Installation method of reinforcing steel bar insulated sleeve

A technology of insulating sleeve and steel bar, which is applied in the field of steel insulating sleeve piercing, can solve the problems of high cost, complex structure of the retrieving device, and non-operation, etc., and achieve a favorable effect for heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

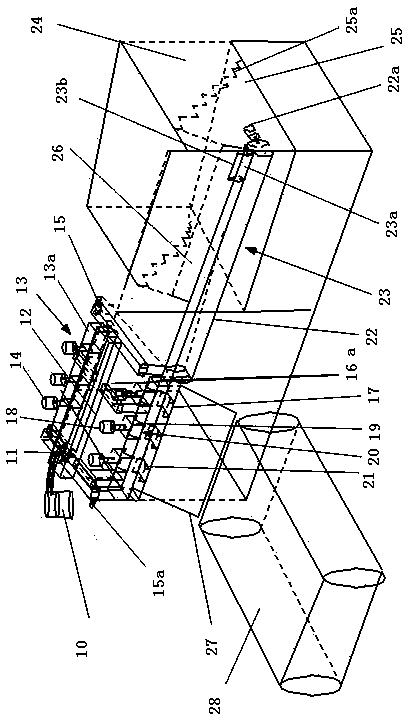

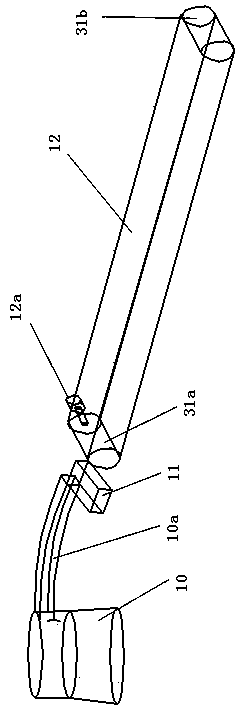

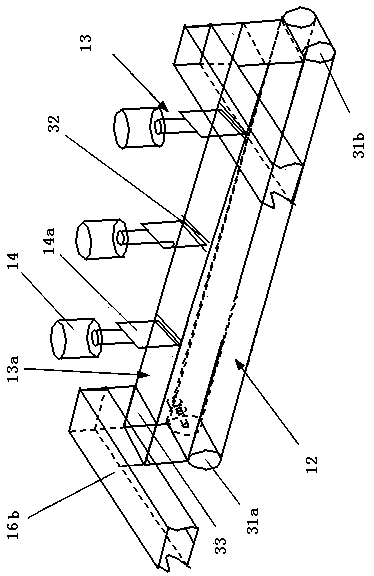

[0045] The specific technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings. In the following description, the left-right direction facing the device is defined as the horizontal direction, the front-rear direction facing the device is defined as the depth direction, and the vertical direction is defined as the vertical direction. It should be noted that, in figure 1 with image 3 as well as Figure 4 The positions of the middle vertical connecting rod 33 and the front depth connecting rod or the rear depth connecting rod are inconsistent, but are consistent in actual use. In actual use, the connection position can be determined according to the actual situation.

[0046] A method for piercing reinforced insulating sleeves, including a vibrating hopper, the method for piercing reinforced insulating sleeves is implemented in a device for piercing reinforced insulating sleeves, the device for piercing reinfo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com