Compressed-Air Rigid Building Blocks

a technology of rigid building blocks and compressed air, applied in the direction of machines/engines, instruments, printing, etc., to achieve the effect of high modulus, high strength and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

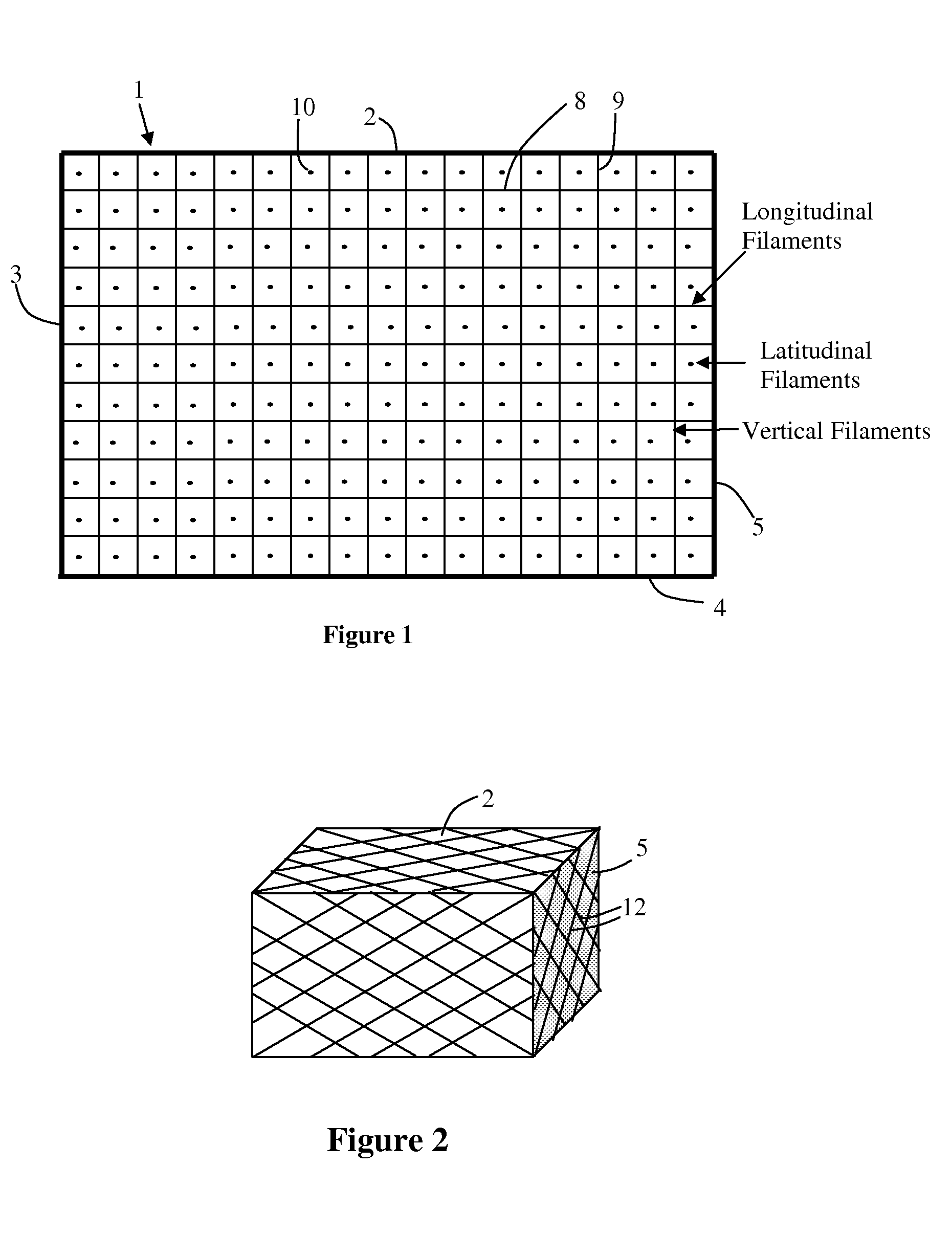

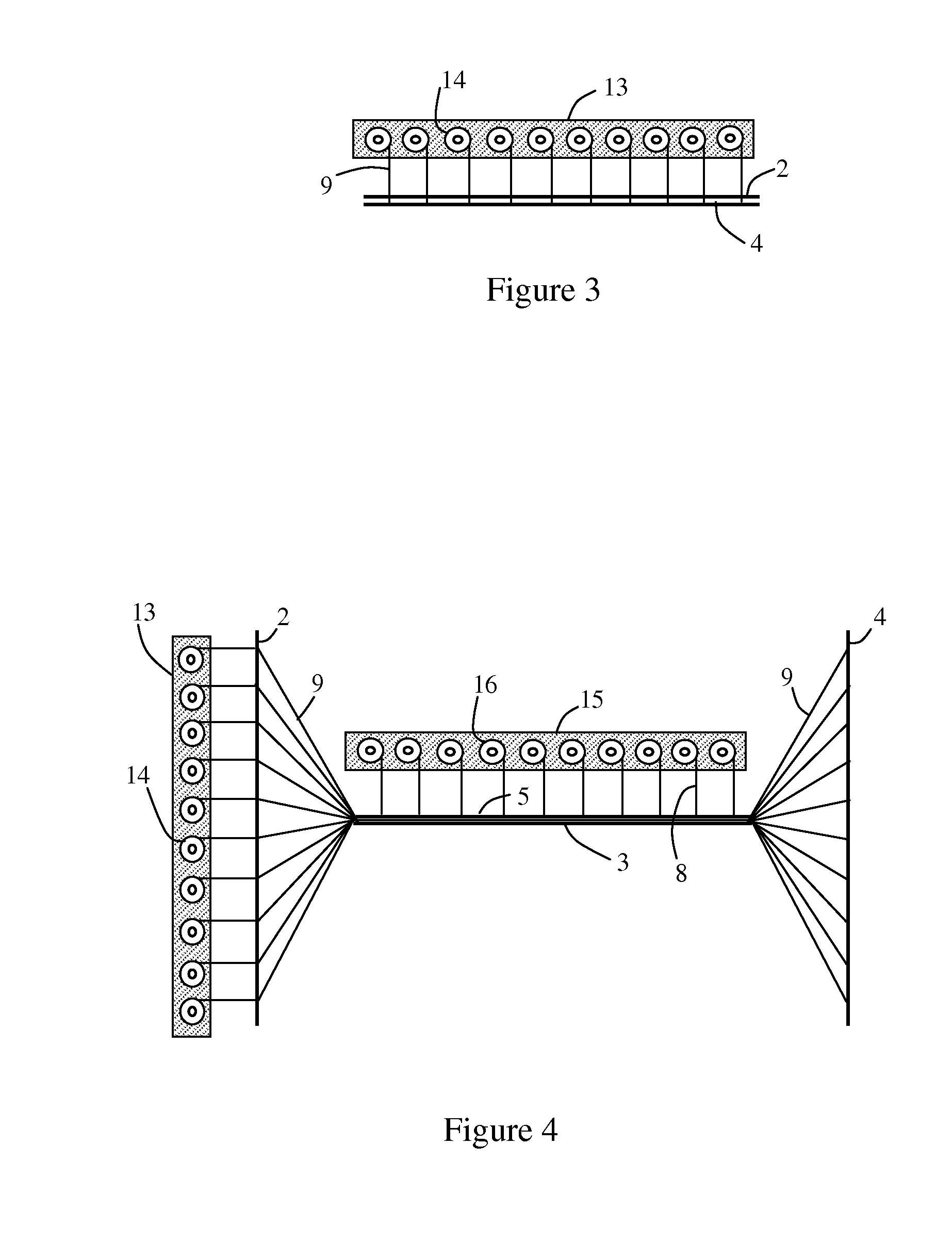

[0041]FIG. 1 shows one design of a CARBB 1 in cross sectional side view. The faces 2, 3, 4 and 5 of the CARBB can be made of thin, tough composite plastic material or other airtight material. The top face 2 and bottom face 4 can be somewhat rigid. Side faces 3 and 5, as well as the front and back faces (not shown) should be flexible so that the box can be folded down for shipping. Horizontal filaments 8 and vertical filaments 9 are shown. The dots 10 represent filaments that run in the third dimension (perpendicular to the page). The filaments hold the faces in place against the inside air pressure. In this design, the filaments 9 and 10 run through the side faces and are attached to rectangular plastic or metal washers, which distribute the force from the filaments to the face material. Filaments 8 pass through the top and bottom faces and are attached to the outside of those faces. On the side faces 3 and 5 (as well as the front and back faces), there should be small gaps between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com