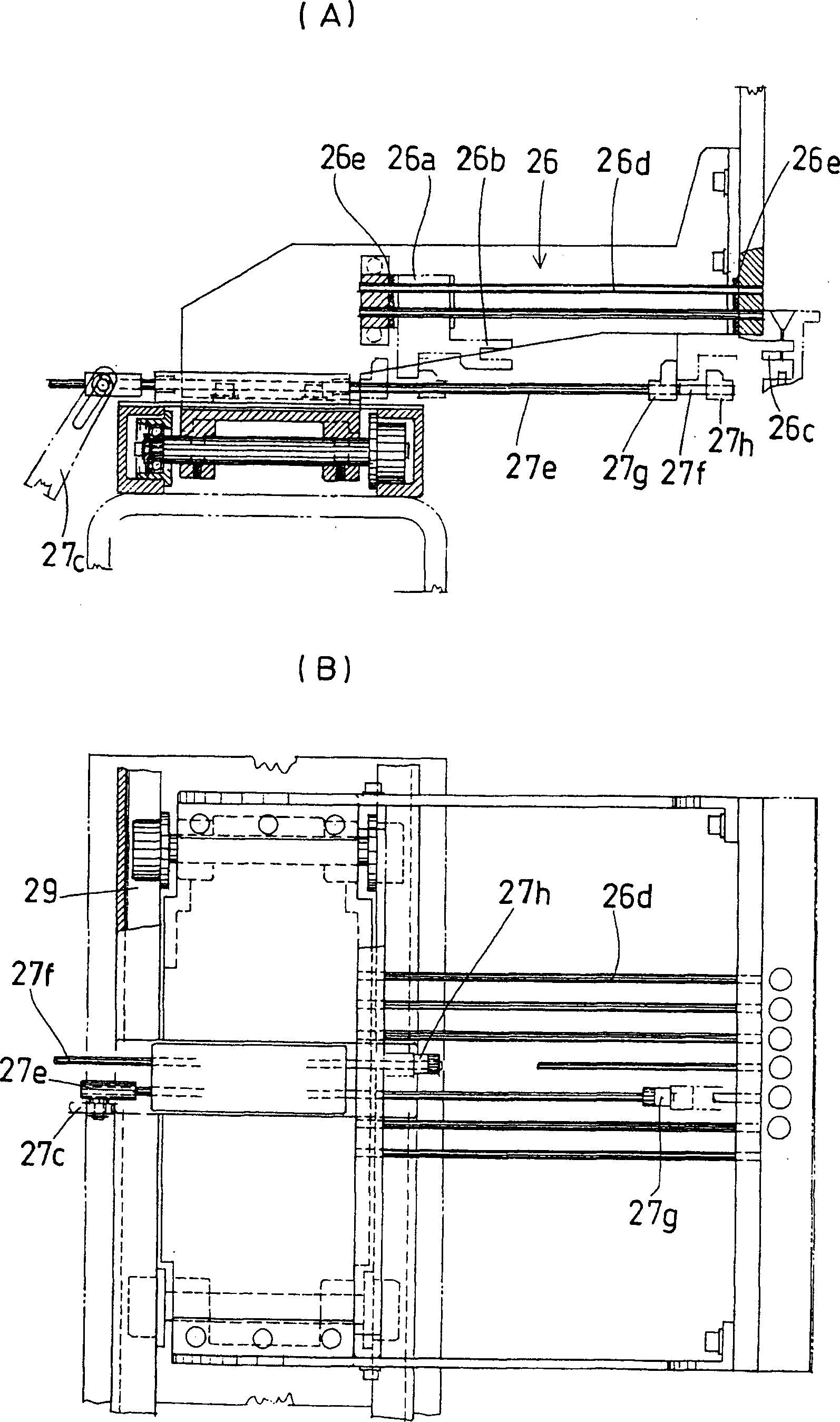

Gas carrying threading device of sewing machine

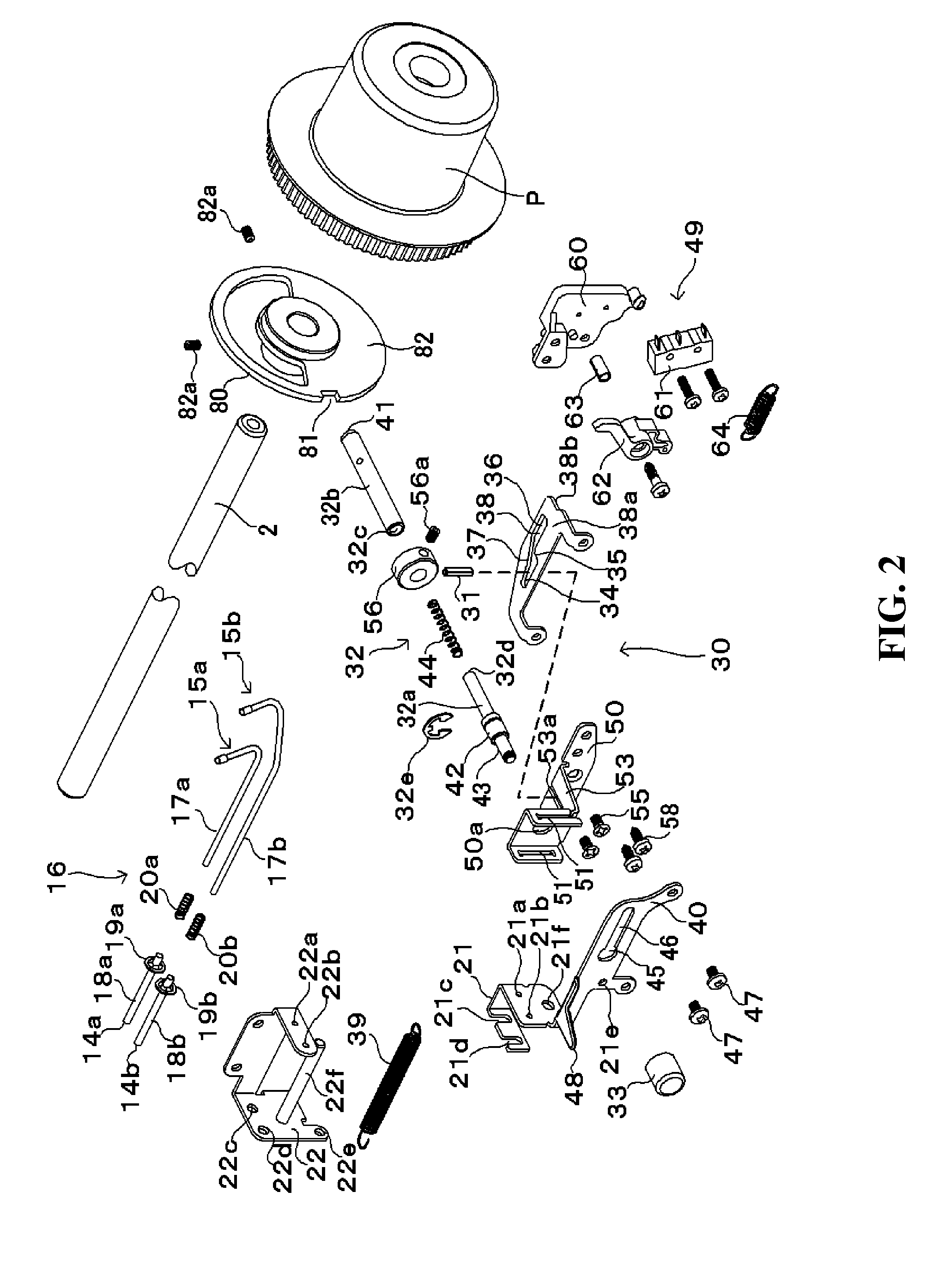

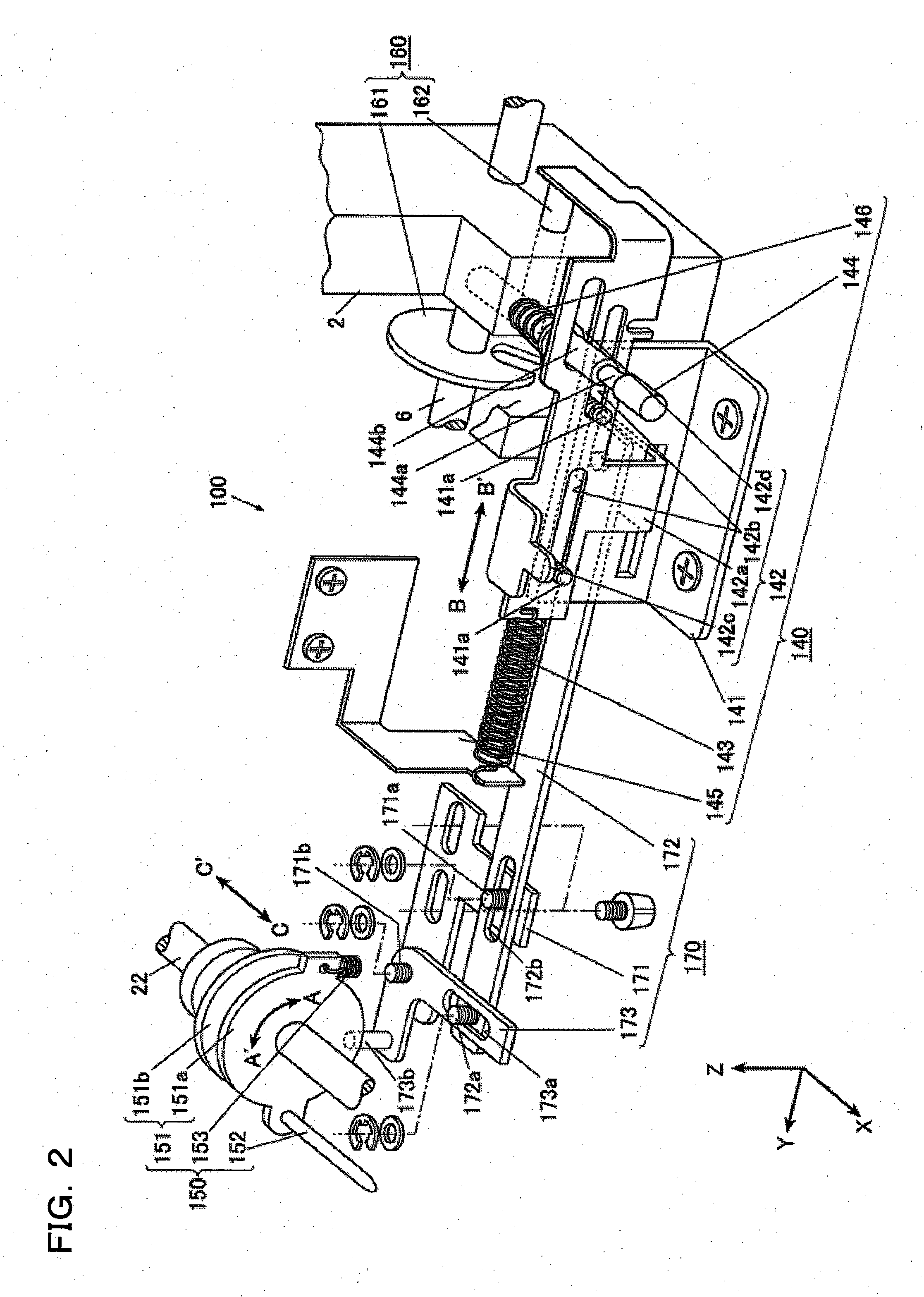

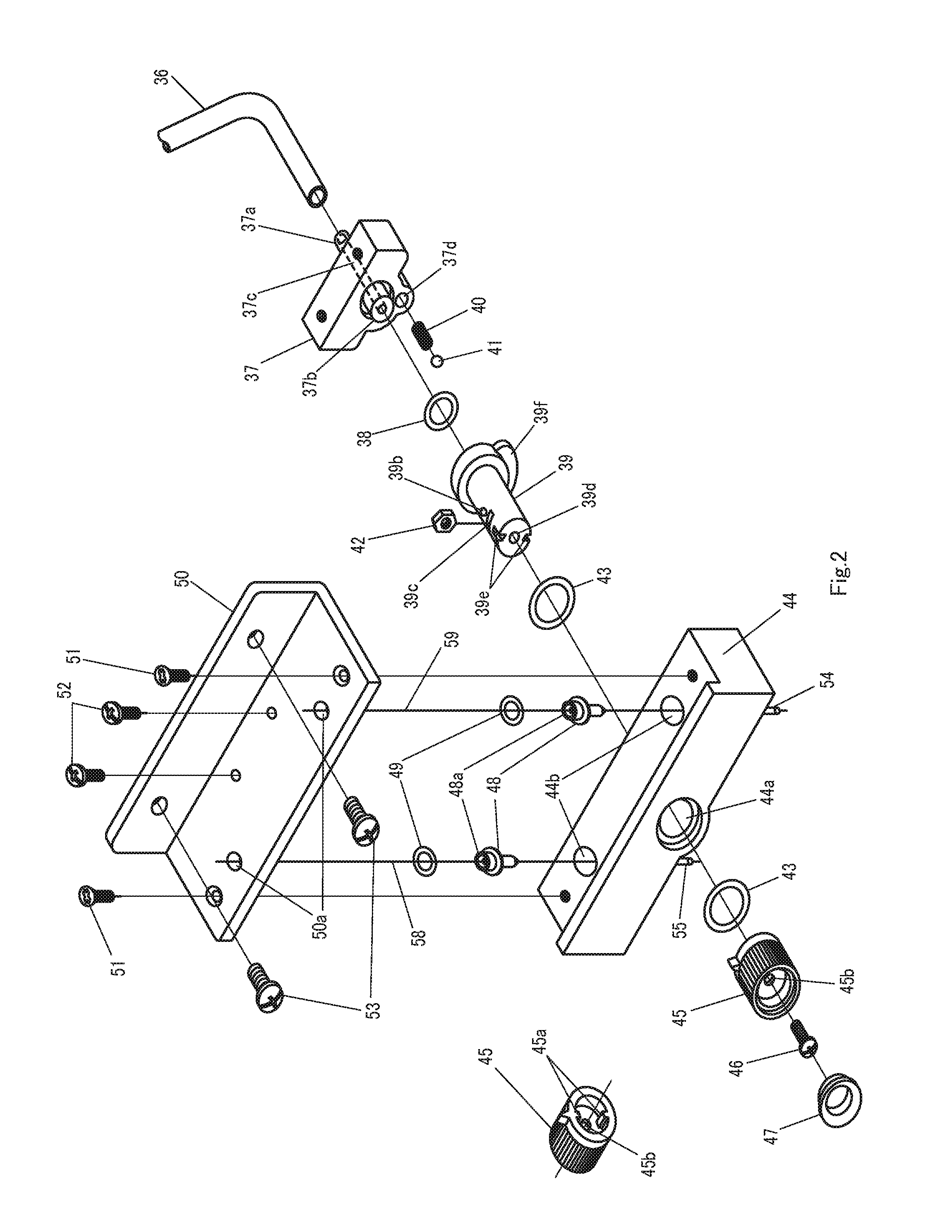

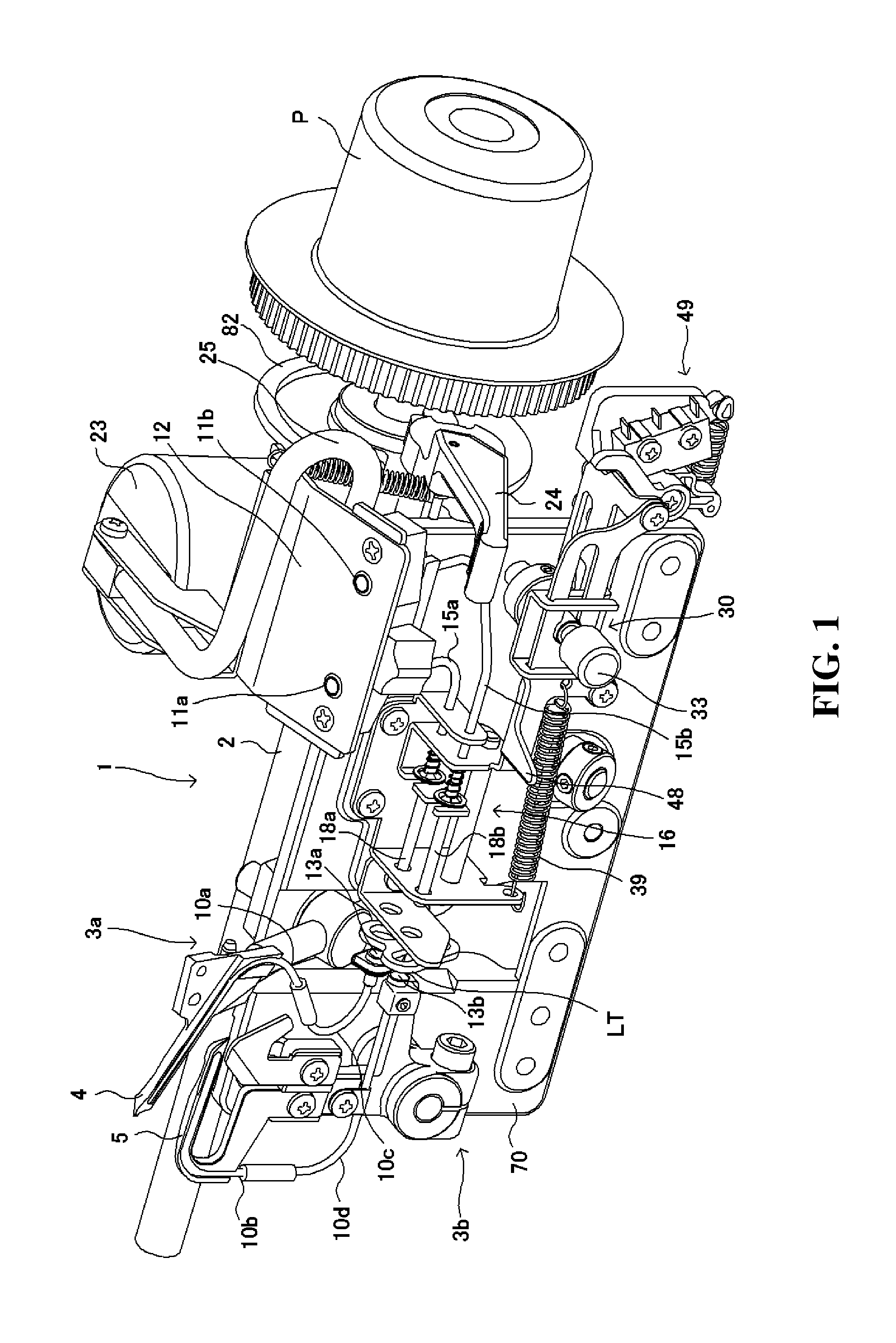

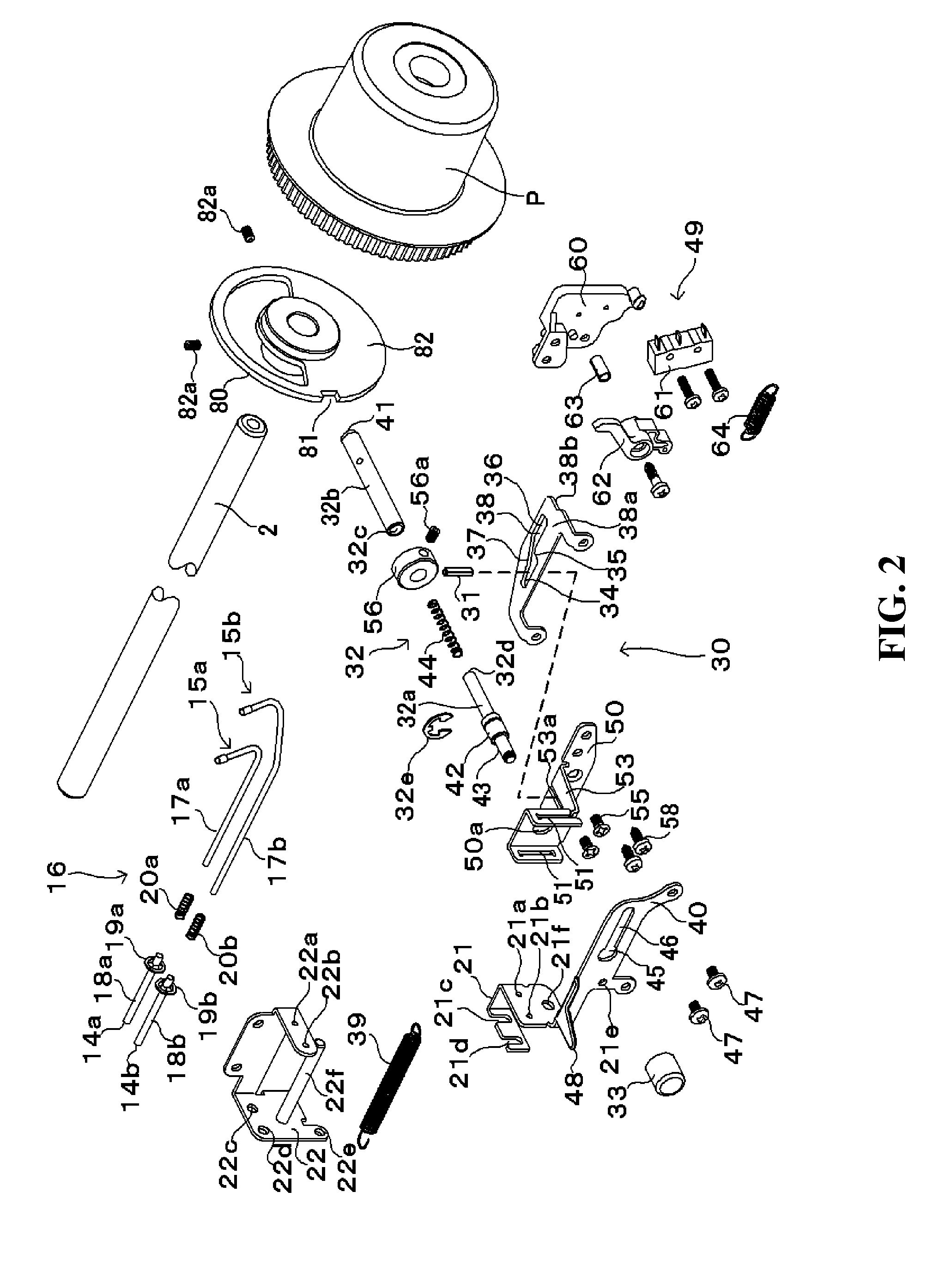

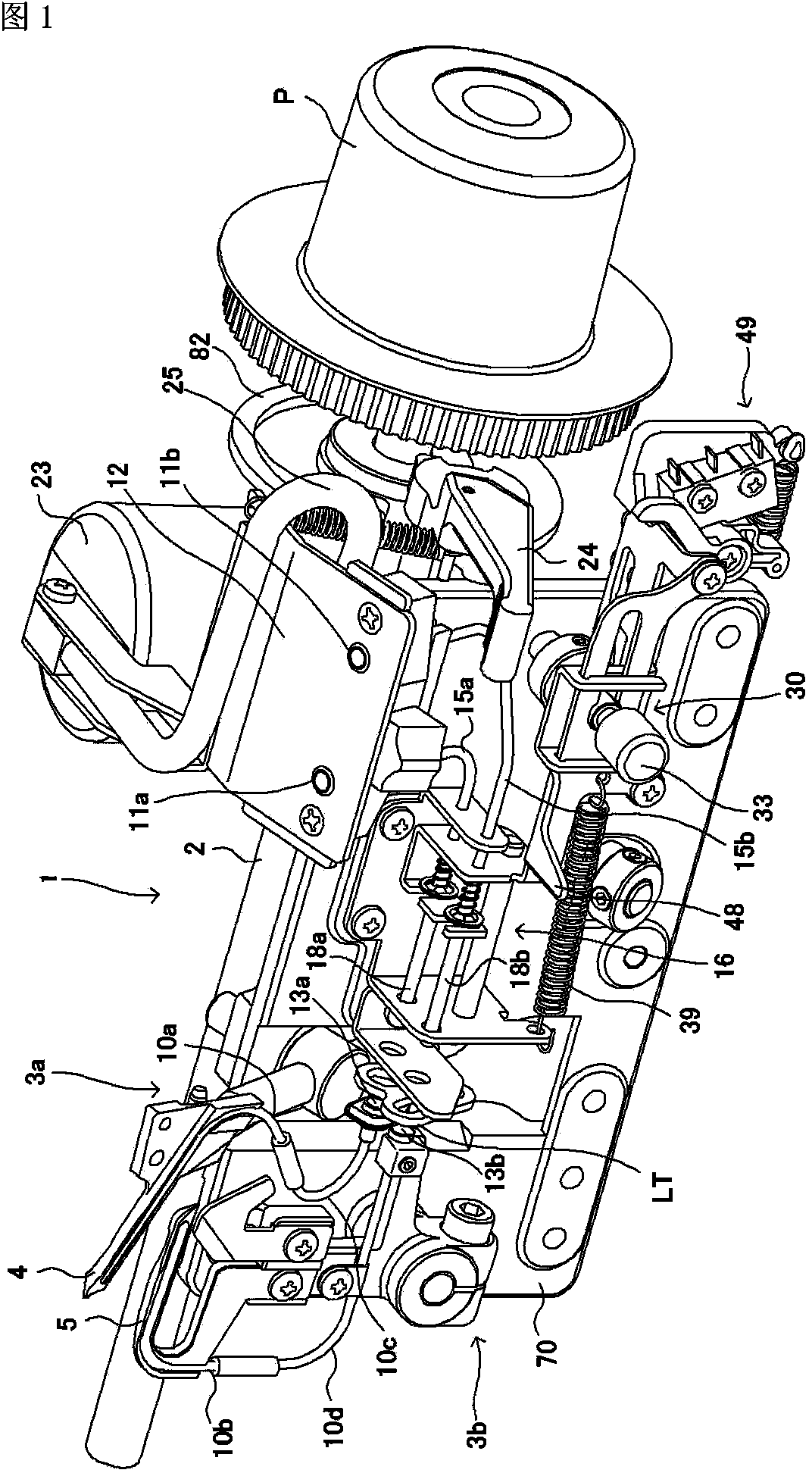

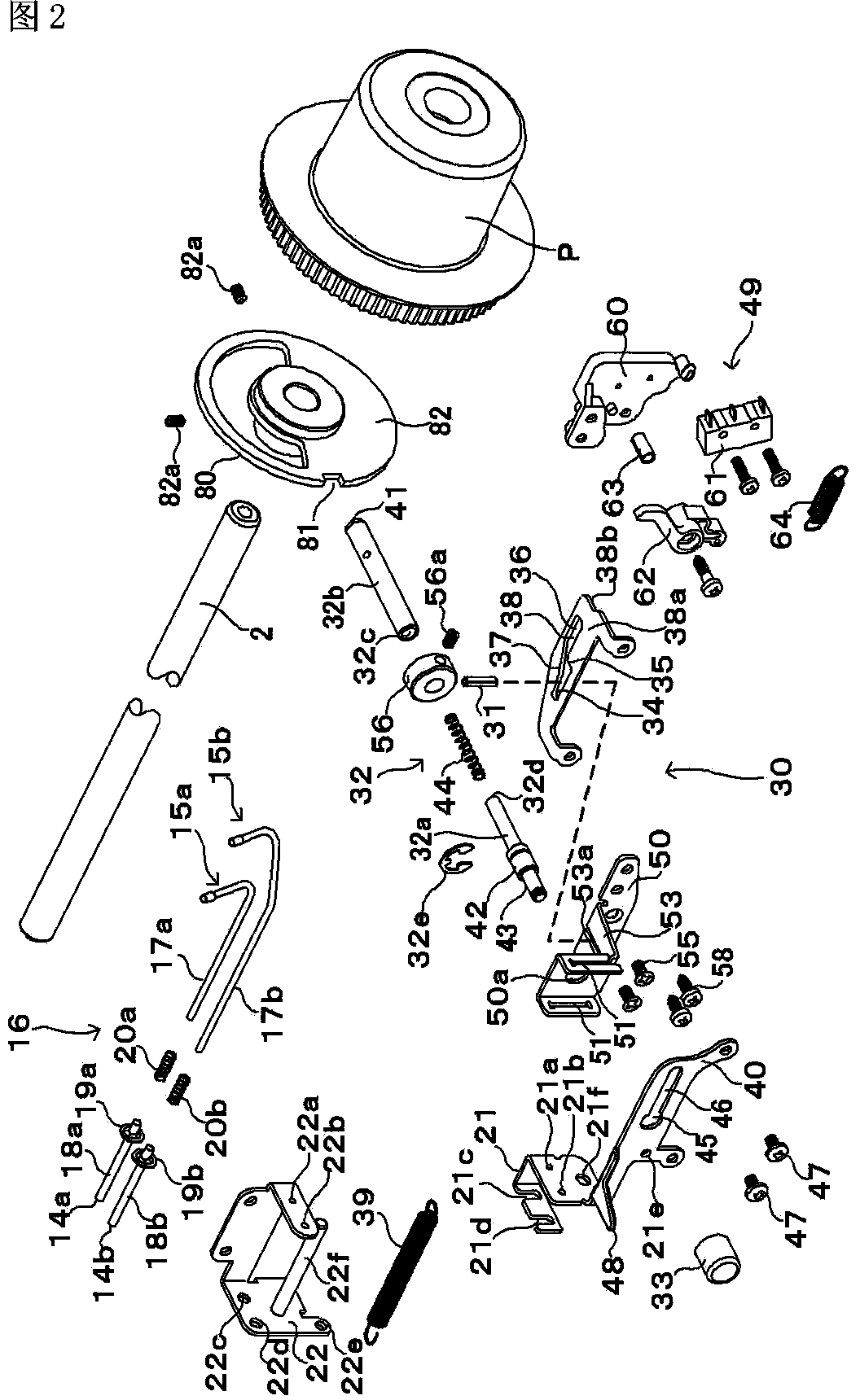

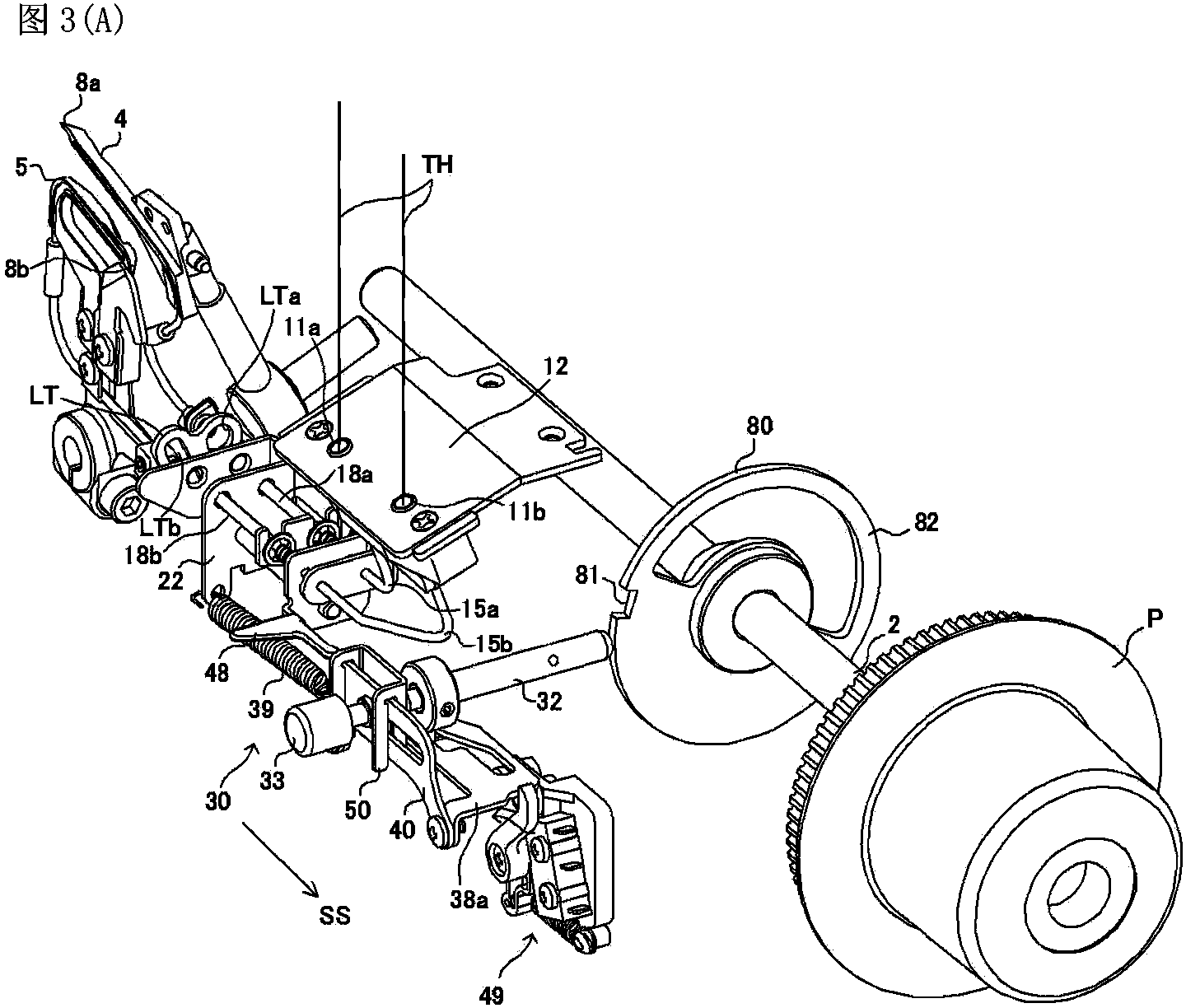

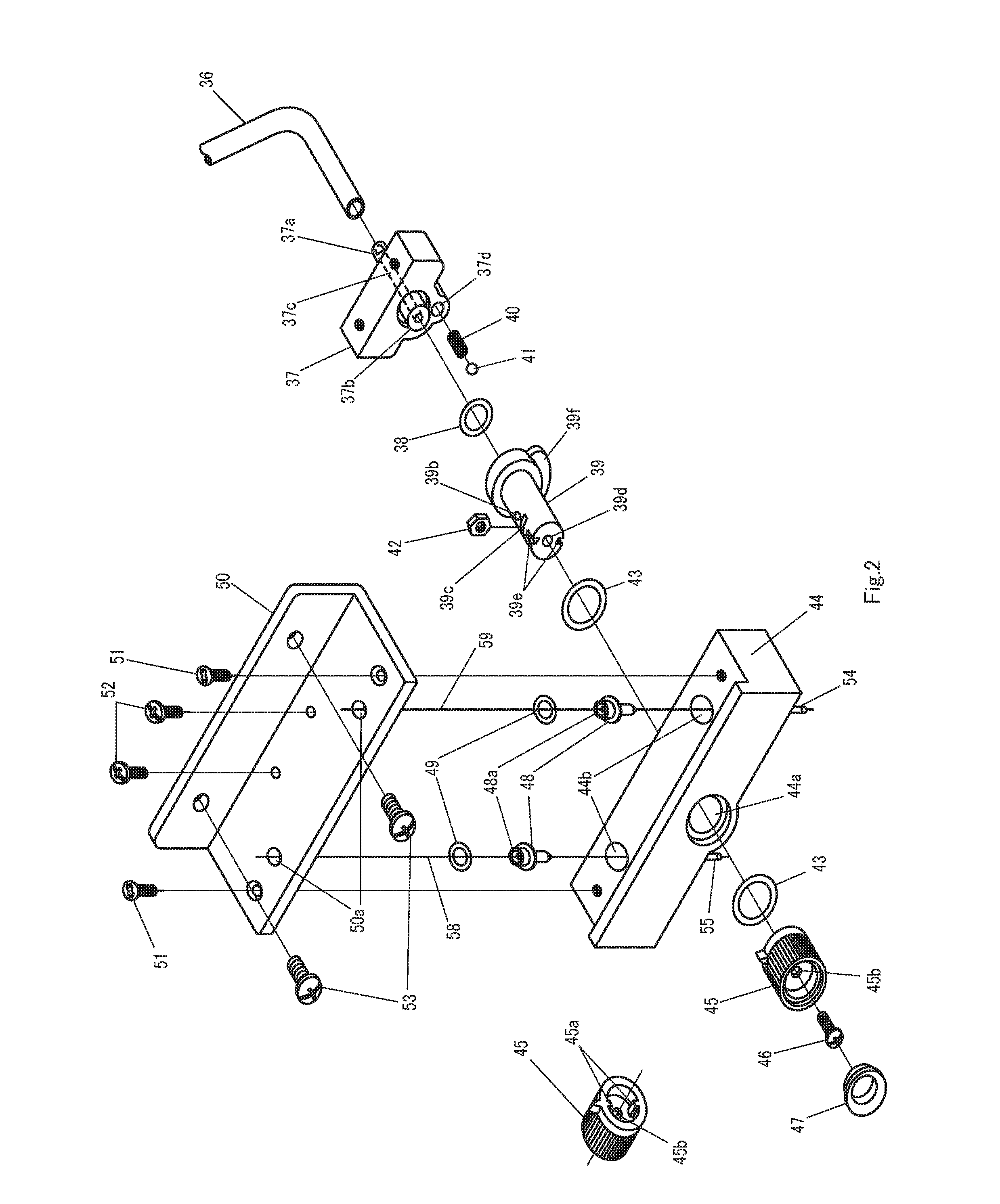

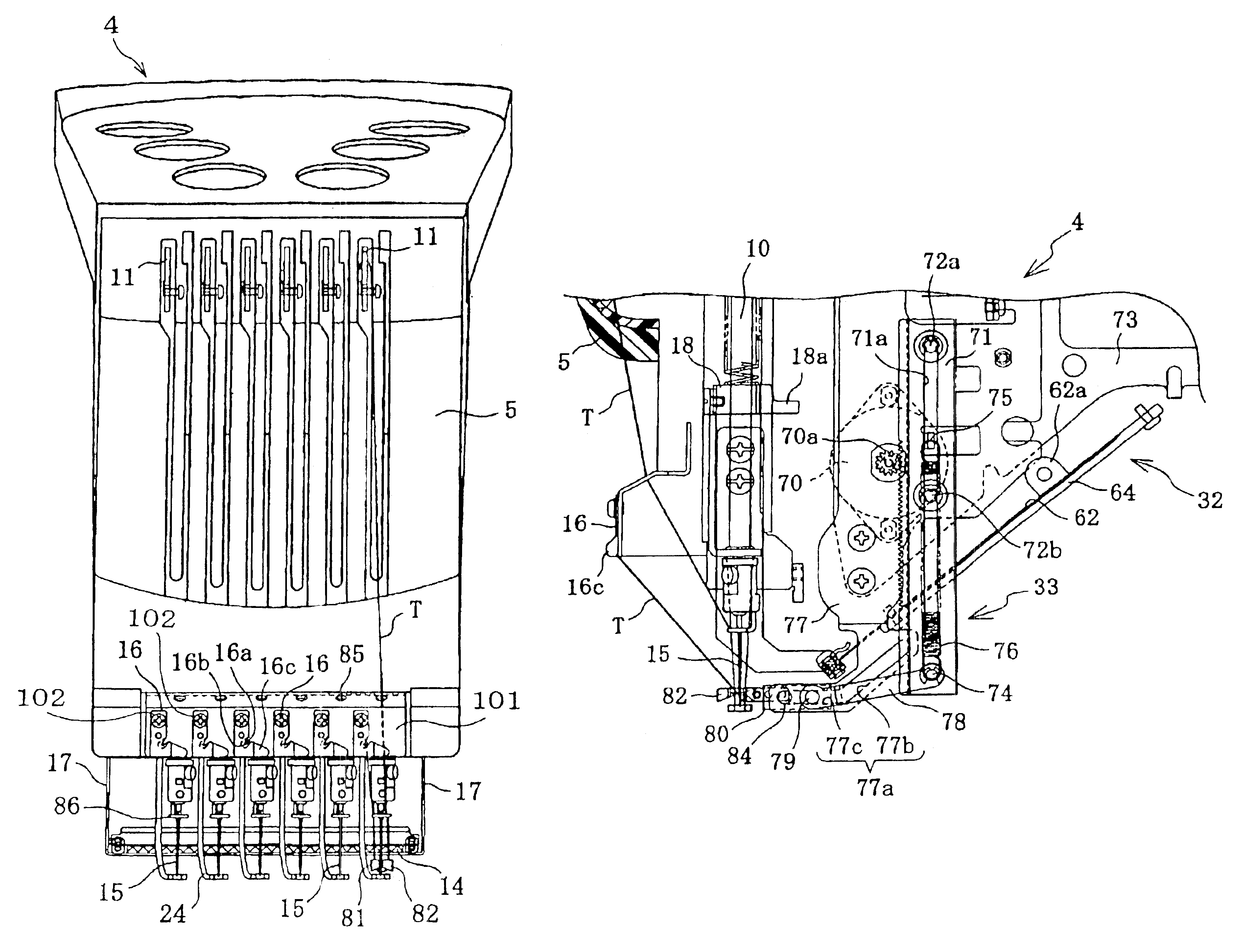

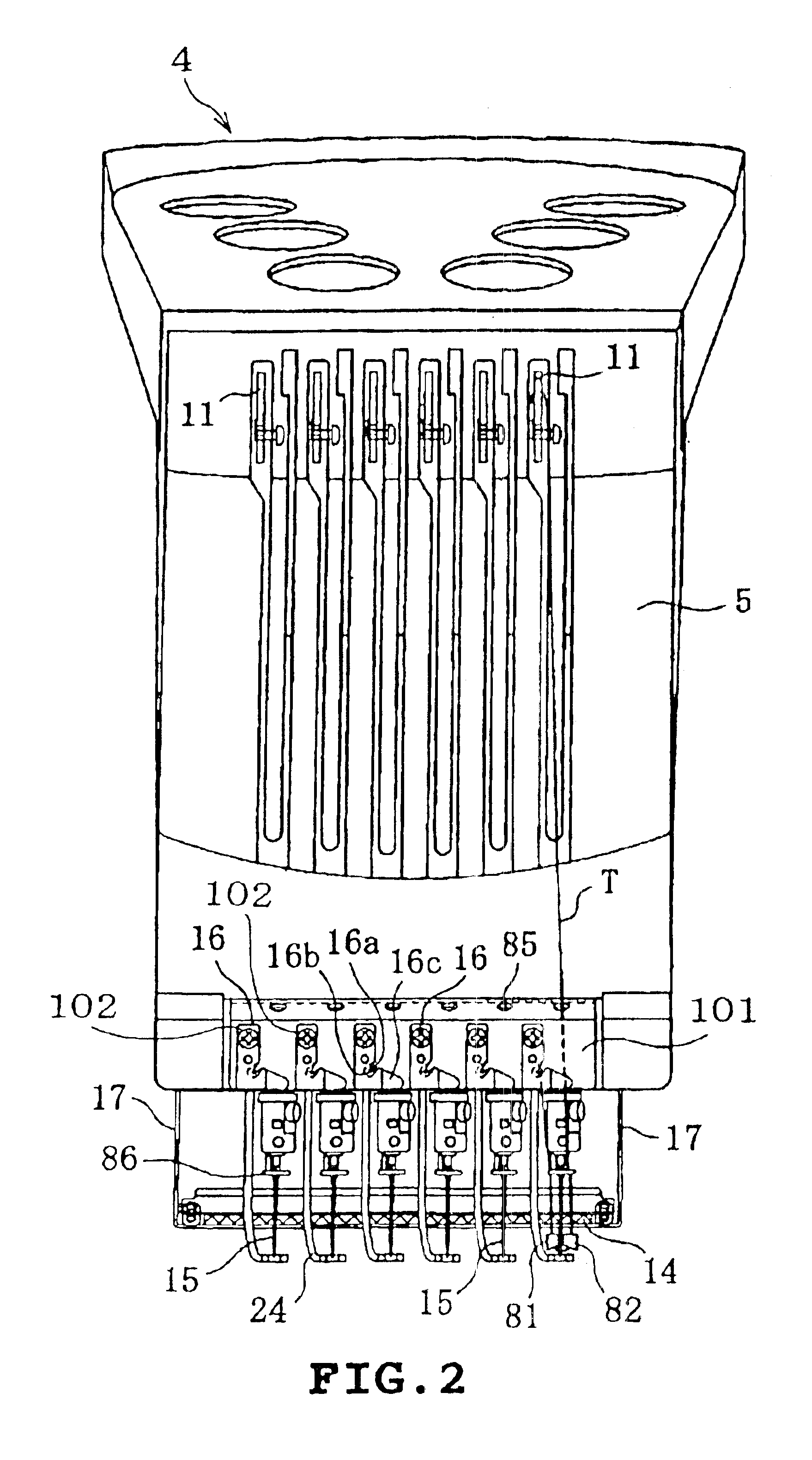

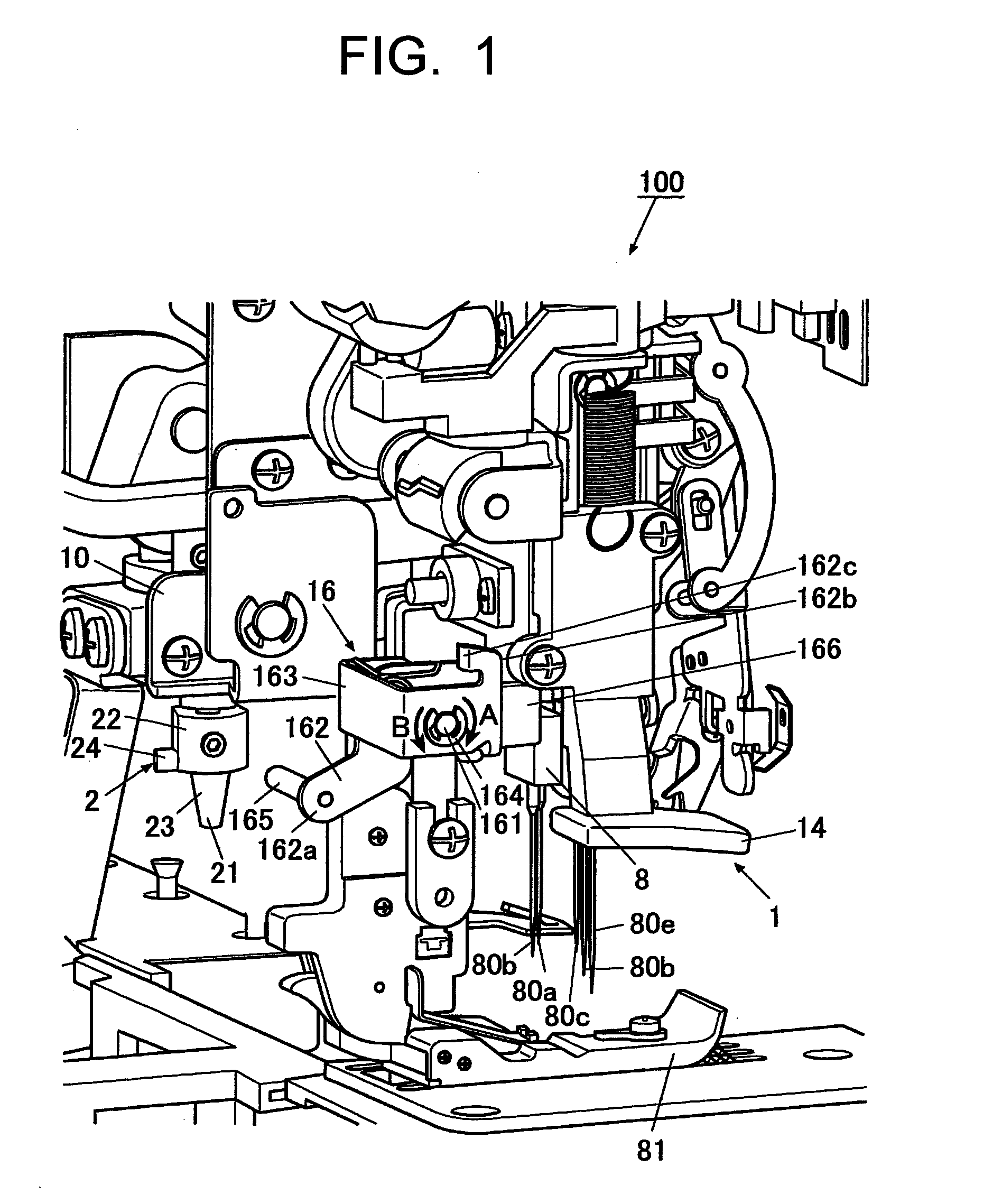

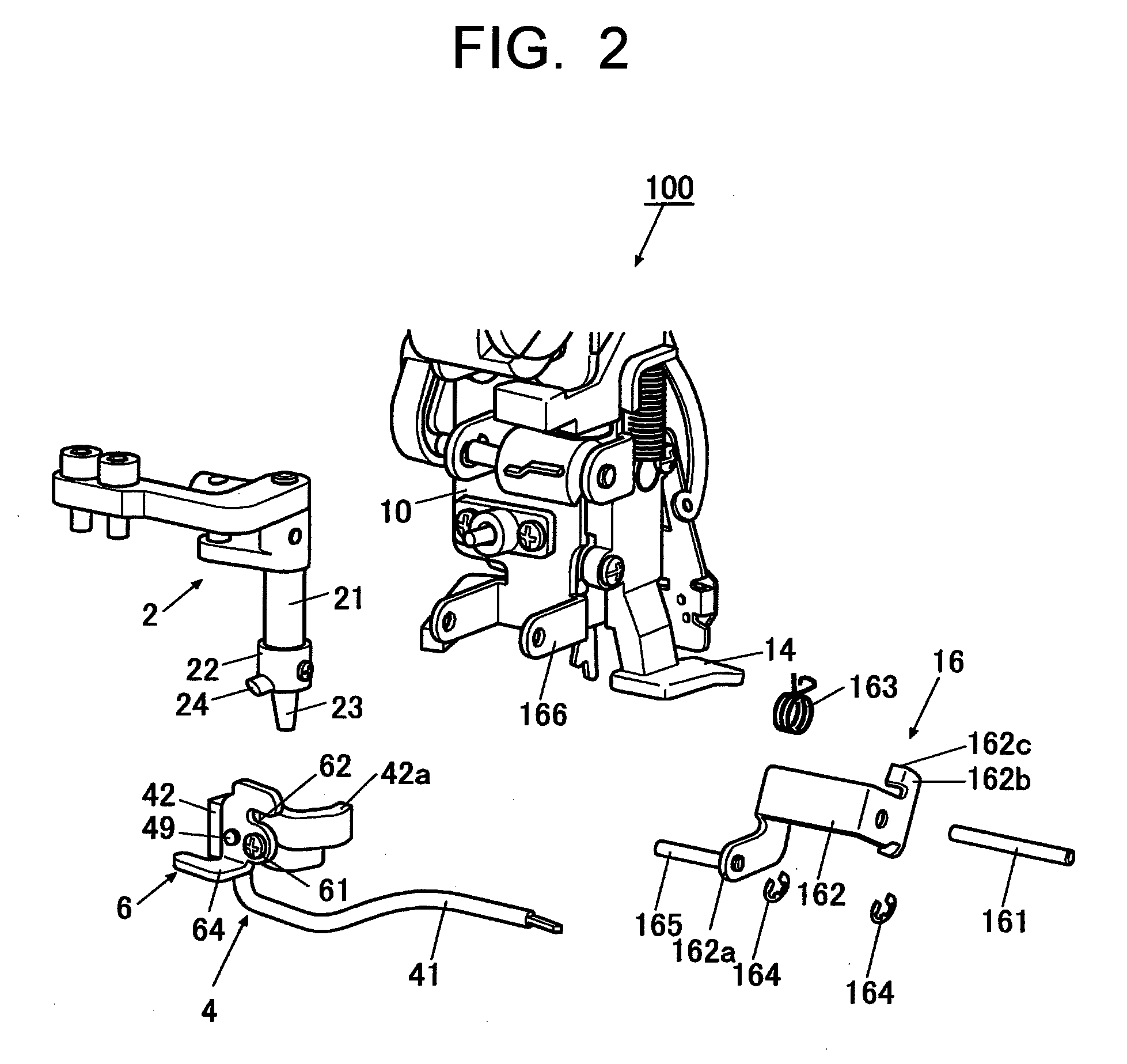

A threading to a looper is performed with one-touch operation. A looper threading / sewing changeover mechanism 30 including a push button 33 for a pressing operation of a push button shaft 32 that a control pin 31 is protruded and provided, a control groove cam 38 which includes a first control groove cam portion 34—a fourth control groove cam portion 37 which receive the control pin, a connecting movement plate 40 which supports a thread guide portion and which is elastically repelled toward a threading state that a thread guide outlet of the thread guide portion contacts to a looper thread inlet of the looper by a first spring 39, and a connecting positioning plate 82 which rotates together with a main shaft 2 integrally and has a peripheral surface 80 that a tip portion 41 of the push button shaft contacts and has a notch portion 81 that the tip portion of the push button shaft is fitted is provided.

Owner:SUZUKI MFG CO LTD

Method and device for threading needles

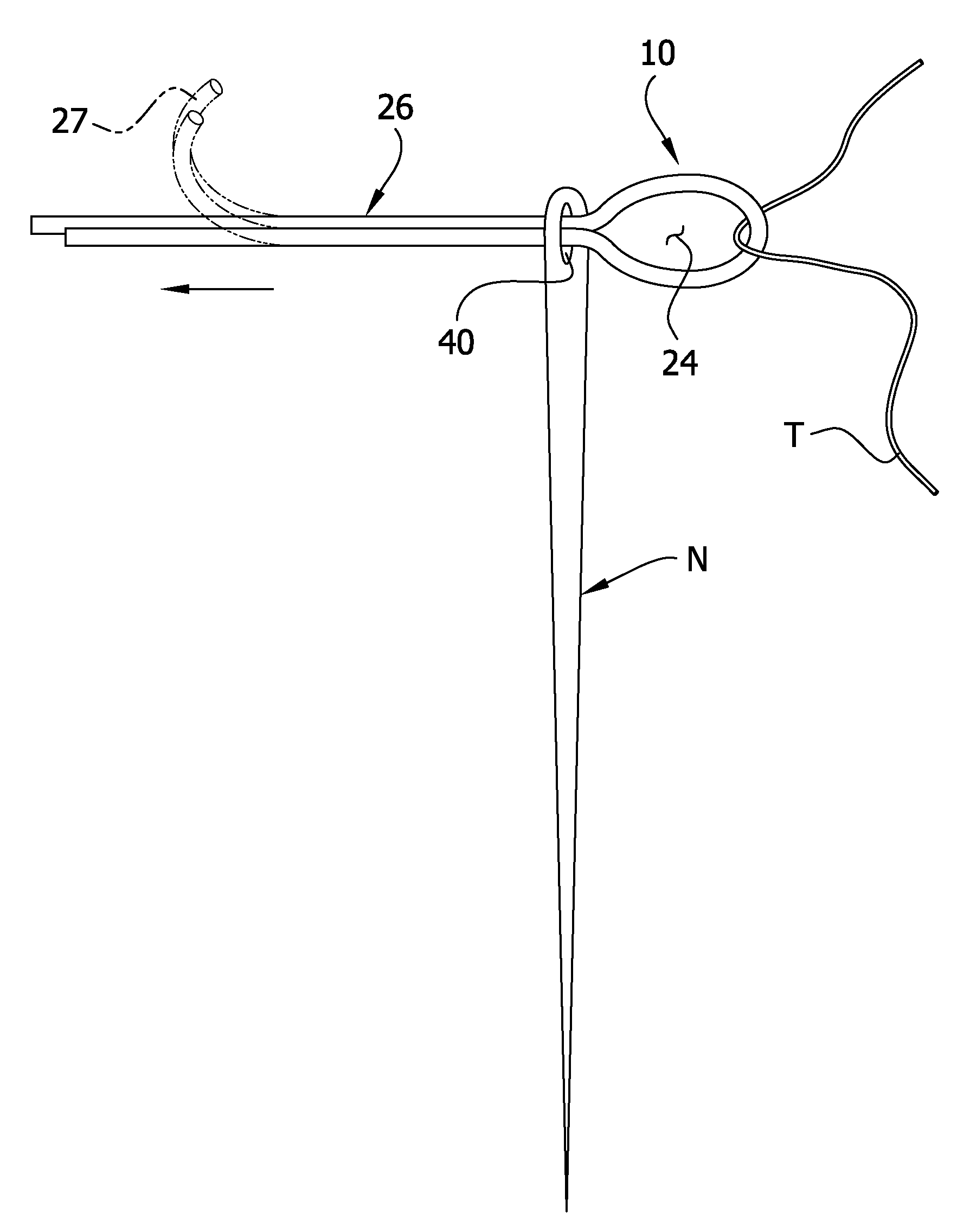

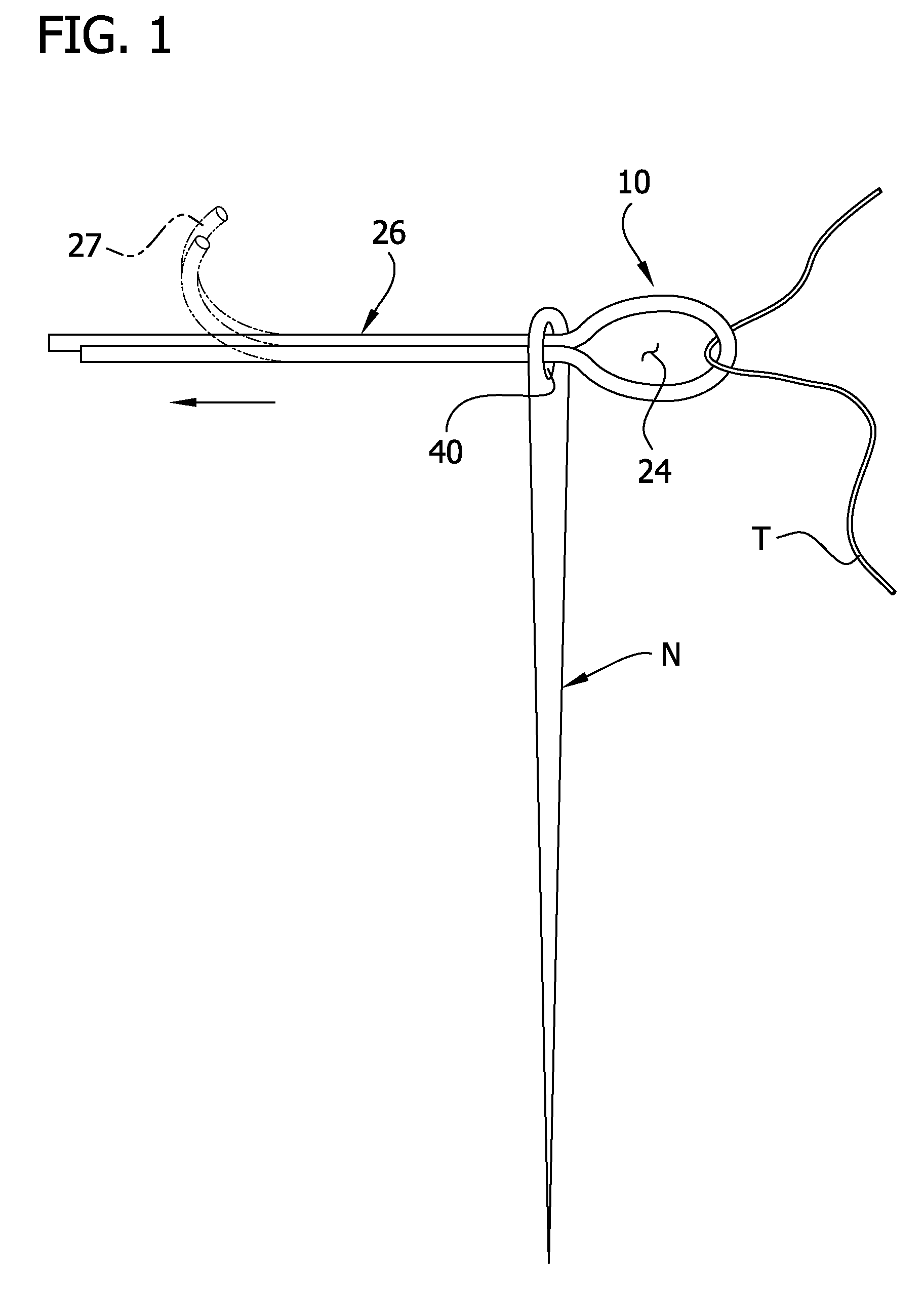

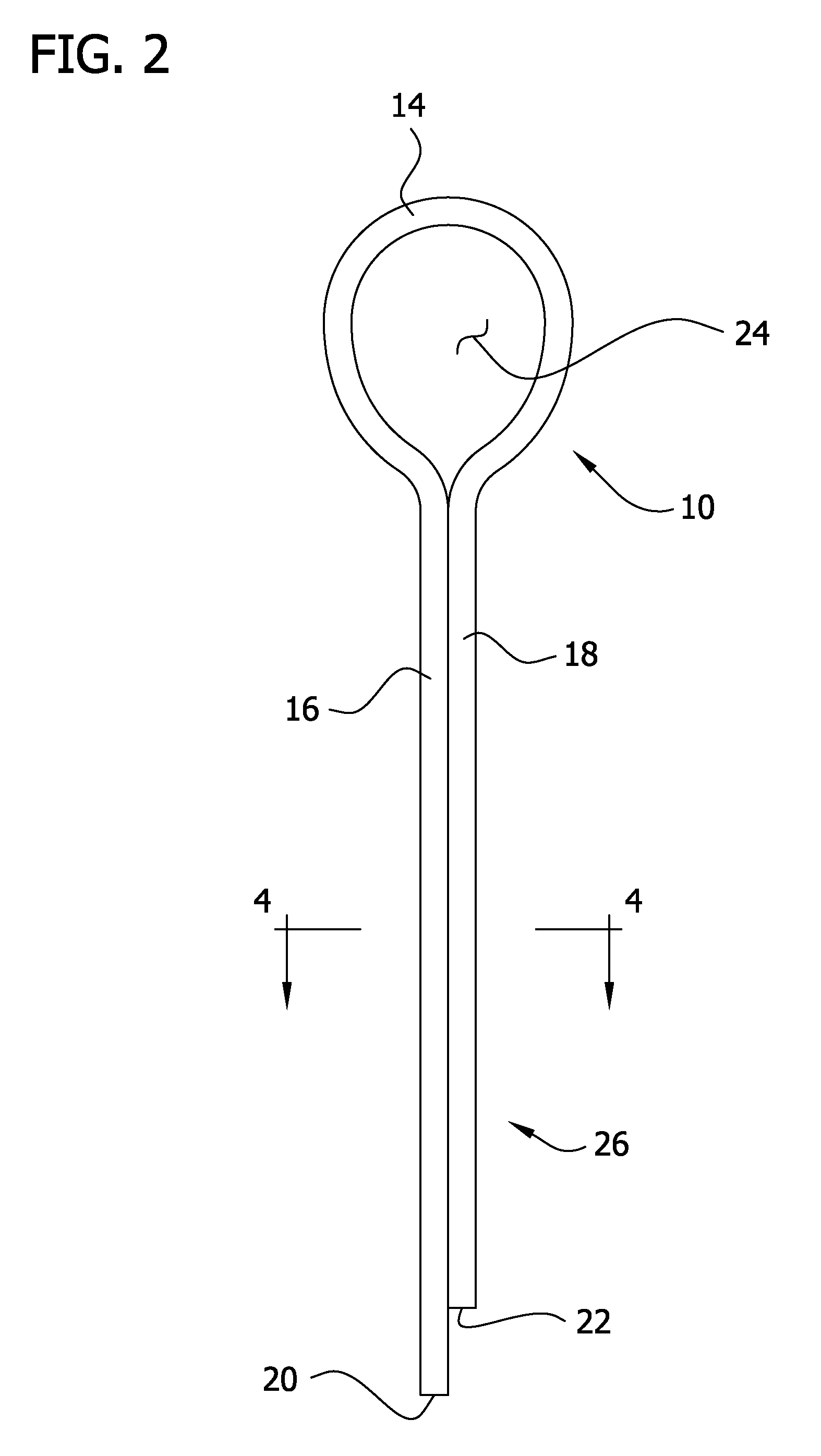

A method and device for inserting a strand of a selected thread or yarn through the eyelet of a needle, in which the device is made from an elongate, unitary non-metallic monofilament having end zones and an intermediate central zone forming a closed strand-carrying loophole; and the method including the steps of forming the device by bringing the end zones into a parallel relationship and bonding them together to form a threading stem and also form the central zone into the closed loophole, placing an end portion of the selected strand through the loophole, inserting the stem into the needle eyelet, and pulling the threading stem to draw the loophole and strand entirely through the needle eyelet.

Owner:HEYWOOD JANE F

Looper threading apparatus for sewing machine

Owner:JUKI CORP

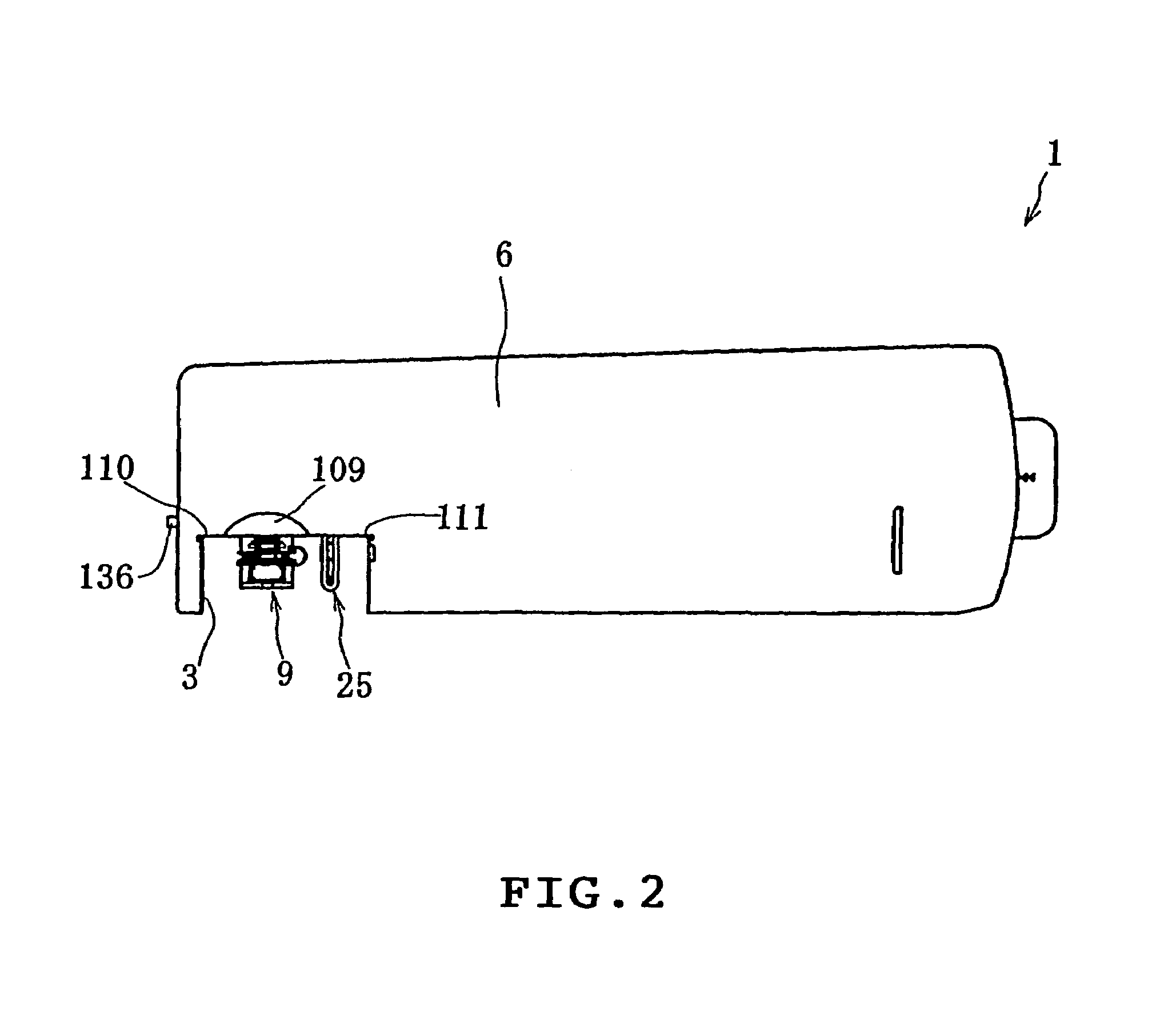

Sewing machine

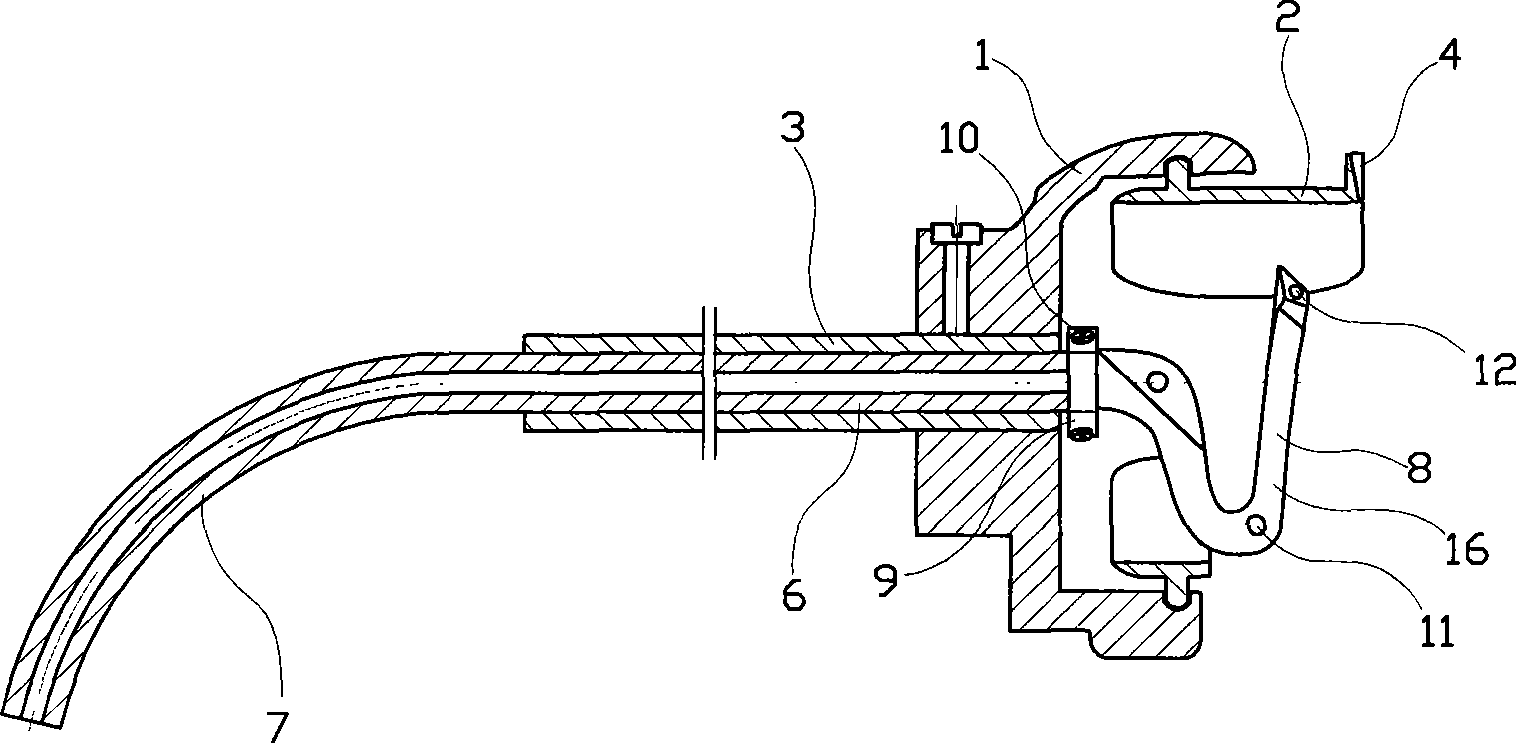

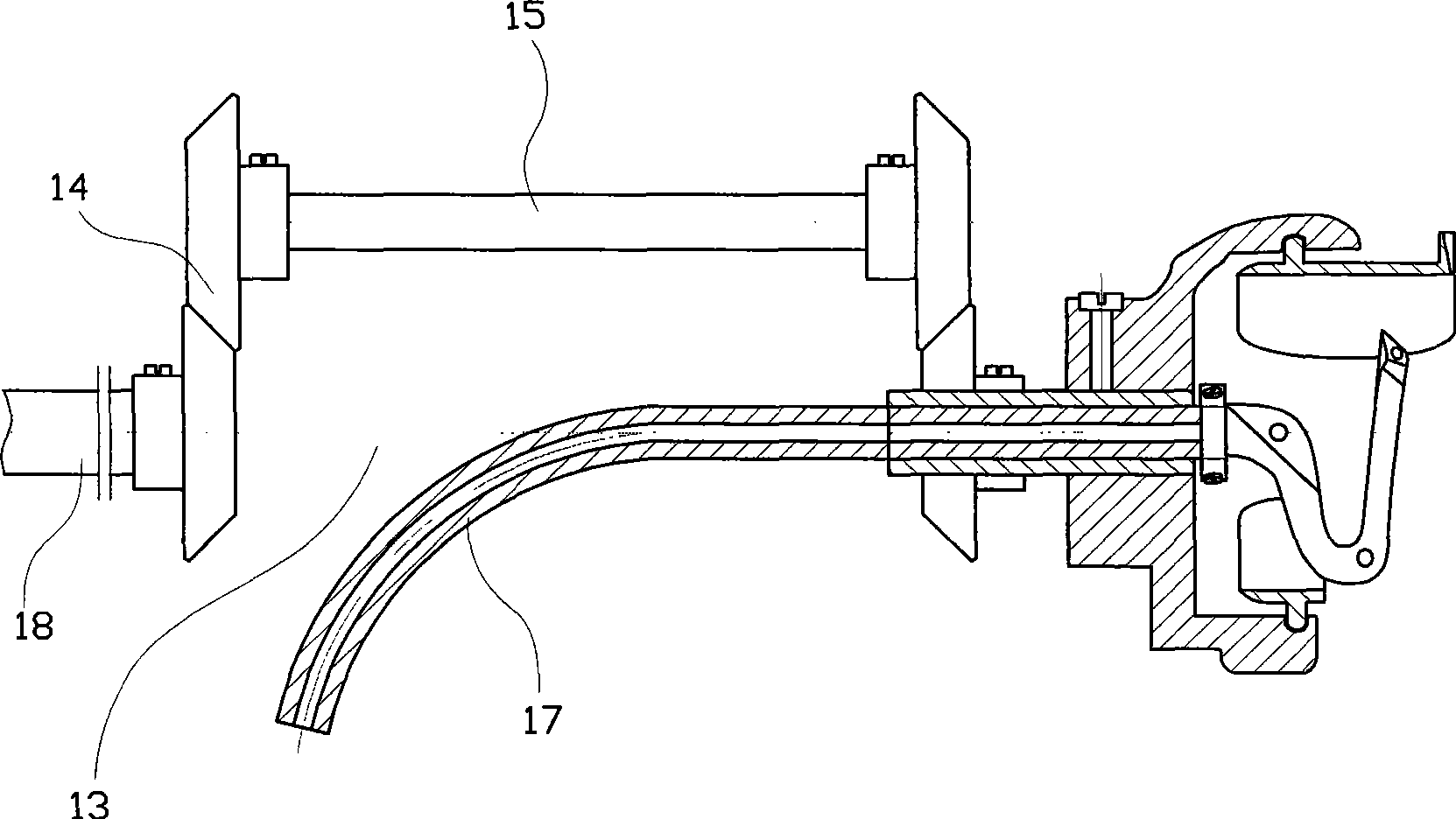

A sewing machine includes a looper formed with a thread hole, a looper shaft holding the looper, and a thread pipe fixed to the looper shaft. The thread pipe includes a thread inserting port at one end and a thread discharging port at the other end. The sewing machine further includes a nozzle from which air is sprayed toward the thread inserting port, a switching mechanism operable to disconnect the looper from the looper shaft when the looper is at a front position, and a moving member which moves the looper to a rear position when the looper is disconnected from the looper shaft by the switching mechanism. When the looper is disconnected from the looper shaft and is moved to the rear position, the thread discharging port matches the thread hole, and the thread inserting port becomes close to the nozzle.

Owner:JUKI CORP

Sewing machine

InactiveUS20080134950A1Easy to optimizeSewing-machine control devicesFilament handlingThreaded pipeEngineering

A sewing machine includes a looper formed with a thread hole, a looper shaft holding the looper, and a thread pipe fixed to the looper shaft. The thread pipe includes a thread inserting port at one end and a thread discharging port at the other end. The sewing machine further includes a nozzle from which air is sprayed toward the thread inserting port, a switching mechanism operable to disconnect the looper from the looper shaft when the looper is at a front position, and a moving member which moves the looper to a rear position when the looper is disconnected from the looper shaft by the switching mechanism. When the looper is disconnected from the looper shaft and is moved to the rear position, the thread discharging port matches the thread hole, and the thread inserting port becomes close to the nozzle.

Owner:JUKI CORP

Threading apparatus for sewing machine

InactiveUS6959656B2Reliably be passed through needle eyeReduce movement speedThread-laying mechanismsNeedle-threading devicesEngineeringSewing needle

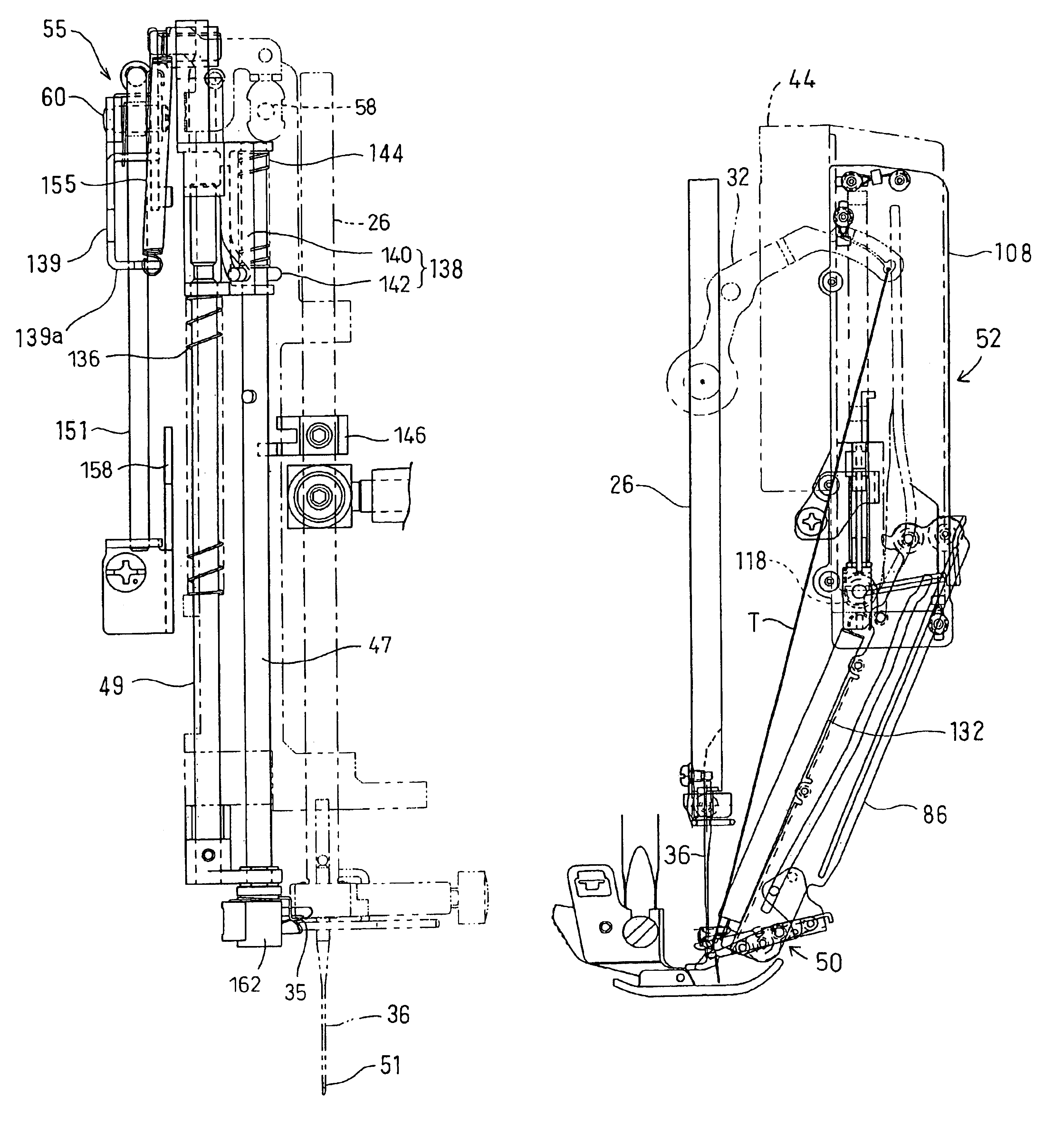

A sewing machine includes a sewing needle having an eye, a threading hook passed through the eye of the needle, a traveling mechanism for traveling the threading hook so that the threading hook is advanced through the eye of the needle and retreated through the eye of the needle, a thread holding member for holding the thread, a moving mechanism for moving the thread holding member between a first position where the thread holding member is close to the threading hook having been advanced through the eye of the needle and a second position where the thread holding member is away from the threading hook having been advanced through the eye of the needle, and a speed reducing mechanism for reducing a moving speed of the thread holding member while the thread holding member is holding the thread and being moved near the threading hook having been advanced through the eye of the needle.

Owner:BROTHER KOGYO KK

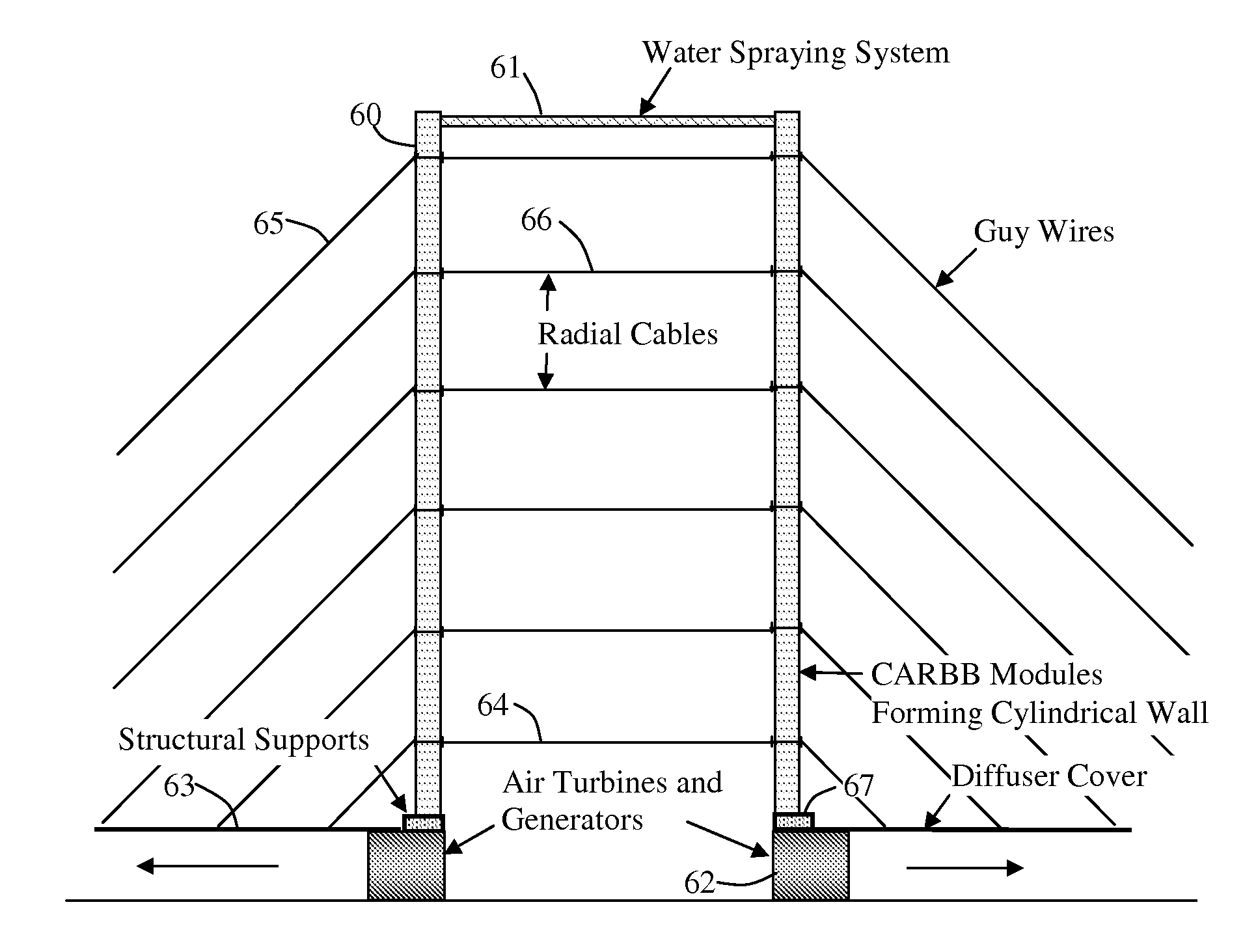

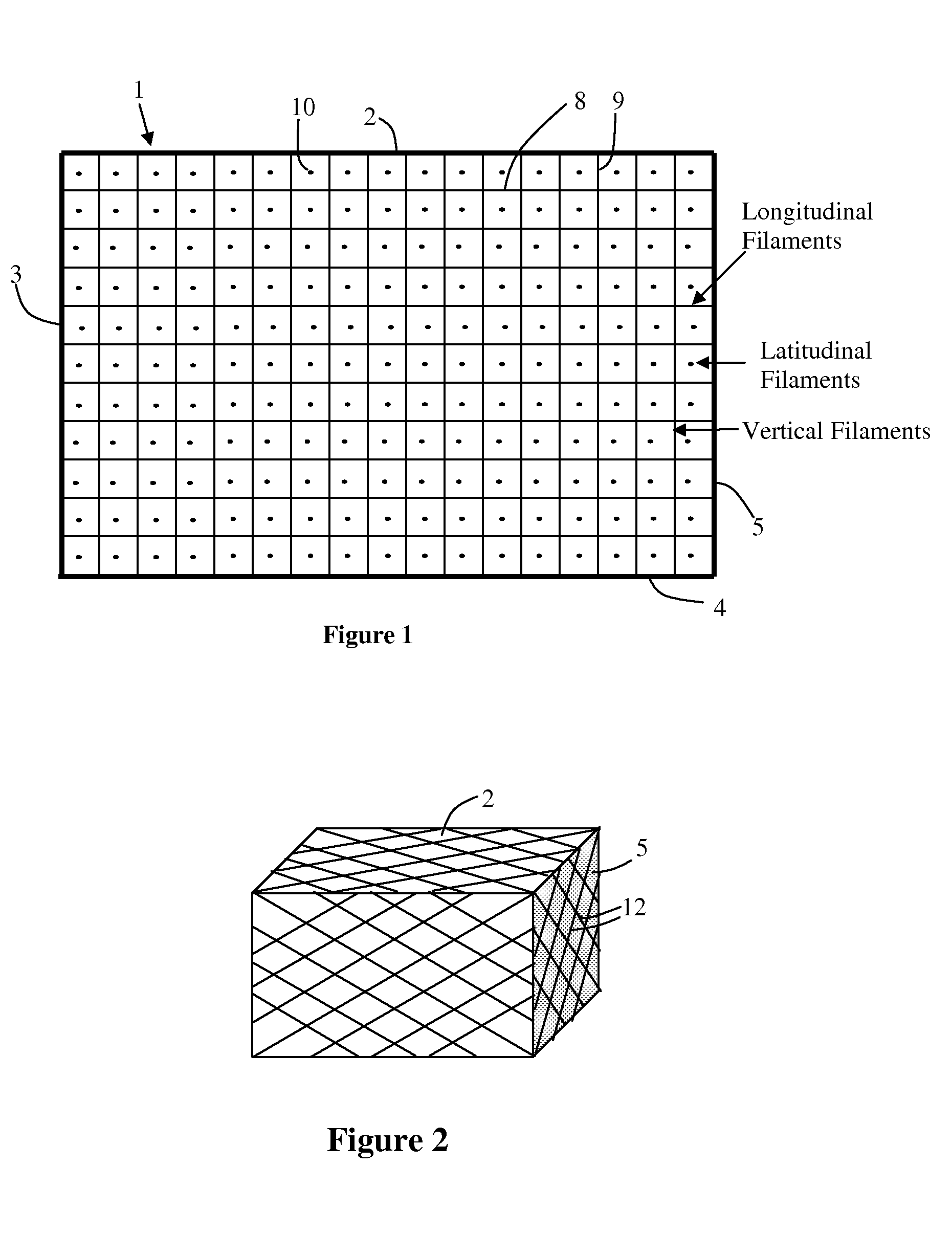

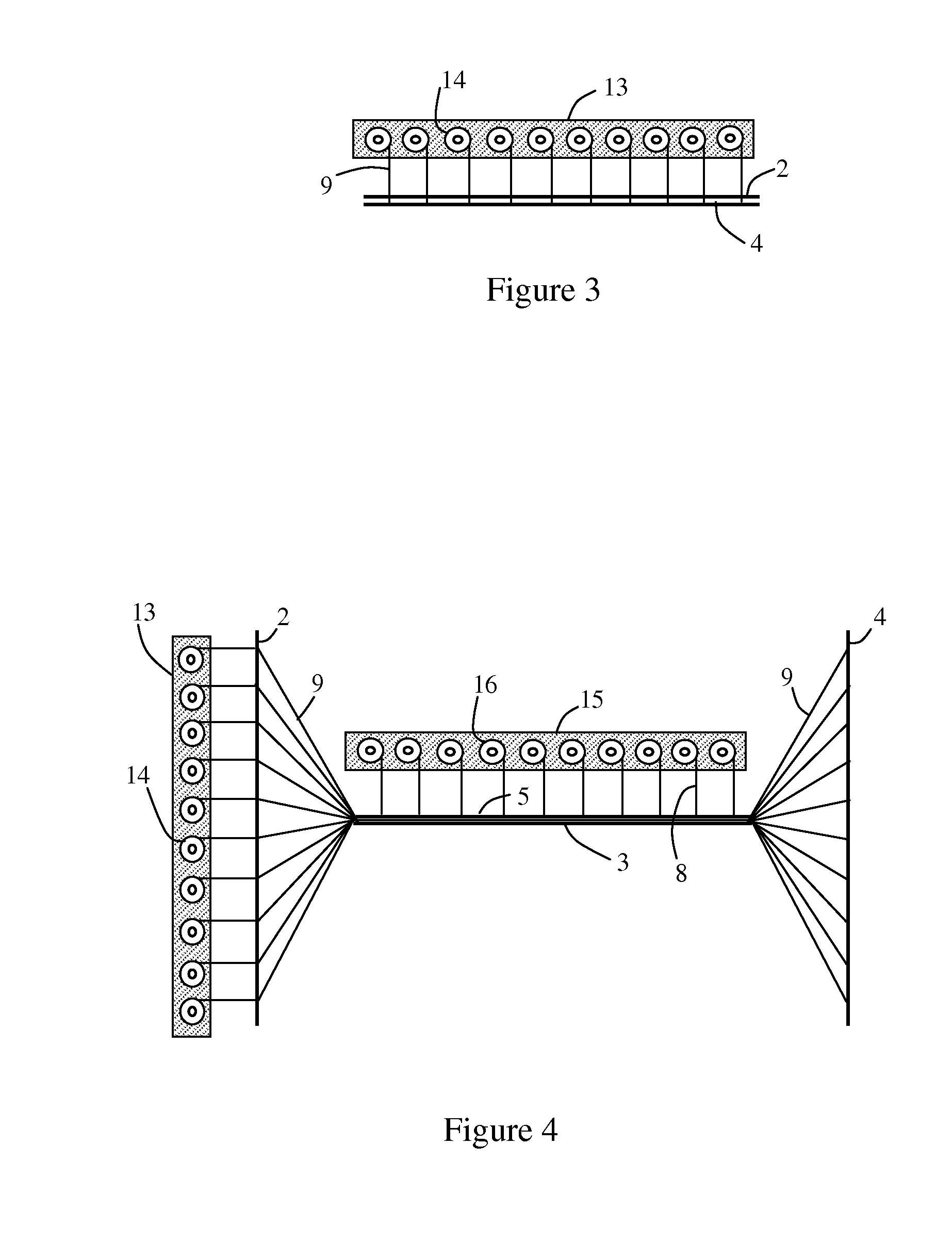

Compressed-Air Rigid Building Blocks

InactiveUS20090260301A1High strengthHigh modulusMould separation apparatusCamera film strip handlingBrickEngineering

The outstanding tensile strength of some materials are used in compression applications by using air pressure to supply the outward force on an enclosure and by using interior tension members to maintain the geometry of the air-pressurized structure. The air pressure on each face of the structure is balanced by the tension in the tension members. Due to the high modulus of the tension members, the air-pressurized structures are very rigid. It is the air pressure that actually supports any load placed on the structure, but it is the tension members that maintain the geometry when the load is removed, and the strength of the tension members determine how much air pressure can be sustained. The mass of tension material required in such a structure is roughly equivalent to the amount of filament material required in a cable to support the same load. The Compressed-air Rigid Building Blocks can be stacked like bricks to form strong, lightweight walls, buildings, towers, and other structures.

Owner:PRUEITT MELVIN L

Threading device of sewing machine

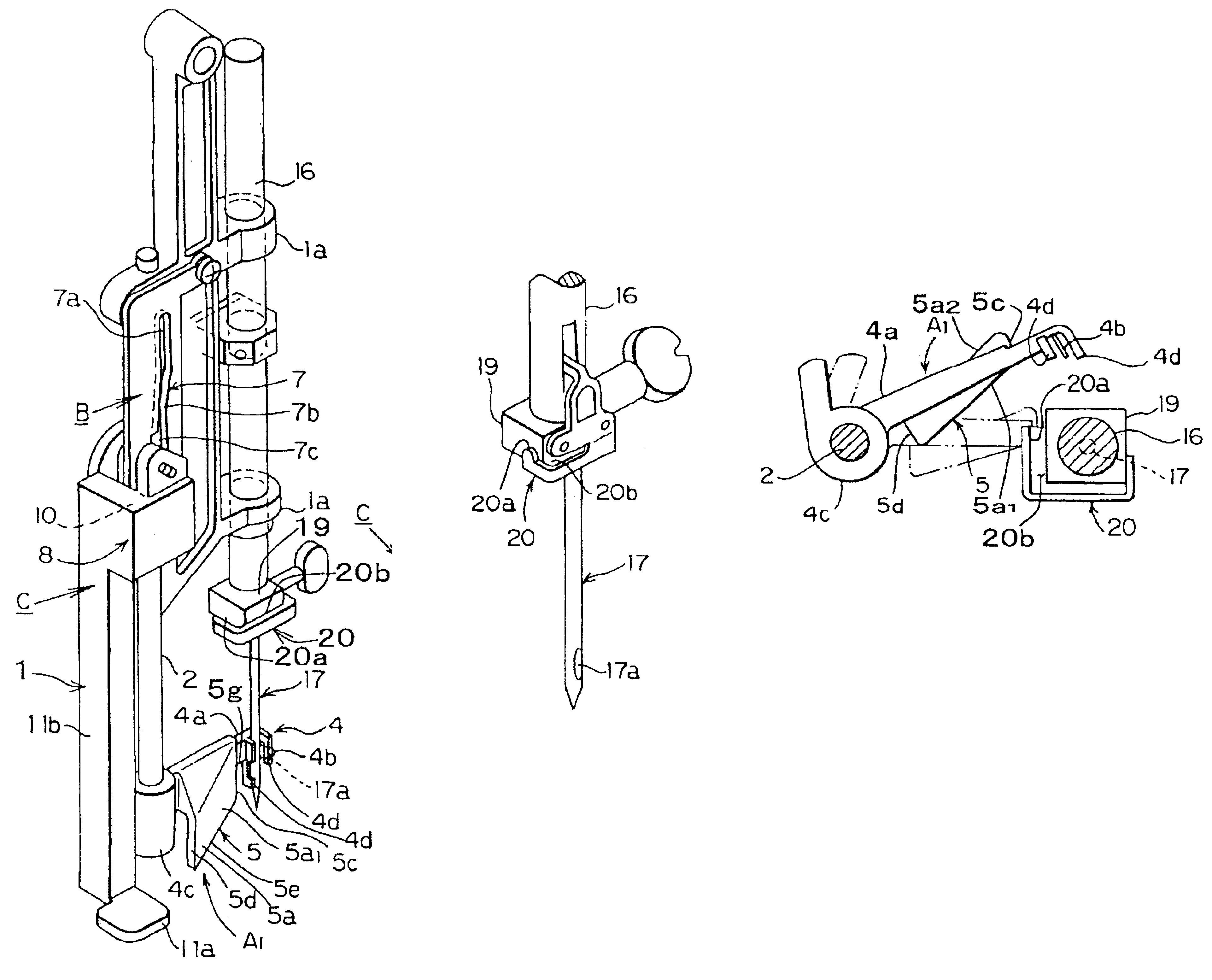

ActiveUS6918344B2Easy to operateSimple structureThread-laying mechanismsNeedle-threading devicesBiomedical engineeringSewing machine

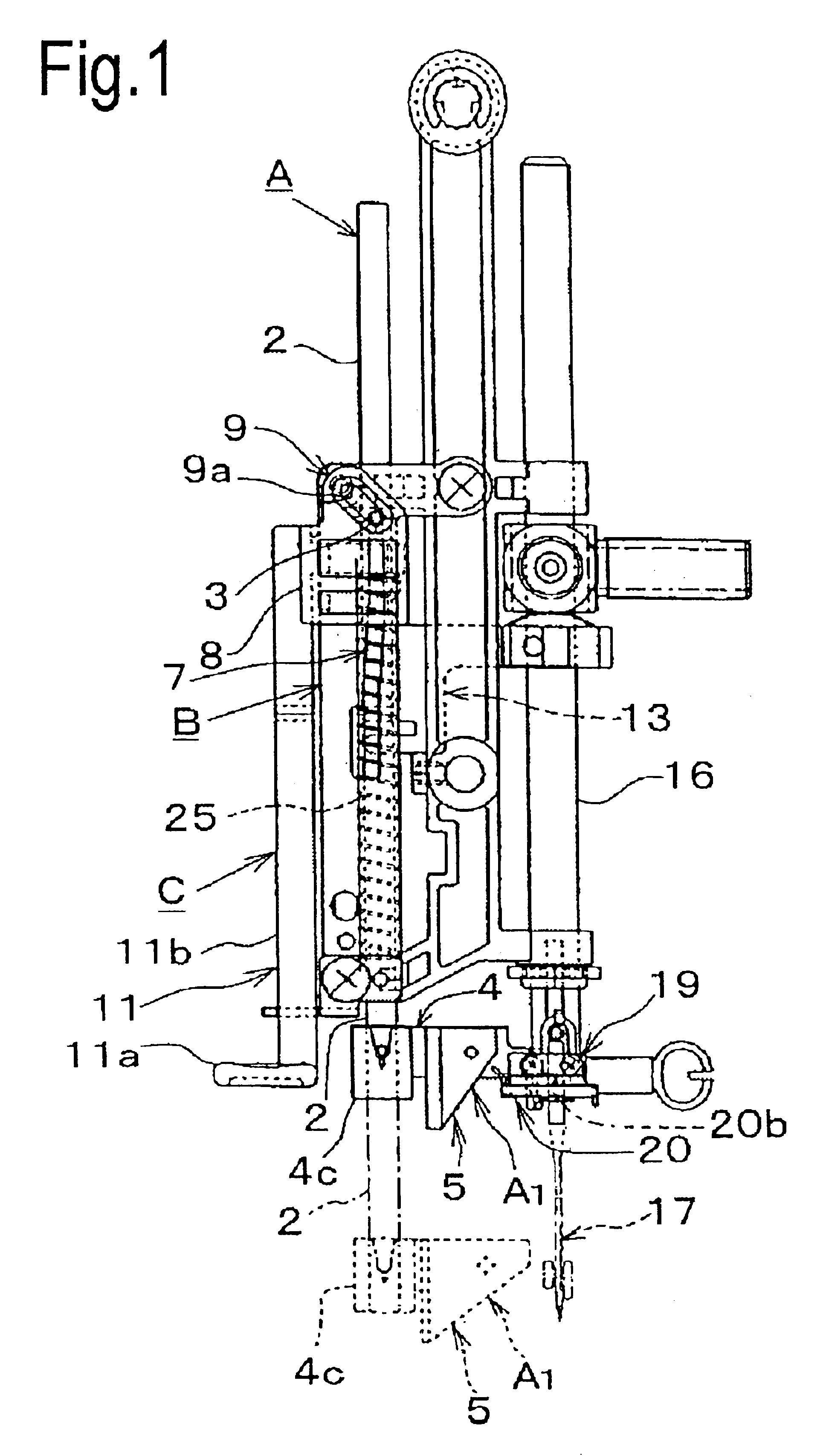

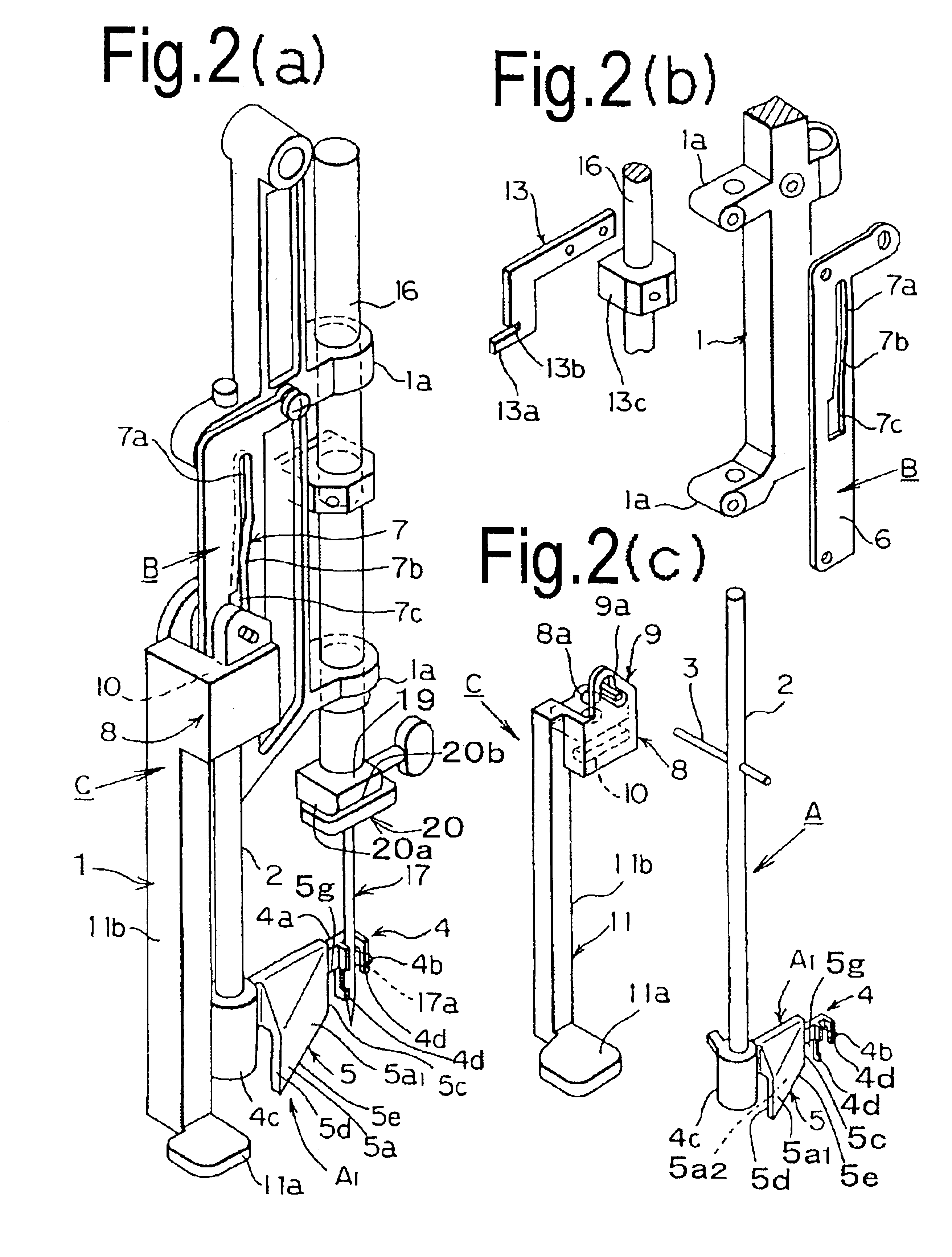

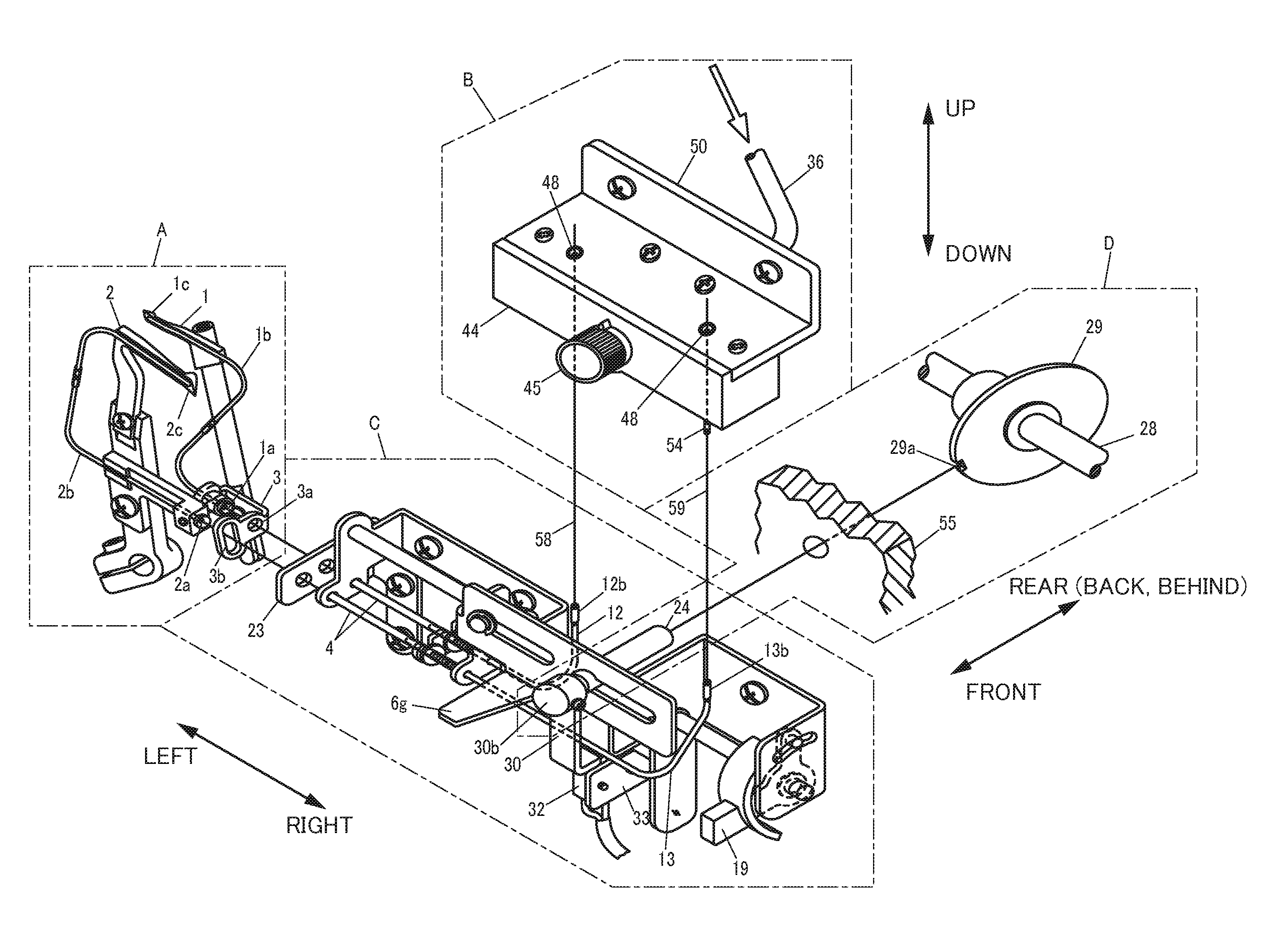

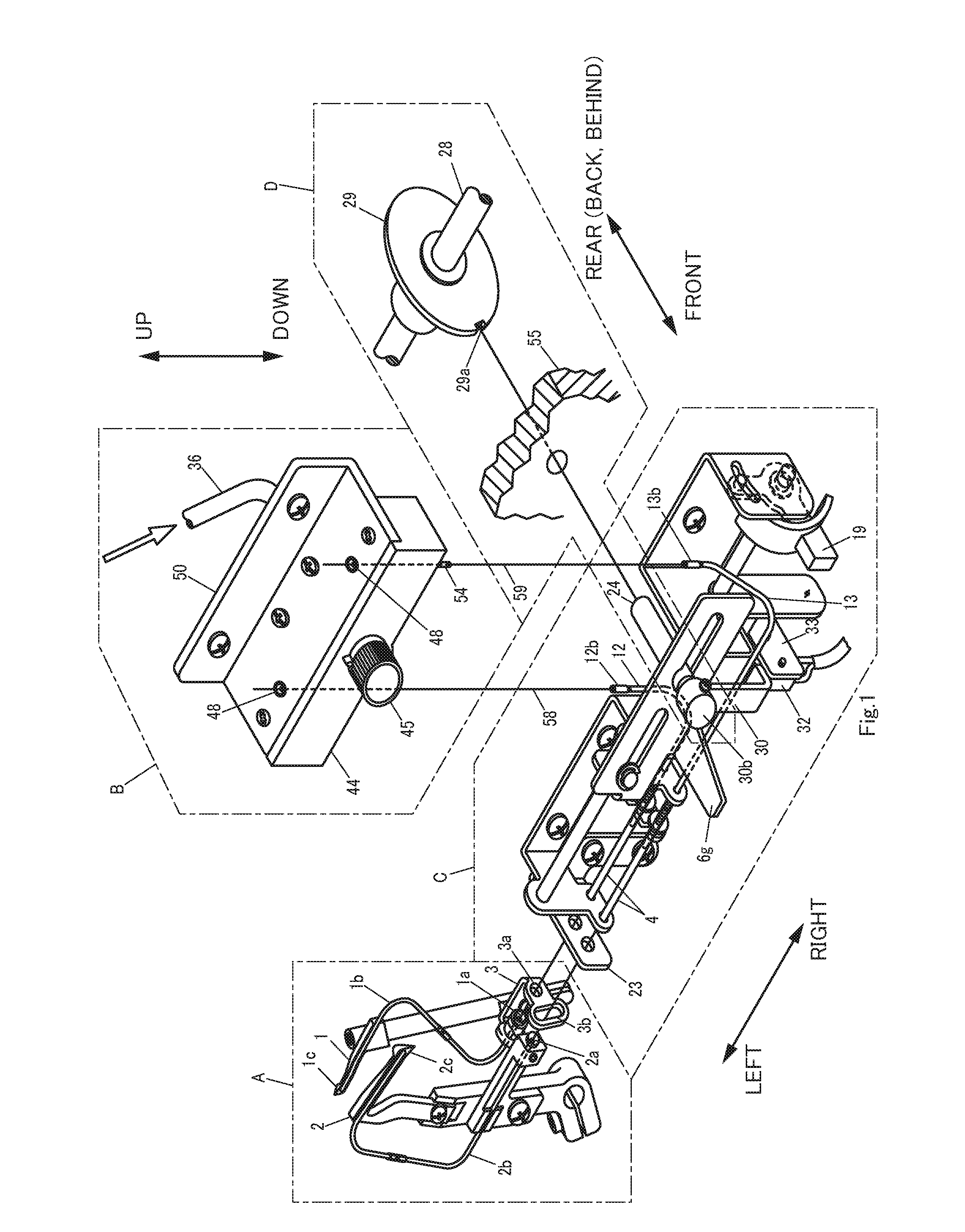

A threading device of sewing machine is disclosed, wherein the upper thread extended from a thread supply mounted on a sewing machine body may be easily and smoothly guided into engagement with a thread holder simultaneously when the threading device is operated to pass the upper thread through the eye of needle attached to the lower end of needle bar, the thread holder being arranged between the thread supply and the needle. The threading device comprises a vertically movable needle bar 16 having a needle attached to the lower end thereof, the needle having a needle eye, a needle bar support 1 for supporting the needle bar 16 such that the same may be vertically movable, a thread holder 20 mounted to the lower end of the needle bar 16, a threading member A1 having a thread engaging portion 5 and a threading hook 4b, a threading shaft 2 for having the threading member A1 secured to the lower end thereof, an operating section C for vertically moving and axially rotating the threading shaft 2 to pass the upper thread n through the needle eye 17a, the threading member A1 being so formed as to provide the thread engaging portion 5 for guiding the upper thread to the needle eye 17a, the needle holder 20 being formed with a groove 20b for holding the upper thread n, the groove 20b having an opening 20a at which the upper thread n is guided into the groove 20b from the rear side of the thread holder 20 while the thread engaging portion 5 is moved down with the upper thread n which is to be passed through the needle eye 17a.

Owner:JANOME CORP

Overlock sewing machine

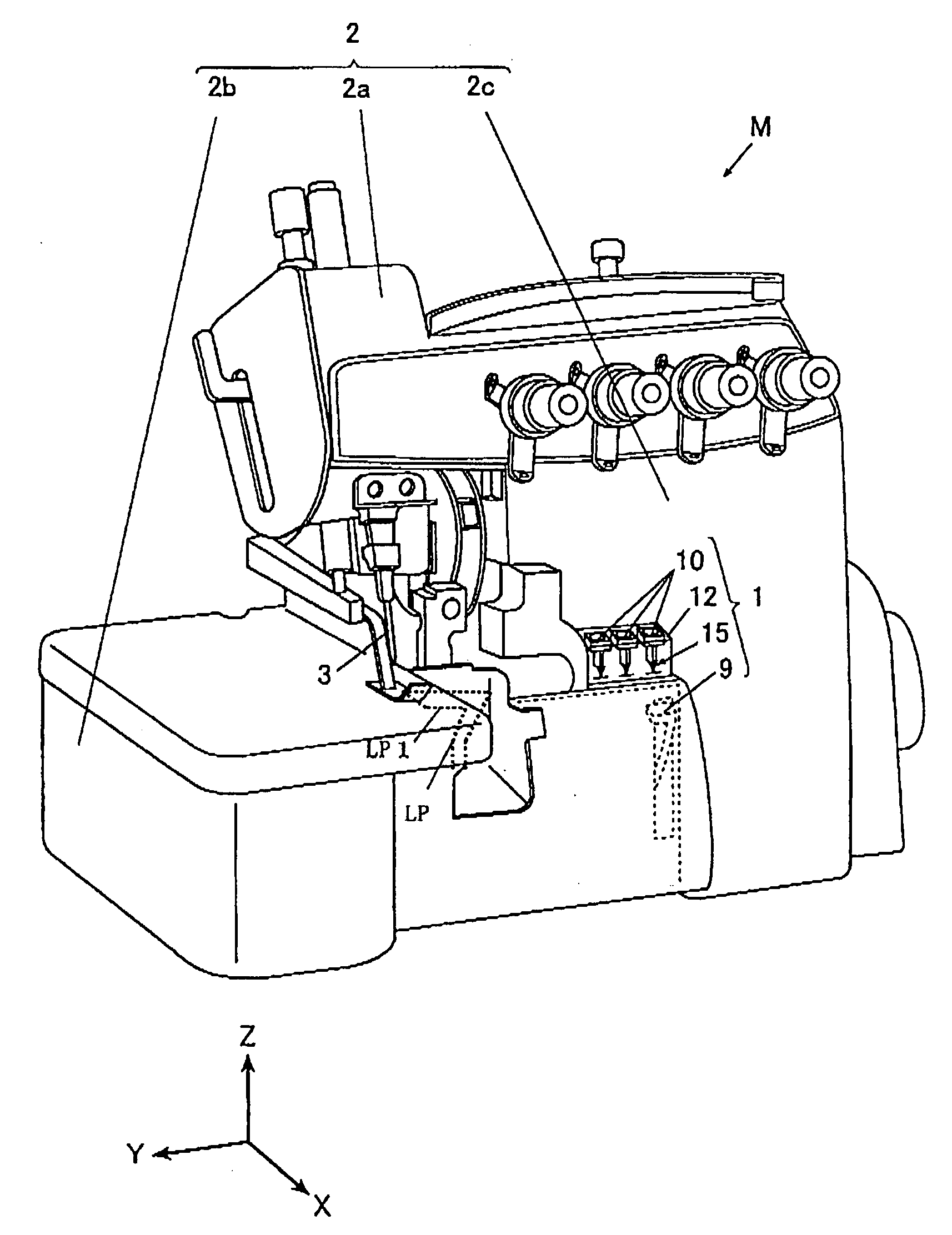

ActiveUS20150267333A1Improve the sense of operationSure easyNeedle-threading devicesLoop takersCamEngineering

An overlock sewing machine includes a main shaft fixing operating arm provided with a shaft pin engaging portion that engages with a fixing inner shaft pin and an arm provided to be operable by a user which are integrally rockable within a specified range, and further includes a main shaft fixing operating spring which urging direction is switched in both directions of an rocking direction by exceeding a neutral point by the rocking movements of the main shaft operating arm and the arm. Further, a switching cam ring is fixed to the main shaft fixing operating shaft that obtains driving force upon abutment of a slide plate pin of the slide plate to rotate the main shaft fixing operating shaft.

Owner:JANOME CORP

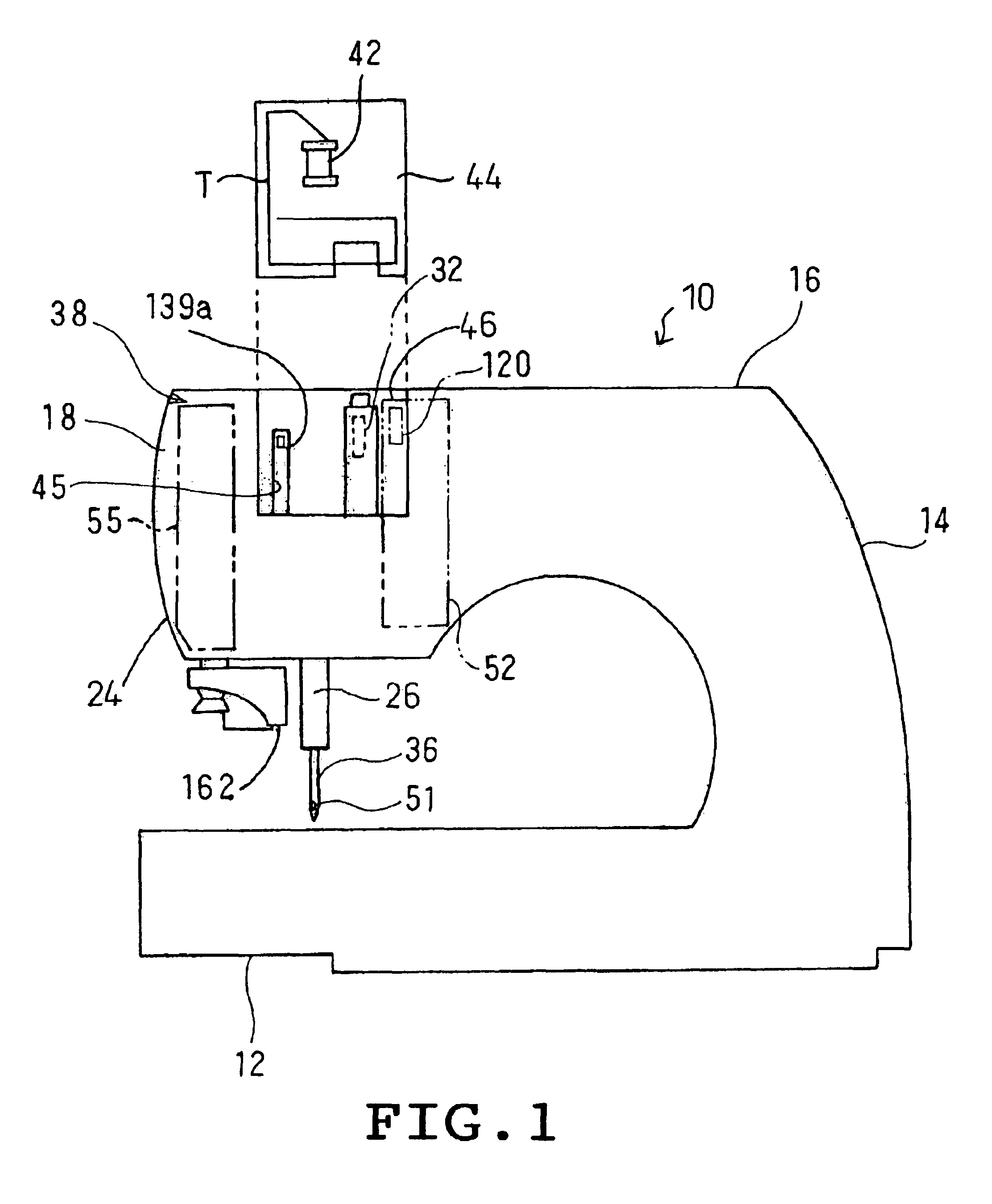

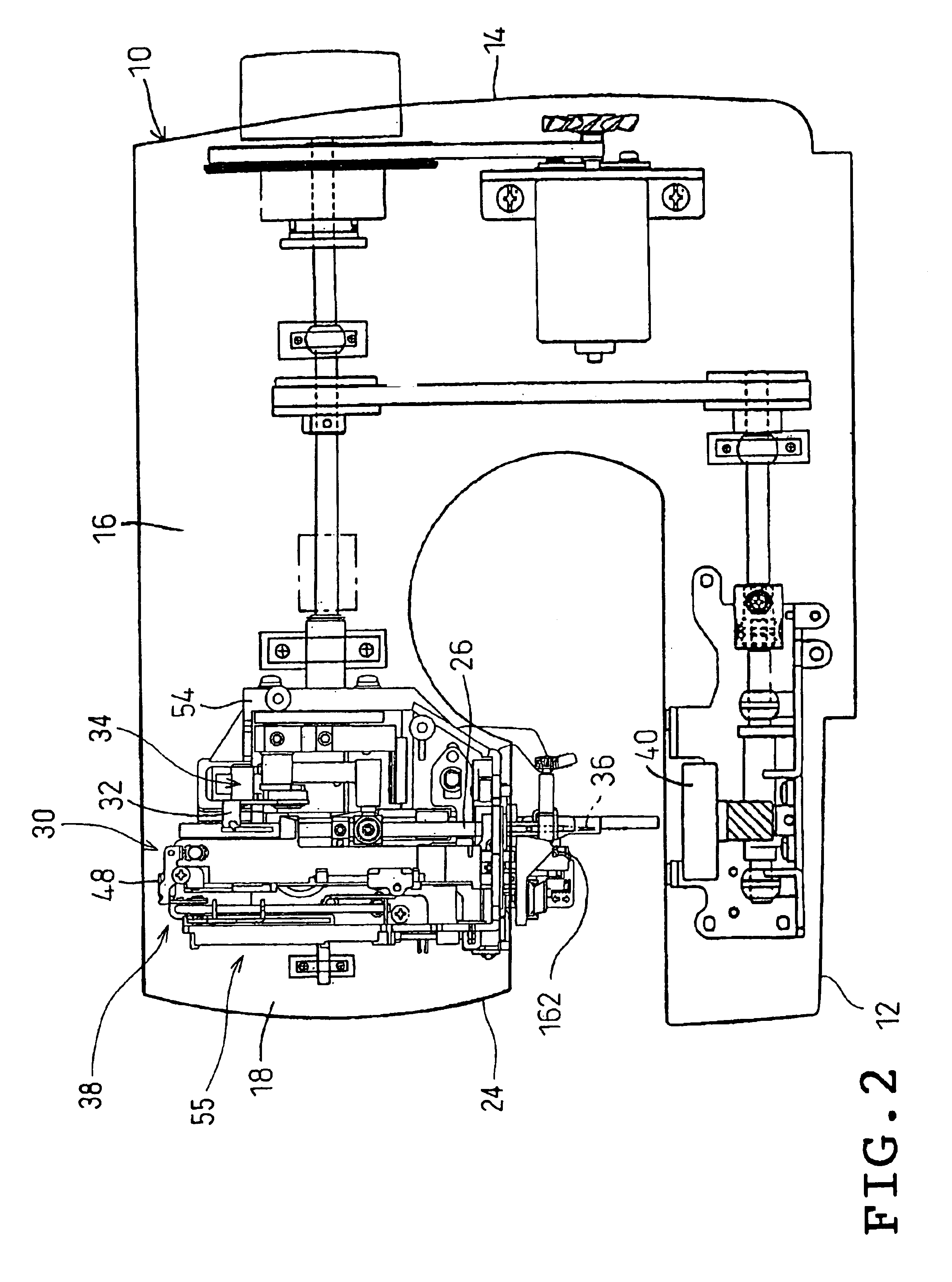

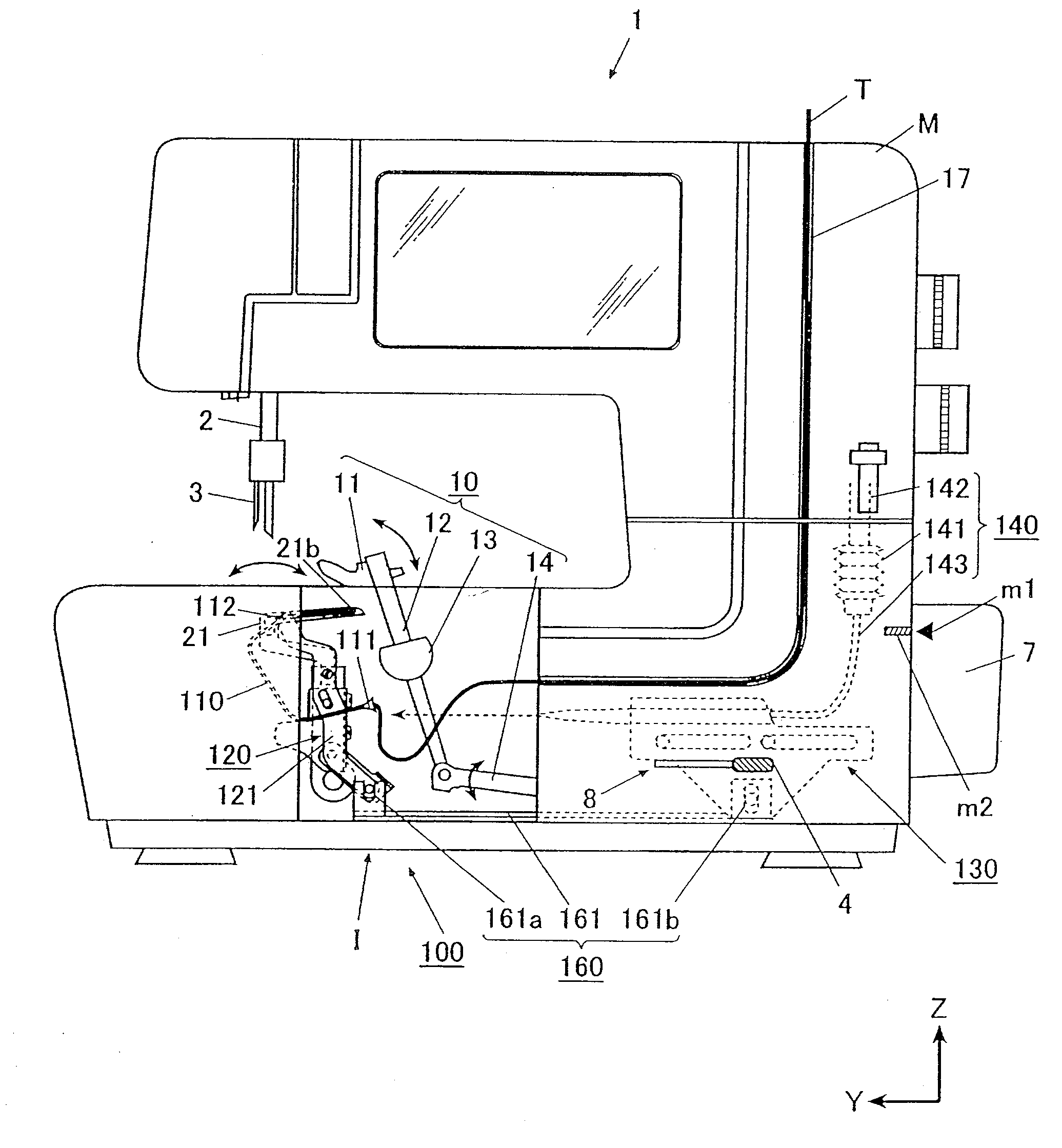

Sewing machine with automatic needle threader

A sewing machine includes a needle bar (11) holding a sewing needle (19) having an eye hole (19a), a needle threading mechanism (17) including a threading hook (74) passing a needle thread (10) through the eye hole (19a) of the sewing needle, a presser bar (12) with a presser foot (20) attached to its lower end, a vertically moving mechanism (80) vertically moving the presser bar (12), a drive mechanism (83) driving the vertically moving mechanism (80), a threading operation unit (25) operating the needle threading mechanism (17), and a drive mechanism controlling unit (C) controlling the drive mechanism (83) vertically moving the presser bar (12) to a position where interference between the presser foot (20) and threading hook (74) is avoided when the needle threading operation unit (25) unit is operated.

Owner:BROTHER KOGYO KK

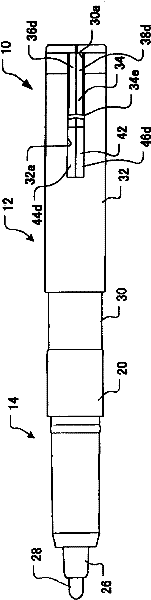

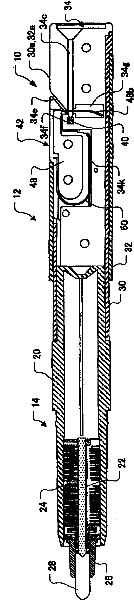

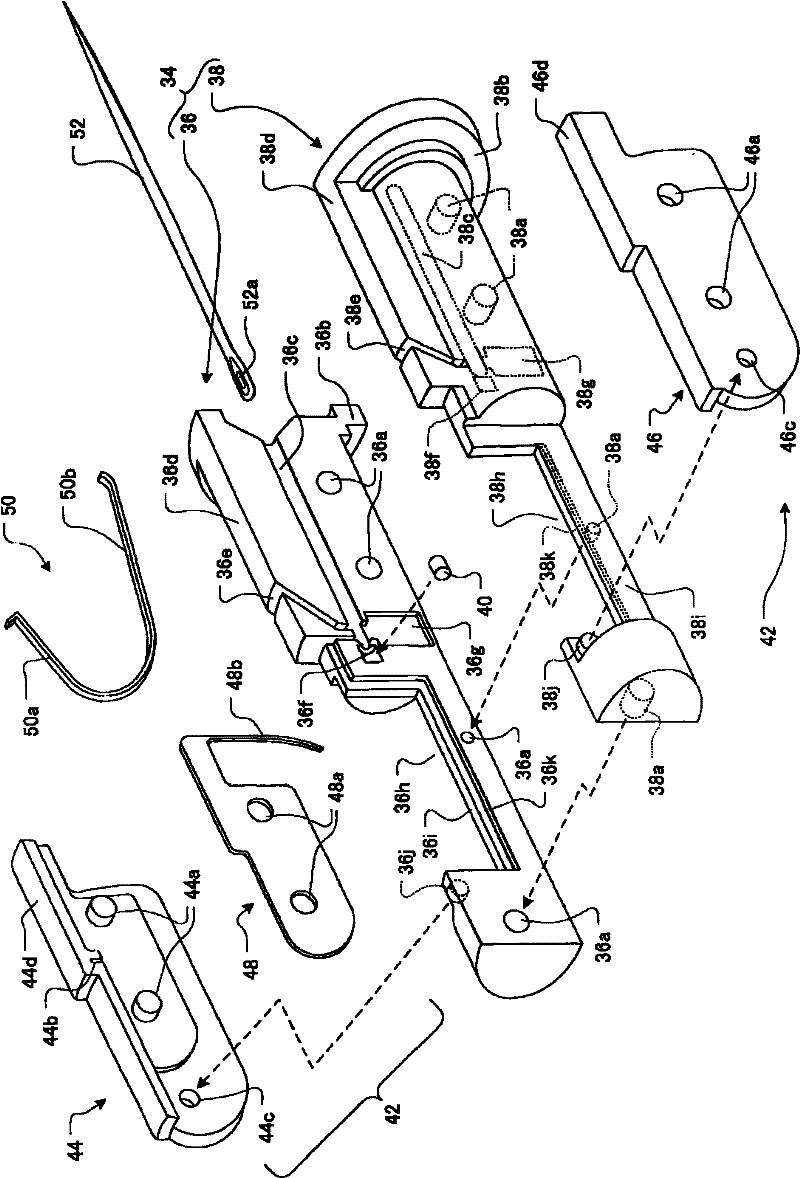

Needle thread passing device

InactiveCN101755084AAvoid interferenceEasy to installSewing needlesNeedle-threading devicesBiomedical engineeringThreaded insert

A needle thread passing device small-sized and conveniently stowable. A needle receiving member (34) has formed therein a needle inserting hole (34c) and a thread inserting slit (34e) having an angle relative to the needle inserting hole (34c). A thread passing member (42) is adapted to be movable between a position at which the thread passing member (42) is separated from the needle receiving member (34) and a position at which the thread passing member (42) is located proximate to the needle receiving member (34). Also, the thread passing member (42) has a thread passing pin (48b) which can, when the thread passing member (42) moves fromthe separated position to the proximate position, push out a thread, inserted in the thread inserting slit (34e), into a needle hole (52a) in a needle (52) inserted in the needle inserting hole (34c). A cover (32) is adapted to be movable relative to a body (30) in which the needle receiving member (34) is housed. The thread passing member (42) is constantly urged to the position at which the thread passing member (42) is separated from the needle receiving member (34). The cover (32) is adapted to be movable between a restraining position for restraining the thread passing member (42) at a position at which the thread passing member (42)is located proximate to the needle receiving member (34) and a permitting position for permitting the thread passing member to move between the separated position at which the thread passing member is separated from the needle receiving member and the proximate position at which thread passing member is located proximate to the needle receiving member.

Owner:KOTOBUKI & CO LTD +1

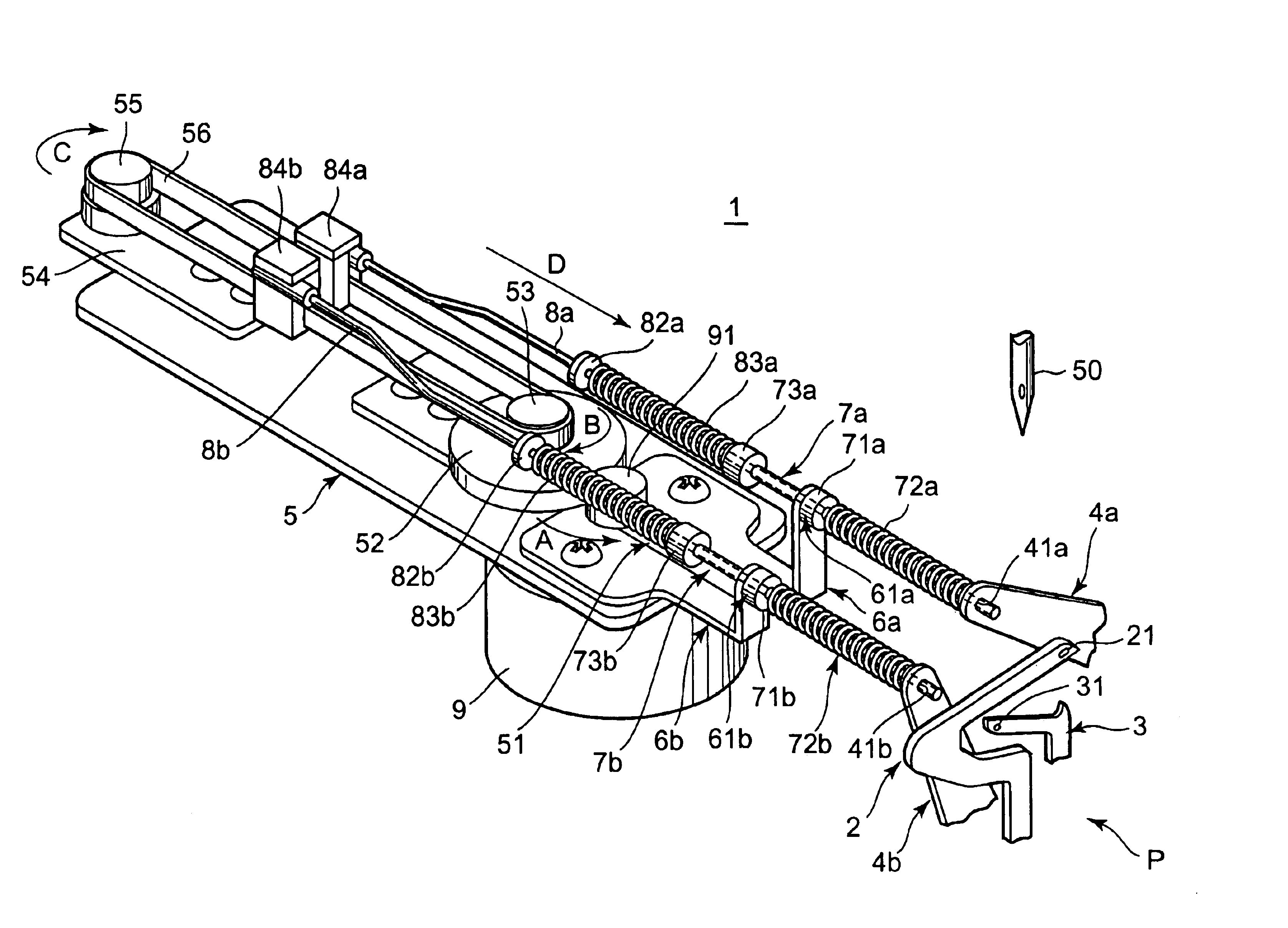

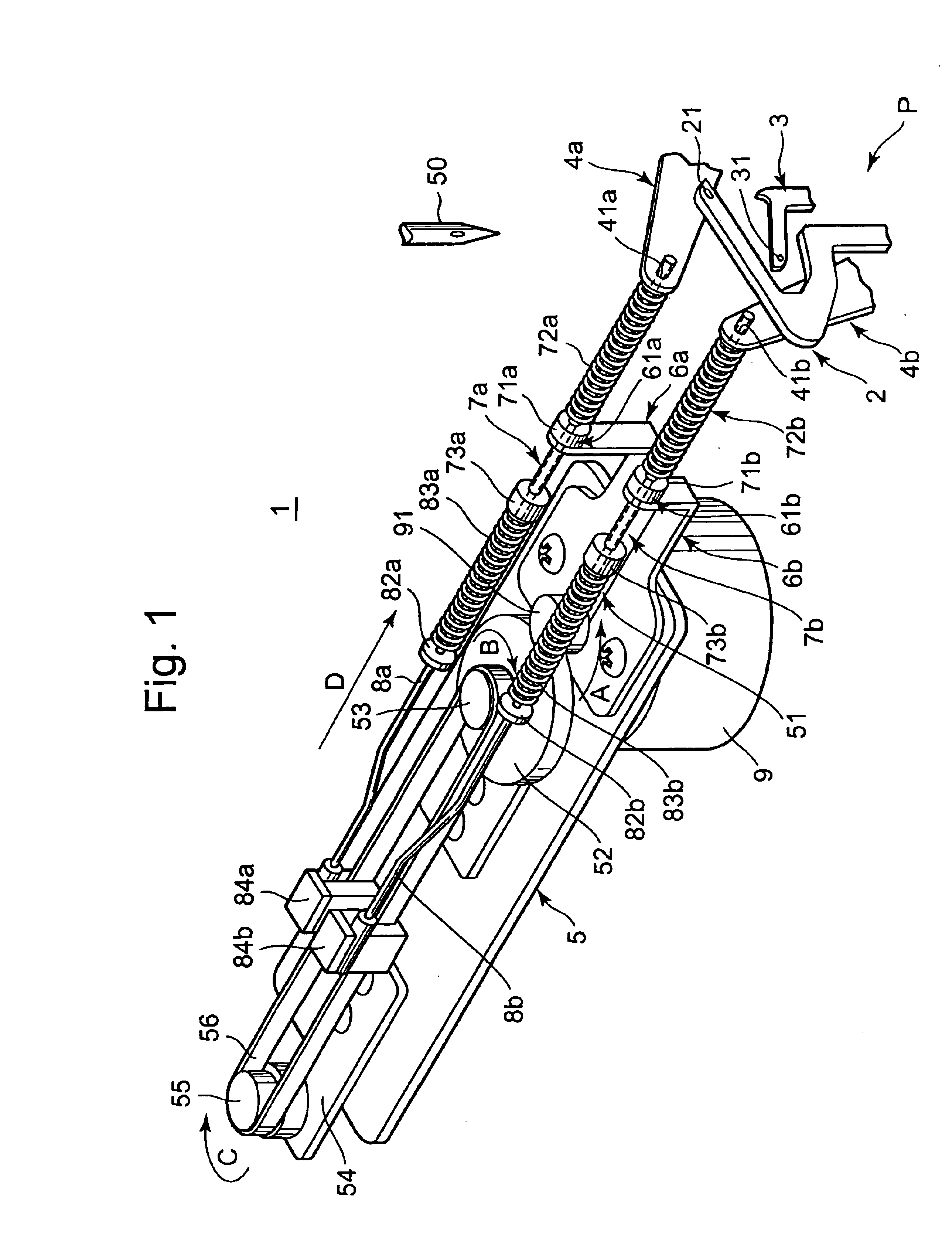

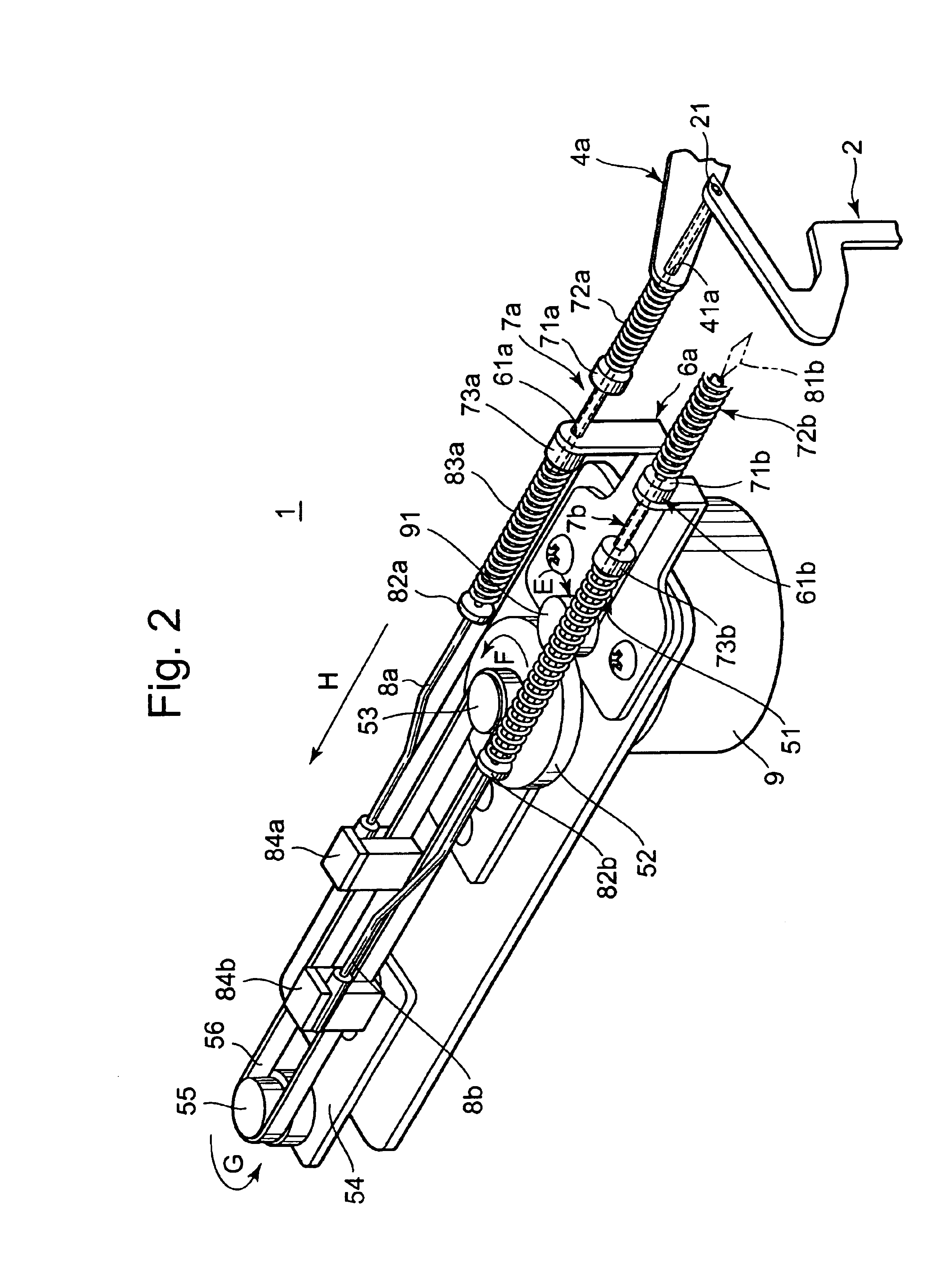

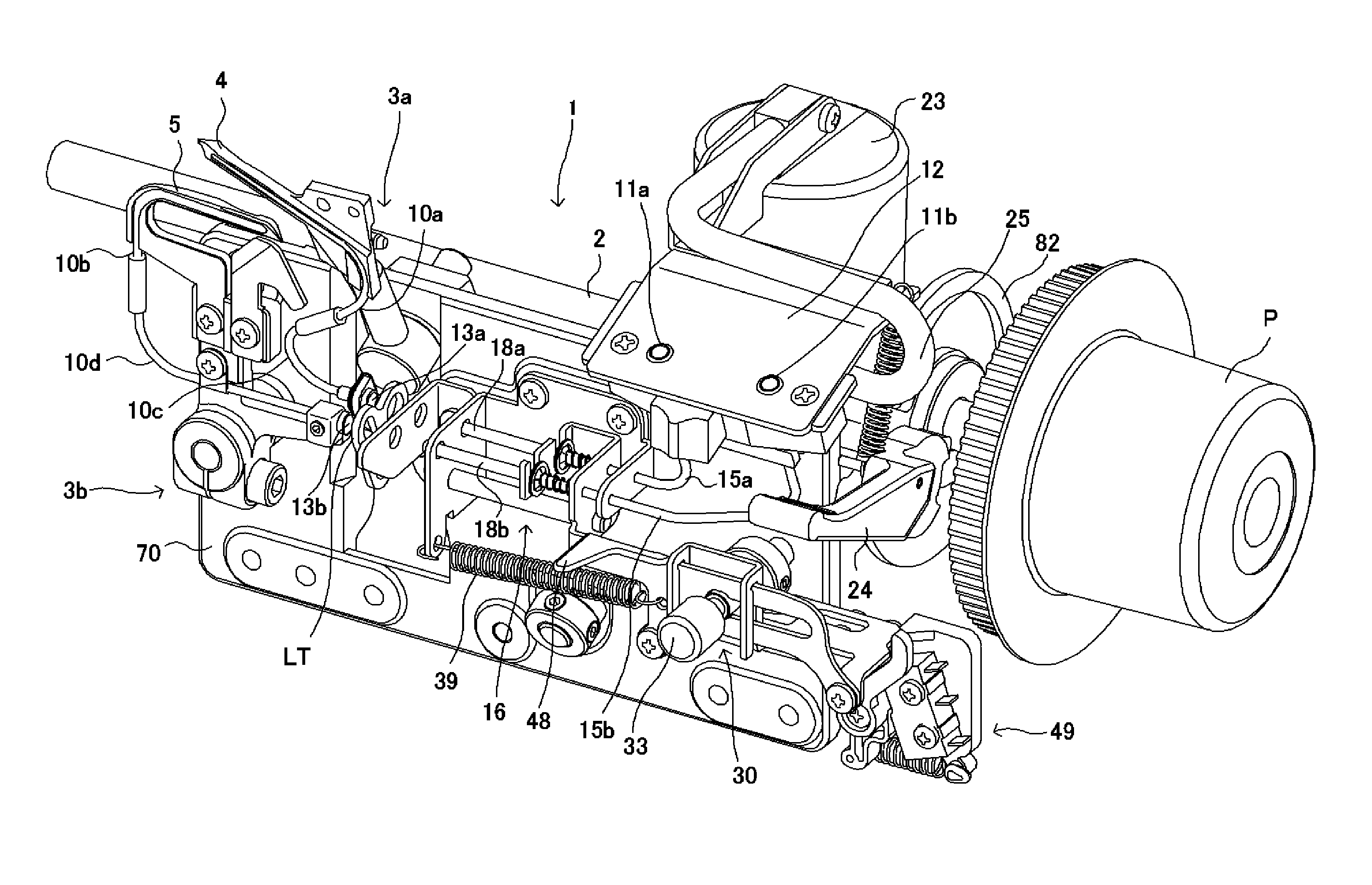

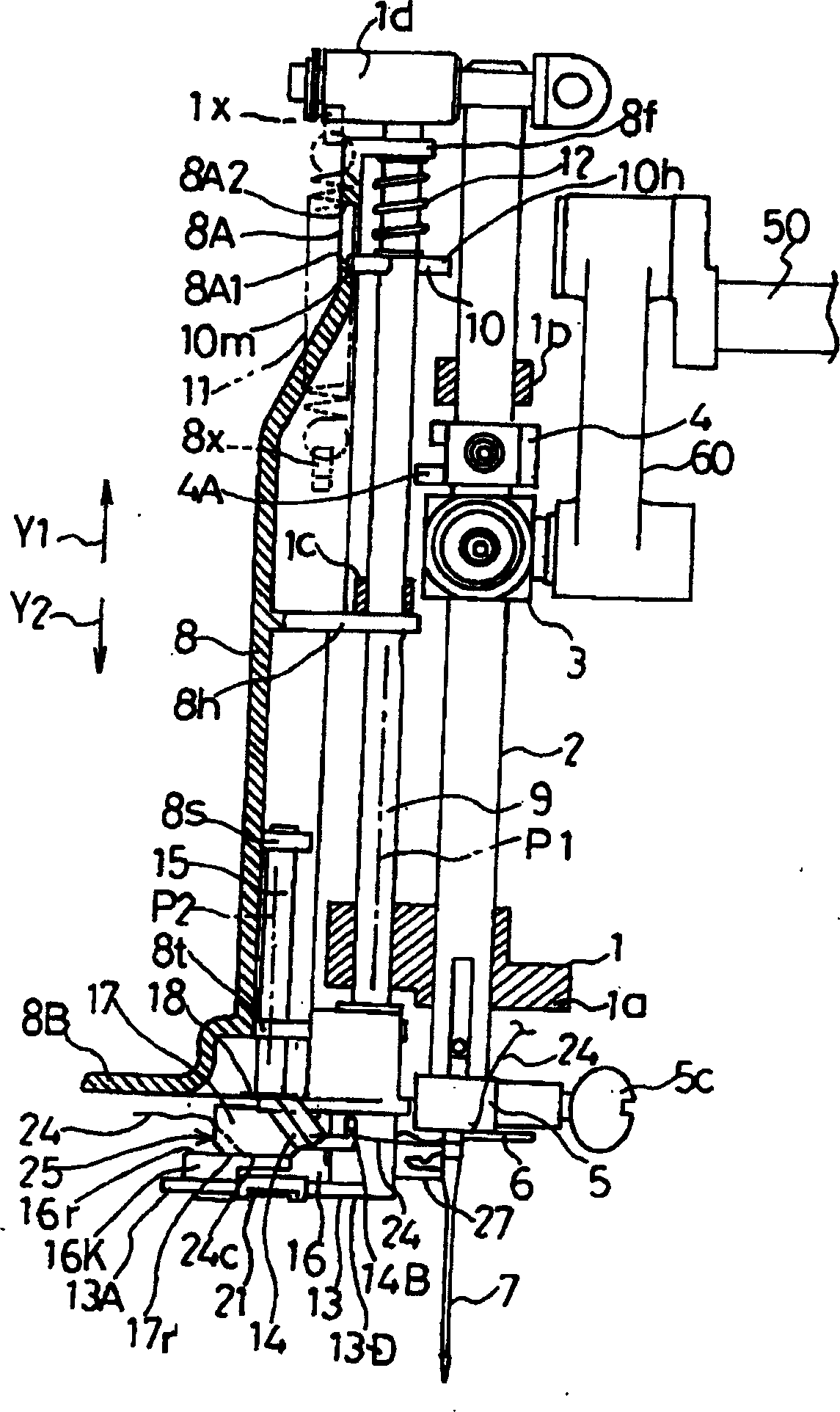

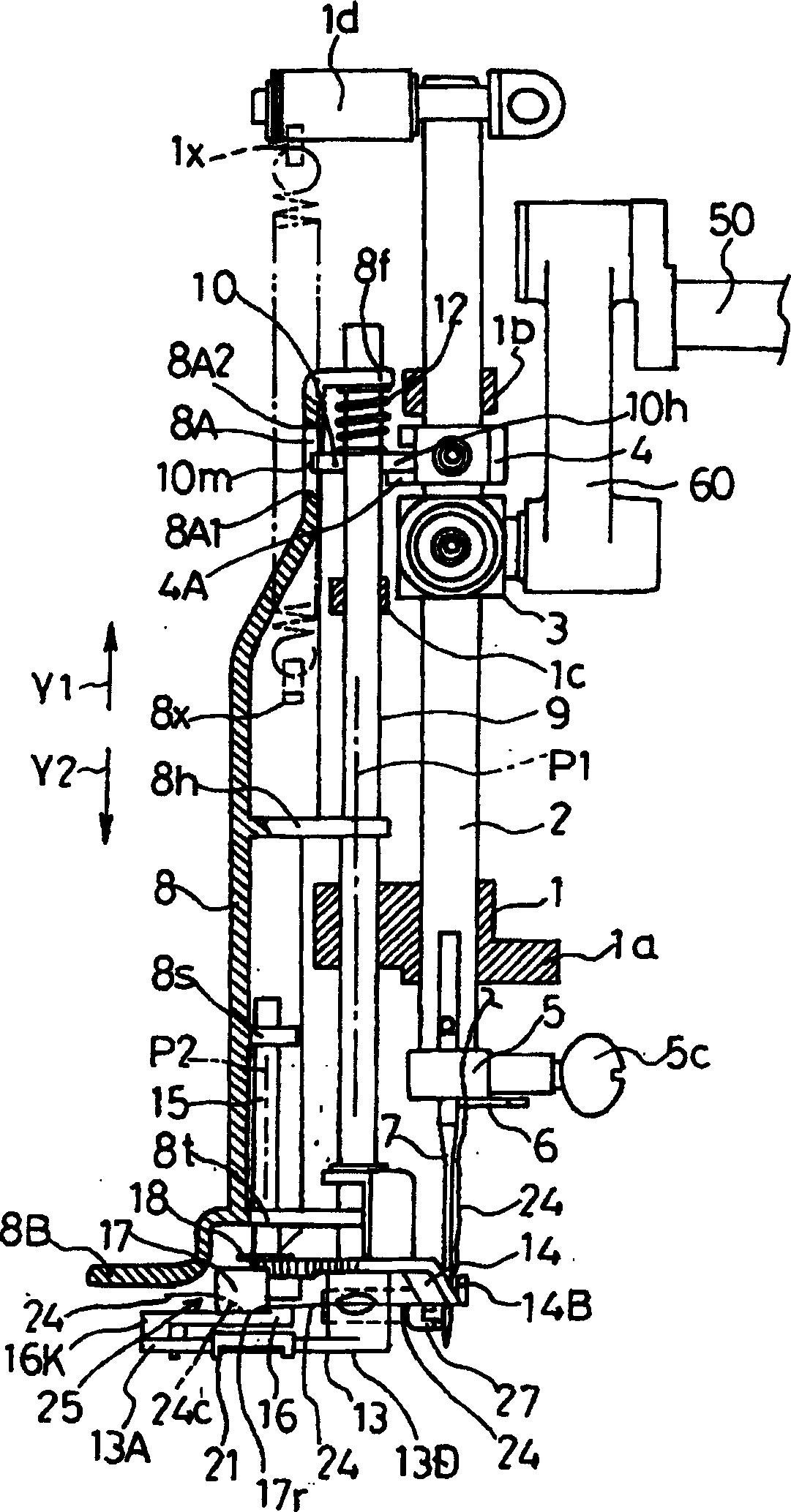

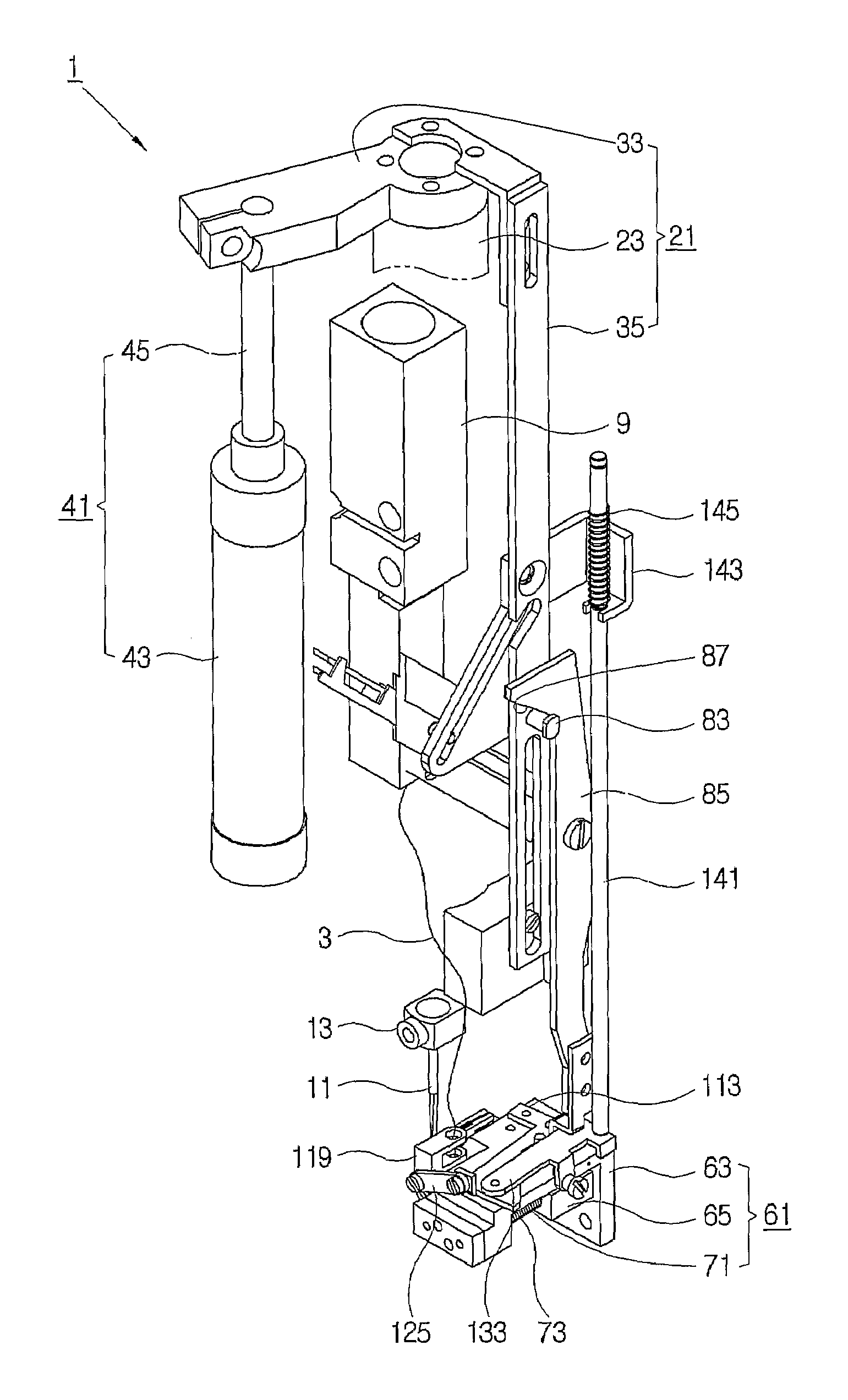

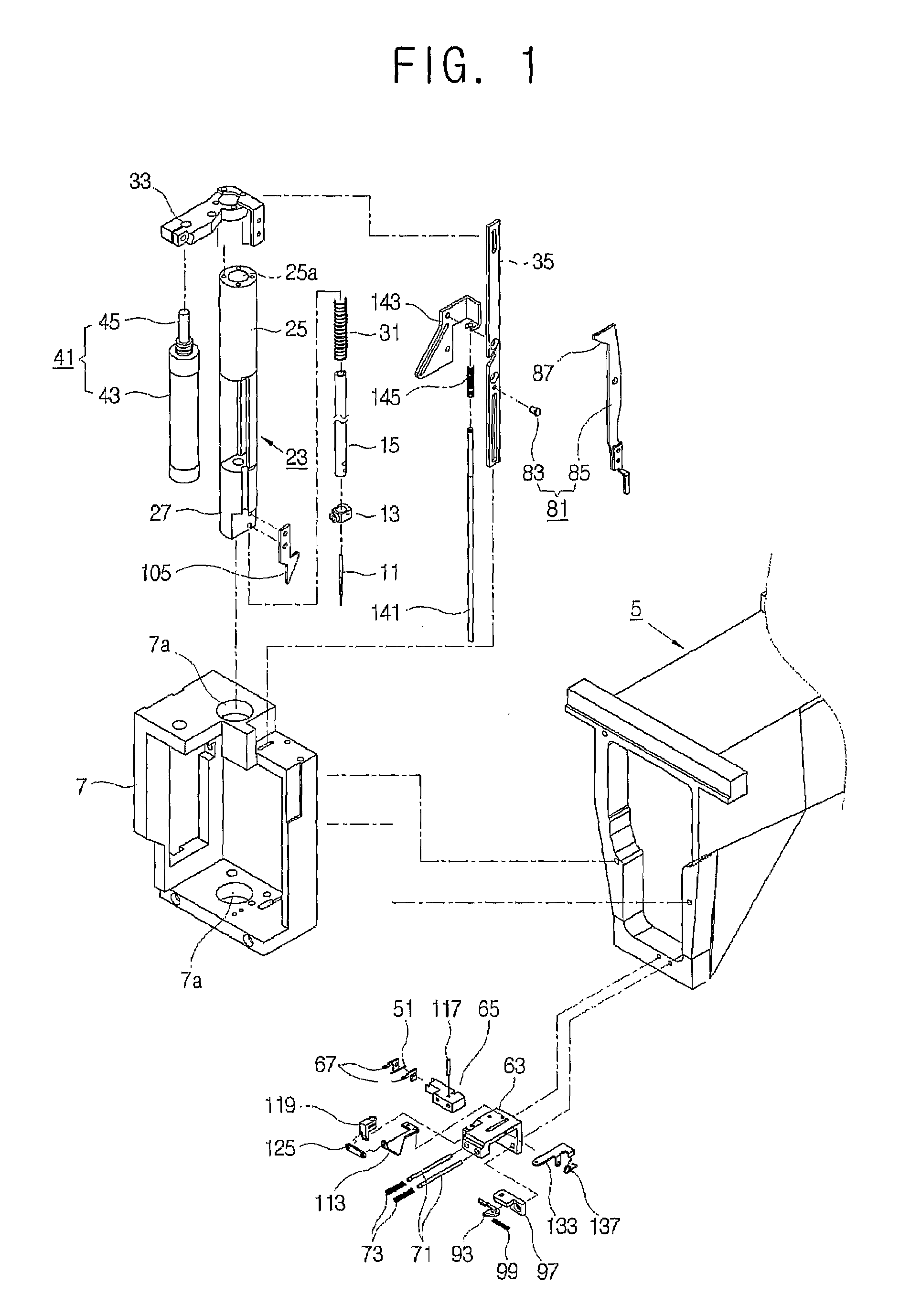

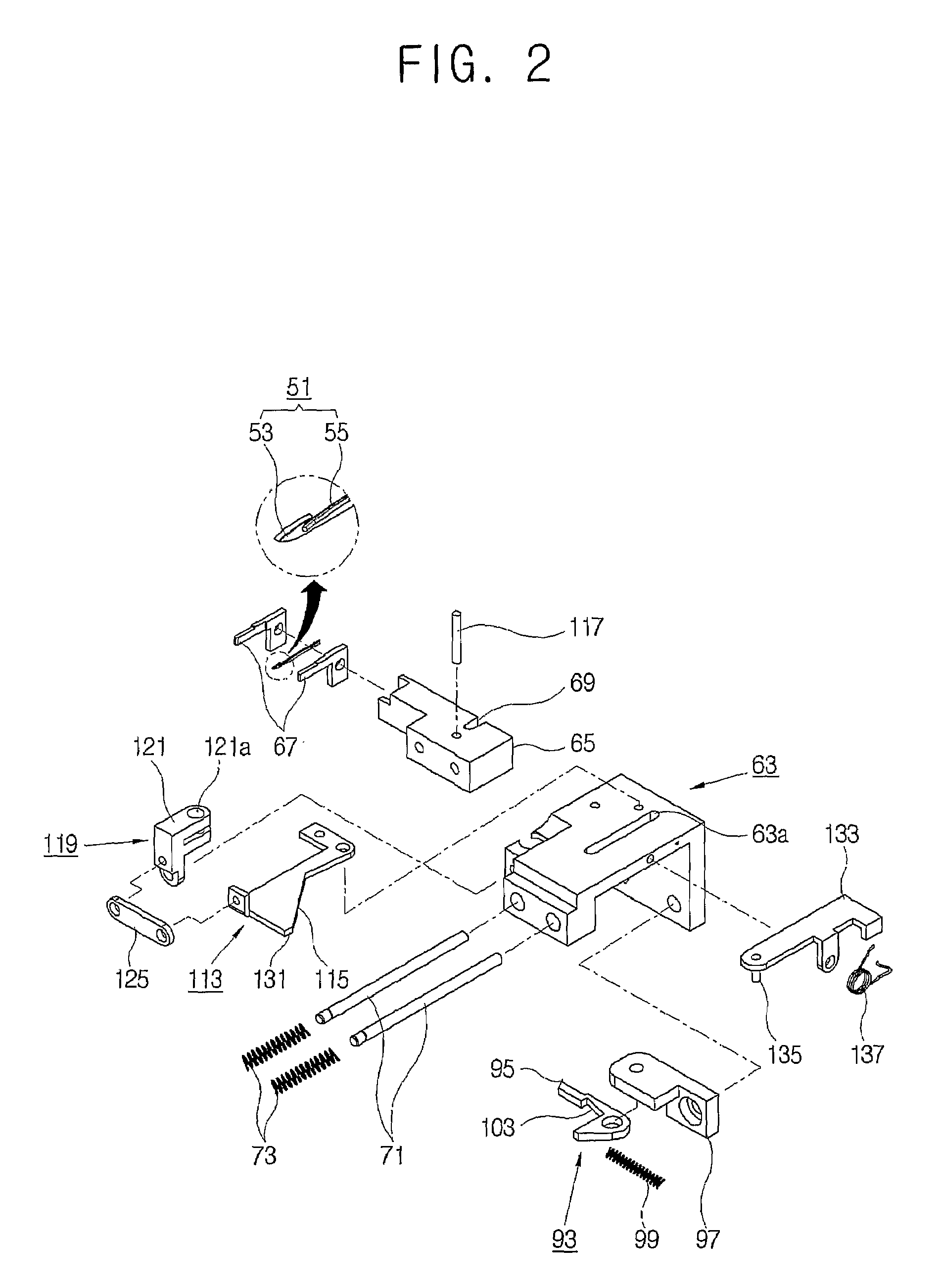

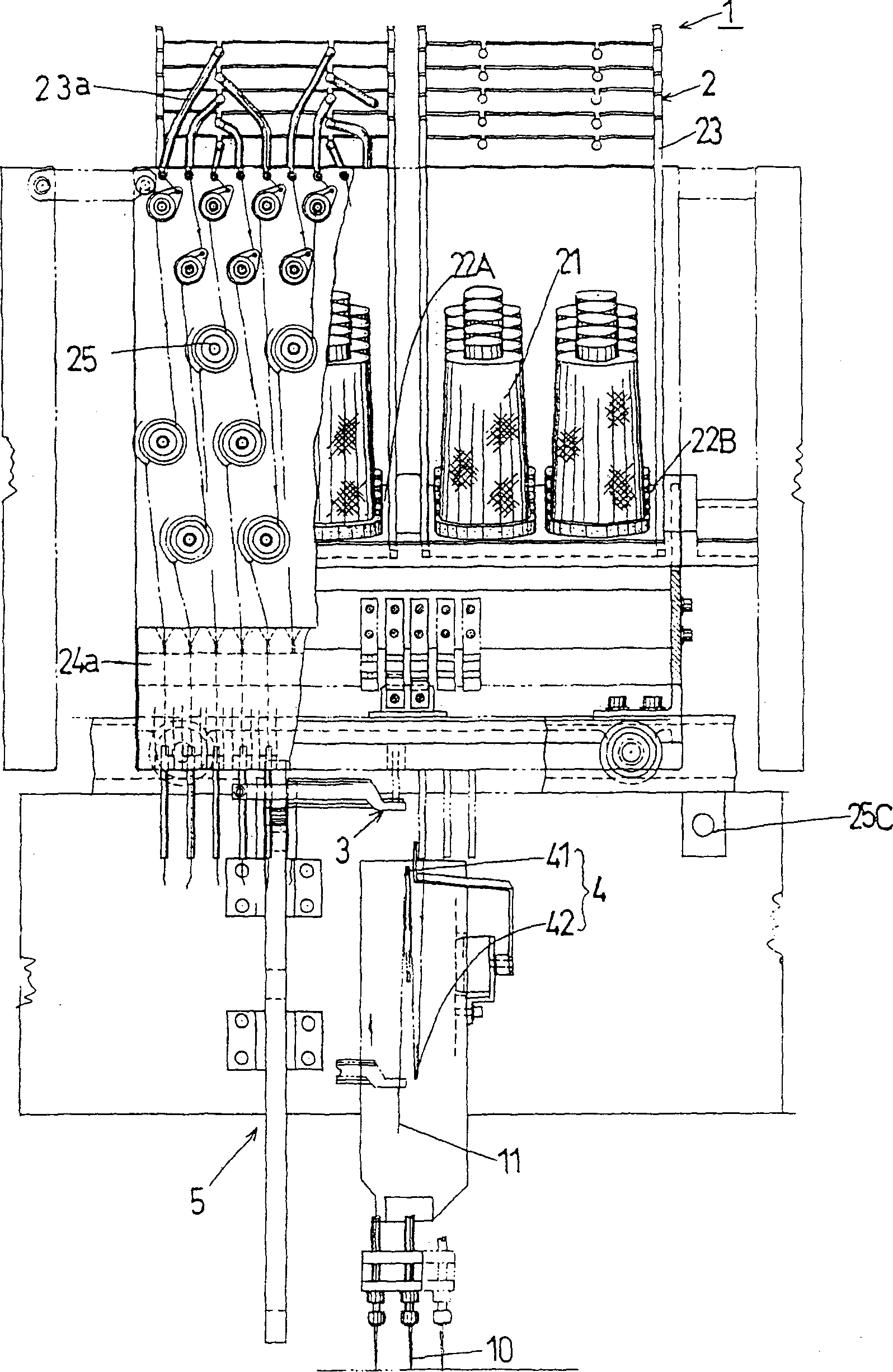

Gas carrying threading device of sewing machine

ActiveUS8857354B2Easy to handleEasy to operateFilament handlingNeedle-threading devicesCamChangeover

A threading to a looper is performed with one-touch operation. A looper threading / sewing changeover mechanism 30 including a push button 33 for a pressing operation of a push button shaft 32 that a control pin 31 is protruded and provided, a control groove cam 38 which includes a first control groove cam portion 34—a fourth control groove cam portion 37 which receive the control pin, a connecting movement plate 40 which supports a thread guide portion and which is elastically repelled toward a threading state that a thread guide outlet of the thread guide portion contacts to a looper thread inlet of the looper by a first spring 39, and a connecting positioning plate 82 which rotates together with a main shaft 2 integrally and has a peripheral surface 80 that a tip portion 41 of the push button shaft contacts and has a notch portion 81 that the tip portion of the push button shaft is fitted is provided.

Owner:SUZUKI MFG CO LTD

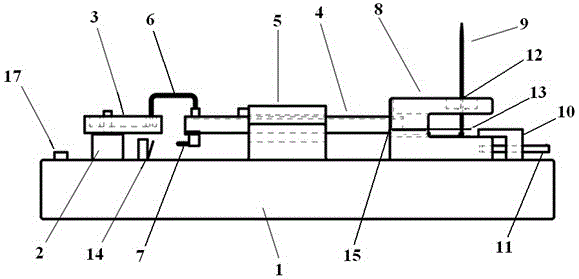

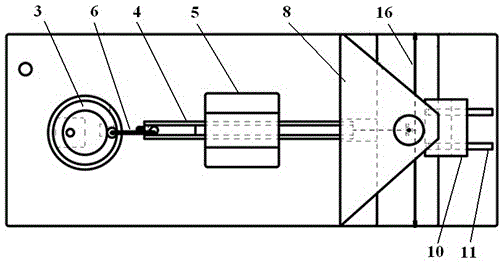

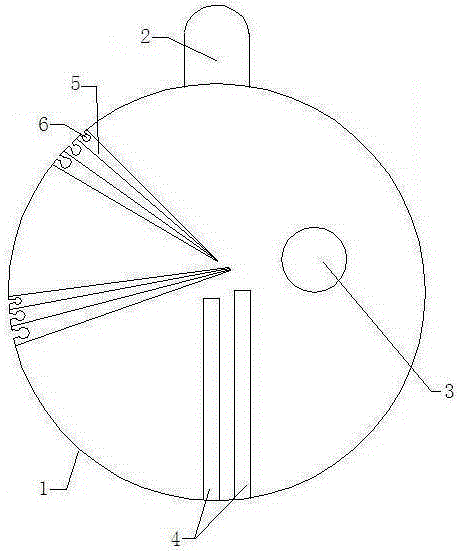

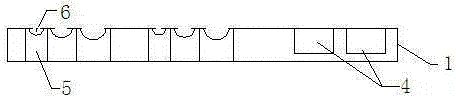

Eccentric wheel type automatic needle threading machine

The invention discloses an eccentric wheel type automatic needle threading machine which comprises a machine plate, a motor, an eccentric wheel, a crochet hook fixing rod, a fixing rod guide rail block, a sewing needle fixing block, a sewing needle positioning block and a travel switch, wherein the motor, the travel switch, the fixing rod guide rail block and the sewing needle fixing block are fixed on the machine plate; the eccentric wheel is fixed on a motor shaft; the part, farthest from the motor shaft, of the eccentric wheel is connected with one end of the crochet hook fixing rod through a lock catch structure; a touch tip part vertically pointing to the travel switch is arranged below the connecting part of the lock catch structure and the crochet hook fixing rod; the crochet hook fixing rod can penetrate through the fixing rod guide rail block in a sliding manner; a crochet hook is arranged at the other end of the crochet hook fixing rod; a sewing needle hole and a crochet hook hole used for allowing the crochet hook to be inserted are formed in the sewing needle fixing block; the sewing needle hole is perpendicular to the machine plate; the crochet hook hole is formed in a position in fit with the sewing needle hole. The needle threading machine provided by the invention can automatically thread a needle, and the convenience and working efficiency of threading the needle are improved.

Owner:NANJING VOCATIONAL UNIV OF IND TECH

Sewing machine

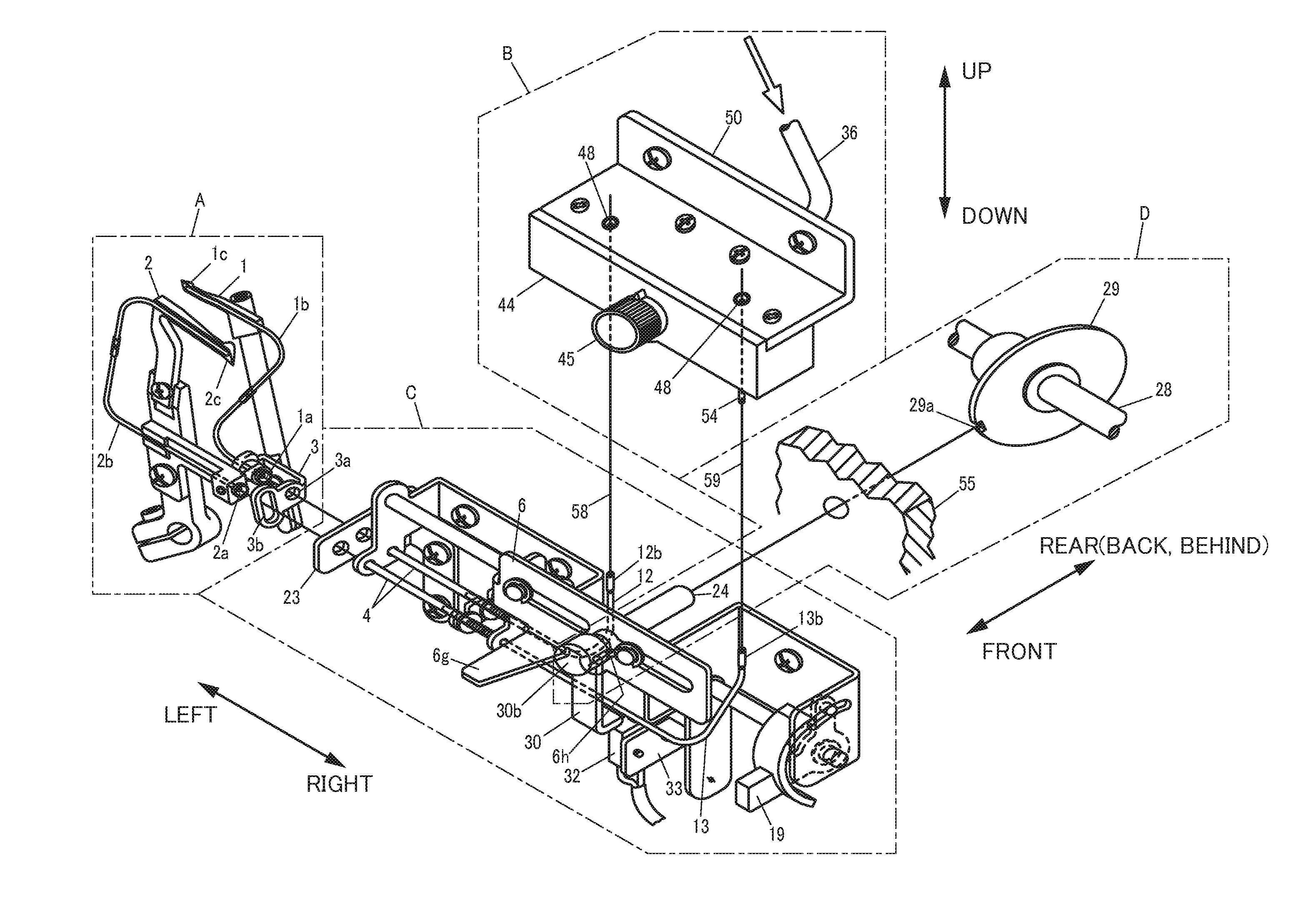

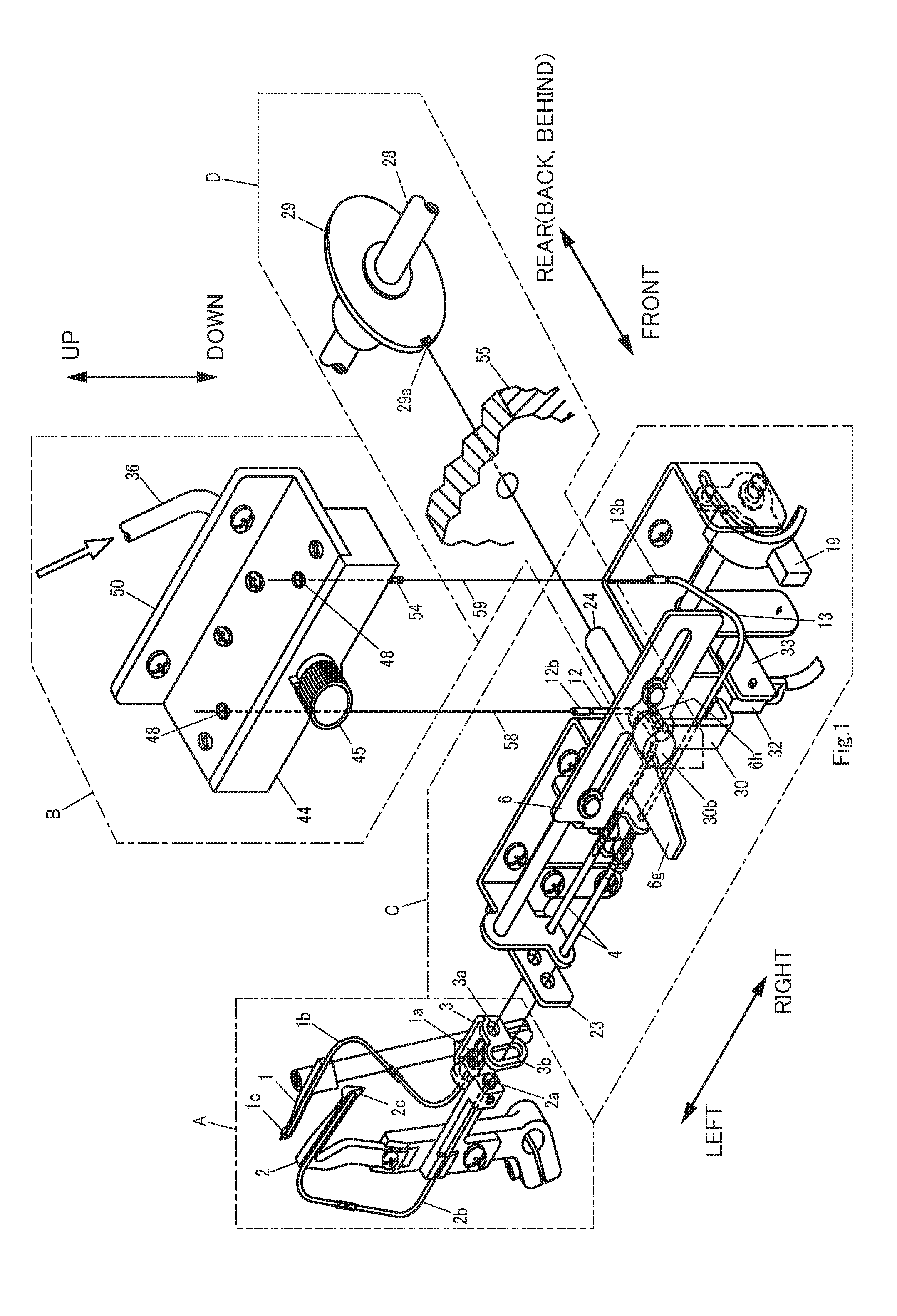

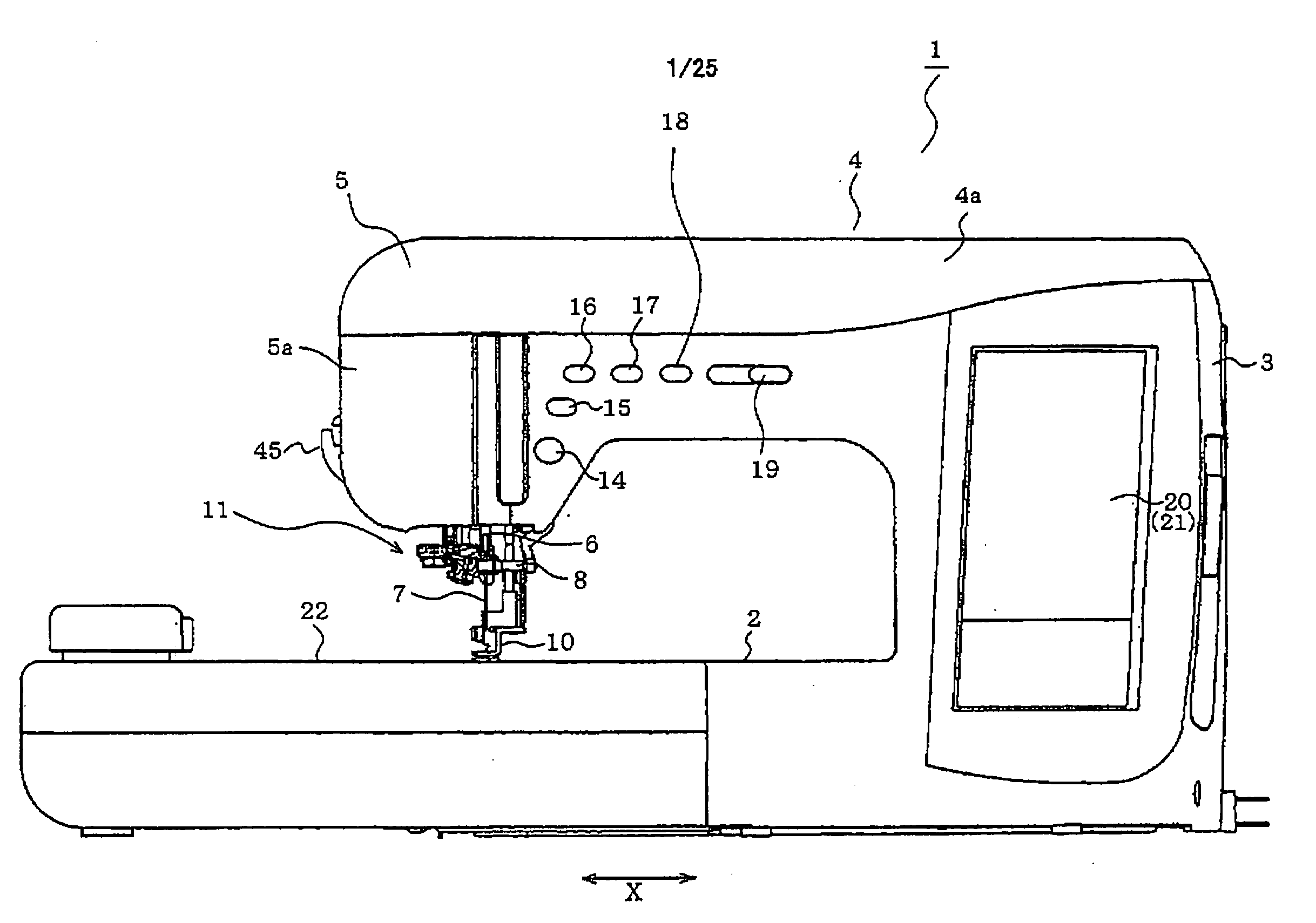

Provided is a sewing machine with a threading device having good operability without simultaneous operation of both hands of a user for threading. This threading device includes: a needle bar thread hanging part 6 for hanging a thread of the needle bar; a thread holding part 25 for holding a thread part 24c of a thread 24; a thread guide body 14 for holding the thread 24 hung on the needle bar thread hanging part 6 and held on the thread holding part 25 in the horizontal direction with rotation; a threading hook body 13 rotatably provided and having a hook part inserted in an eye of a needle 7; a cam part 21 for automatically releasing pressing and holding of the thread holding part 25 to the thread part 24c when the hook part of the threading hook body 13 is on standby or rotated in the reverse direction; and an operating lever part 8B for interlocking rotation of the thread guide body 14, rotation of a mediating gear 16, reverse rotation of the threading hook body 13 and the operation of the cam part 21.

Owner:AISIN SEIKI KK

Sewing machine

InactiveUS20080308027A1Made evenlyEasy to carryThread-laying mechanismsNeedle-threading devicesThreaded pipeScrew thread

A lower end of a thread guide lever, which is rockably attached to a lower looper and supports a thread pipe, and an air ejecting unit, which faces a thread inserting hole of the thread pipe and ejects air toward the thread inserting hole, are coupled via a coupling member so that they are interlocked with each other. The coupling member is moved such that a discharging port of an air nozzle is positioned at an ejecting position close to the thread inserting hole when a thread discharging hole is positioned at a threading position which is coincident with a thread hole of a lower looper, and such that the air nozzle is moved to a standby position when the thread discharging hole is moved to a retreating position.

Owner:JUKI CORP

Structure facilitating needle threading and working method thereof

InactiveCN105177883AEfficient and safe storageAddressing Fast Lead RequirementsNeedle-threading devicesHand heldBiomedical engineering

The invention belongs to the technical field of production and life application and particularly discloses a structure facilitating needle threading. The structure comprises a needle threading box, a lifting lug, a hand-holding groove, multiple needle storage boxes, multiple needle threading slotted holes, thread holes, a lamp trough, a prompt device, a blade storage groove, a foldable lamp, a thread breaking knife and a storage batter, wherein the lifting lug is arranged at one side of the needle threading box, the hand-holding groove is formed in the needle threading box, the multiple needle storage boxes are arranged in the needle threading box, the multiple needle threading slotted holes are formed in the needle threading box, the thread holes are formed in the multiple needle threading slotted holes in a corresponding mode respectively, the needle threading box is provided with the lamp trough, the prompt device and the blade storage groove, the foldable lamp is arranged in the lamp trough, the thread breaking knife is arranged in the blade storage groove, and the storage battery is arranged in the needle threading box and connected with the foldable lamp and the prompt device. According to the structure, threading, needle storage, operating time, thread breaking and operating illumination are integrated into the single needle threading box, functions of efficient threading, safe needle-storage, eyestrain prompt, safe thread-breakage and safe illumination are achieved, rapid needle threading requirements of a family or a manufacturing enterprise such as a clothes manufacturer are effectively satisfied, and body health of a user is protected.

Owner:罗增益

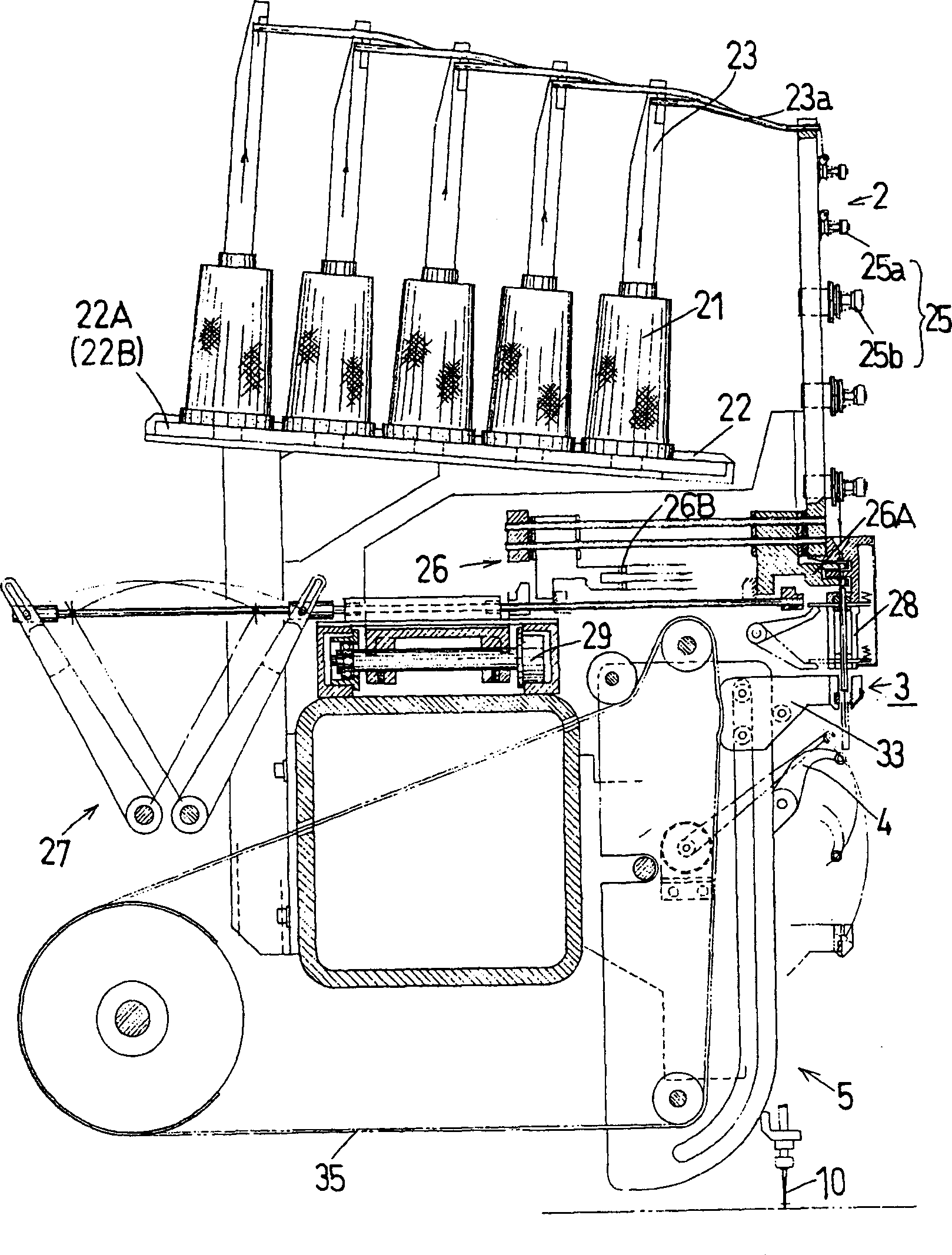

Gas carrying threading device of sewing machine

ActiveUS8925472B2Easy to handleFilament handlingNeedle-threading devicesDrive shaftTransmitted power

Pressurized gas for carrying looper thread by gas is generated by gas supply pump operated by changing over a sewing-machine motor, which drives stitch forming device, looper threading is performed through loopers by one-touch operation. Gas carrying threading device of sewing machine, comprising: looper thread introduction mechanism inserts looper thread guided to loopers; hollow looper thread guide extends from looper thread introduction mechanism to looper thread inlets and has looper thread guide outlets; gas supply pump for performing looper threading by carrying looper thread by gas from looper thread introduction area through hollow looper thread guide to looper thread loop-taker point outlets; clutch for transmitting power from sewing machine motor M to drive shaft which drives stitch forming device including loopers at time of stitch formation or to gas supply pump at time of looper threading.

Owner:SUZUKI MFG CO LTD

Threading apparatus for sewing machine

InactiveUS6067920AEffective guidanceReduce the impact of collisionThread-laying mechanismsNeedle-threading devicesYarnEngineering

The present invention provides an air suction device for a threading apparatus that creates an air flow to be directed toward a needle eye in order to guide a yarn through the eye. The air suction device is comprised of: (a) an air device externally provided for generating reduced pressure; (b) an air suction pipe connected to the external air device; and (c) an air path leading to a front portion of the air suction pipe. The air path is comprised of a pair of leaf springs to horizontally hold a needle, and upper and lower elastic members which run parallel between the pair of leaf springs. To effectively direct air into the needle eye, an air-tight environment is provided around the needle eye: (1) air entry above and beneath the needle eye is prevented by the body of the needle; (2) air entry from both sides of the needle is prevented by the pair of leaf springs that hold the needle; and (3) air inflow behind the needle is prevented by rear-positioned elastic members which tightly fit the needle.

Owner:STEP Y K

Air-driven threading device for sewing machine

ActiveCN103597136AEasy to operateAvoid damageNeedle-threading devicesLoop takersEngineeringSewing machine

Problem: To thread a looper with a one-touch operation. Solution: Provided is a looper threading and sewing switching mechanism (30) comprising a push-button (33) for push operation of a push-button shaft (32) from which a control pin (31) protrudes; a control groove cam (38) comprising first through fourth control groove cam sections (34 - 37) that receive the control pin; a link shift plate (40) that supports a thread guide section and that by using a first spring (39) is snapped toward a threading state in which a thread guide outlet of the thread guide section is in contact with a looper thread inlet; and a link positioning plate (82) comprising a peripheral surface (80) and an interlocking cutaway section (81) that rotate integrally with a main shaft (2) and with which a top section (41) of the push-button shaft comes into contact.

Owner:SUZUKI MFG CO LTD

Needle threader for sewing machine

ActiveUS20090183663A1Smoothly be moved verticallyReliable retentionThread-laying mechanismsNeedle-threading devicesEngineeringSewing machine

A needle threader for a sewing machine includes a threading mechanism including a threading hook mounted on a lower end of a threading shaft and a thread guide member. The threading hook and the thread guide member are movable among a thread guide preparation position where the threading hook and the thread guide member are located near a height position of a needle clamp, a threading operation position where a threading operation is carried out with the threading hook being level with an eye of a needle, and a retreat position which is located above the thread guide preparation position and to which the threading hook and the thread guide member are retreated. A vertical moving mechanism moves the threading shaft vertically so that the threading mechanism is moved between the thread guide preparation position and the threading operation position.

Owner:BROTHER KOGYO KK

Overlock sewing machine

ActiveUS20150267332A1Easy to operateSure easyFilament handlingNeedle-threading devicesControl theorySewing machine

An overlock sewing machine includes a main shaft fixing operating arm provided with a shaft pin engaging portion that engages with a fixing inner shaft pin and an arm provided to be operable by a user which are integrally rockable within a specified range, and further includes a main shaft fixing operating spring which urging direction is switched in both directions of an rocking direction by exceeding a neutral point by the rocking movements of the main shaft operating arm and the arm.

Owner:JANOME CORP

Sewing machine

A sewing machine includes a head on which a needle bar for fixing a needle is mounted, a thread cutting blade mounted in the head so as to be capable of cutting an end of a thread which is threaded so as to be passed through an eye of the needle, and a holder mounted in the head so as to be capable of holding the thread end after the thread end has been cut by the thread cutting blade. The thread cutting blade is positioned so that a first amount of thread from the eye of the needle mounted in the head to the thread end held by the holder equals a second amount of thread by which the thread end is drawn to an underside of a cloth in a stitch formed immediately after start of a sewing operation.

Owner:BROTHER KOGYO KK

Threading device of sewing machine

InactiveUS20090064914A1Avoid breakingAvoid collisionThread-laying mechanismsNeedle-threading devicesEngineeringMotion transfer

A threading device of a sewing machine is provided. The threading device includes a threading hook which moves forward to enter an eye of a needle to catch a needle thread, and moves rearward with the needle thread being caught to insert the needle thread through the eye, a threading shaft which holds the threading hook, an operating member which is operated to move the threading shaft, a threading operation mechanism which transmits the movement of the threading shaft to the threading hook to move the threading hook back and forth, and a restricting device which makes the threading operation mechanism inoperable when the spreader mechanism is attached to the sewing machine main body, and makes the threading operation mechanism operable when the spreader mechanism is detached from the sewing machine main body.

Owner:JUKI CORP

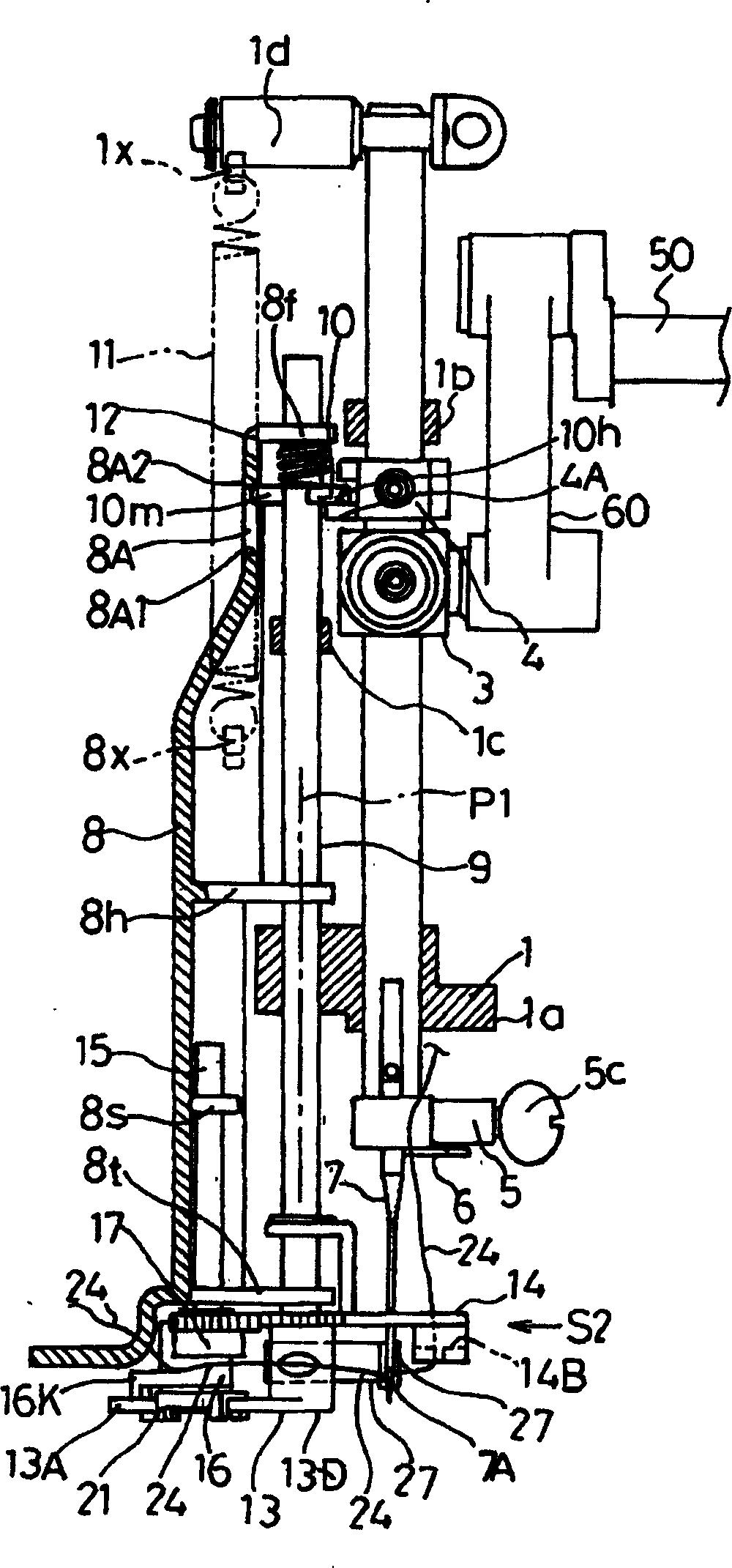

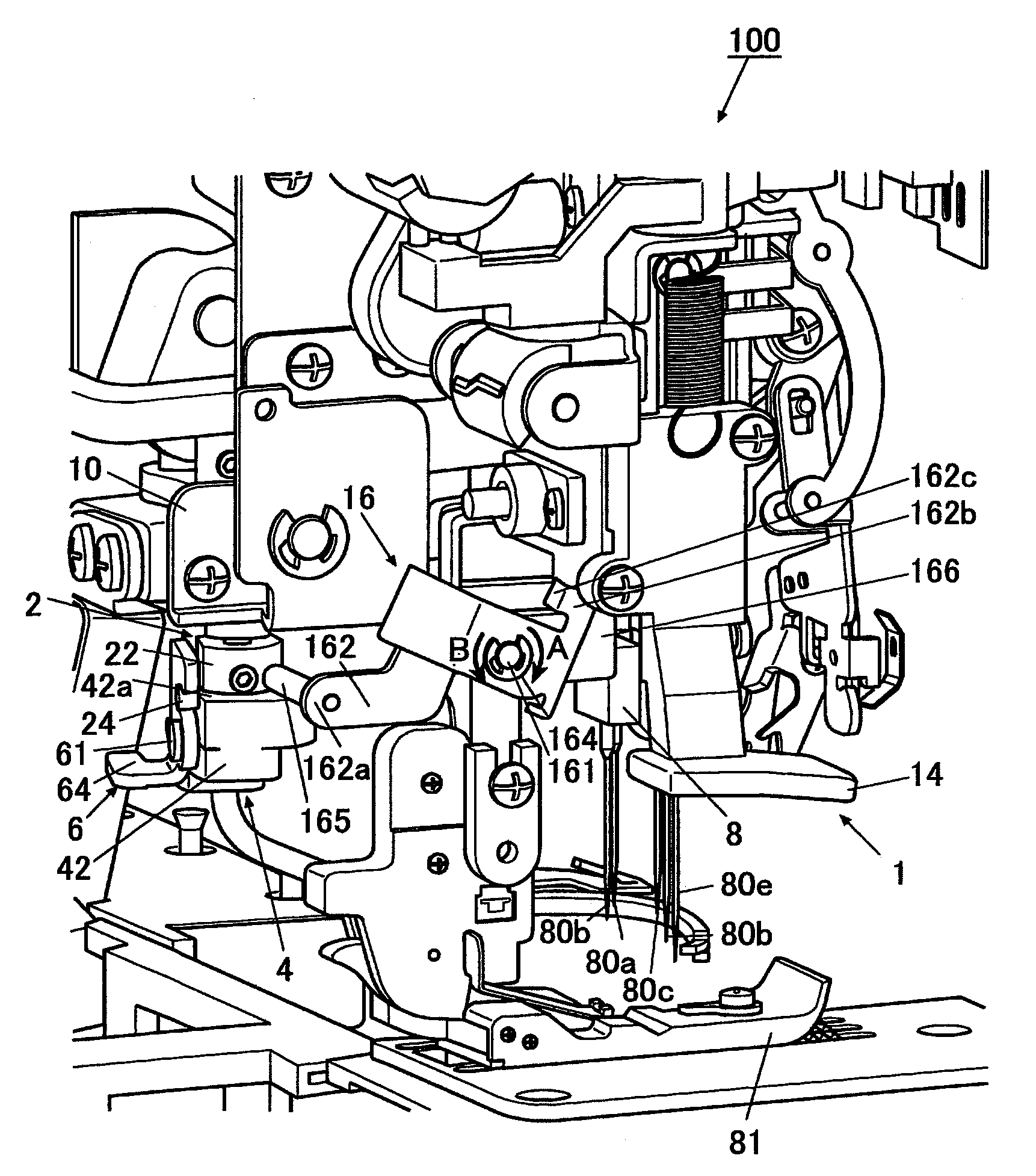

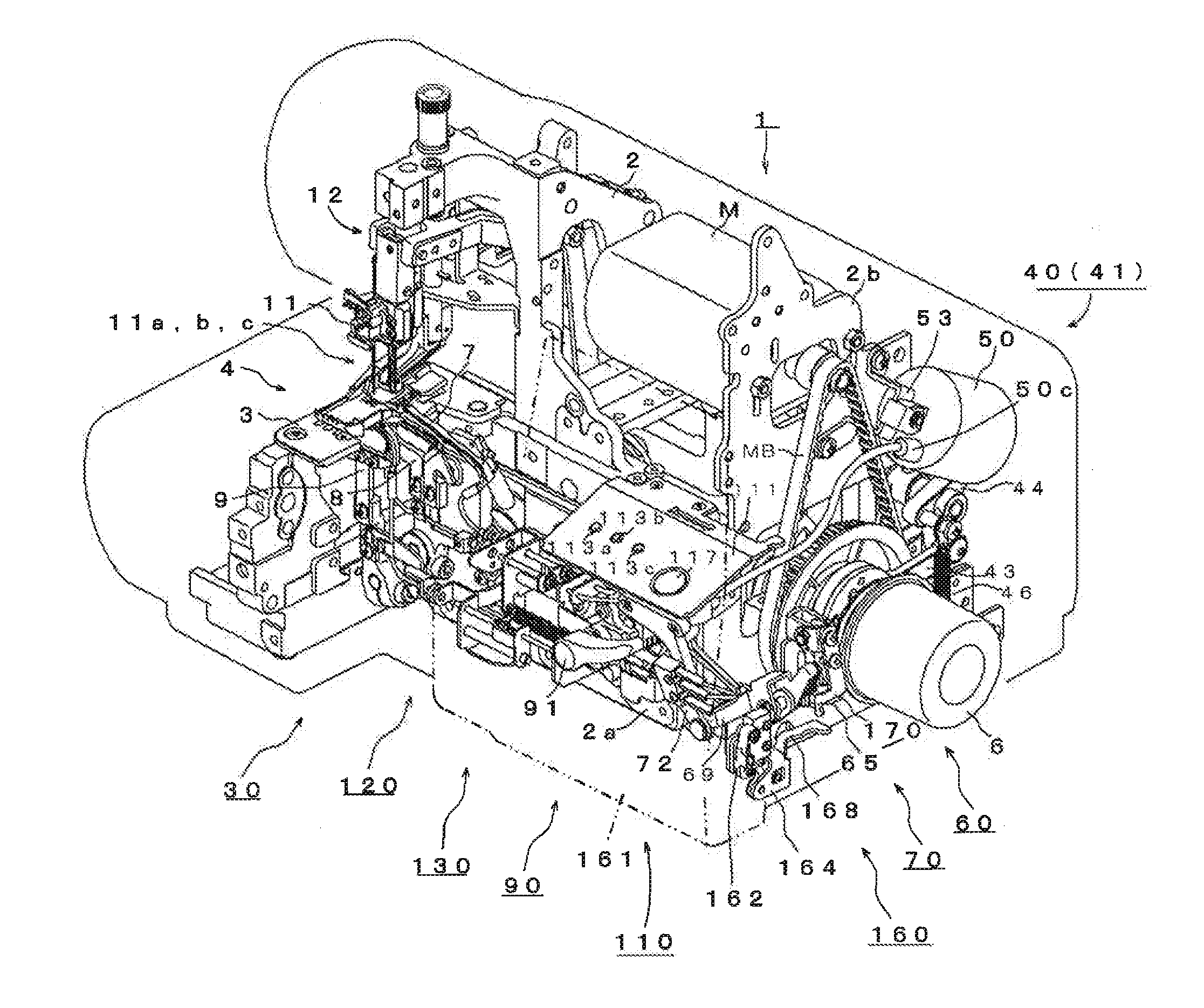

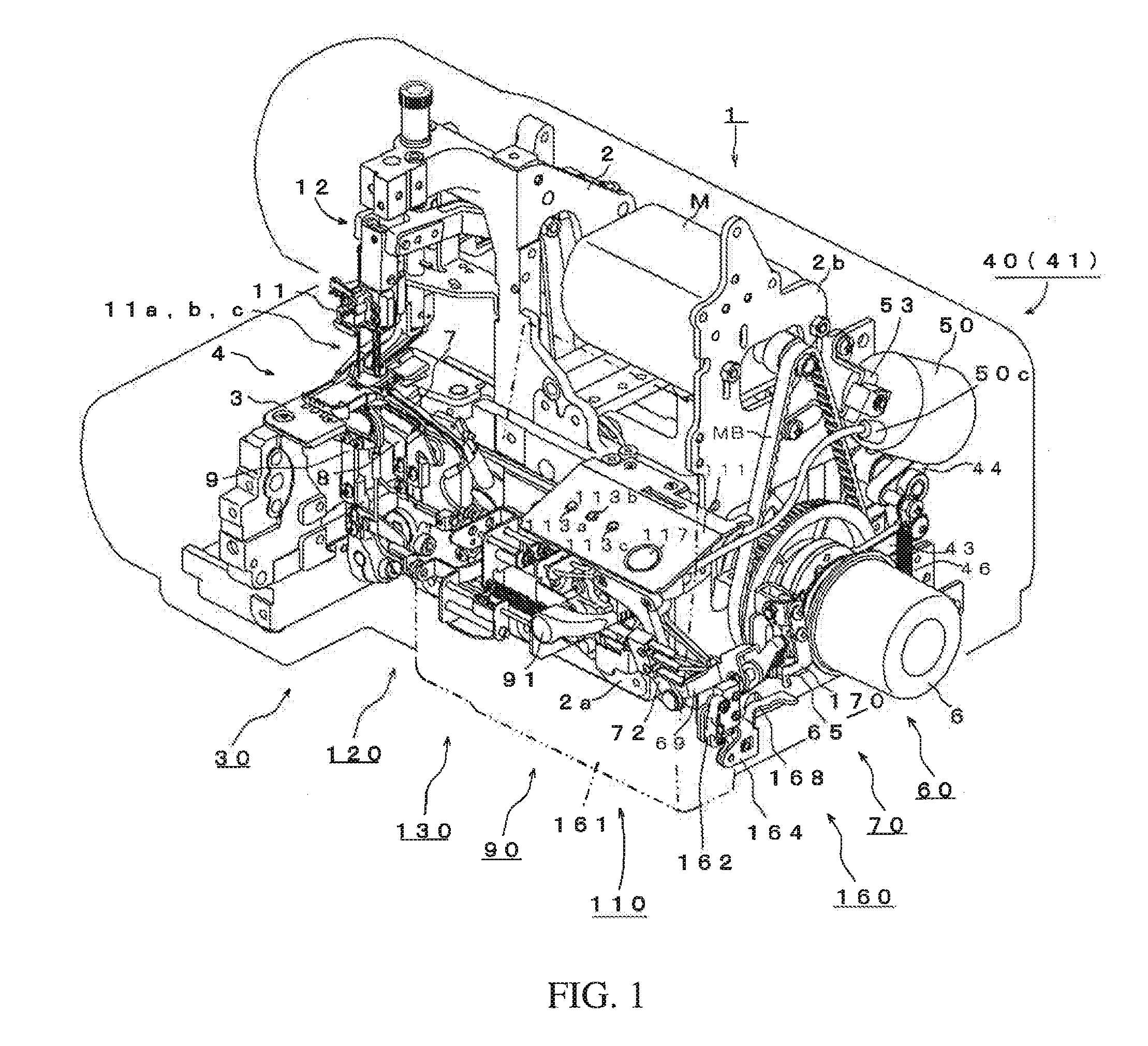

Gas carrying threading device of sewing machine

ActiveUS20140190383A1Simple structureQuality improvementSewing-machine control devicesThread-laying mechanismsElectric power transmissionDrive shaft

When performing the threading to the looper by one-touch operation, the abnormal changeover to the stitch forming state of the looper threading / stitch forming changeover mechanism during the gas supply operation of the gas supply pump is prohibited. The device comprises: a clutch (60) for transmitting the power from the sewing machine motor (M) to the drive shaft (5) that drives the stitch forming device (30) including the looper (7, 8, 9) at the time of the stitch formation or to the gas supply pump (41) at the time of the looper threading respectively; a looper threading / stitch forming changeover mechanism (90) for changing over the clutch so that the transmission of the power to the stitch forming device is interrupted and the power is transmitted to the gas supply pump at the time of the looper threading and the power is transmitted to the stitch forming device and the transmission of the power to the gas supply pump is interrupted at the time of the stitch formation; and a changeover prohibition mechanism (160) for prohibiting the abnormal changeover to the stitch forming state of the looper threading / stitch forming changeover mechanism during the gas supply operation of the gas supply pump.

Owner:SUZUKI MFG CO LTD

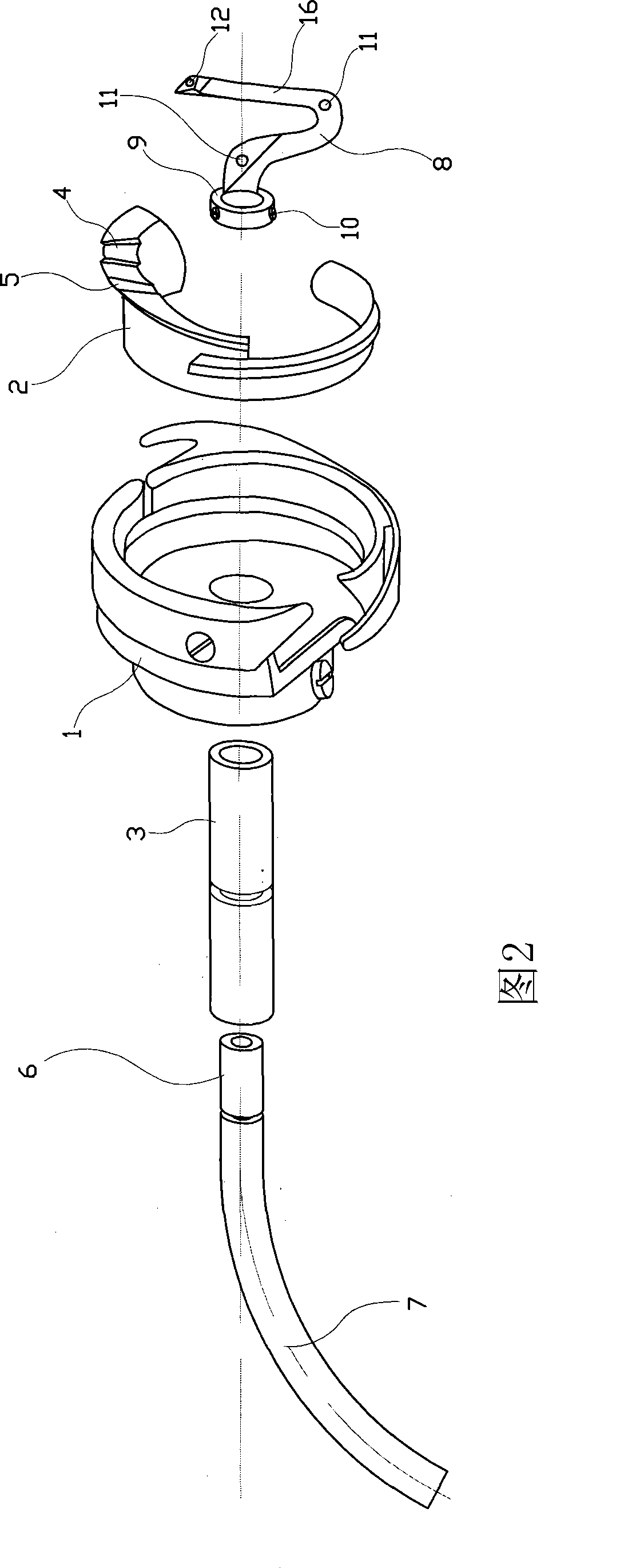

Sewing machine shuttle for continuously feeding ground thread

The invention relates to a sewing machine spindle head which can continuously supply underlines. The spindle head comprises a ring rotating shuttle and a ring fixed shuttle which is arranged in the rotating shuttle; the rotating shuttle is connected with a shuttle shaft; the outer edge of the fixed shuffle is provided with a positioning gap; the side of the positioning gap is provided with an underline outlet; the fixed shuffle is an open looped ring-shaped fixed shuffle; the shuffle shaft is a tubular hollow shuffle shaft; the hollow shuffle is internally sleeved with an underline tube, the axis of which is collinear with the axis of the shuffle shaft; the outer end of the underline tube extends out of the shuffle shaft; one section of the underline tube which is arranged outside the shuffle shaft is a bend pipe section; the inner end of the underline tube extends into the ring of the fixed shuffler; the inner end of the underline tube is connected with an underline curved needle which is provided with a threading hole; the threading hole arranged at the pinpoint of the underline curved needle is arranged near the underline outlet of the fixed shuffle outer edge. The underlines of the invention is led in and supplied from the spindle head; the spindle head can continuously and reliably supply underlines; when in use, the underlines are not polluted by engine oil, and are not blocked and intertwined.

Owner:马越龙

Needle threading machine

InactiveUS7444949B2Work lessImprove productivitySewing needlesThread-laying mechanismsProduction rateReciprocating motion

Disclosed is a needle threading machine of putting a thread through an eye of a needle provided in a sewing machine, the needle treading machine comprising a thread supplying unit supplying the thread along a predetermined thread guiding path; a thread catcher comprising a hook to hook the thread, and a hook supporter extended from the hook and supporting the hook; a thread catcher driver driving the thread catcher to reciprocate allowing the hook to be inserted in and return from the eye of the needle; and a thread guiding unit hooking the thread supplied from the thread supplying unit on the hook passed through the eye of the needle. Thus, the present invention provides a needle threading machine, in which a thread is stably hooked on a hook, thereby reducing a defective needle threading work and enhancing productivity.

Owner:INBRO

Sewing machine

InactiveUS6981459B2Operation efficiency can be improvedSimple engagementSewing-machine casingsFilament handlingBobbinEngineering

A sewing machine includes a thread take-up lever and a thread tension regulator each disposed along a predetermined needle thread passage from a thread bobbin to a needle, an arm having a front face, and a movable controller disposed in the front of the arm so as to be movable at least within a predetermined range. The movable controller does not protrude out of the front face of the arm when moved in the predetermined range. The needle thread is engaged with at least one of the thread take-up lever and the thread tension regulator when the movable controller is moved within the predetermined range while the needle thread has been drawn from the thread bobbin near to the needle substantially along the predetermined needle thread passage.

Owner:BROTHER KOGYO KK

Yarn passing device of sewing machine for embroidery

InactiveCN1416486ASmooth throughPrevent needle deflectionHand sewingFilament handlingYarnEngineering

The aim of the present invention is to provide a threading device for embroidery machinery realized in such a way that it performs threading accurately regardless of the type of thread, for embroidery machinery, etc. capable of performing the processing for change of colored thread automatically without intervention of an operator, for example, comprises a needle support mechanism (7), disposed movably facing the hooking member (61a), for preventing deflection of the needle (10), by correcting deflection of the needle (10), when inserting the hooking member (61a) formed in the shape of a hook at the tip of the thread pull-out mechanism (61) in the needle hole (10a).

Owner:MIYAMOTO MFG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com