Yarn passing device of sewing machine for embroidery

A technology of threading device and sewing machine, which is applied in the direction of threading device, sewing machine components, embroidery machine mechanism, etc., can solve the problem of low reliability of threading, improve work efficiency and productivity, reduce width, and ensure smooth driving. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

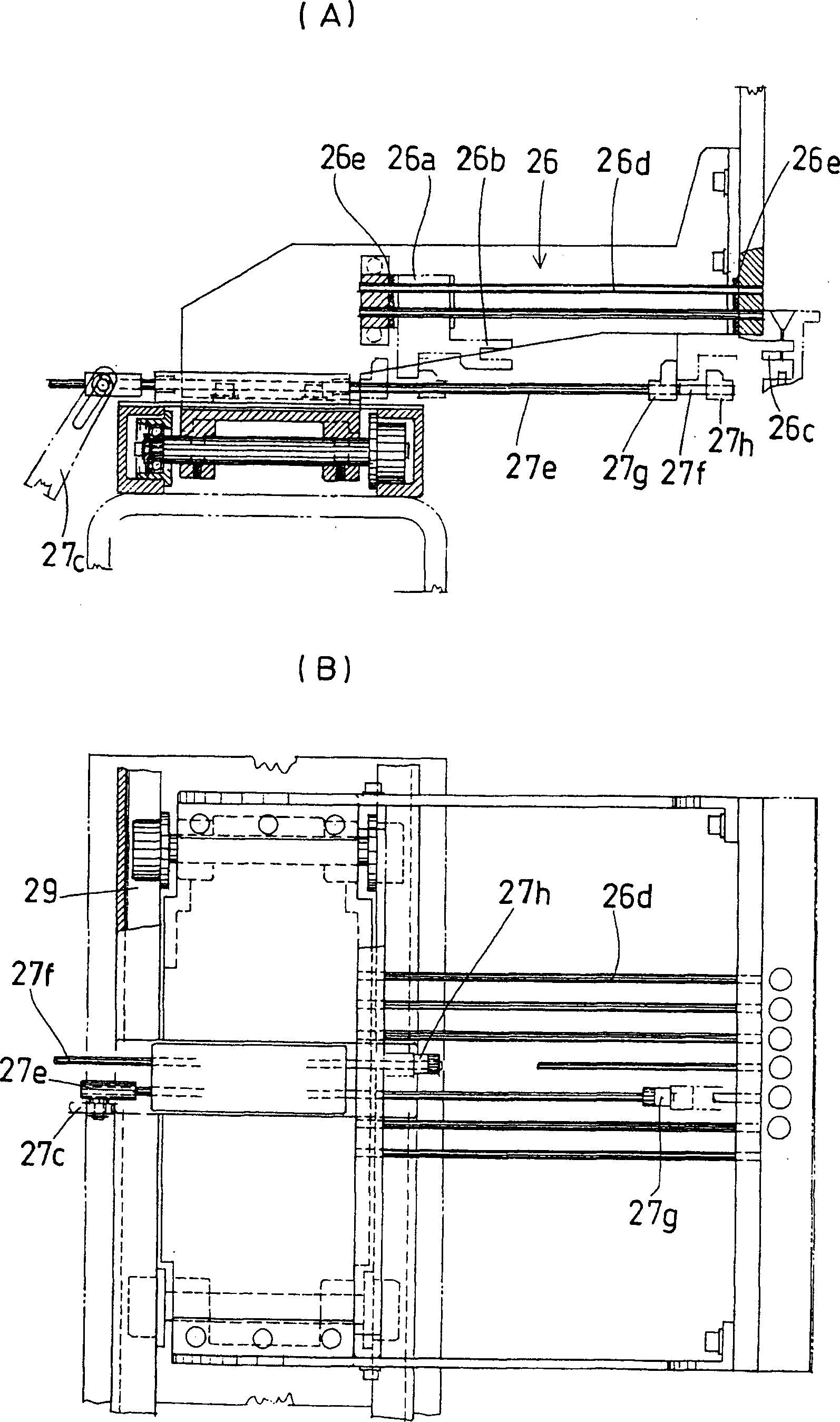

[0081] Embodiments of the threading device in the embroidery sewing machine of the present invention will be described below with reference to the accompanying drawings.

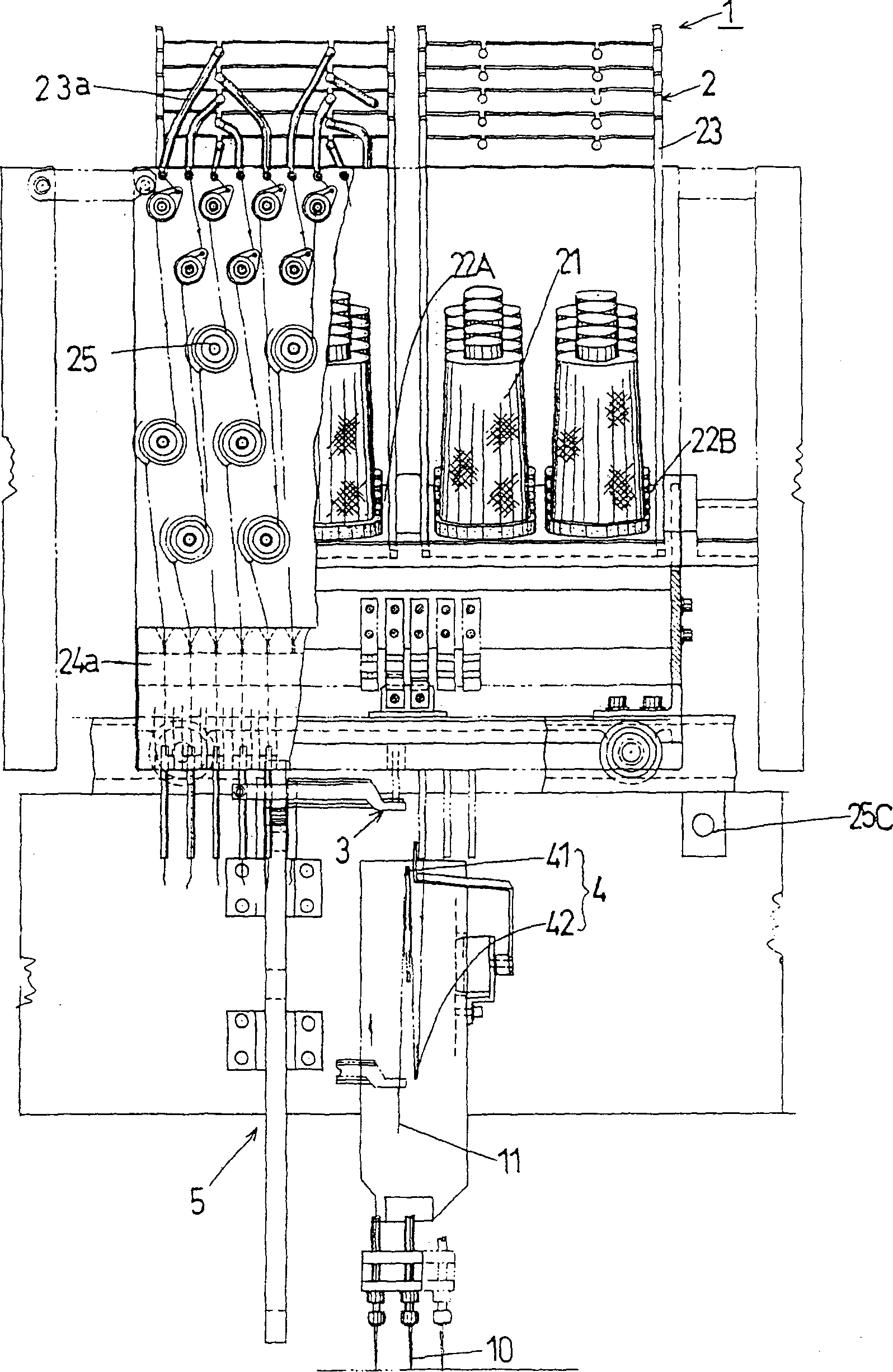

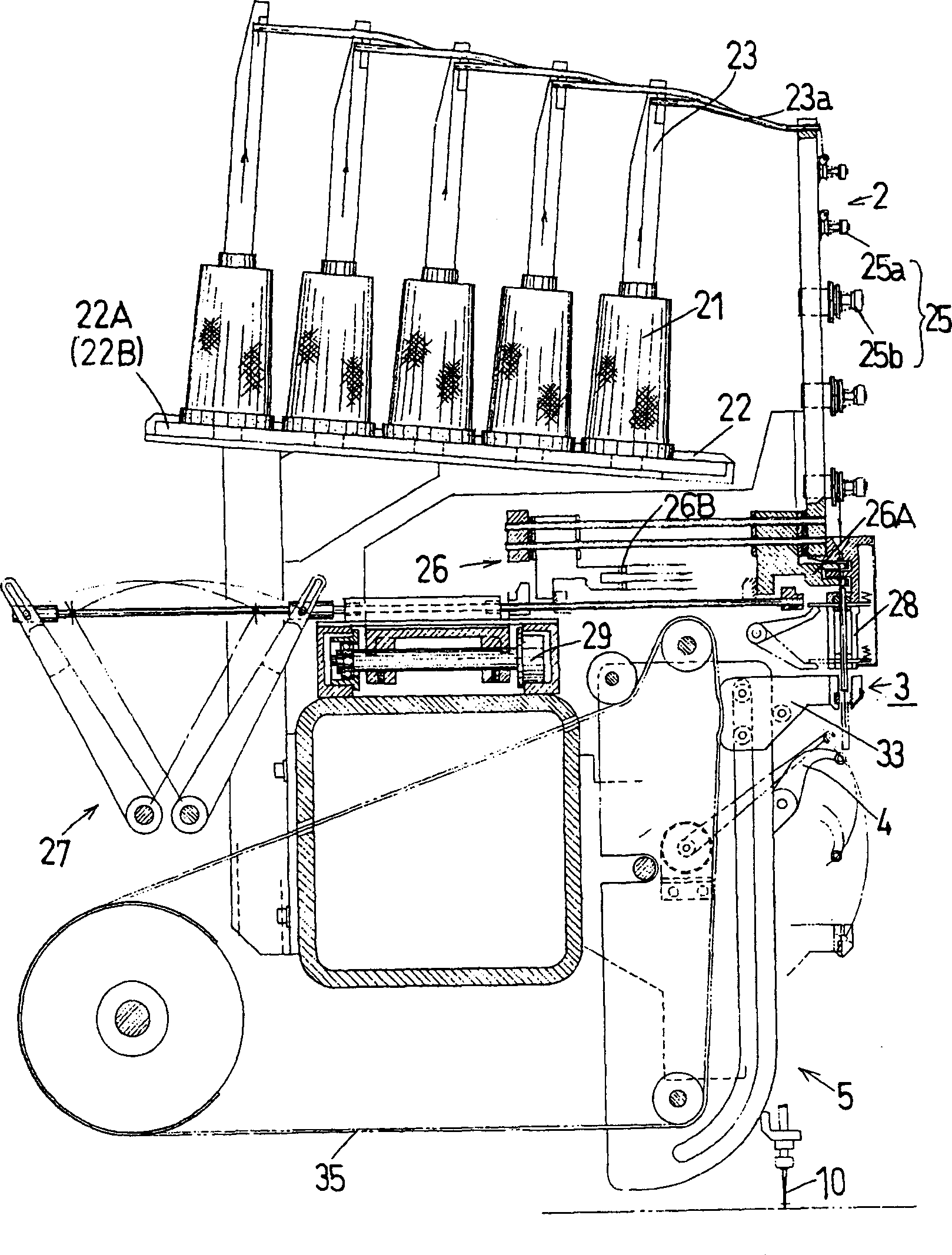

[0082] Such as Figure 1 ~ Figure 2 As shown, the sewing machine for embroidery is composed of a plurality of sewing heads 1, a thread supply and recovery device 2, a thread take-up mechanism 4, a threading device 5 and the like to form its main parts.

[0083] The figure of the present embodiment schematically shows a part of the sewing machine head provided with about 30 heads in the case of a large number of heads in one embroidery sewing machine. Moreover, other sewing heads other than those shown in the illustrations also adopt the same structure as the embodiment, and at the same time, they are made to synchronously drive each sewing head by common various drive sources. Between the source and each sewing machine head, or configure an independent drive source for each sewing machine head, so that it c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com