An automatic button-threading machine and its application in shoe-making

An automatic threading and buttoning machine technology, which is applied in the field of threading and buttoning technology and shoemaking, can solve the problems of large capacity constraints, high employment costs, and high costs, and achieve the effects of saving manpower and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

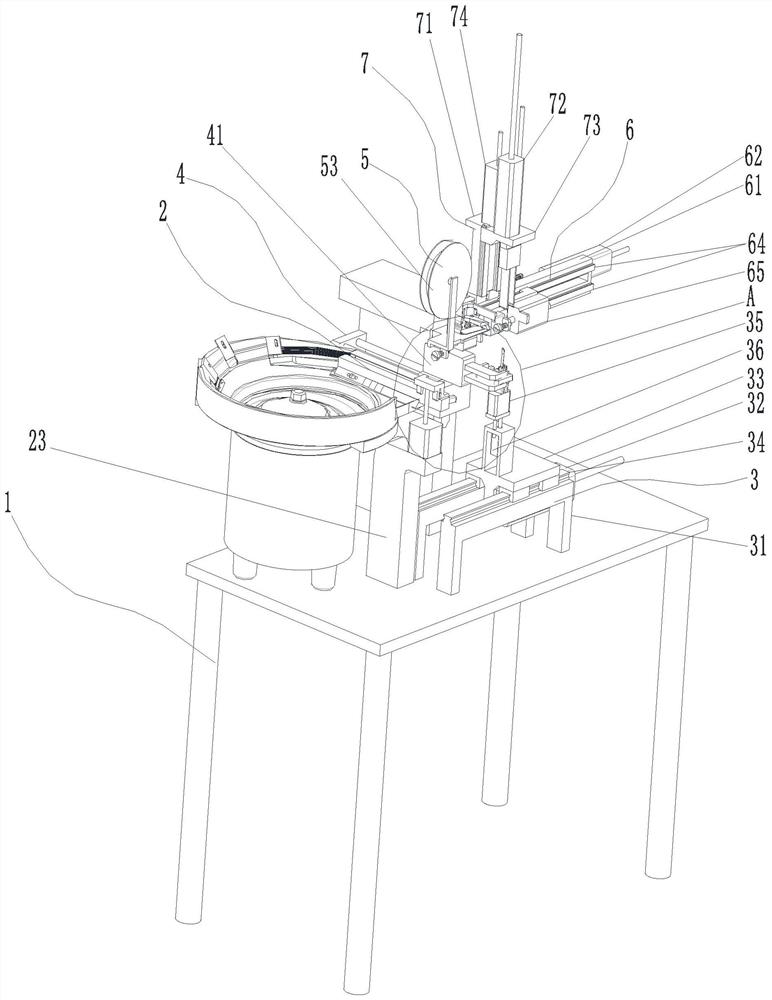

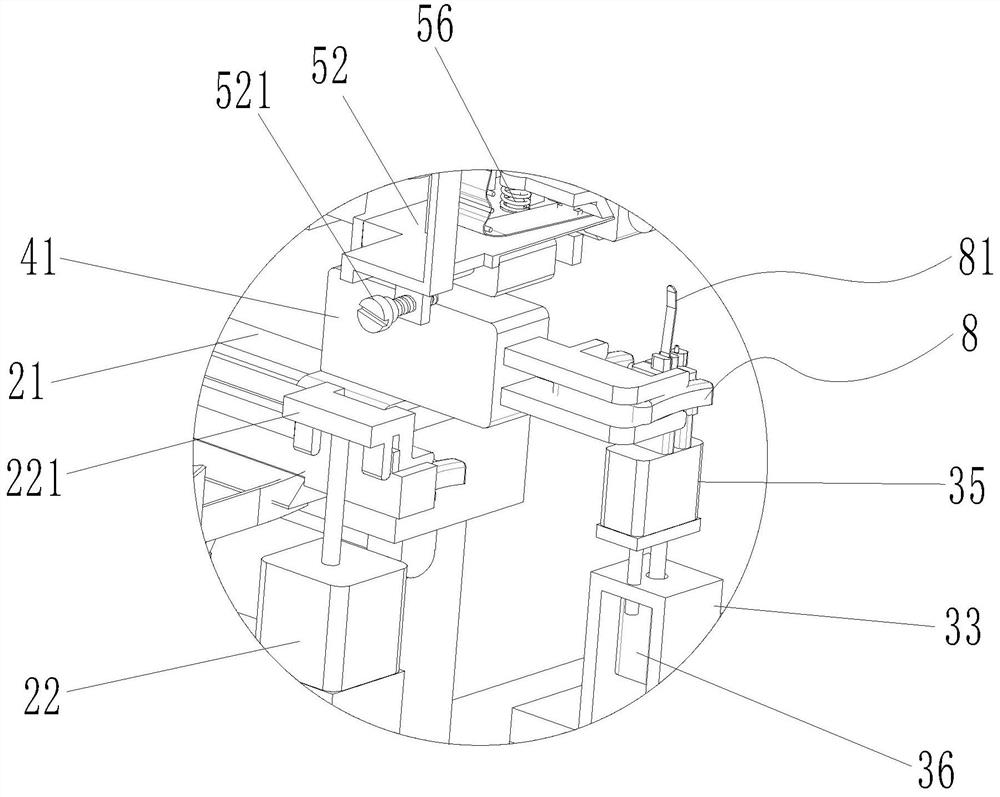

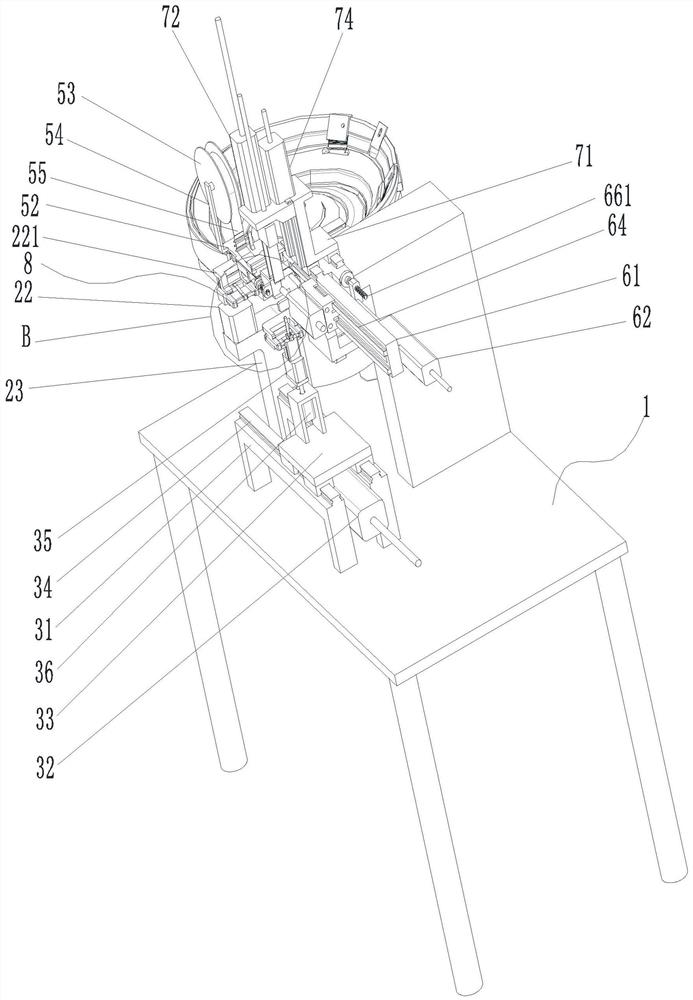

[0037] Such as Figures 1 to 14As shown in one of them, the automatic button threading machine of the present invention is used for threading the needle button 8. The needle button 8 includes a frame body 81 and stitches 82 that are rotatably connected to the frame body 81. The automatic button threading machine include:

[0038] machine 1;

[0039] The input mechanism 2 is used to input the needle buttons 8, which includes a transmission frame 21 and a first clamping device, and the transmission frame 21 is fixed on the machine table 1 and is used for inputting the needle buttons 8; the first clamping device The device is arranged at the output end of the transmission frame 21 and is used to press and fix the pin button 8 located at the output end of the transmission frame 21;

[0040] The buckle threading mechanism 7 is provided on the machine table 1 and is used to drive the buckle bar 55 required for the needle buckle 8 to wear cloth to descend and cooperate with the pin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com