Method for quickly aligning steel strands in tension construction of front-clamping jack and centring plate

A technology for steel strands and jacks, which is applied in the field of centering plates to ensure rapid alignment of steel strands, and can solve problems such as reduced work efficiency, alignment obstacles and waste of steel strands in front clamping jacks, and achieve rapid alignment operation, avoiding the difficulty of aligning holes, and saving alignment time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

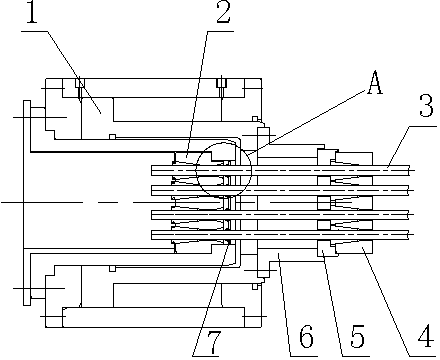

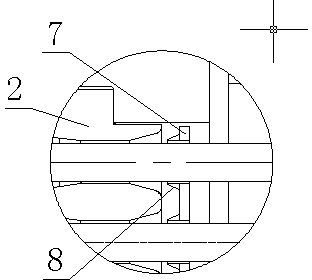

[0020] Below in conjunction with accompanying drawing, the present invention will be further described:

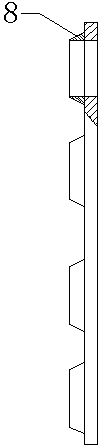

[0021] As shown in the accompanying drawings, a method for quick alignment of steel strands in the tensioning construction of the front clip jack uses a centering plate 7 for alignment. The centering plate 7 is a circular plate-shaped structure with a For the holes 9 that steel strands pass through, the pitch, quantity and position of the holes 9 on the centering plate 7 correspond to the holes on the tension limiting plate 5 . At least two holes 9 on the centering plate 7 are welded with tapered guides 8 on their outer sides. The tapered guides 8 are cone cylinders coaxial with the holes 9, and the small ends of the tapered guides 8 face outward. The outer diameter of the centering plate 7 is smaller than the inner diameter of the transition sleeve 6 for tensioning. It includes the following steps:

[0022] (1) First combine a pair of centering plates 7 and a limiting p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com