Sewing machine shuttle for continuously feeding ground thread

A sewing machine and bobbin thread technology, which is applied in the field of sewing machine shuttles, can solve the problems that the bobbin thread is easily polluted by engine oil, affects product quality, and continuously supplies bobbin thread.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

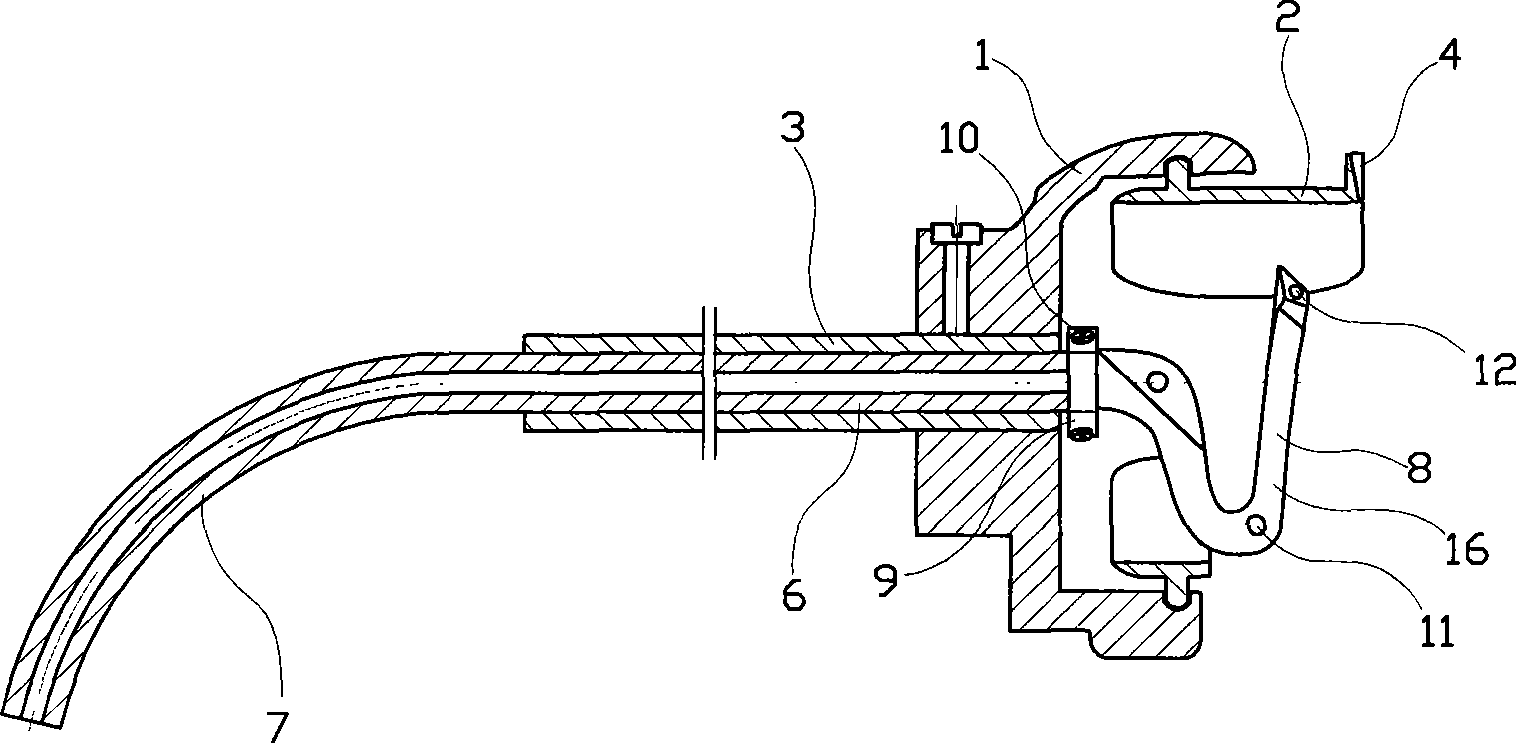

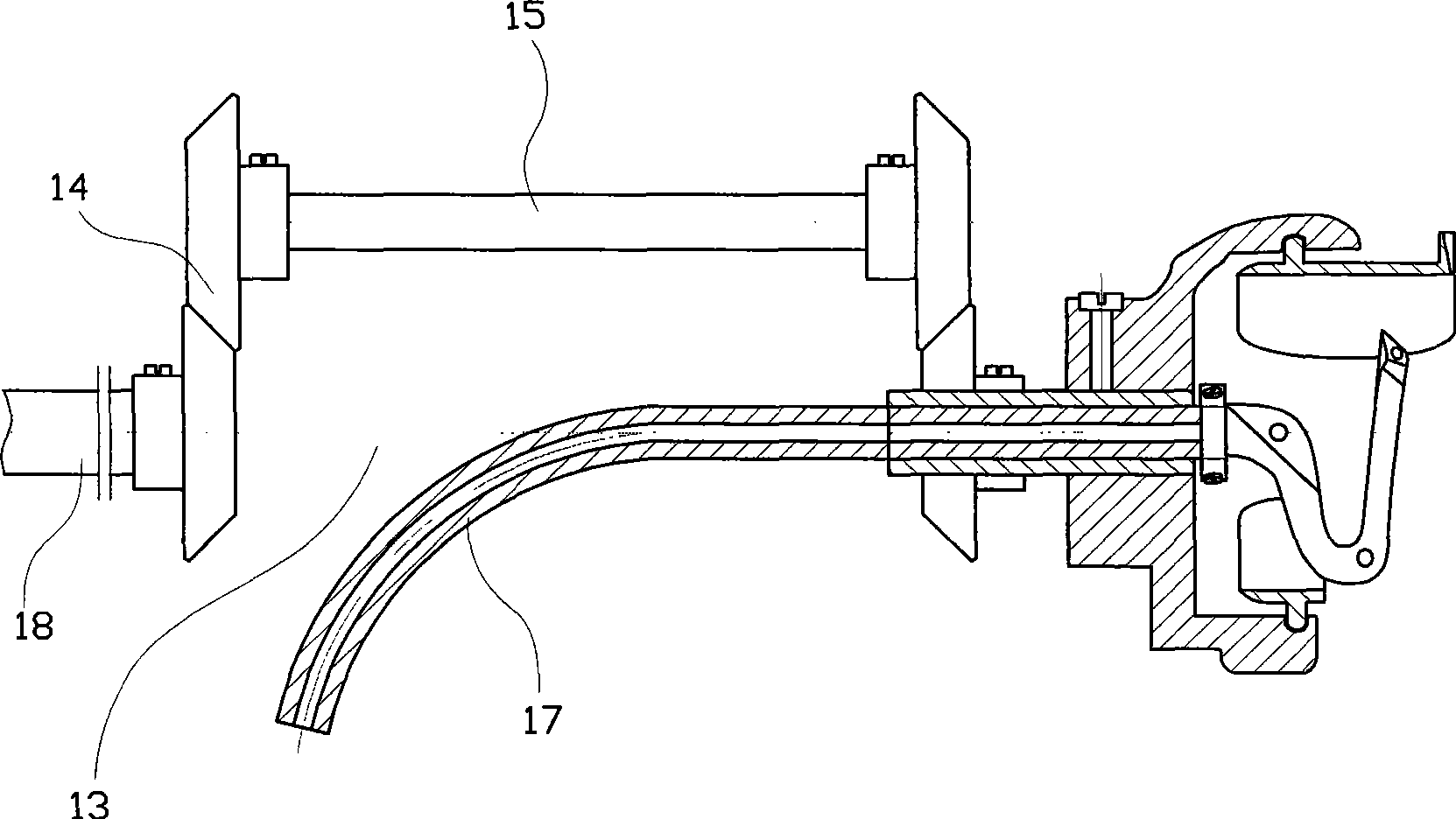

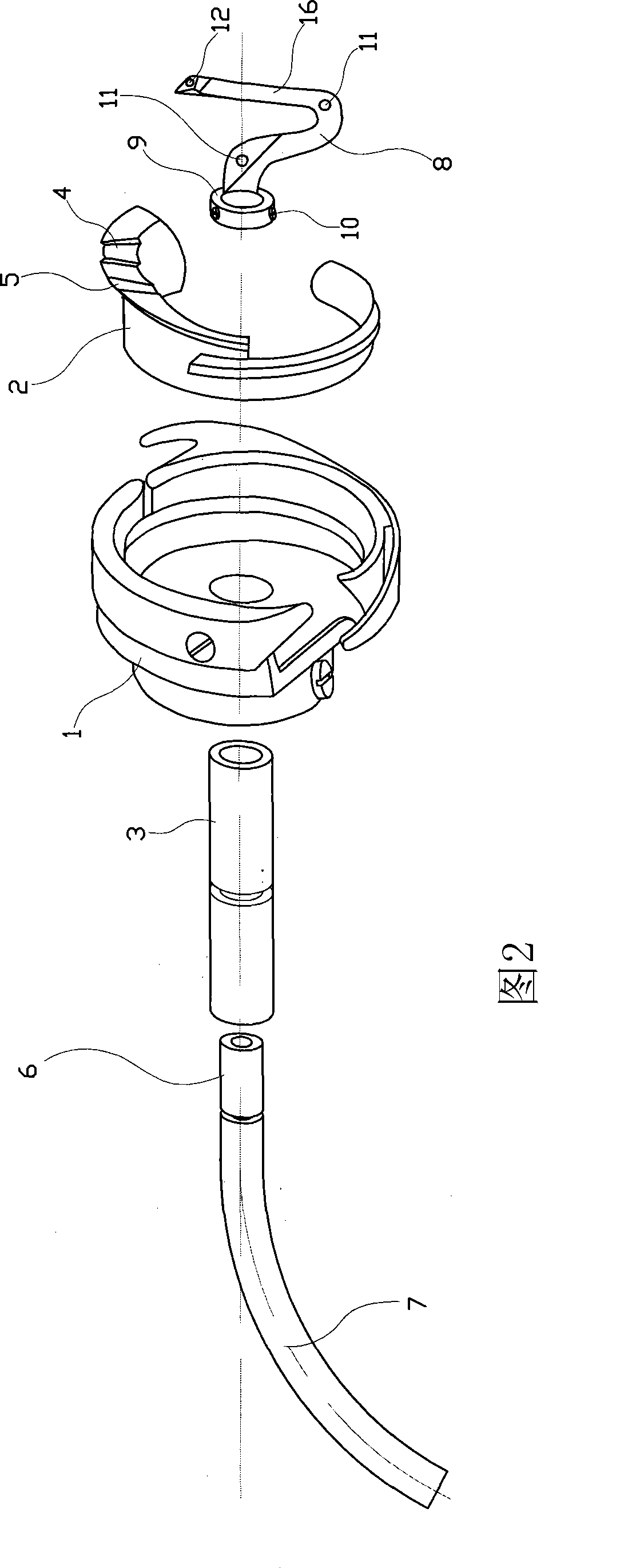

[0012] figure 1 , in Figure 2, the sewing machine hook that can continuously supply bobbin thread has a circular rotary hook 1 and a circular fixed shuttle 2 inside the rotary hook. Bottom thread outlet 5 is arranged, and the fixed shuttle is an open-loop ring-shaped fixed shuttle. end stretches out of the shuttle shaft, the section of the bottom thread pipe outside the shuttle shaft is the curved pipe section 7, the inner end of the bottom thread pipe stretches into the fixed shuttle ring, and the bottom thread looper 8 is connected with the bottom thread looper at the inner end of the bottom thread pipe, and the bottom thread looper has a curved Needle body 16, one end of the looper body is connected with annulus 9, and the inner circle hole of annulus is enclosed within the bottom line pipe inner end, and fastening screw 10 is evenly distributed on the circumference of annulus, and the other end of looper body is needle tip, and There is a threading hole 11 on the needle b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com