Hand bag rope penetrating mechanism

A technology of handbags and hand ropes, which is applied to bag making operations, paper/cardboard containers, containers, etc., can solve the problems of low production efficiency and high manual processing costs, and achieve the goals of improving work efficiency, saving manual operations, and reducing production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

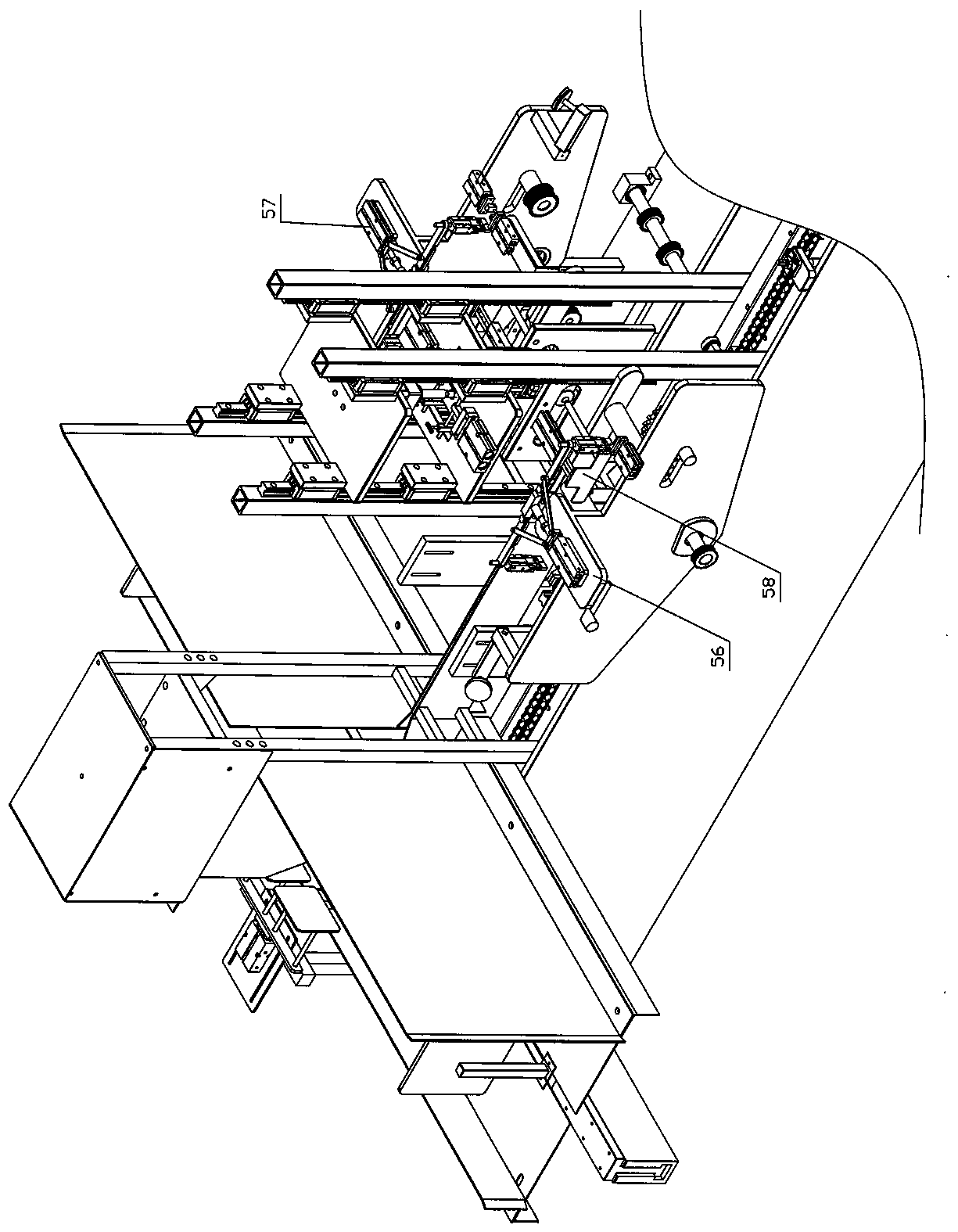

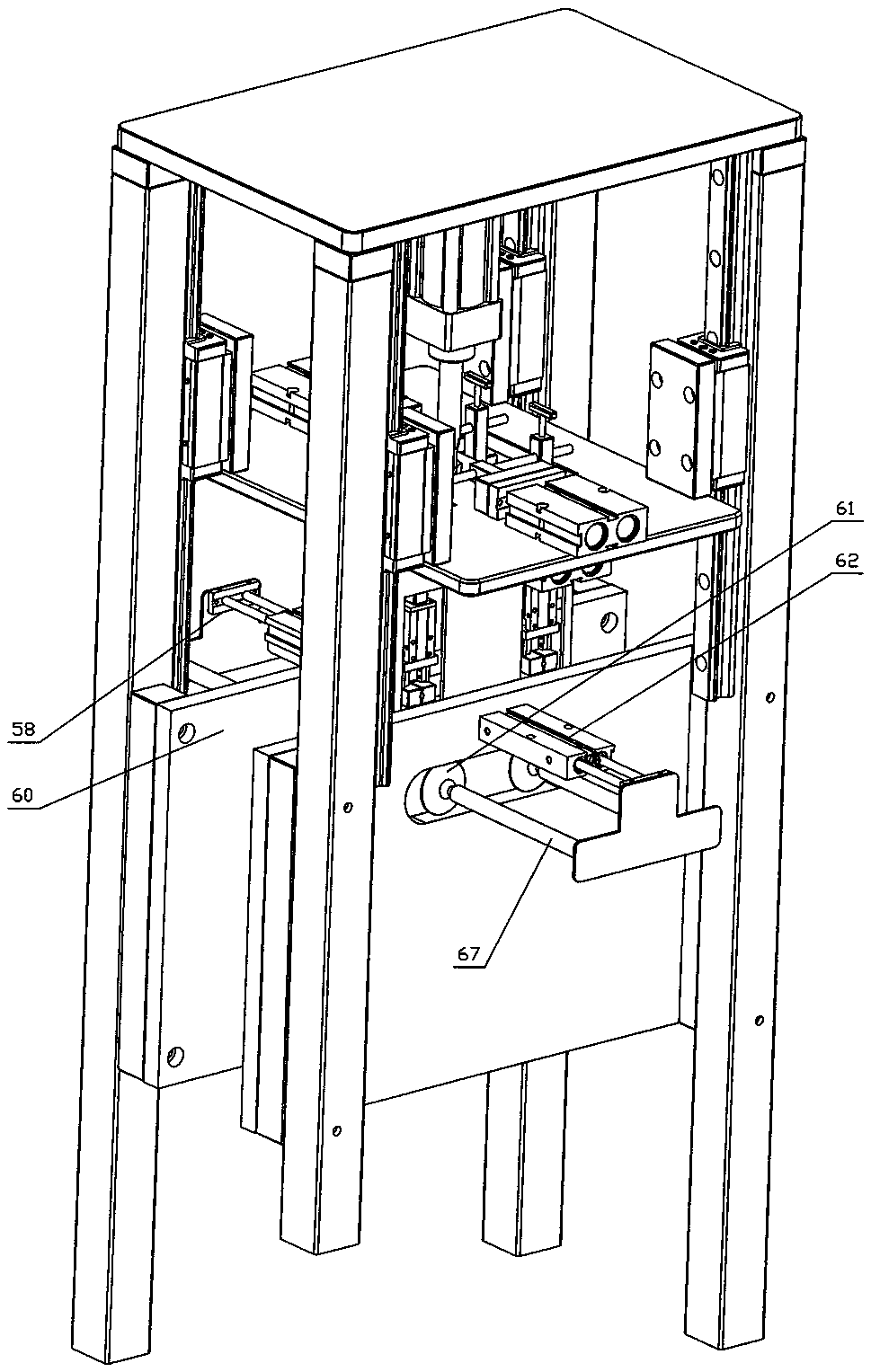

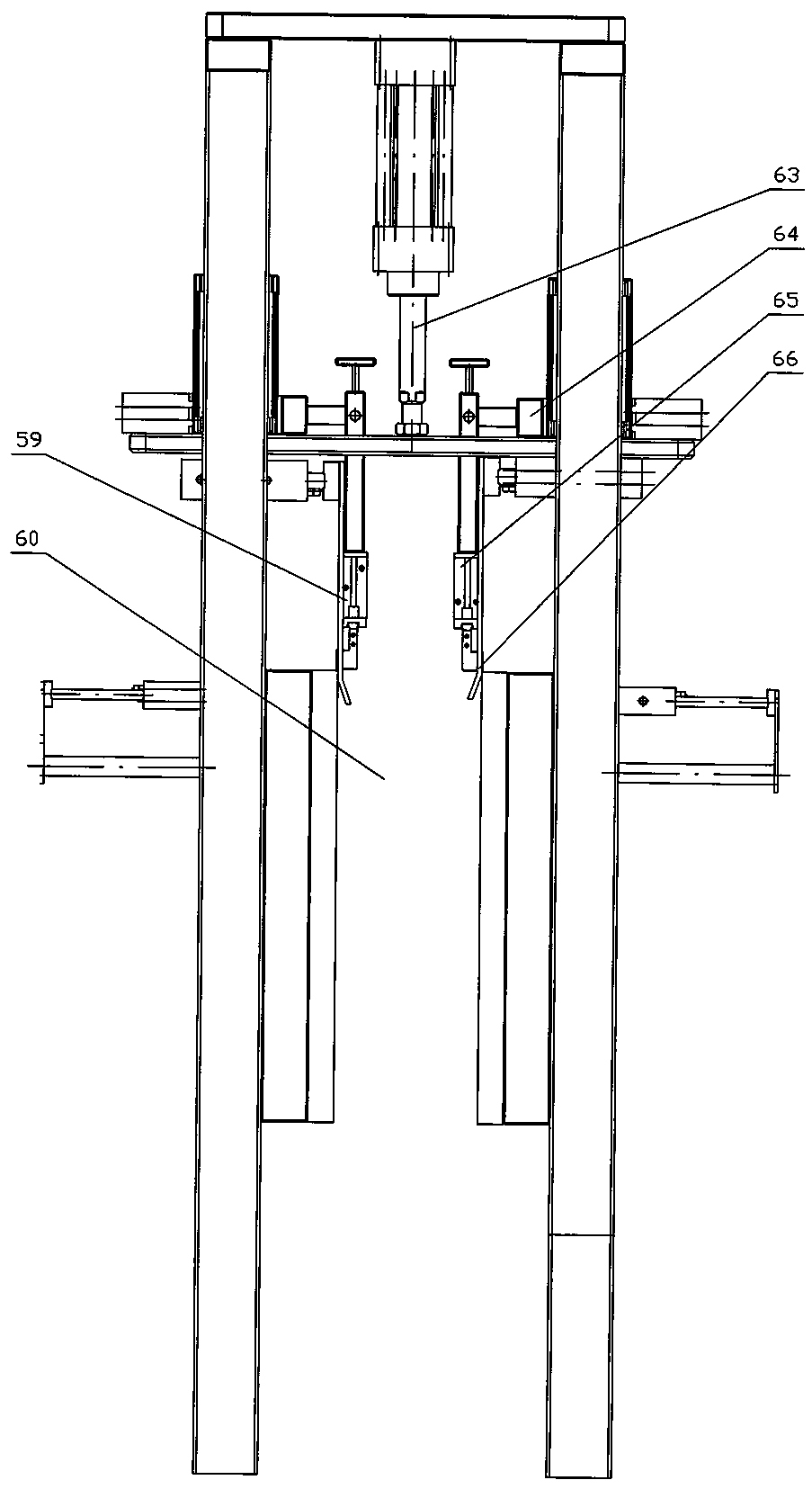

[0022] The working principle and related details of the present invention will be further described below in conjunction with the accompanying drawings. With reference to the drawings, the transport of the portable rope of the present invention is arranged in parallel with the transport of the bag body, and the threading direction is perpendicular to the transport direction of the portable rope. The insertion devices 56, 57 need to turn the chuck to make the card The head is in the same direction as the rope, and then the clip head is inserted into the rope hole on the bag body.

[0023] This kind of hand bag stringing mechanism includes a frame, a bag opening device 58, an insertion device 56 and 57 that grabs the cut hand string and inserts the clip into the string hole, and allows the inserted clip to enter the bag The extraction device 59, 65 in the body; the insertion device includes a left insertion device 56 and a right insertion device 57, the extraction device includes a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com