Needle thread passing device

A needle threading and threading technology, which is applied in the field of needle and thread threading devices, can solve the problems of large devices and inconvenient storage, and achieve the effects of excellent accommodation, good accommodation, and good space efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Embodiments of the present invention will be described below using the drawings.

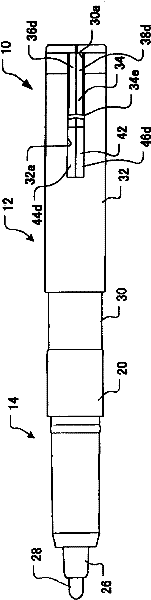

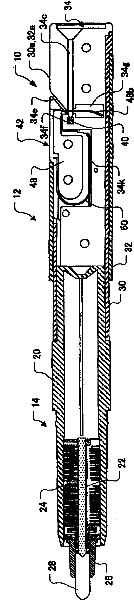

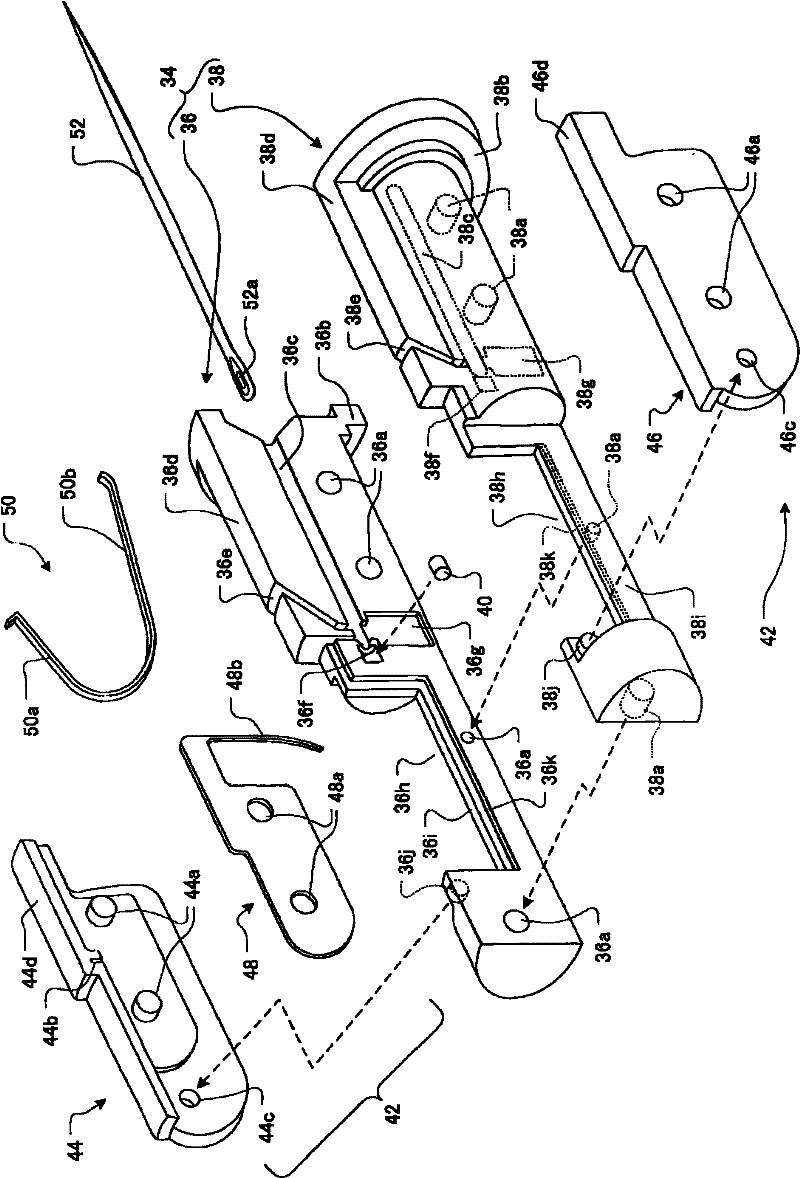

[0041] figure 1 It is an overall view when the needle thread threading device according to the first embodiment of the present invention is stored, figure 2 It is a longitudinal sectional view at the time of storage, image 3 It is an exploded perspective view of the inside of the threading device.

[0042] In the figure, the needle thread threading device 10 of this example is formed as a slender cylindrical structure as a whole, a needle thread threading unit 12 constituting the needle thread threading device 10 is provided at one end side, and a writing tool unit 14 is provided at the other end side. , the two units are connected axially to become one. As a method of integrating the two units, any joining method such as press-fitting, bonding, and screw fitting may be used, and the integration may be detachable or non-detachable. Of course, the pen unit itself may be omitted, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com