Structure facilitating needle threading and working method thereof

A working method and needle threading technology, which can be applied to threading devices, textiles, papermaking, sewing equipment, etc., can solve problems such as difficulty in threading work, reduce clothing production efficiency, and time-consuming problems, and meet the requirements of fast threading of needles and protect the health of the body , Efficient threading effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

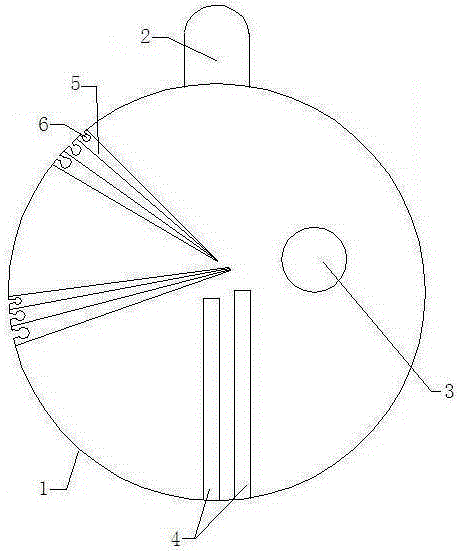

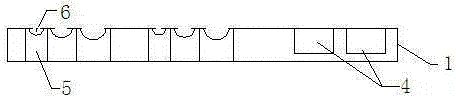

[0025] This technical solution, such as figure 1 with figure 2 A needle threading structure is shown, including a needle threading box 1, a lifting ear 2 arranged on one side of the needle threading box 1, a hand-held slot 3 arranged on the needle threading box 1, and a needle threading box 1 Several needle storage boxes 4, and several needle threading slots 5 arranged on the needle threading box 1, and corresponding threading holes 6 respectively arranged on several needle threading slots 5, wherein the threading holes 6 are set as Concave structure, a U-shaped opening is provided on one side and the needle box 1 is set as a circular structure, the circular structure is made of metal or plastic, and several different sizes are arranged on the needle box 1 for matching with The needle threading slots 5 used in conjunction with needles of different sizes, and the threading holes 6 respectively correspondingly arranged on several needle threading slots 5 have different sizes, ...

Embodiment 2

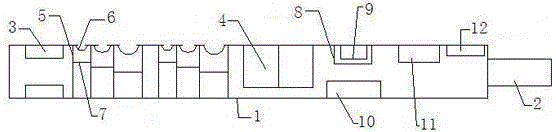

[0028] This technical solution, such as image 3 with Figure 4 A needle threading structure is shown, including a needle threading box 1, a lifting ear 2 arranged on one side of the needle threading box 1, a hand-held slot 3 arranged on the needle threading box 1, and a needle threading box 1 Several needle storage boxes 4, and several needle threading slots 5 arranged on the needle threading box 1, and corresponding threading holes 6 respectively arranged on several needle threading slots 5, wherein the threading holes 6 are set as Concave structure, one side is provided with a U-shaped opening and the needle box 1 is arranged as a rectangular structure, and the rectangular structure is made of metal or plastic, and several sizes are arranged on the needle box 1 for different sizes. Needle-threading slots 5 used in conjunction with the needles, and the threading holes 6 correspondingly arranged on several needle-threading slots 5 are different in size, and are used to coope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com