Pearl necklace automatic threading machine

A technology for automatic wearing and necklaces, applied in jewelry, clothing, applications, etc., can solve the problems of manpower consumption, low degree of automation in the processing process, and low processing efficiency, and achieve the effect of convenient control, simple structure, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

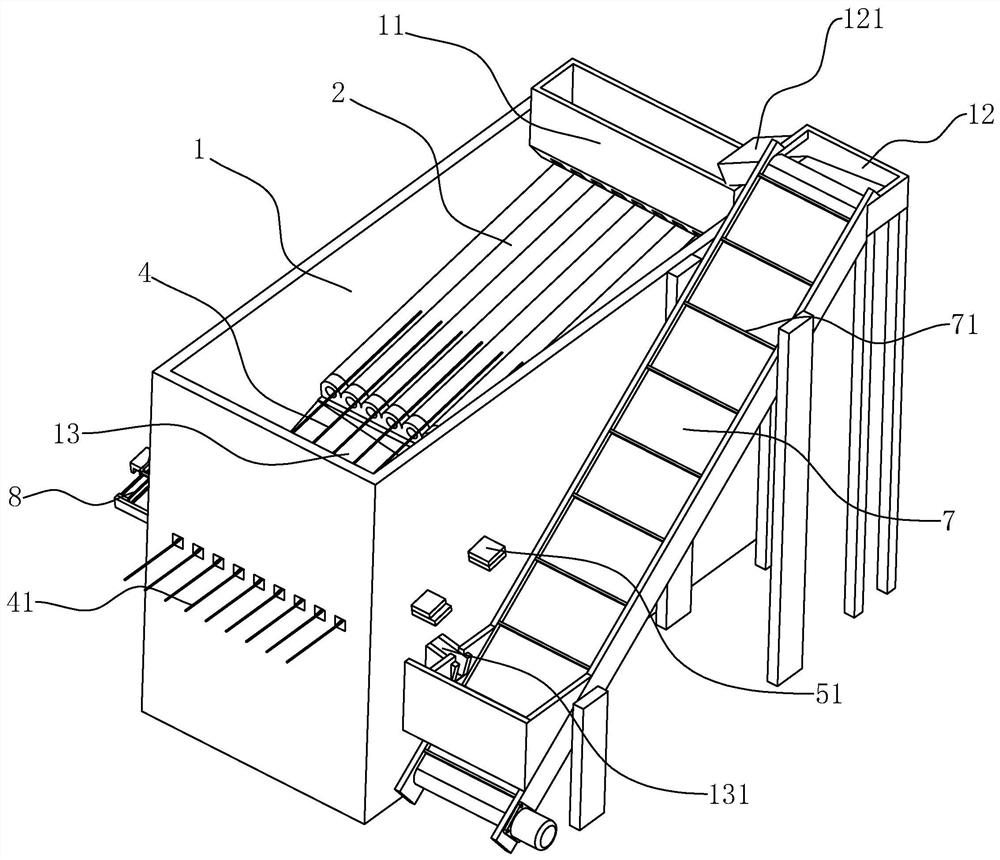

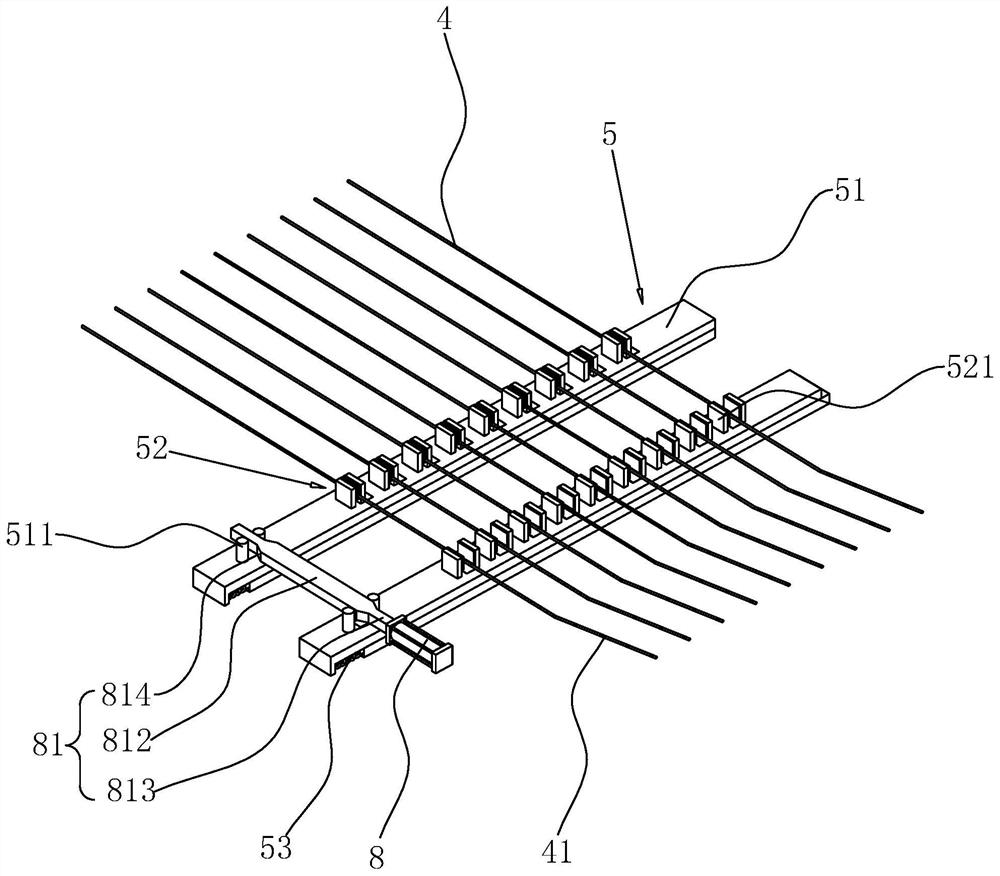

[0036] refer to figure 1 , an automatic threading machine for pearl necklaces, comprising a frame 1, a storage box 11 is installed at one end of the length direction of the frame 1, the user puts pearls to be threaded into the storage box 11, and the lower end of the storage box 11 is opened There are several feeding holes, and the pearls roll out through the feeding holes under the action of gravity; the upper end of the frame 1 is rotatably connected with a number of parallel round rollers 2, and each feeding hole is aligned with the middle of two adjacent round rollers 2 position, the pearl falls between two adjacent round rollers 2, and several long needles 4 are installed on the frame 1, and the pearls are strung on the long needles 4 when they fall, and a soft rope 41 is installed on the end of the long needles 4 away from the round roller 2, Pearl is stringed on the soft rope 41 along long needle 4.

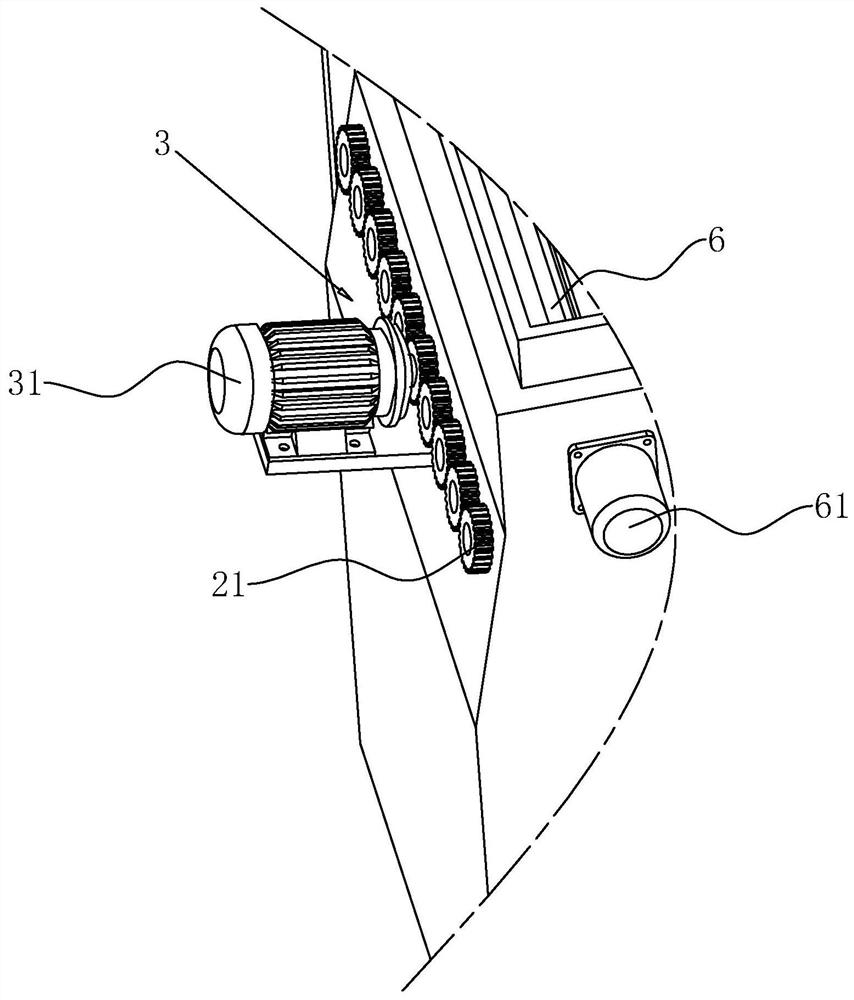

[0037] refer to figure 1 and figure 2 , the storage box 11 is equ...

Embodiment 2

[0055] refer to Figure 4 and Figure 5 , the main difference between this embodiment and Embodiment 1 is that both sides of the adjustment rod 81 are equipped with limit rods 811, both ends of the limit rod 811 are fixedly connected with the adjustment rod 81, and the adjustment blocks of the two fixing devices 5 511 all extend from between the limit rod 811 and the adjustment rod 81 to the top of the adjustment rod 81, that is, when the piston rod of the cylinder 8 stretches, the adjustment block 511 moves relative to the adjustment rod 81 between the limit rod 811 and the adjustment rod 81, The adjustment blocks 511 are all cylindrical with vertical axes, and the distance between the limit rod 811 and the adjustment rod 81 along its length direction is always adapted to the diameter of the adjustment block 511. When the rod section 813 is in contact, it is always in close contact with the two sides of the adjustment rod 81 under the action of the limit rod 811. The transmi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com