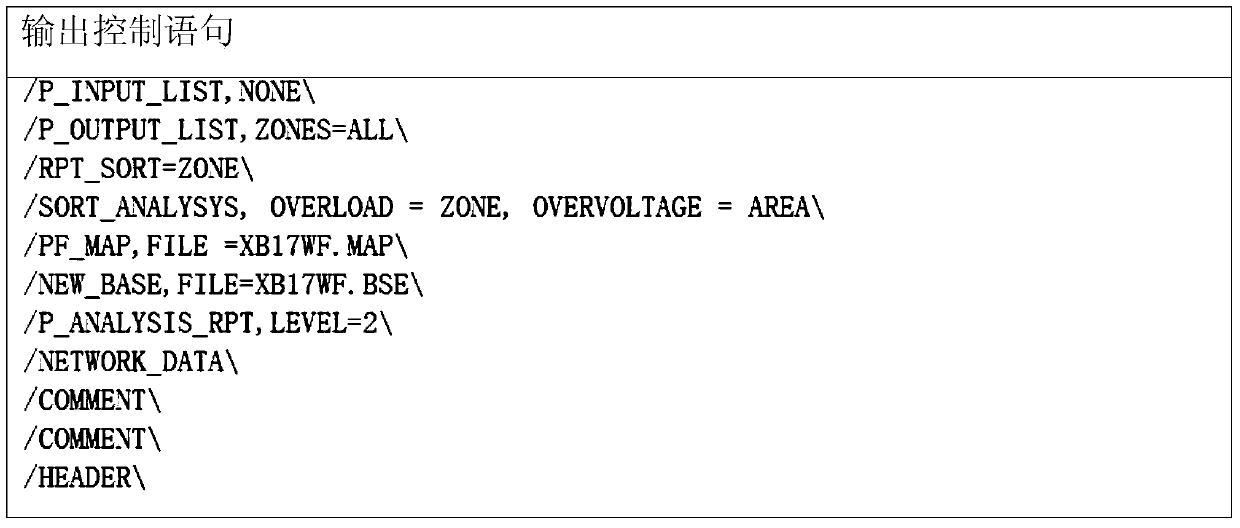

Patents

Literature

43results about How to "Accurate import" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

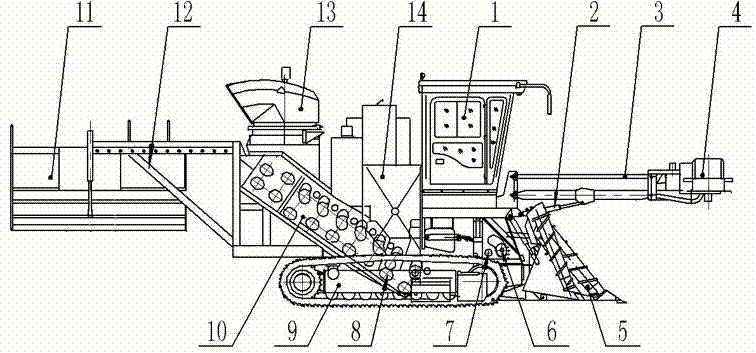

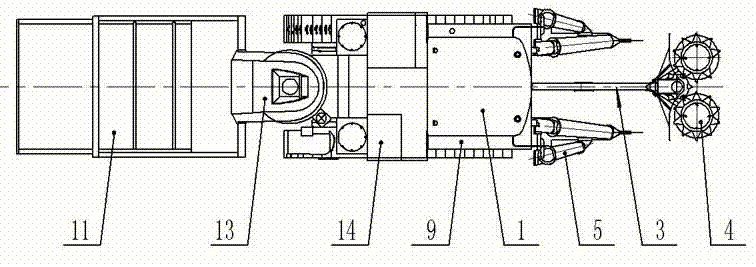

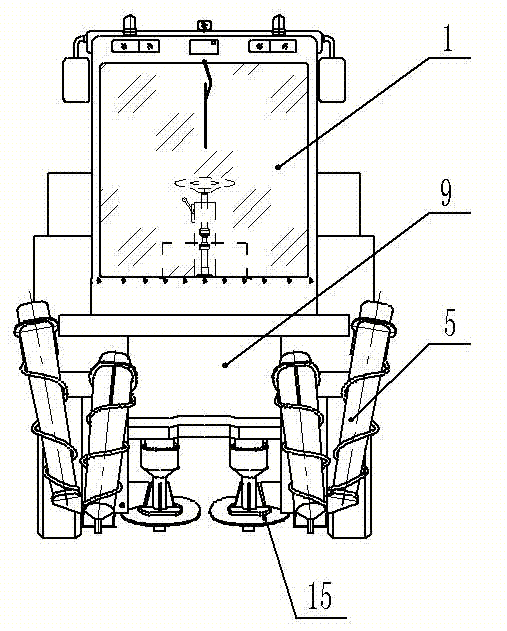

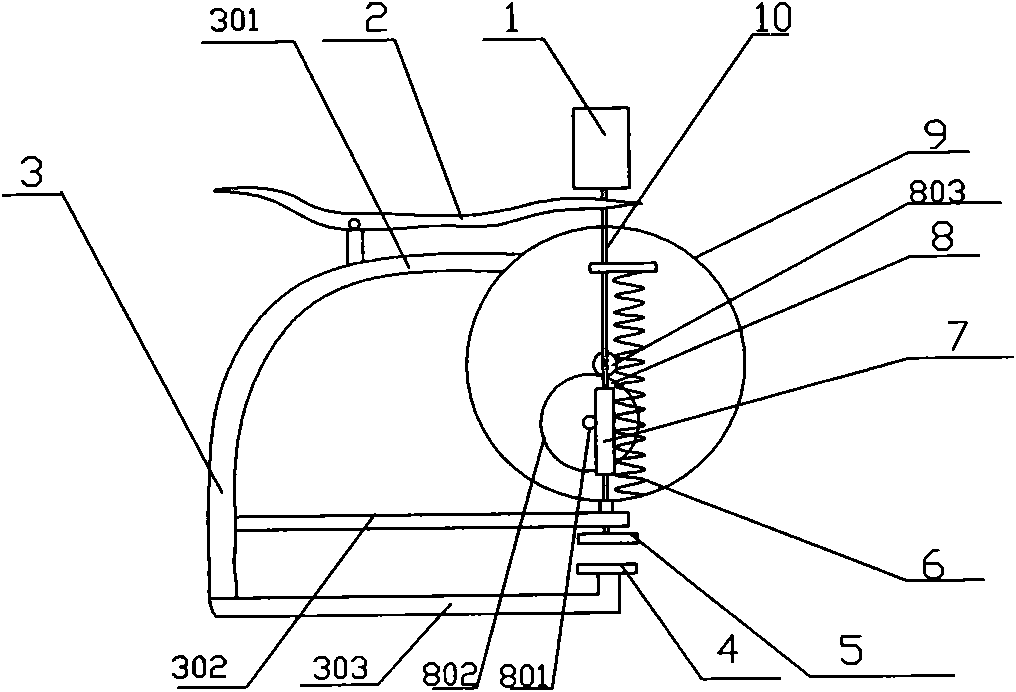

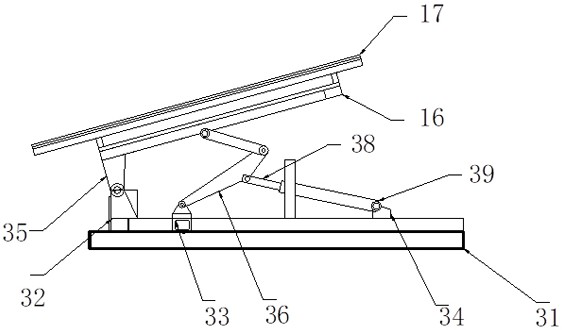

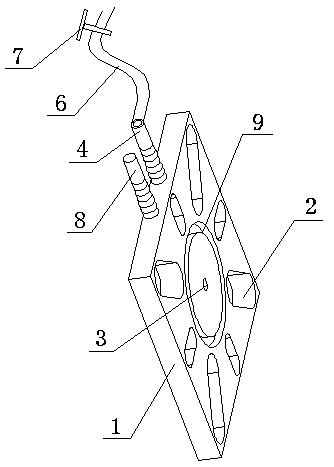

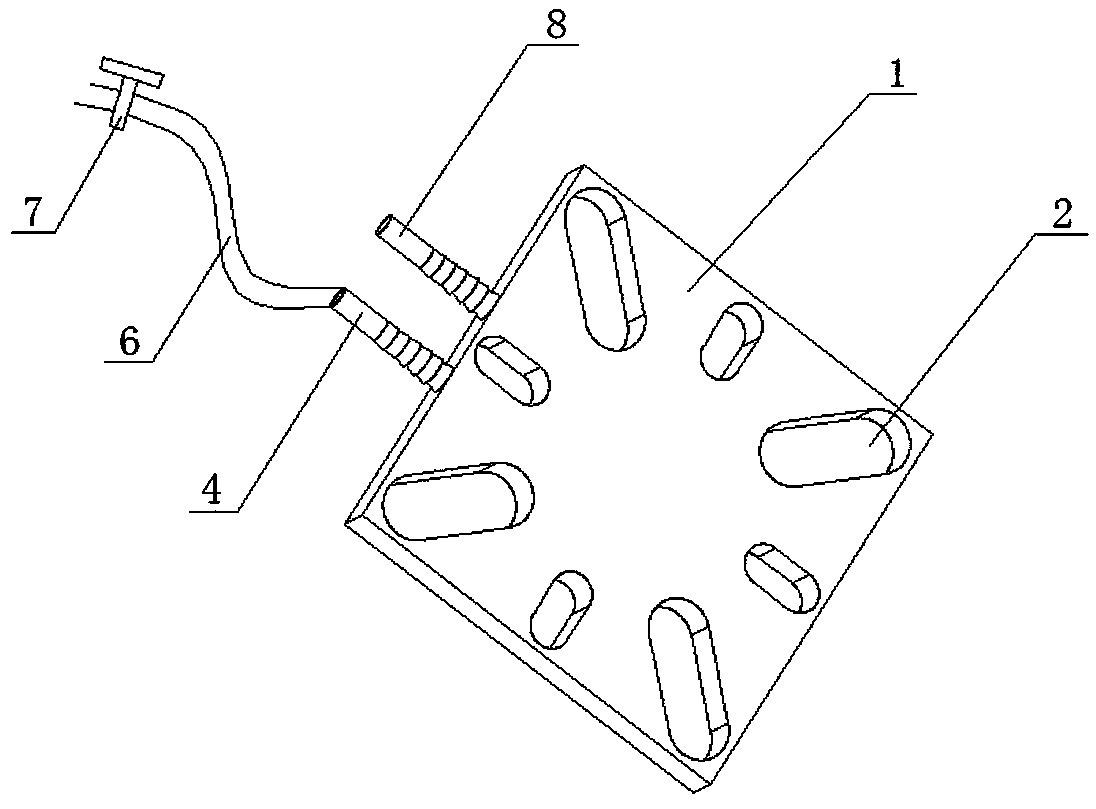

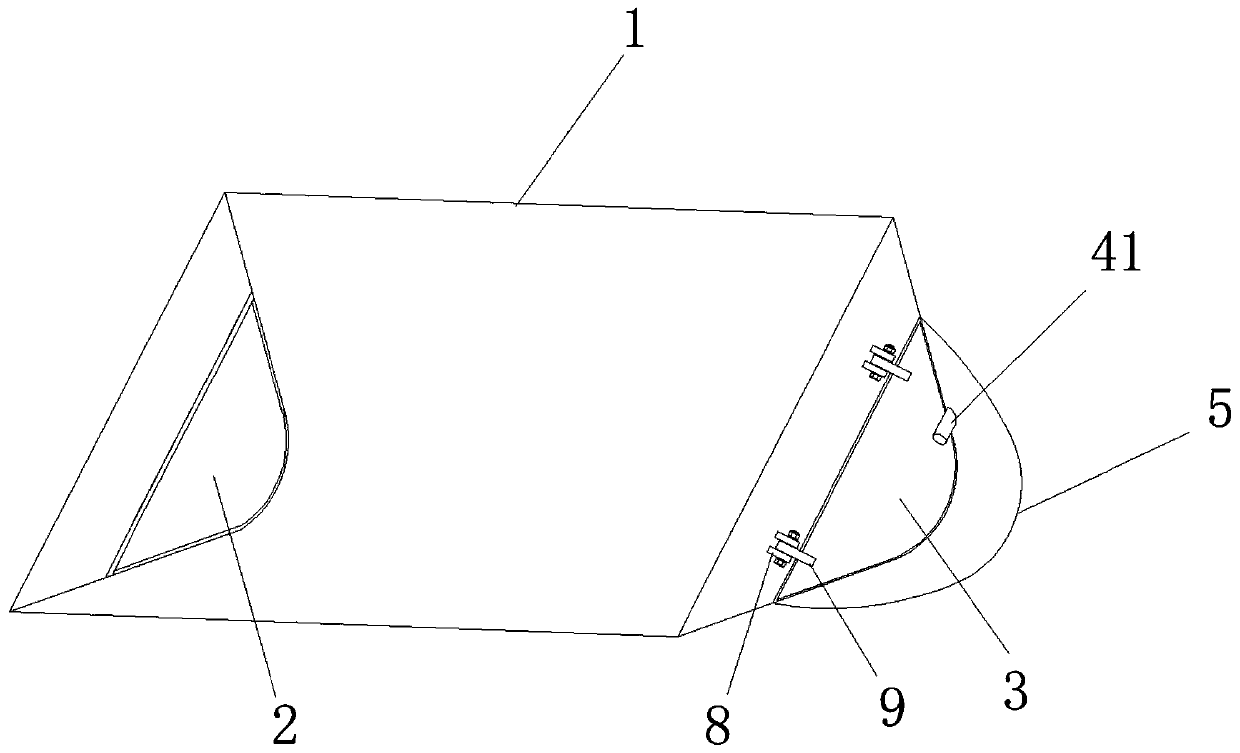

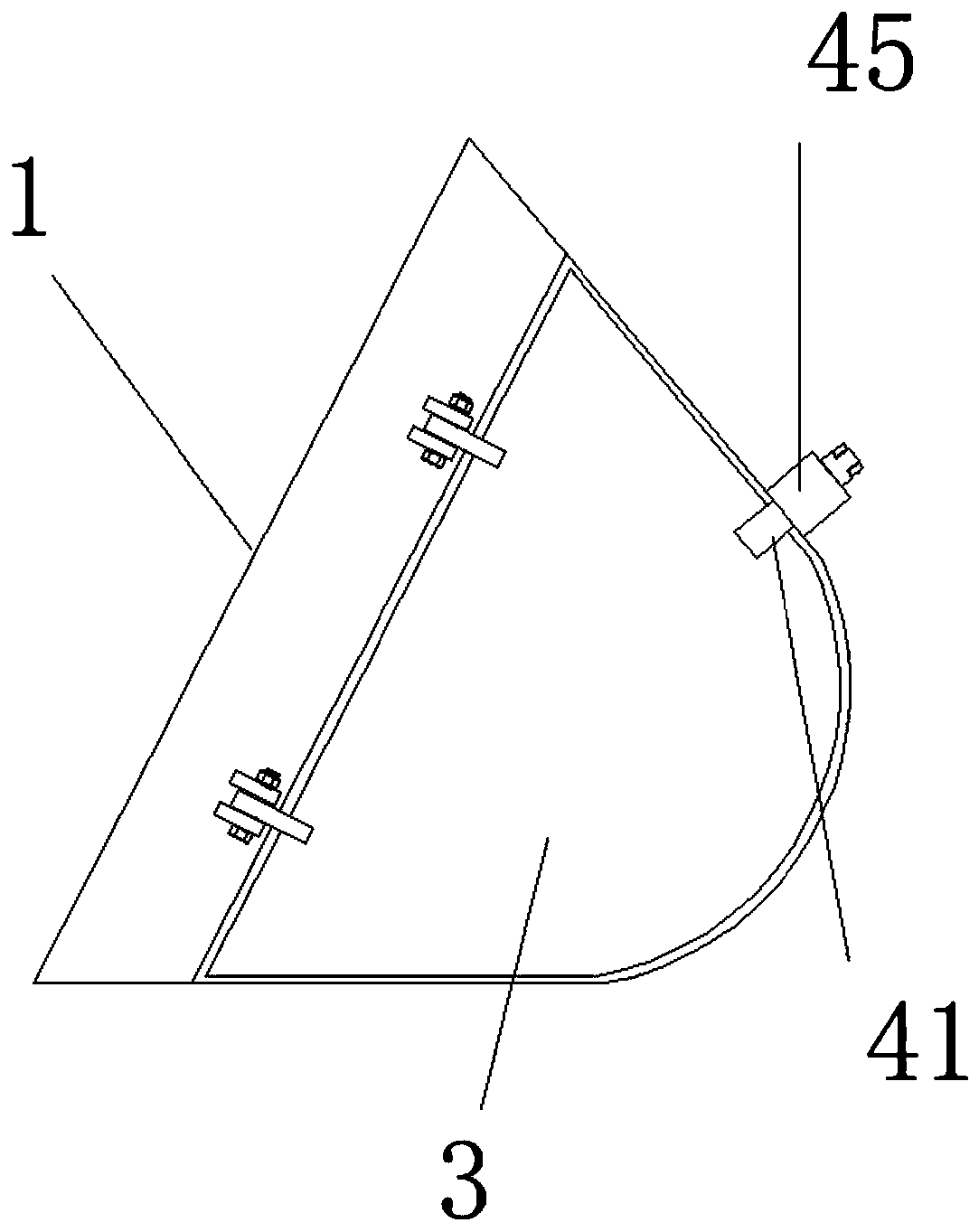

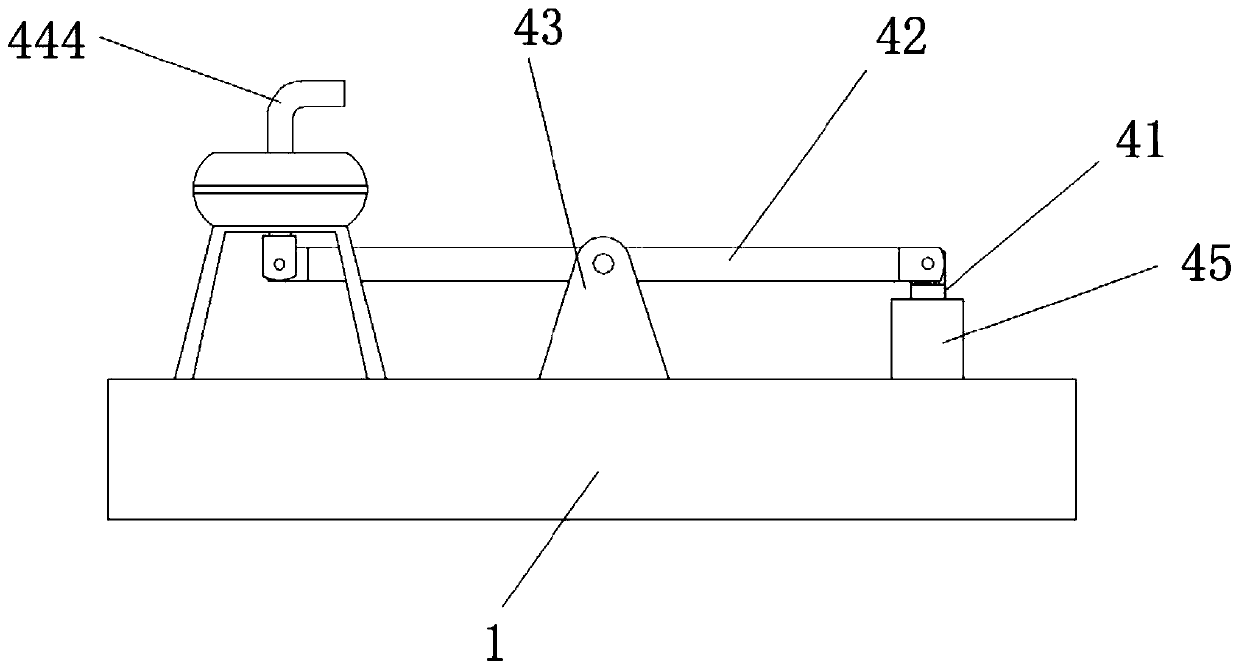

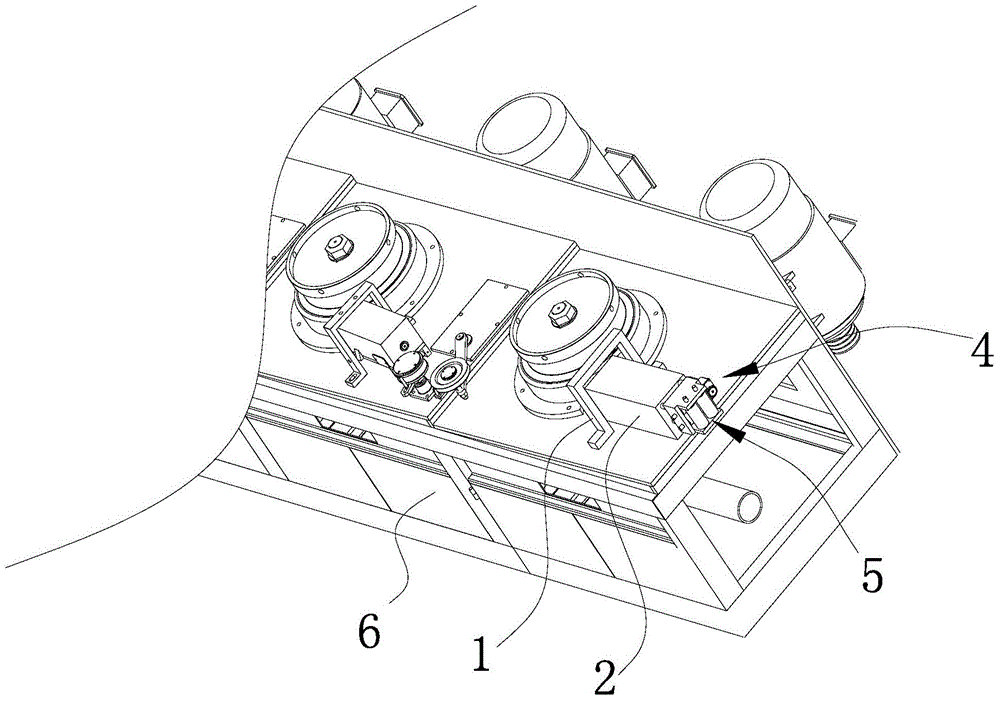

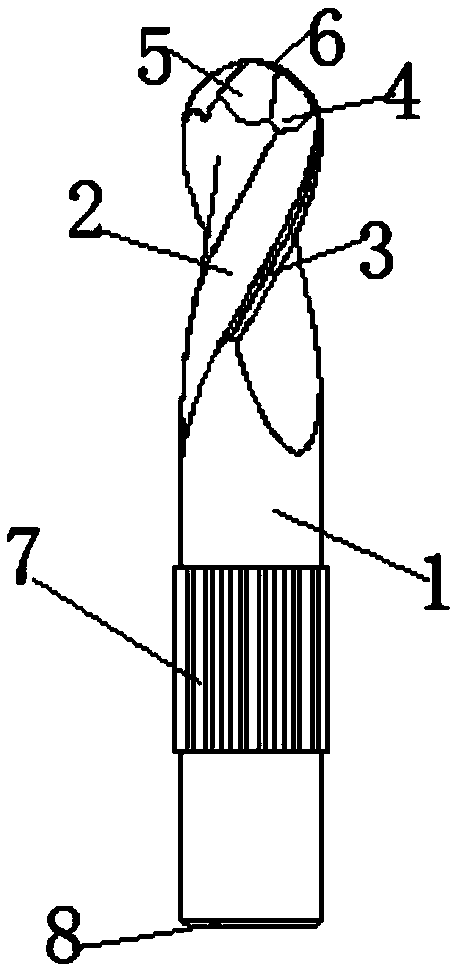

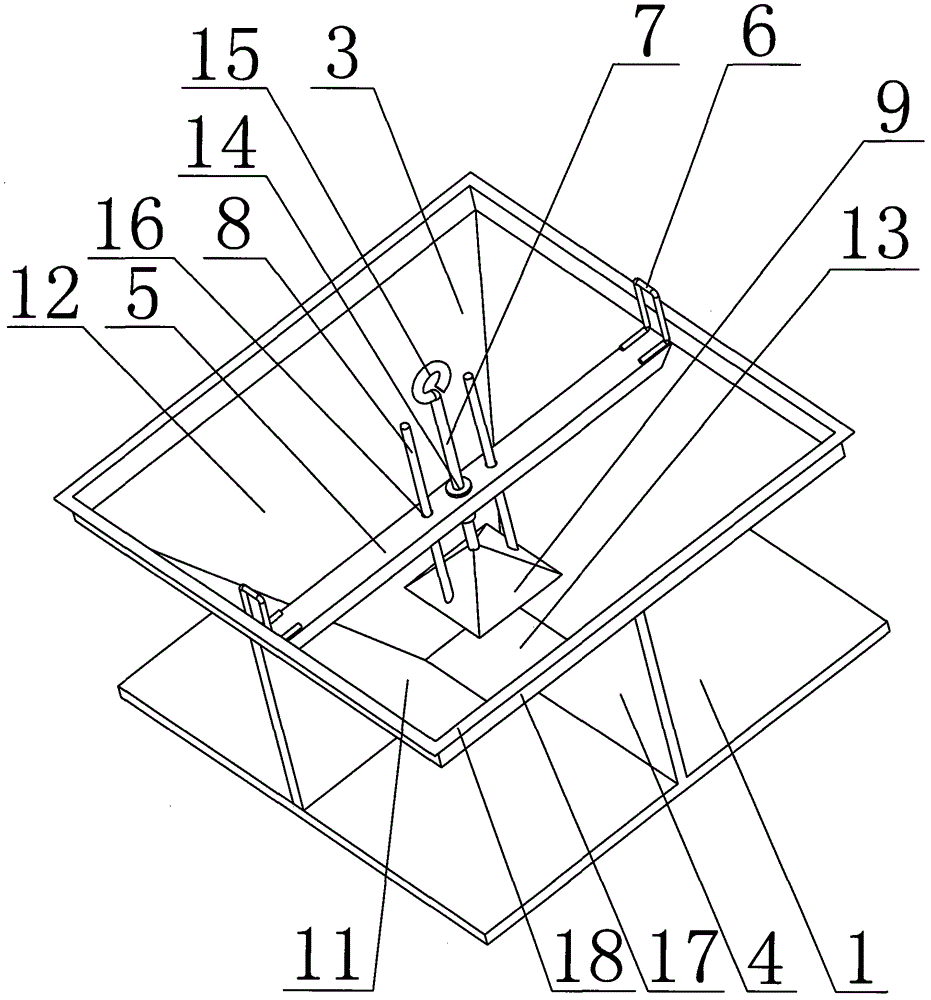

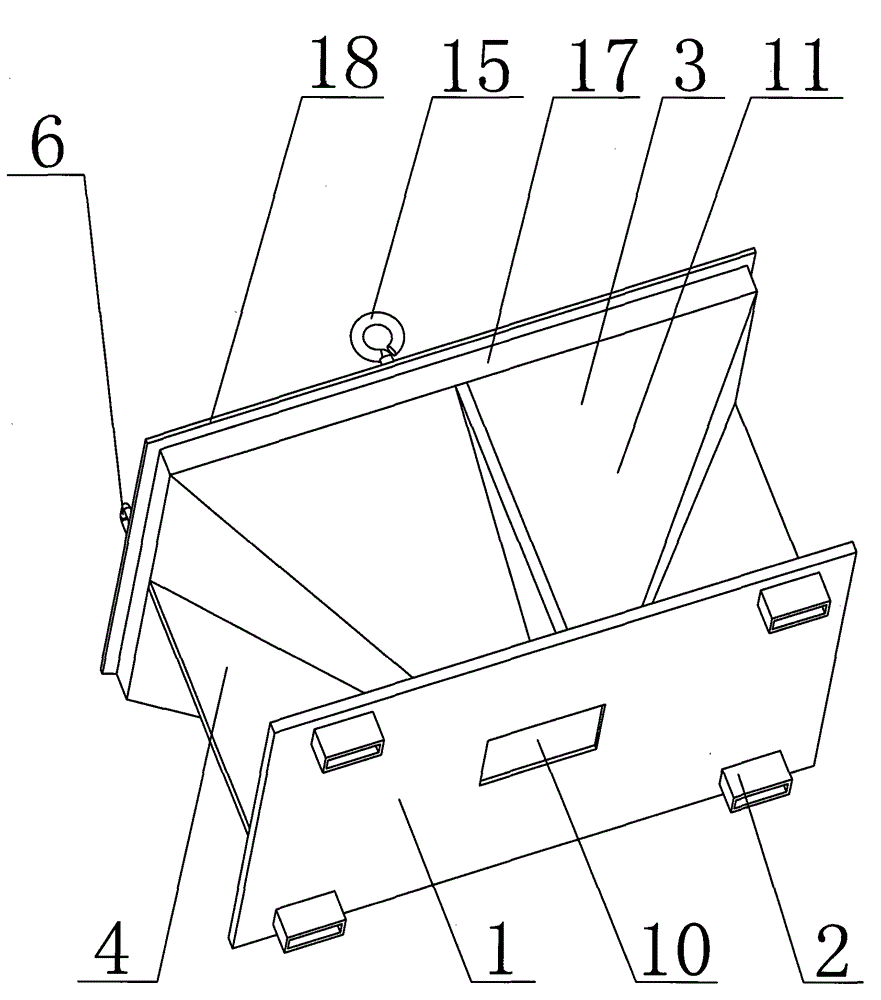

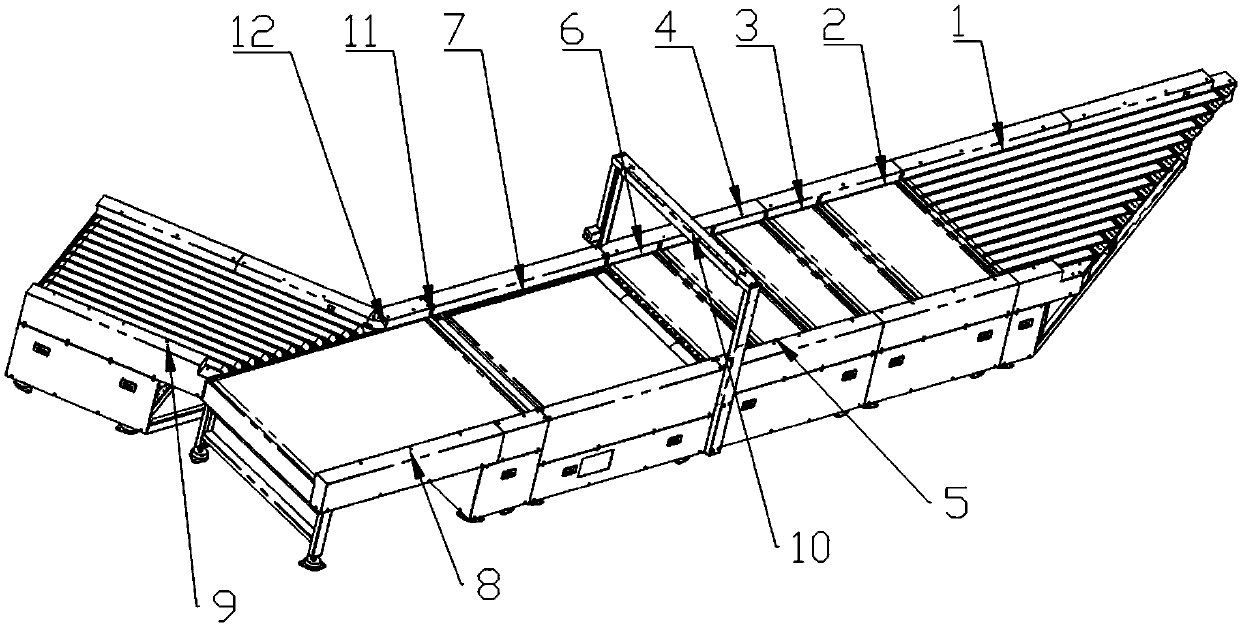

Integrated-rod type sugarcane harvester

InactiveCN103168557AMeet the requirements of small turning radiusAccurate importHarvestersAgricultural engineeringFarm machine

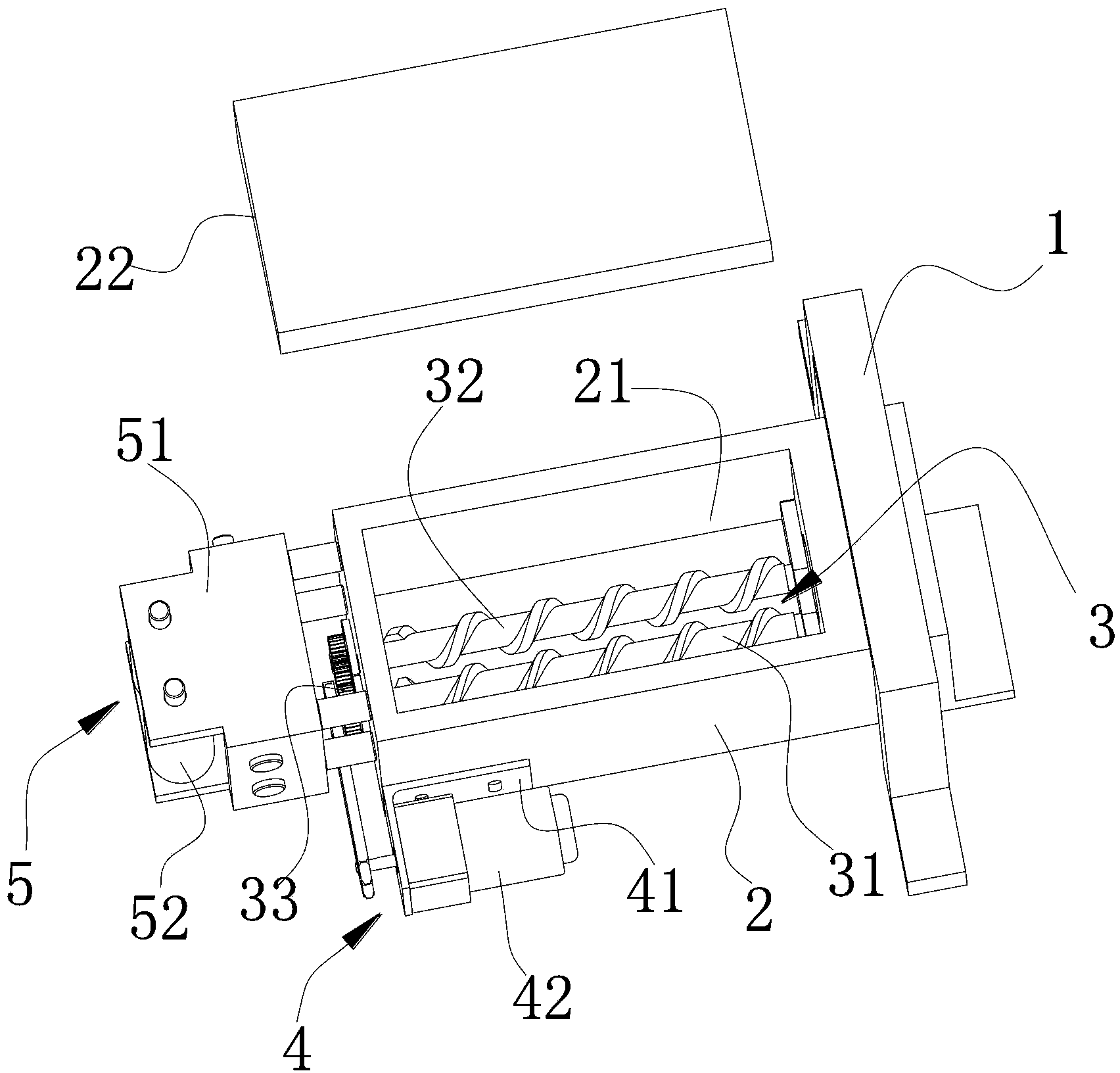

The invention discloses an integrated-rod type sugarcane harvester which belongs to agricultural machinery, and aims at providing a sugarcane harvester capable of meeting the requirement on the operation in a hilly land. The integrated-rod type sugarcane harvester comprises a stander, a tip cutting device, a straightening device, a sugarcane pressing roll, a feeding roll, a harvesting device, a leaf peeling device, an impurity removing device and a collecting frame, wherein the tip cutting device comprises an oil cylinder (2) fixed on a bracket (3) and tip cutting disks (4), the straightening device comprises two spiral rolls (5), the sugarcane pressing roll (6) and the feeding roll (7) are arranged behind the straightening device, the harvesting device is composted of harvesting disks (15) arranged at the bottom of the stander (9), the leaf peeling device is composed of leaf peeling rolls (8) arranged in a channel (10), the impurity removing device (18) is arranged at an outlet of the channel, and the collecting frame (11) fixed at the tail end of the stand (9) is communicated with an outlet of the channel (10). The integrated-rod type sugarcane harvester does not roll ridge banks, and has the advantages of high efficiency, stable gravity center, flexibility, no damage to sugarcane, and the like.

Owner:贵州益众兴业实业有限责任公司

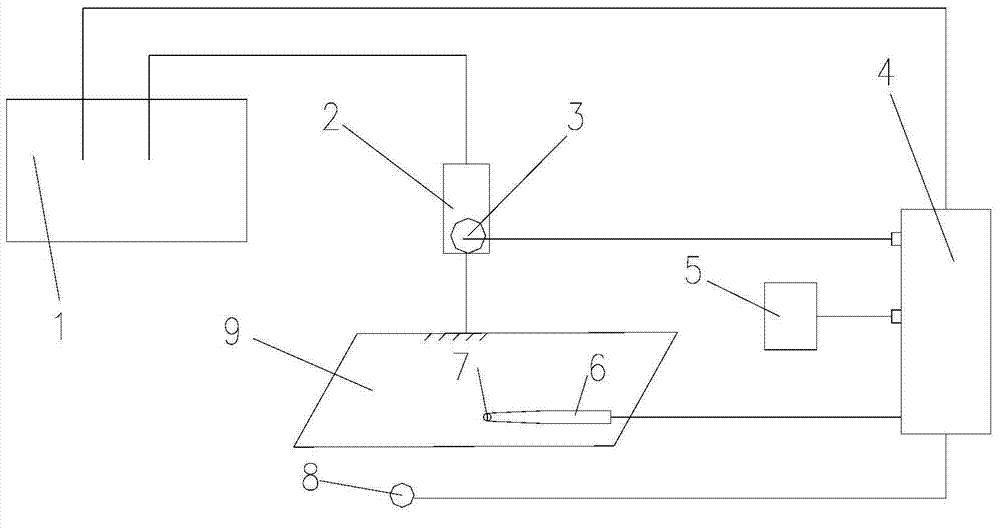

Electromagnetic positioning system and selection method for three-dimensional image view angle of electromagnetic positioning system

InactiveCN104771232AAccurate diagnosis and treatment processHigh precisionUltrasonic/sonic/infrasonic diagnosticsSurgeryThree dimensional displayMedical device

The invention relates to the technical field of medical devices, in particular to an electromagnetic positioning system and a selection method for the three-dimensional image view angle of the electromagnetic positioning system. The system comprises an electromagnetic positioning instrument, a magnetic field transmitter, an ultrasonic probe, an intervening device and an ultrasonic image system. The ultrasonic image system comprises a view angle selection module, a signal processing module and a three-dimensional display module which are connected in sequence. The magnetic field transmitter and the ultrasonic image system are connected with the electromagnetic positioning instrument. The ultrasonic probe is connected with the ultrasonic image system, a first positioning sensor is arranged on the ultrasonic probe, a second positioning sensor is arranged on the intervening device, and the first positioning sensor and the second positioning sensor are connected with the electromagnetic positioning device. When the electromagnetic positioning system is used, a proper view angle selection method is adopted automatically, a diagnosis and treatment part can be displayed in real time, a three-dimensional image of the diagnosis and treatment part can be basically identical with that of a doctor, and the intervening device can be conveniently and accurately guided to conduct diagnosis and treatment of operation and the like. According to the electromagnetic positioning system and the selection method for the three-dimensional image view angle of the electromagnetic positioning system, safety is high, use is convenient and reliable, the medical technology is improved, and the medical risks are lowered.

Owner:UNITED IMAGING SYST BEIJING CO LTD

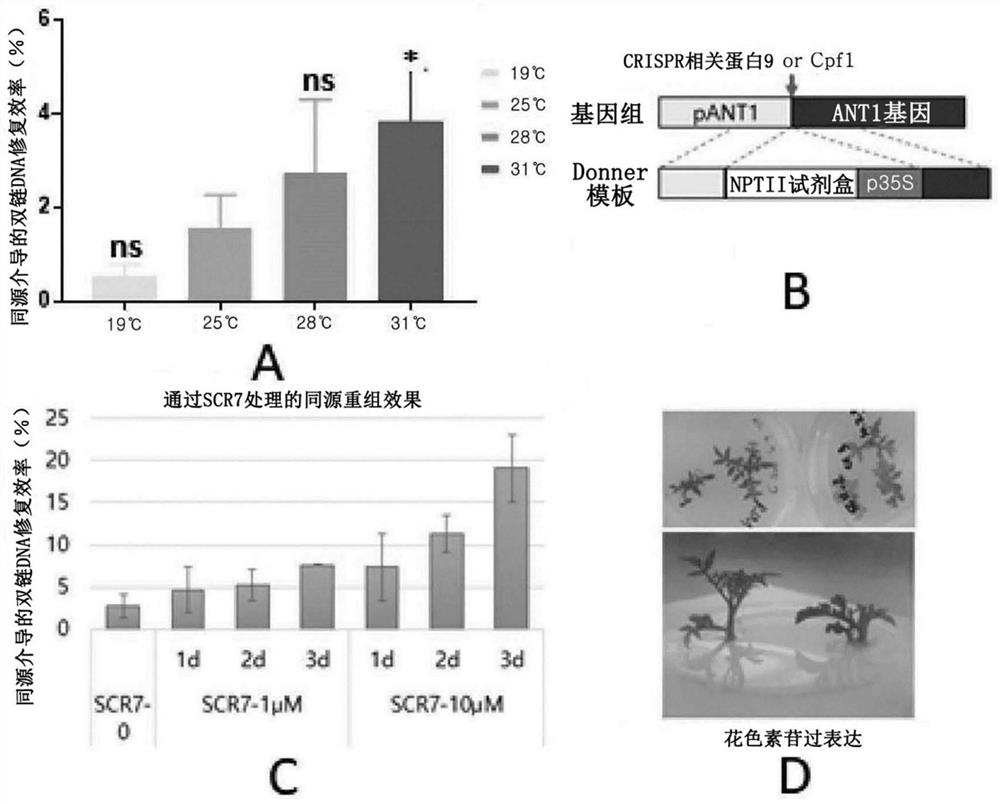

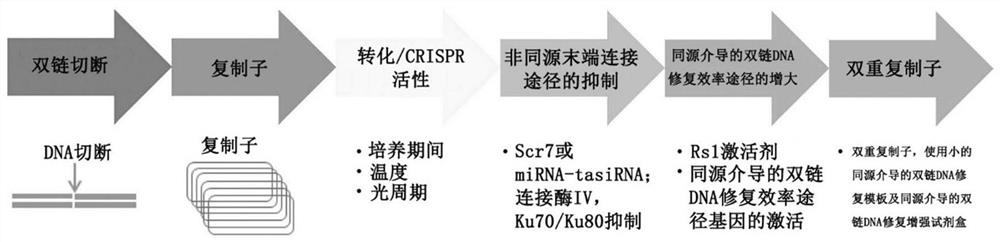

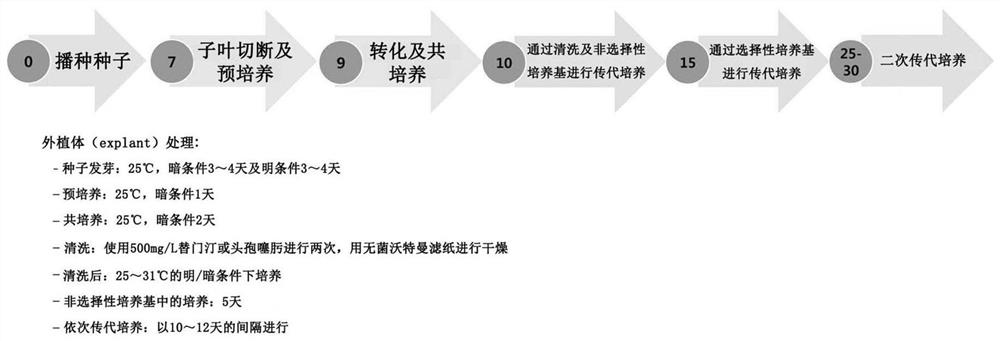

Method for increasing efficiency of homologous recombination-based gene editing in plant

The present invention relates to a method for increasing the efficiency of homologous recombination-based gene editing in a plant, comprising a step of optimizing temperature and photoperiod conditions, expressing factors necessary for homology-directed DNA repair (HDR) and factors for increasing the efficiency of HDR by using multiple replicons, or regulating an HDR pathway or a non-homologous end joining (NHEJ) pathway, during tissue culturing of plant cells.

Owner:IND ACADEMIC COOP FOUND GYEONGSANG NAT UNIV

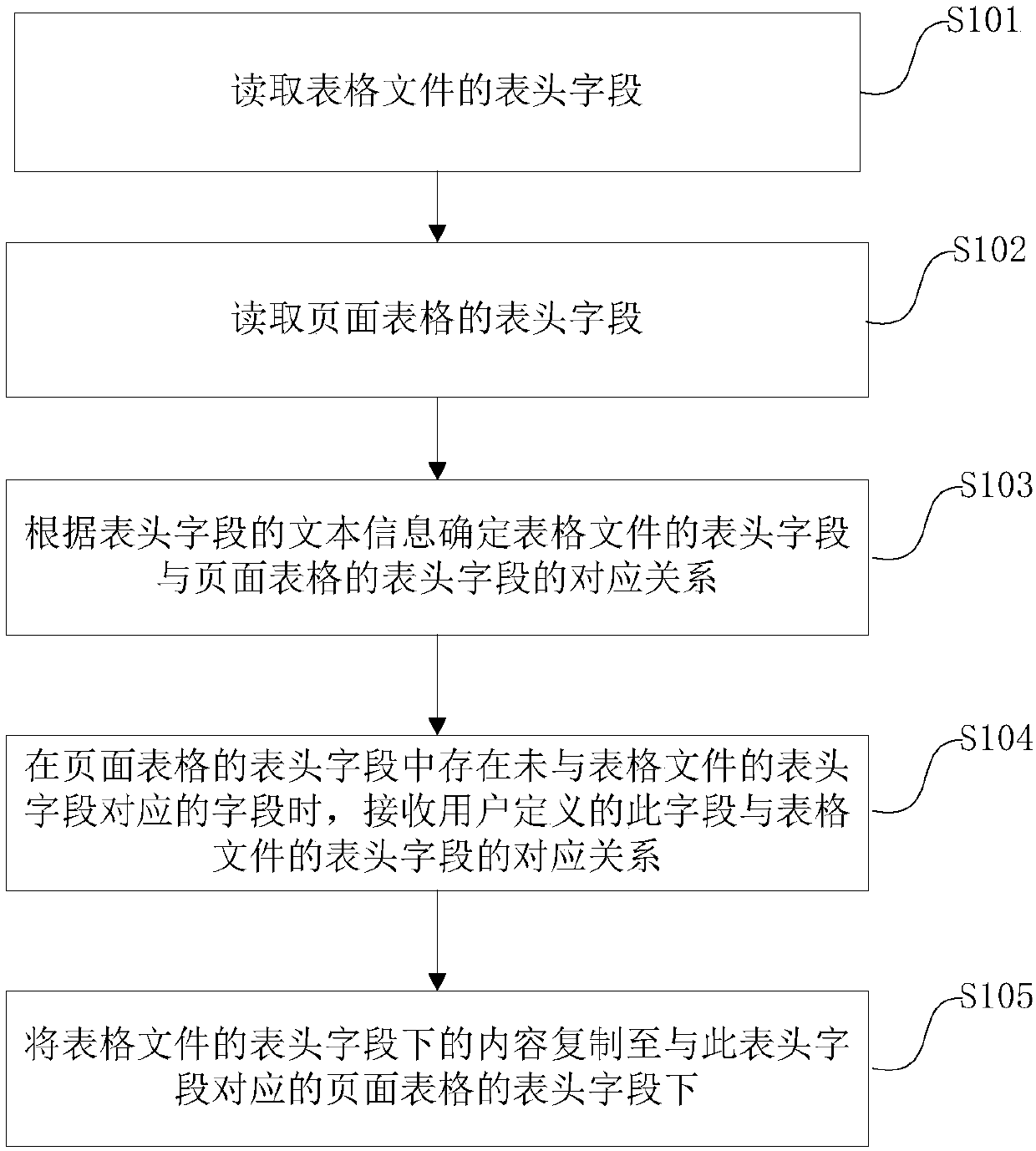

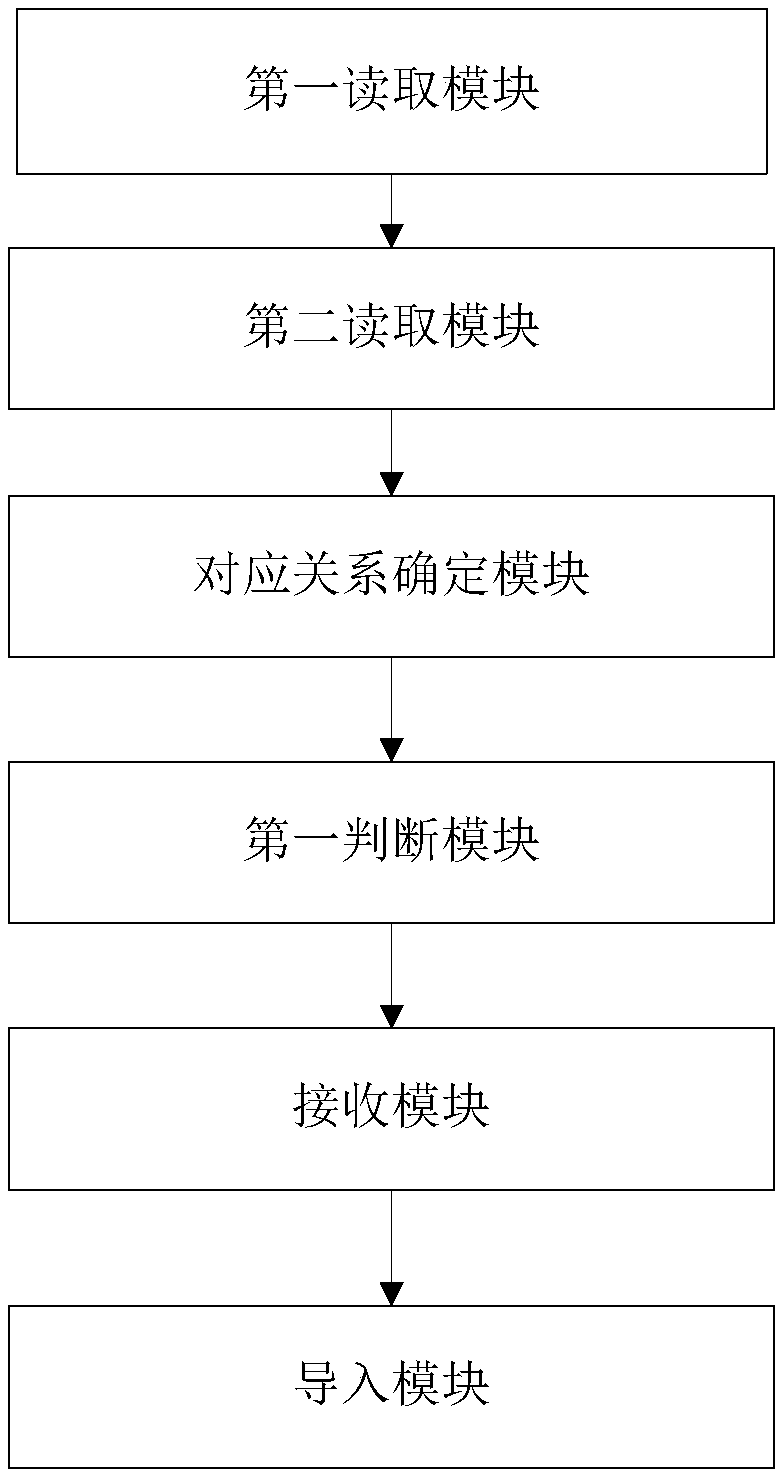

Data importing method and device, medium and equipment

ActiveCN110019478AMeet control needsAccurate importDatabase management systemsDatabase distribution/replicationPage tableDatabase

The invention discloses a data importing method and device, medium and equipment. The method comprises the following steps of reading a header field of a table file; reading a header field of the pagetable; determining the corresponding relationship between the header field of the table file and the header field of the page table according to the text information of the header field; when a fieldwhich does not correspond to the header field of the table file exists in the header field of the page table, receiving the corresponding relation between the field defined by a user and the header field of the table file; and copying the content under the header field of the table file to the header field of the page table corresponding to the header field. According to the present invention, the content of each field in the data table can be accurately imported into the corresponding field of the page table, a manual selection mode of the user is provided, the control requirement of the user on the special conditions is met, a function of editing the page table is also provided, and the page table completely contains the content of the data table.

Owner:GUIZHOU BAISHANCLOUD TECH CO LTD

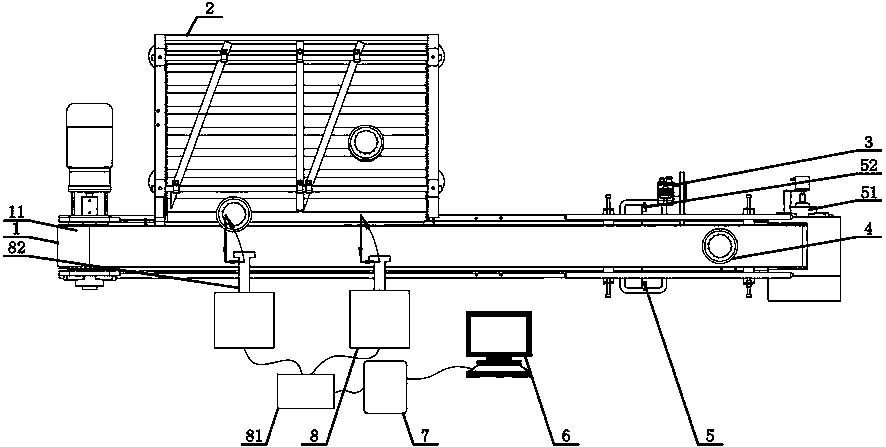

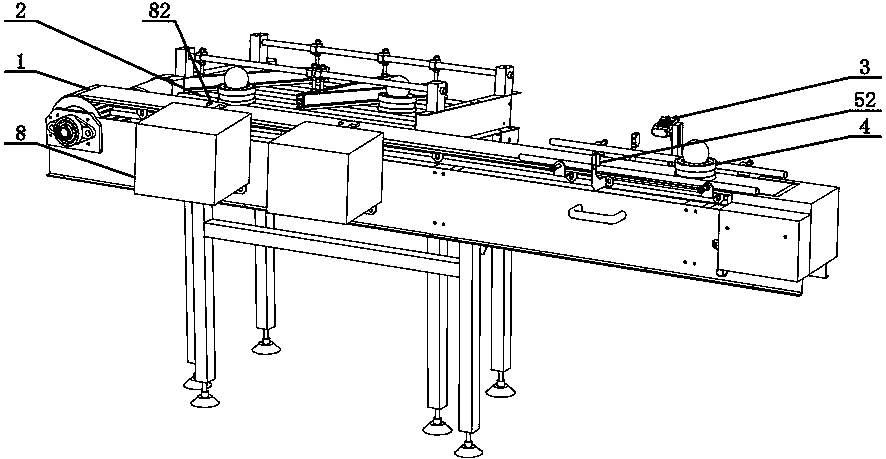

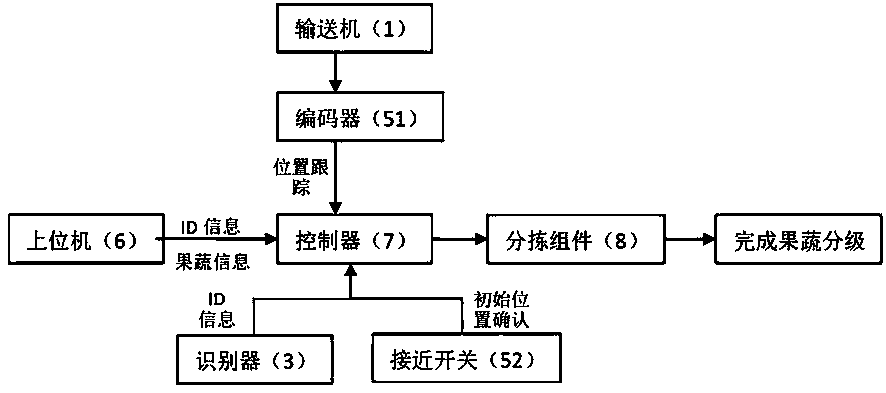

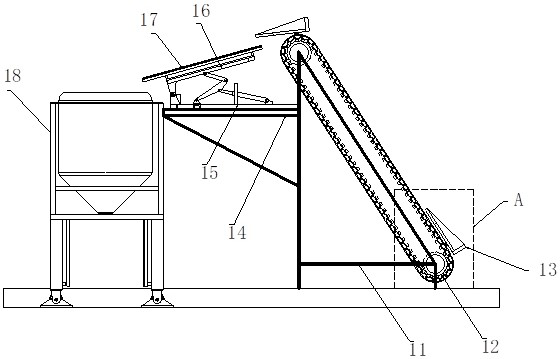

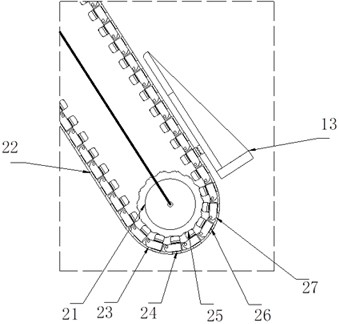

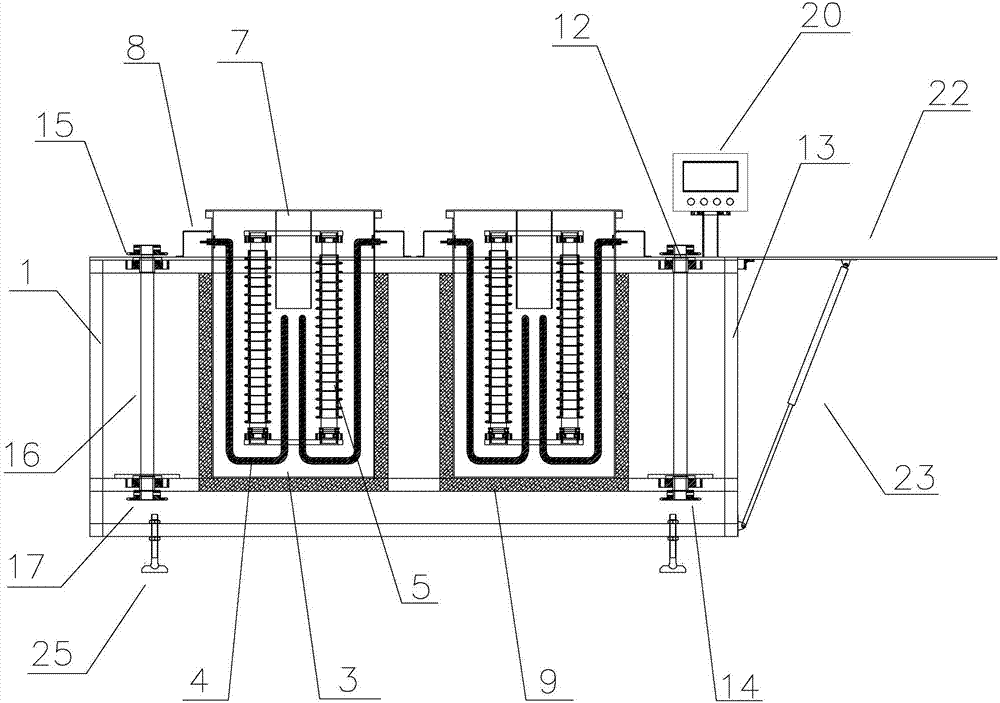

Free conveying type fruit and vegetable sorting device and sorting method thereof

PendingCN109772757AGuaranteed accuracyAffect qualitySortingAgricultural engineeringFruits and vegetables

The invention discloses a free conveying type fruit and vegetable sorting device and a sorting method thereof. The free conveying type fruit and vegetable sorting device comprises a conveyor and a tray. The tray is located on the conveyor. The free conveying type fruit and vegetable sorting device further comprises a recognizer, a distance measuring assembly, a controller, an upper computer, a sorting assembly and a discharging roller way. The recognizer and the distance measuring assembly are arranged on the upstream of the conveyor. The tray is provided with an identification tag. The sorting assembly and the discharging roller way are arranged on the downstream of the conveyor. The sorting method comprises the following steps that firstly, the conveyor conveys the tray; secondly, the upper computer inputs fruit and vegetable ranked data to the controller; thirdly, an initial position of the tray is acquired through a proximity switch, and the recognizer sends the identification information to the controller; fourthly, the controller matches the fruit and vegetable ranked data with the identification information, and the sorting position of the tray is determined; fifthly, an encoder inputs conveying distance into the controller in real time; sixthly, when the tray arrives at a sorting position, the controller controls the sorting assembly (8) to work, and fruit and vegetablesorting is completed. By means of the free conveying type fruit and vegetable sorting device and the sorting method thereof, the fruit and vegetable sorting efficiency is improved, and secondary manual sorting at the later period is avoided.

Owner:浙江德菲洛智能机械制造有限公司

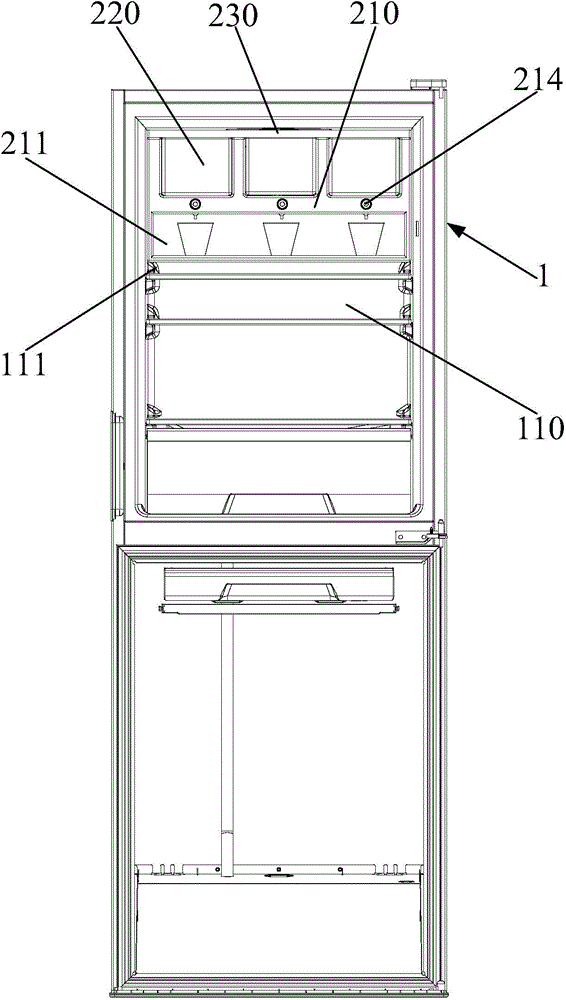

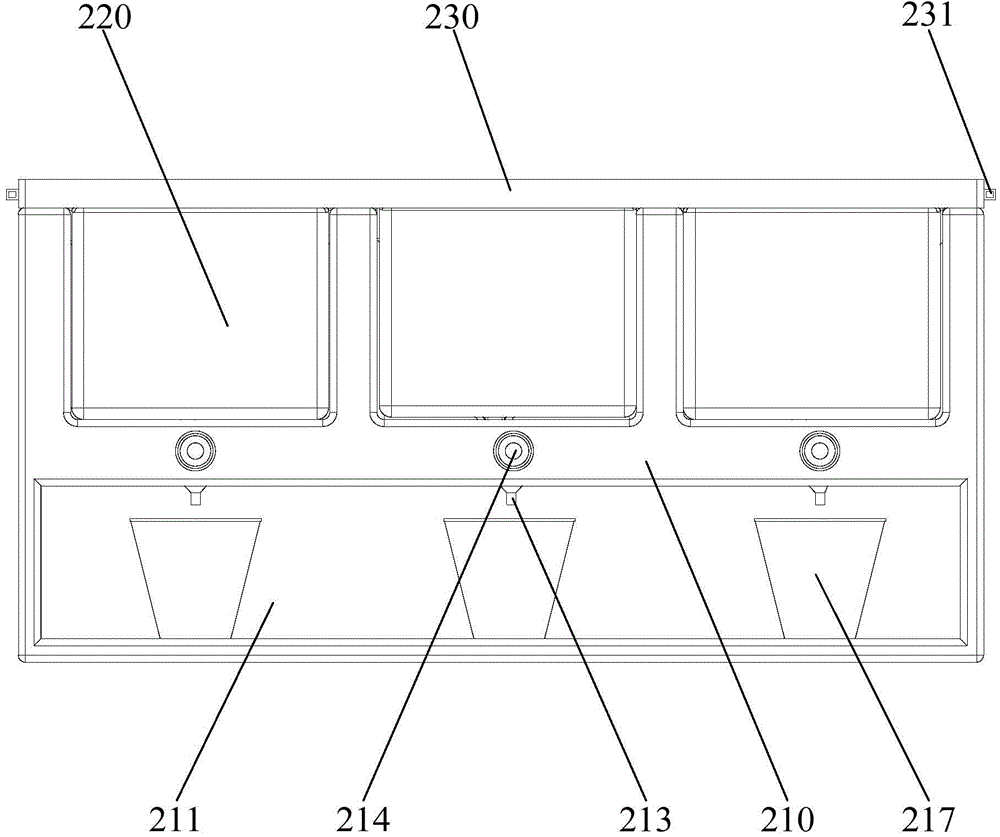

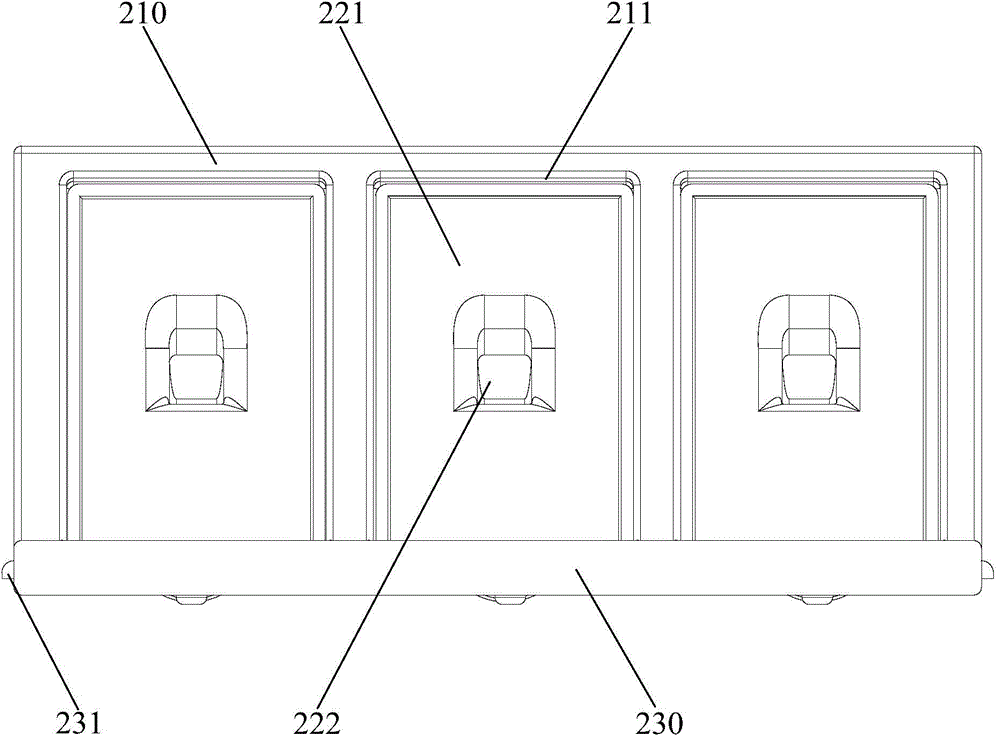

Refrigerator

ActiveCN104792086AImprove practicalityGood value for moneyLighting and heating apparatusDomestic refrigeratorsEngineeringRefrigerated temperature

The invention provides a refrigerator. The refrigerator comprises a refrigerating chamber, an object containing support, a valve and a beverage box, wherein the object containing support is detachably assembled in the refrigerating chamber, an upper object containing groove is formed in the upper portion of the object containing support, and a lower object containing groove is formed in the lower portion of the object containing support; the valve is arranged on the object containing support and is used for being communicated with the upper object containing groove and the lower object containing groove; the beverage box is detachably assembled in the upper object containing groove and is communicated with the valve. According to the above structure characteristics, a user can flexibly use the object containing support of the refrigerator according to seasons; in addition, as the object containing support is matched with the beverage box to serve as a beverage machine in use, the user can mix a beverage by himself; the beverage box is assembled in the upper object containing groove so that not too much space in the refrigerator can be occupied; if necessary, the user can take out the object containing support from the refrigerating chamber of the refrigerator to serve as the beverage machine to be singly used; the refrigerator is simple in structure and flexible and convenient to use, and the practicability and the cost performance of the refrigerator are improved.

Owner:HEFEI MIDEA REFRIGERATOR CO LTD +1

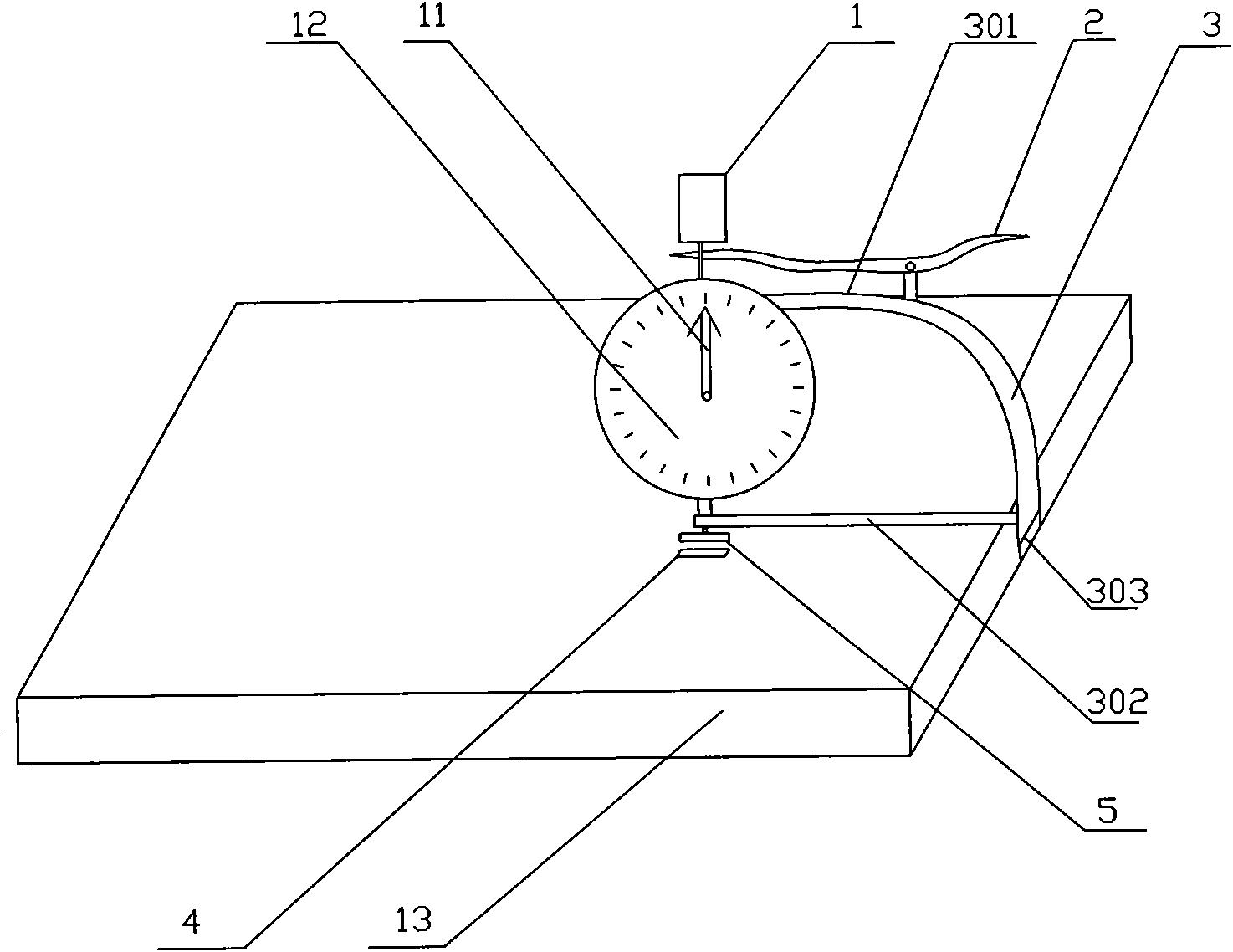

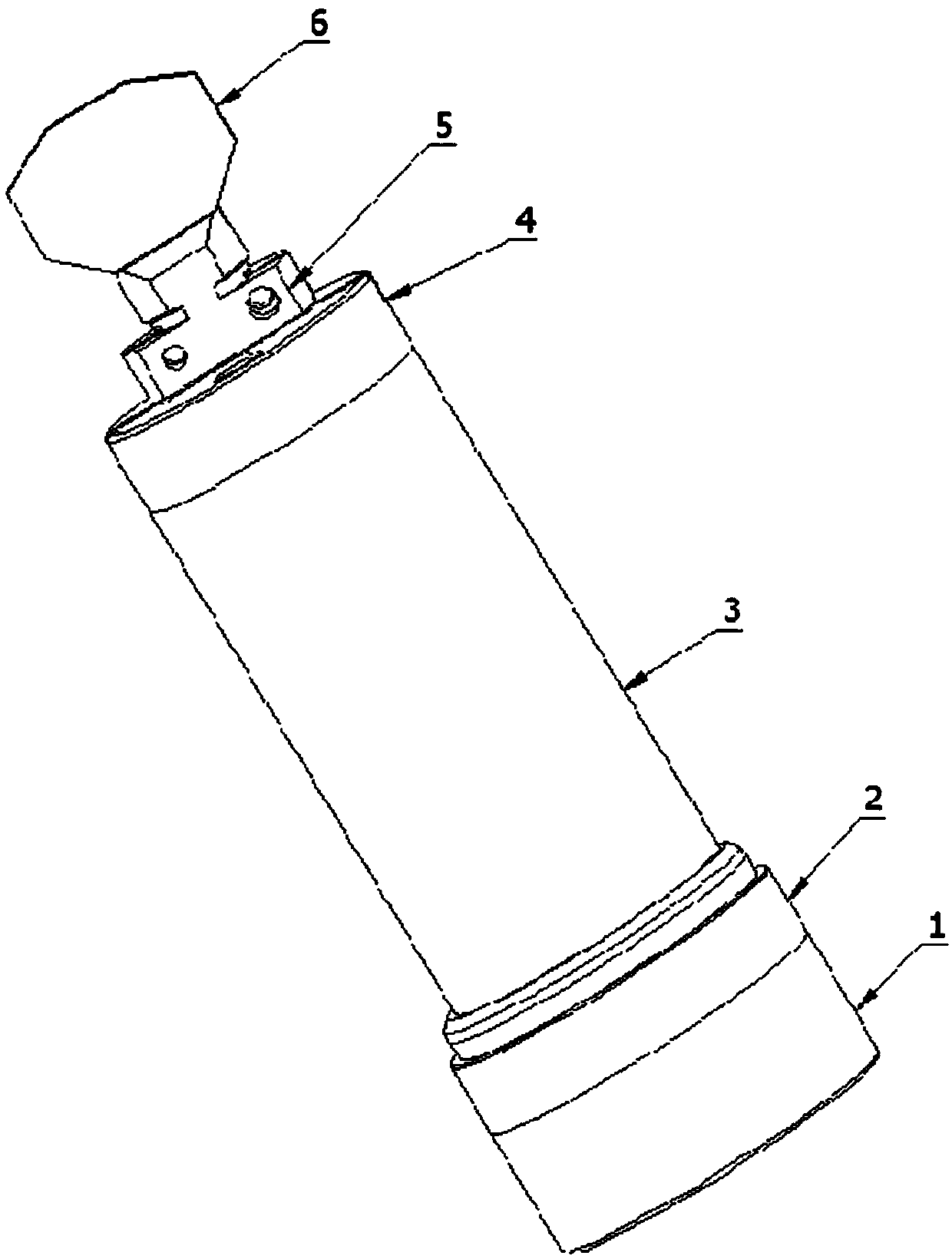

Device for measuring thickness of rubber-coated steel cord

InactiveCN102213579ANo creepAccurate importMechanical thickness measurementsMeasuring instrumentEngineering

The invention relates to a device for measuring thickness of a rubber-coated steel cord. The device comprises a dial gauge thickness measuring instrument consisting of a gauge frame, a counter weight, a measuring rod, a shifting fork, upper and lower measuring heads, a return spring, a gauge body, a pointer and a dial, wherein the gauge body is arranged on a supporting guide part of the gauge frame; the measuring rod passes through the gauge body and the supporting guide part; the top and bottom ends of the measuring rod are connected with the counter weight and the upper measuring head; the lower measuring head is arranged on a base of the gauge frame; two ends of the return spring in the gauge body are connected to the measuring rod and the gauge body; the shifting fork hinged on a hinge part of the gauge frame is connected to the measuring rod; and the measuring rod changes linear displacement into angular displacement of the pointer through a transmission piece so as to indicate the thickness value on the dial. The device is characterized by also comprising a measuring platform, wherein the base of the gauge frame is embedded in the platform; and an upper surface of the lower measuring head and an upper surface of the measuring platform are positioned on the same plane. The samples to be tested can be flatly put on the measuring platform and are accurately introduced between the upper and lower measuring heads, sample rubber cannot generate creep deformation, and the device is accurate in measurement and easy and convenient to operate.

Owner:CHENGSHAN GROUP

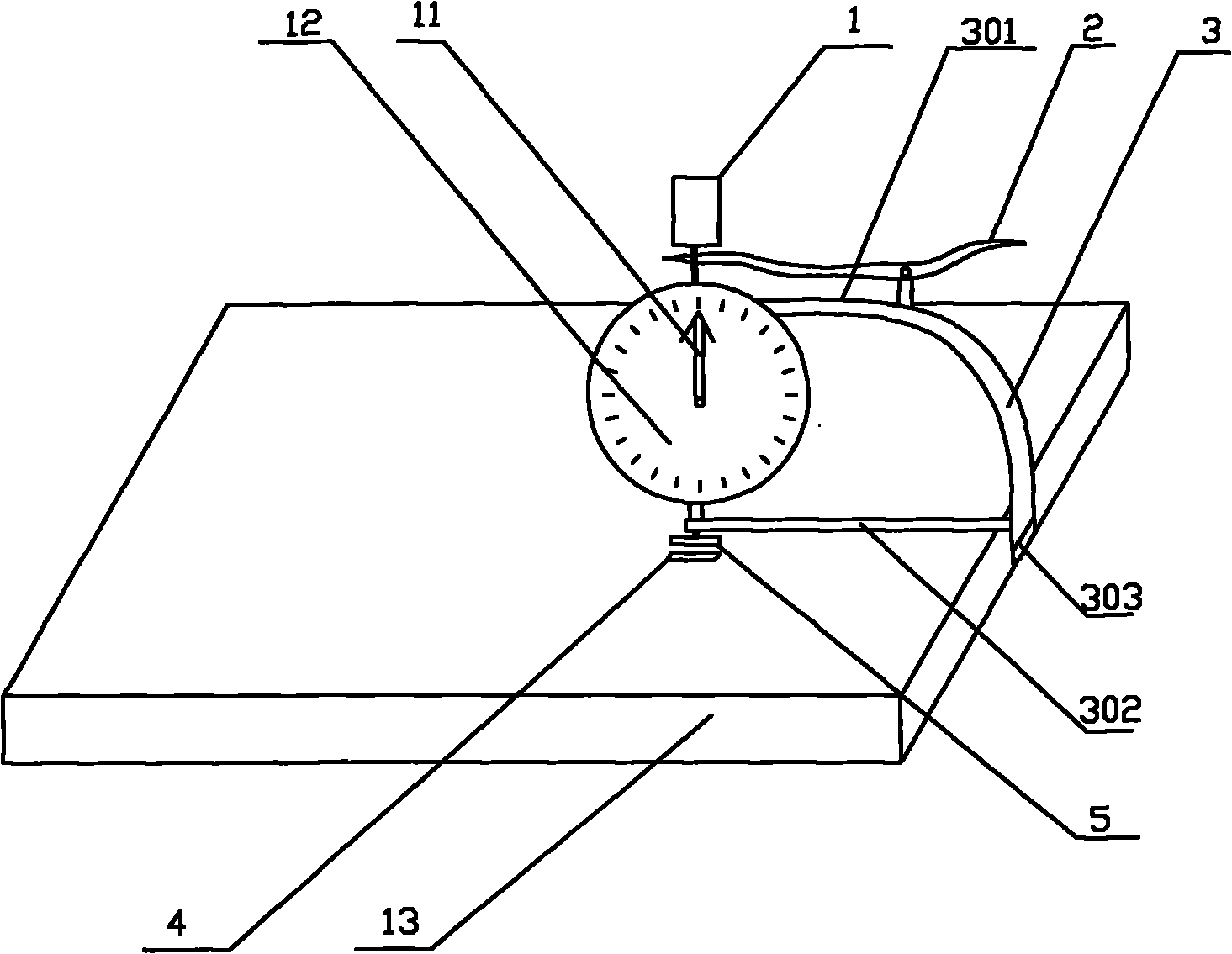

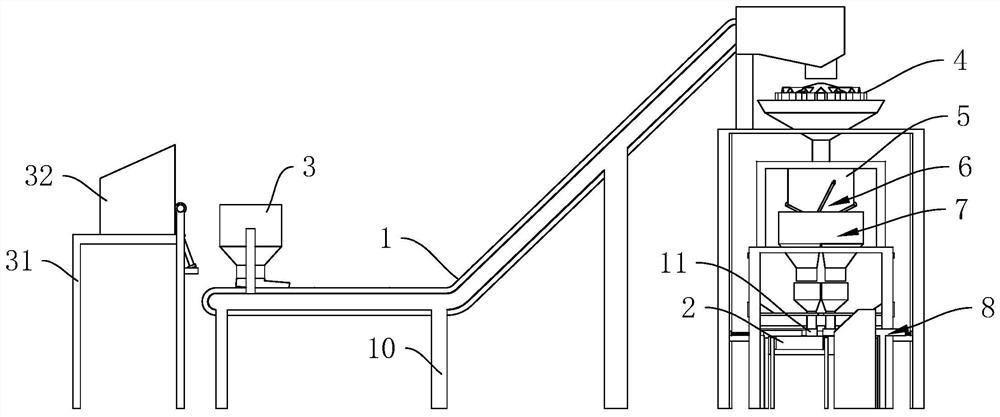

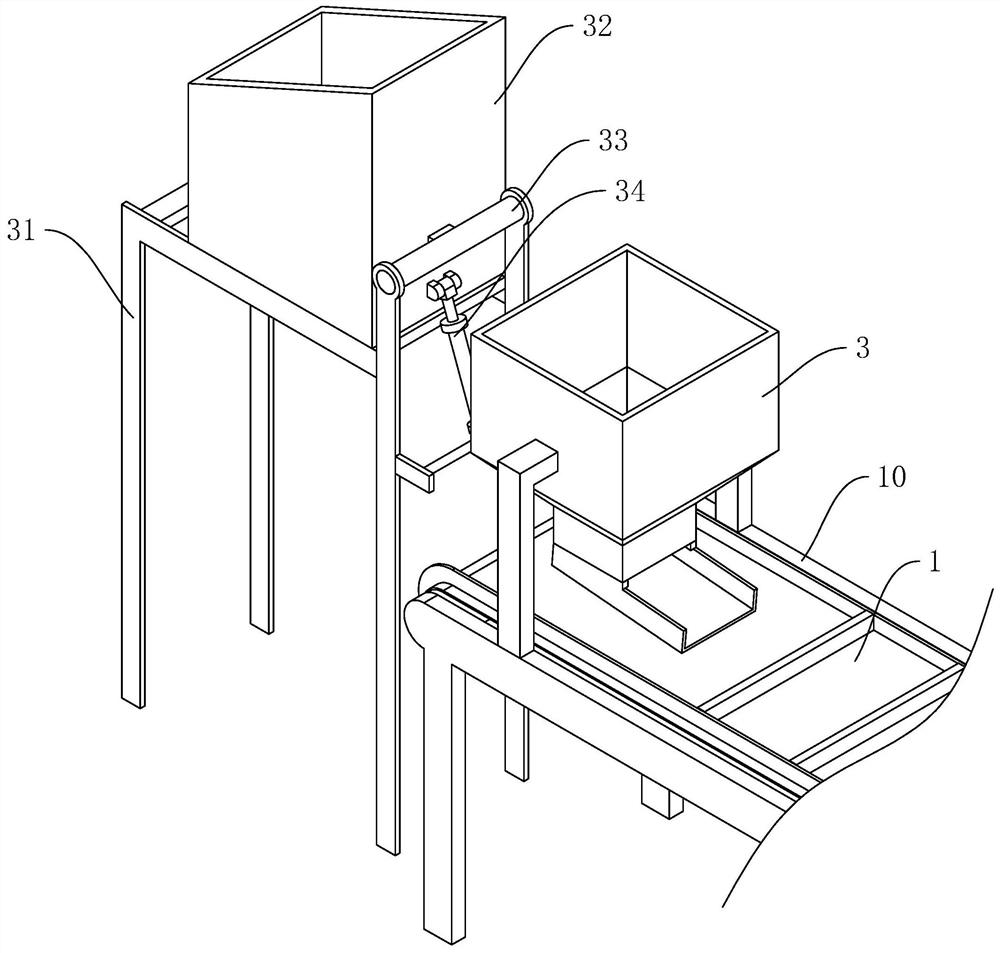

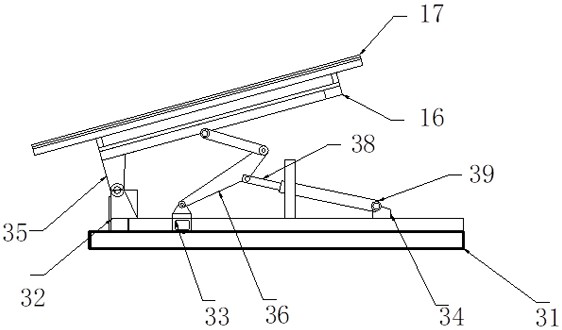

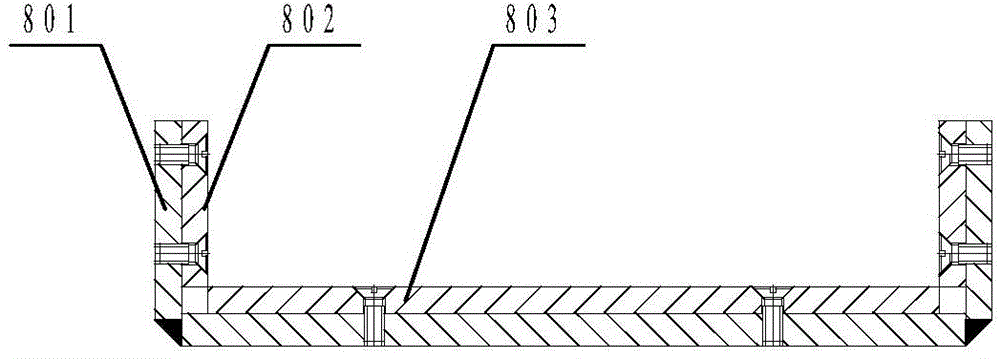

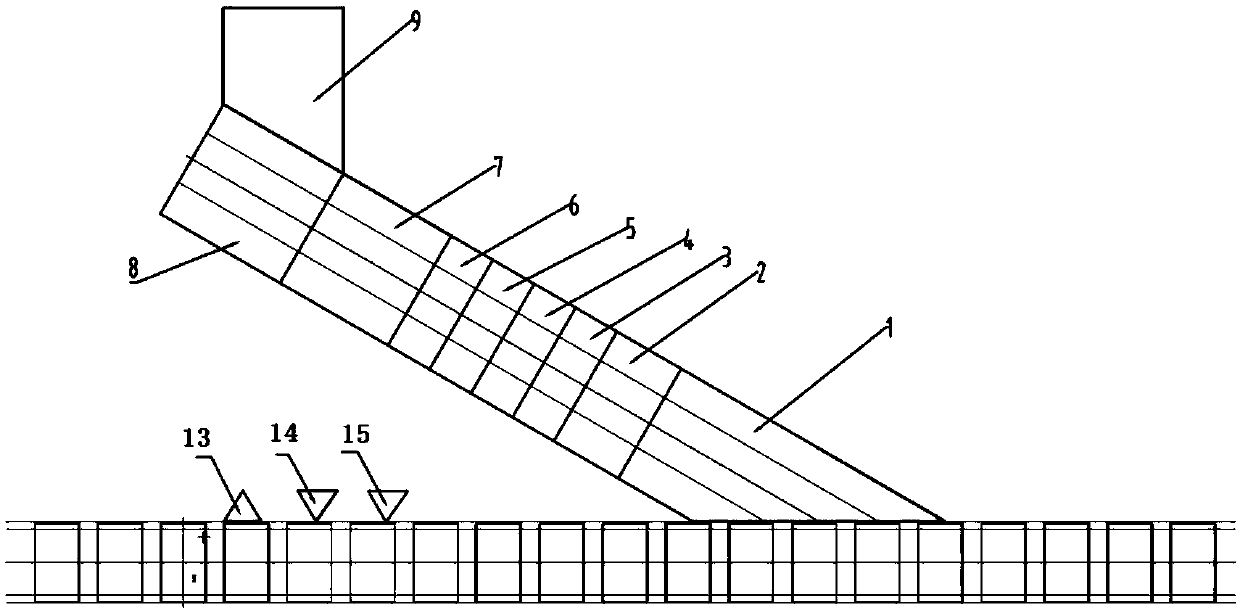

Ash material lifting device for cement preparation

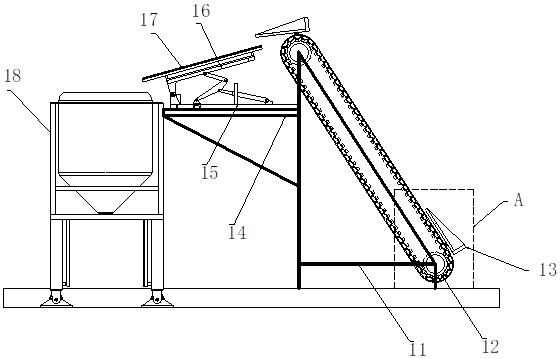

ActiveCN113526017APersistent loadingTurnaround docking is effectiveConveyorsLoading/unloadingStructural engineeringCement Material

The invention relates to the technical field of cement preparation, in particular to an ash material lifting device for cement preparation. The ash material lifting device comprises a lifting machine frame, the lifting machine frame is provided with a lifting conveying assembly, a material bearing part, a turnover support, a turnover assembly and a material conveying bearing part, and the lifting conveying assembly is obliquely erected on the lifting machine frame; the material bearing part is used for bearing ash materials; the material bearing part is installed on the lifting conveying assembly and reciprocates from the horizontal low position to the horizontal high position along with the lifting conveying assembly. the turnover support is erected on the top of the lifting machine frame; the turnover assembly is mounted on the turnover support through the adjusting assembly; and the material conveying bearing part is movably mounted on the turnover assembly and used for being in butt joint with the material connecting bearing part and guiding the materials into a cement preparation kettle. The lifting conveying assembly is adopted as a medium tool for material lifting, and a full-automatic material turnover and butt joint device is arranged, so that material lifting and butt joint with cement preparation kettles of different models are effectively carried out.

Owner:江苏新喜地新材料科技有限公司

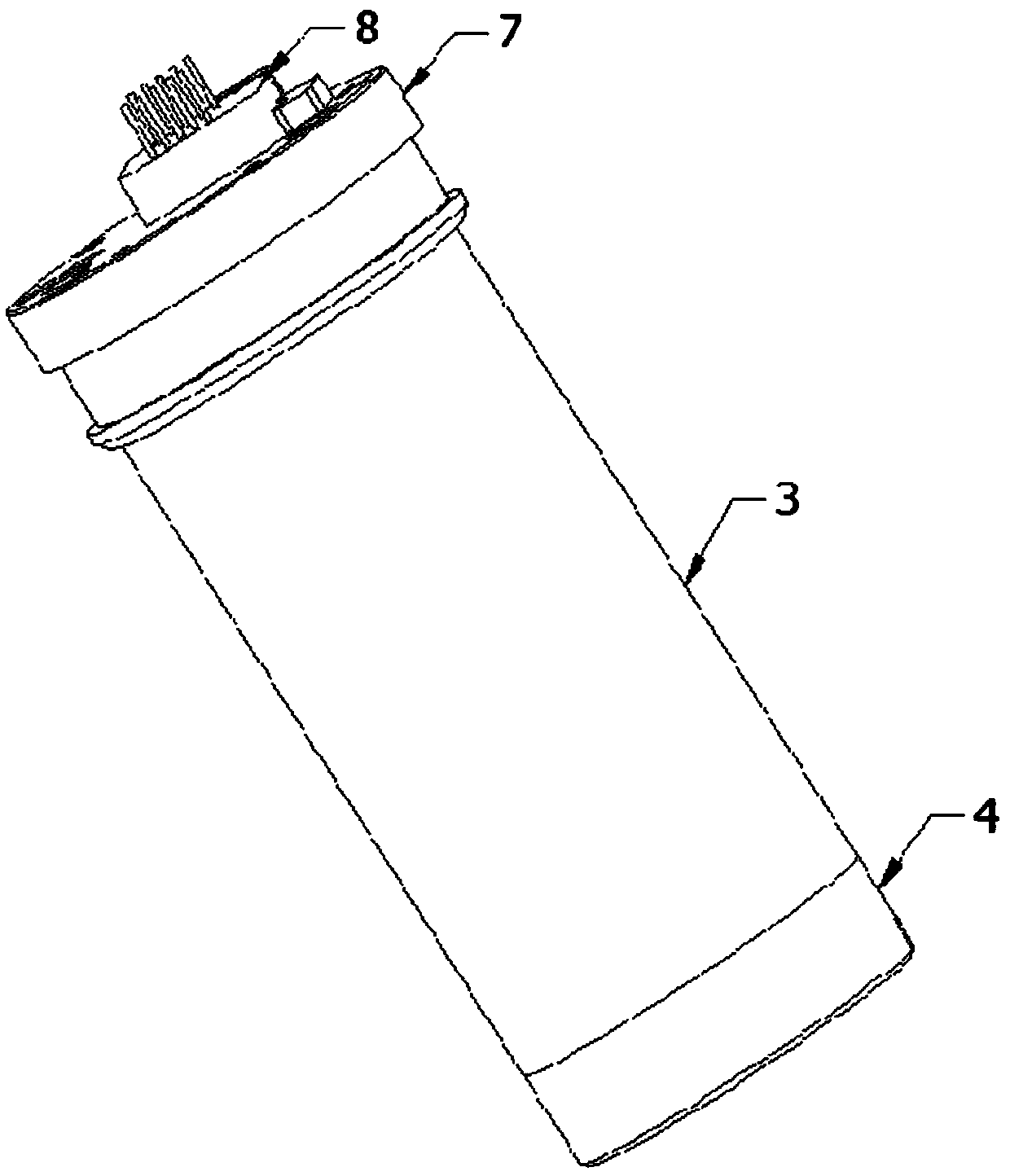

High-speed spectroscopic application galvanometer motor

PendingCN109560637ACompact structureQuick responseWindingsMagnetic circuit rotating partsGratingGalvanometer

The invention discloses a high-speed spectroscopic application galvanometer motor. The high-speed spectroscopic application galvanometer motor comprises a stator, a rotor relatively rotated with the stator and a digital grating feedback encoder located at one end of the rotor, the stator comprises a coil sleeve and a coil located in the coil sleeve, the coil sleeve is formed by whole turning of permeability magnetic materials, and the coil is glued and fixed with the coil sleeve by pouring sealant; the rotor comprises a cylindrical permanent magnet rotationally installed in the coil, and two ends of the cylindrical permanent magnet are respectively fixedly provided with first stainless and second stainless. The spectroscope is directly glued on a lens clamp through glue, the whole structure is compact, the rigidity is high, the response speed is fast, and a digital optical grating feedback encoder capable of real-time and rapid synchronous feedback of the motor angle and position is employed to greatly improve the position precision and repeat location precision of the galvanometer motor.

Owner:深圳市欧亚激光智能科技有限公司

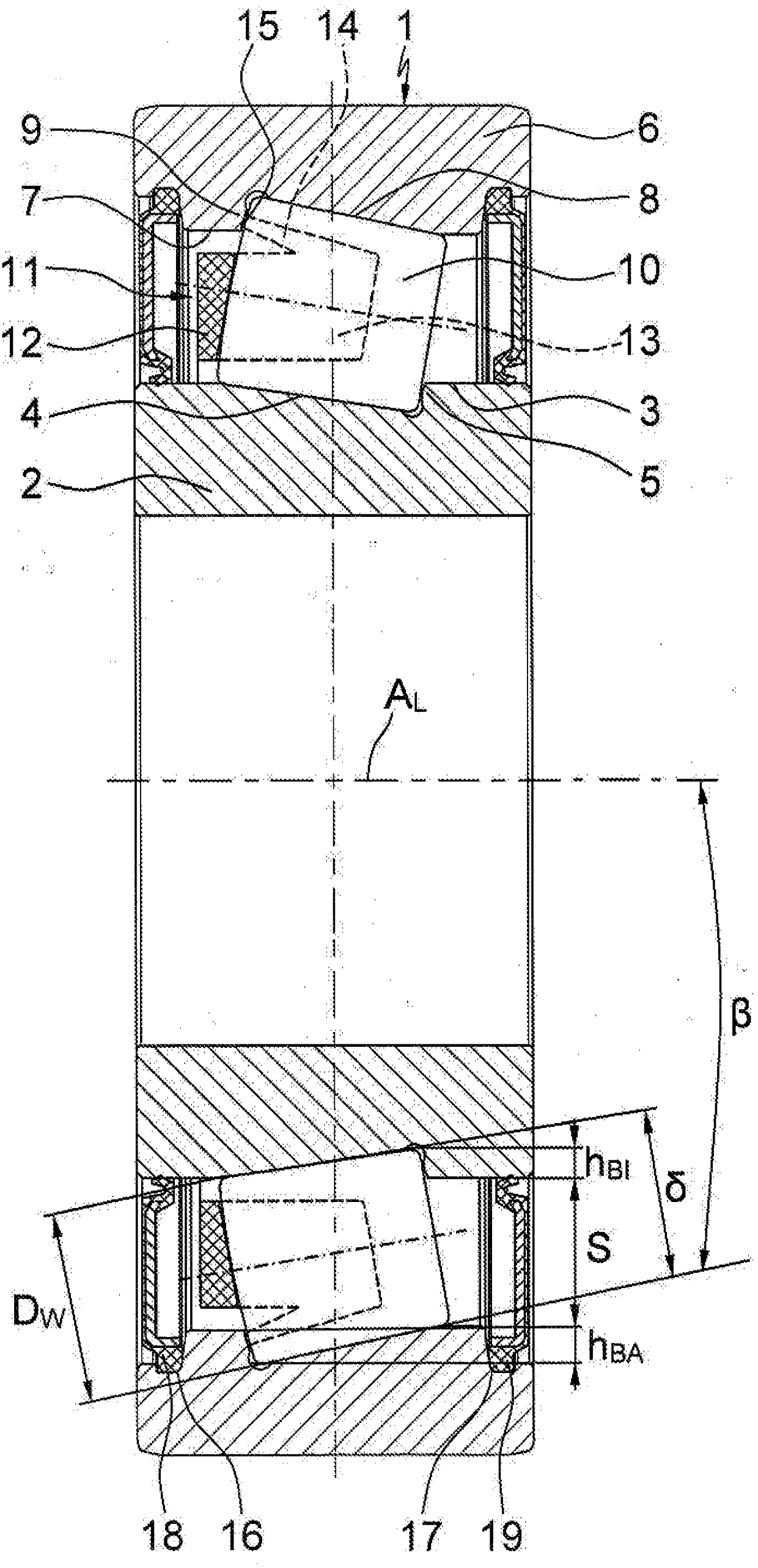

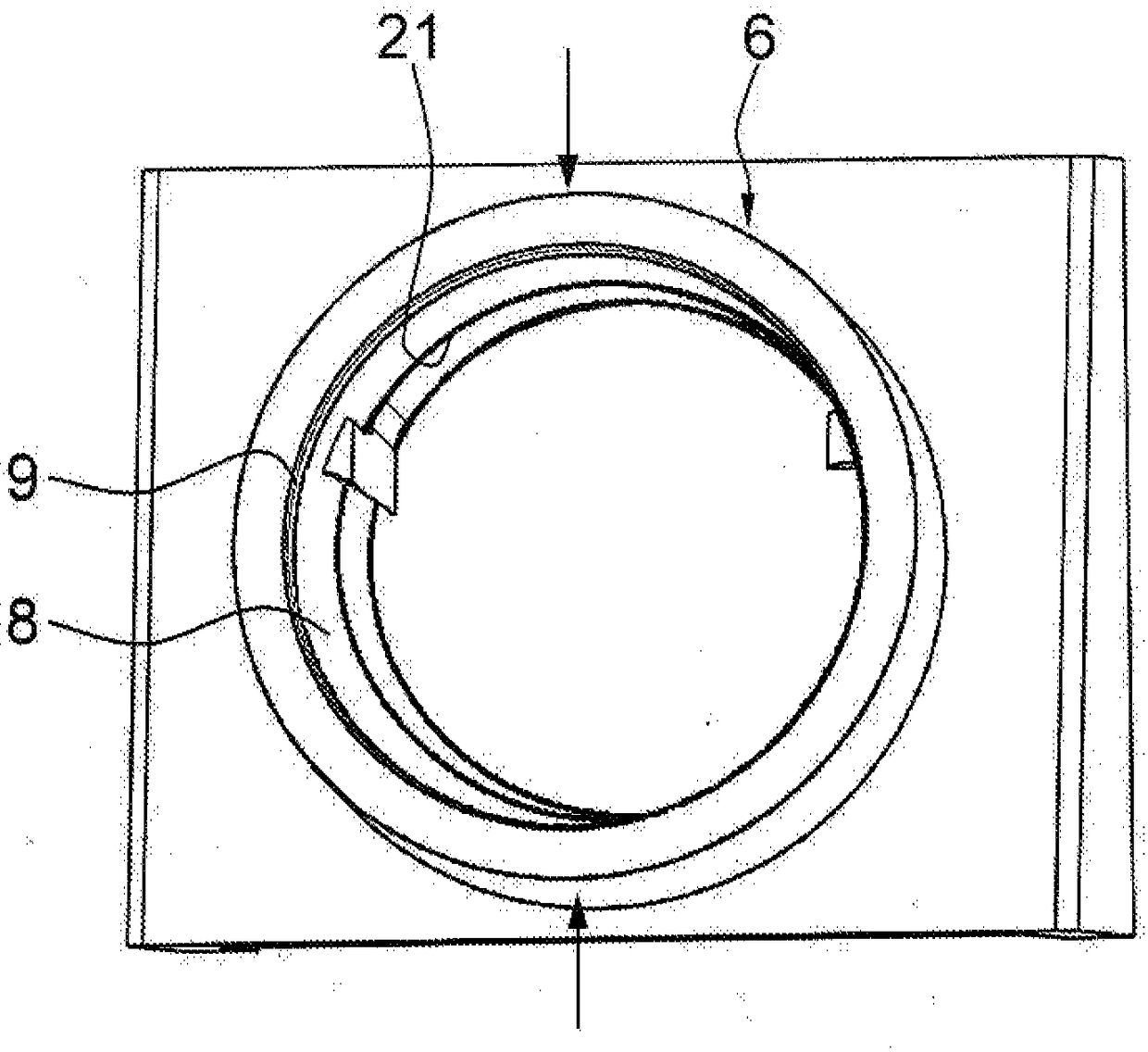

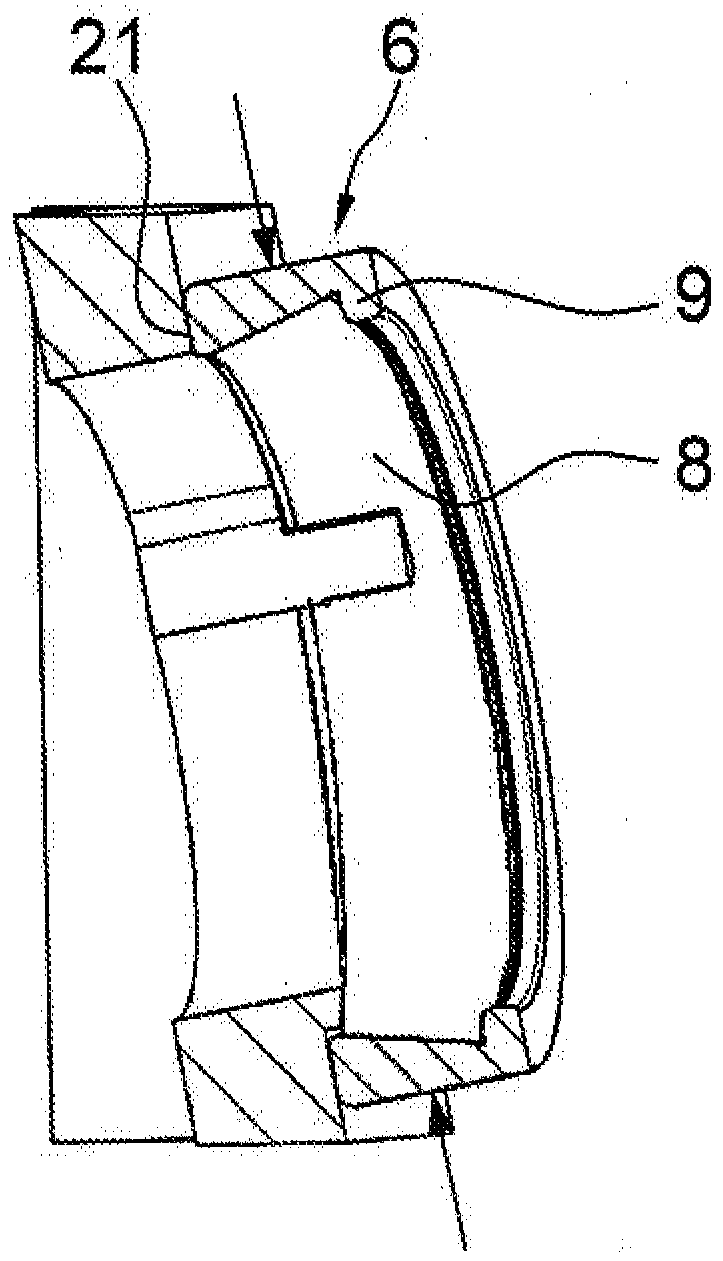

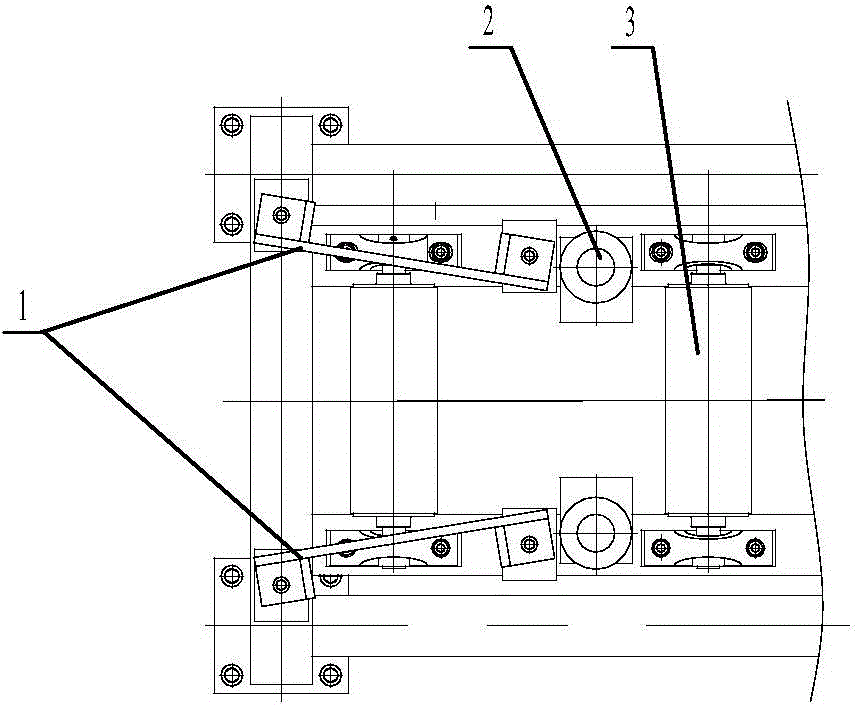

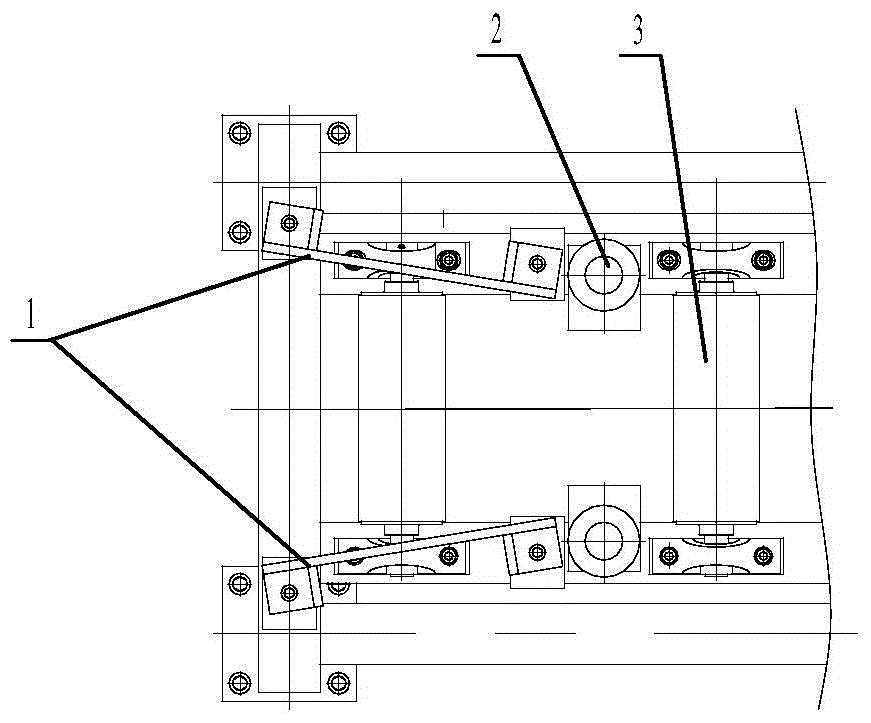

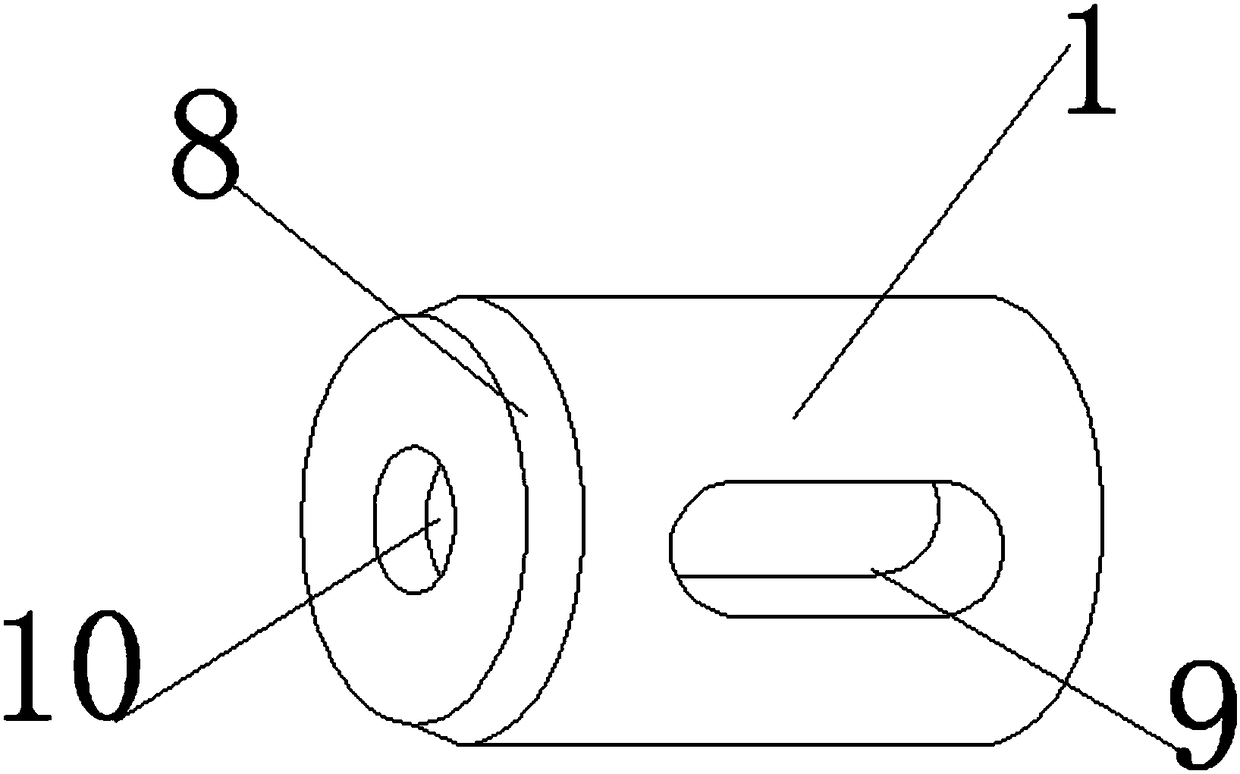

Method and device for fitting angular contact roller bearing

ActiveCN109477523AAccurate importImprove carrying capacityRoller bearingsBearing componentsBall bearingPhysics

The invention relates to a method for fitting an angular contact roller bearing (1), comprising an inner bearing ring (2) having an inner track (4) arranged on the outer peripheral surface (3) of theinner bearing ring and inclined with respect to the axis of rotation of the bearing (AL), and a rim (5) delimiting said track at the smallest diameter thereof, an outer bearing ring (6) having an outer track (8) arranged on the inner peripheral surface (7) of the outer bearing ring and inclined with respect to the axis of rotation of the bearing, and a rim (9) delimiting said track at the greatestdiameter thereof, and also comprising a plurality of roller bearing elements (10) which are arranged between the bearing rings and roll on the track and are held at uniform distances from one anotherin the circumferential direction by a bearing cage (11). The outer peripheral surface of the inner bearing ring and the inner peripheral surface of the outer bearing ring are in each case cylindricaland extend outside the tracks at least in some sections coaxially with respect to the axis of rotation of the bearing, and the tracks of both bearing rings are in each case integrated conically intothe cylindrical peripheral surfaces, such that the rims which are produced in this way and in each case delimit the tracks on one side are in each case formed in one piece with the bearing rings. According to the invention, the fitting of the angular contact roller bearing takes place according to an eccentric pivot fitting method borrowed from the eccentric fitting method known for deep groove ball bearings. The invention further relates to a device for performing the fitting method.

Owner:SCHAEFFLER TECH AG & CO KG

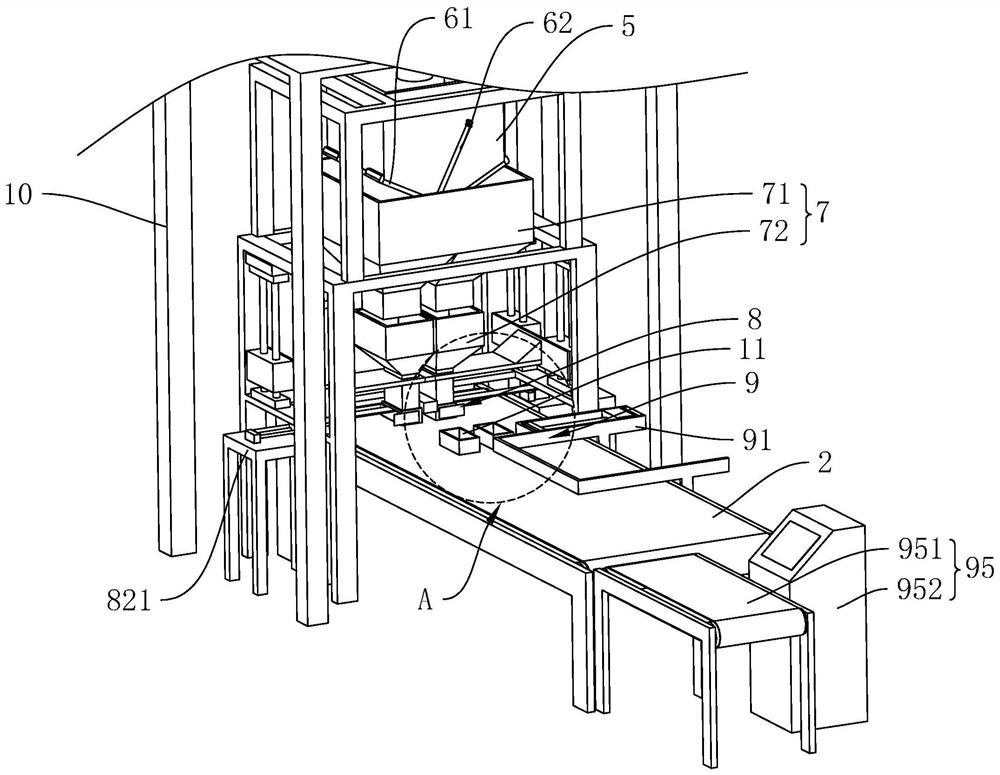

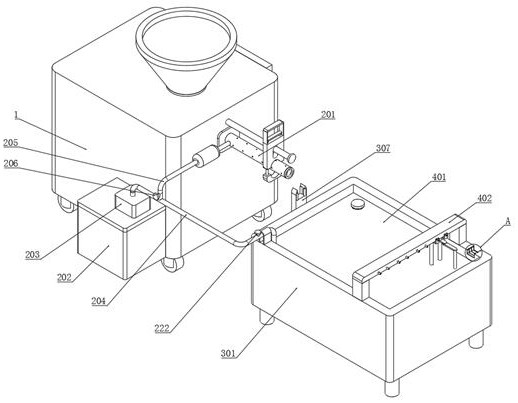

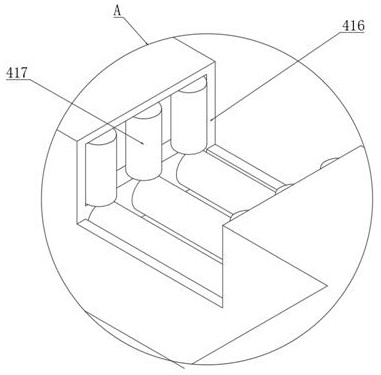

Automatic standard part distributing system

ActiveCN112758371AAutomate the packaging processImprove packaging efficiencySolid materialProcess engineeringTransfer line

The invention relates to an automatic standard part distributing system. The system comprises a rack, a feeding conveying line and a combined scale are arranged on the rack, the combined scale is located at the discharging end of the feeding conveying line, and the combined scale is used for quantitatively distributing standard parts. The system is characterized in that the feeding conveying line is arranged to a rating climbing conveying line, a material collecting hopper used for temporarily storing materials is arranged at the feeding end of the rating climbing conveying line, a material guiding hopper is arranged at the position, located at the discharging end of the combined scale, of the rack, a material distributing device used for distributing materials is arranged at the discharging end of the bottom of the material guiding hopper, and a material receiving device is arranged at the position, located at the discharging end of the material distributing device, of the rack. The material receiving device is used for conveying the distributed standard parts into packaging boxes, a discharging conveying line used for conveying the packaging boxes is arranged at the discharging end of the material receiving device, and packaging box positioning devices are arranged at the two sides of the discharging conveying line. According to the scheme, the standard parts are quantitatively packaged in an automatic conveying, automatic weighing and automatic material distributing manner, and the packaging efficiency of the standard parts is effectively improved.

Owner:佛山市南海区伟业高强度标准件有限公司

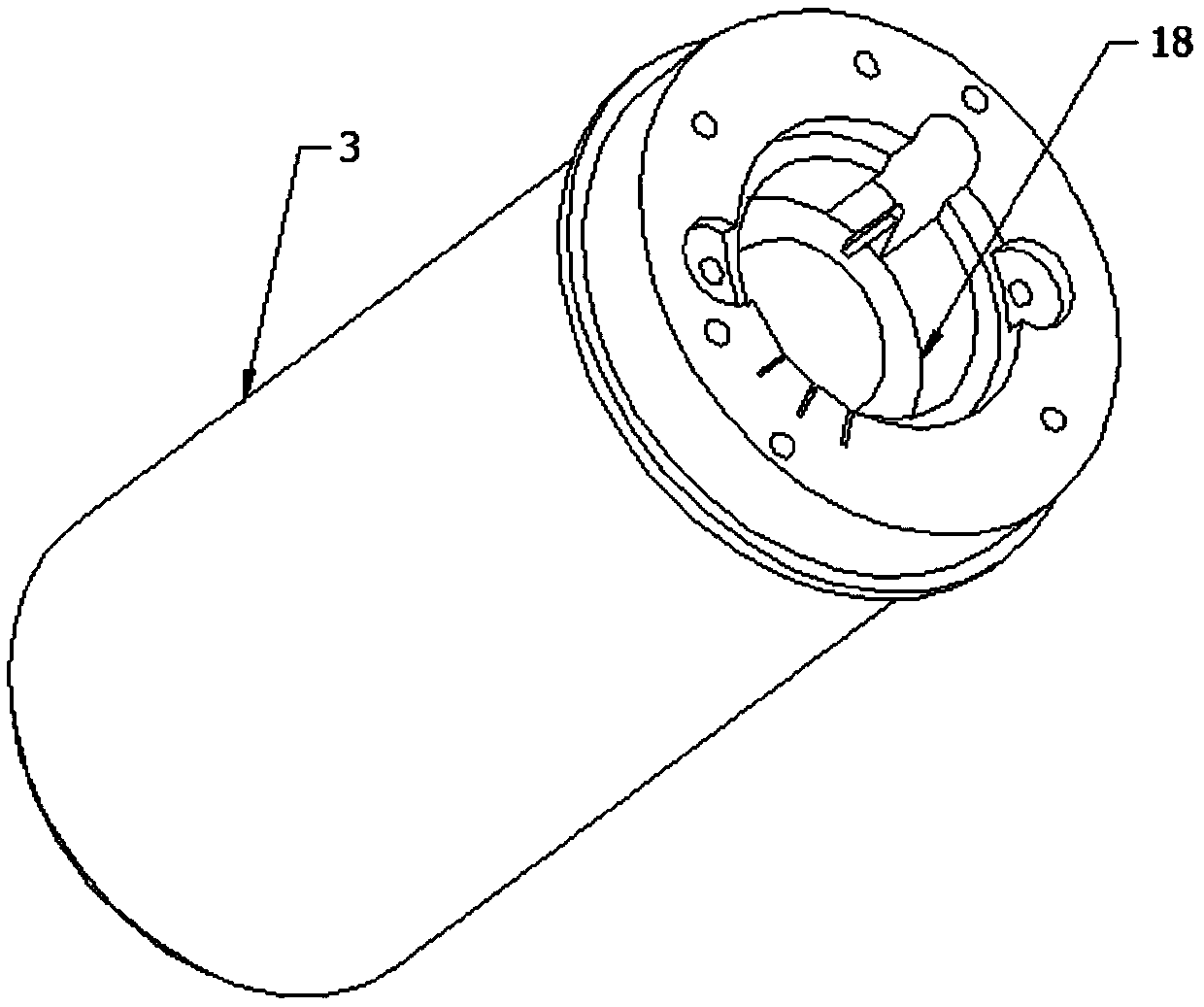

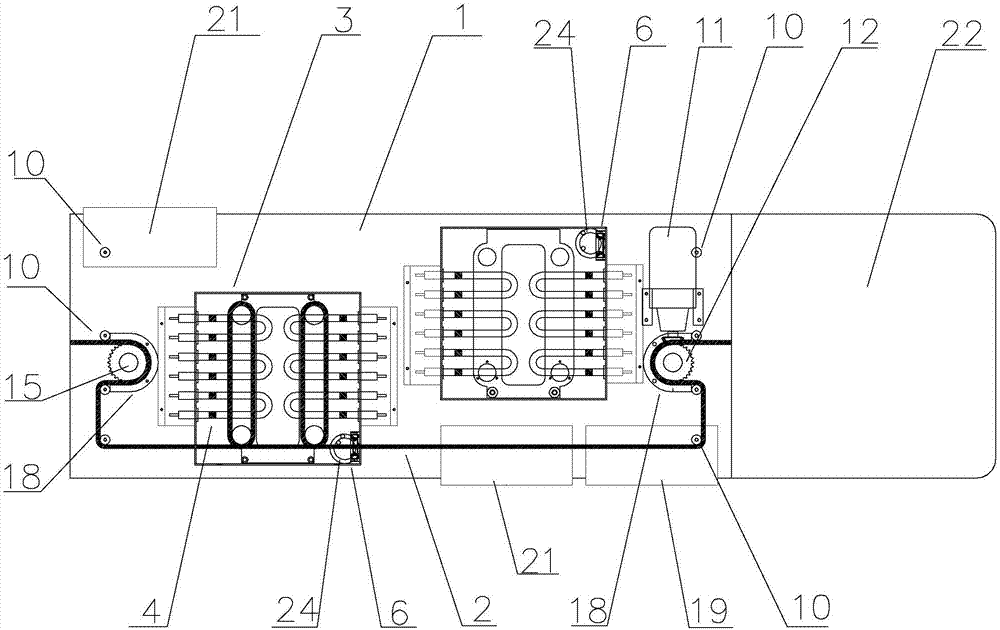

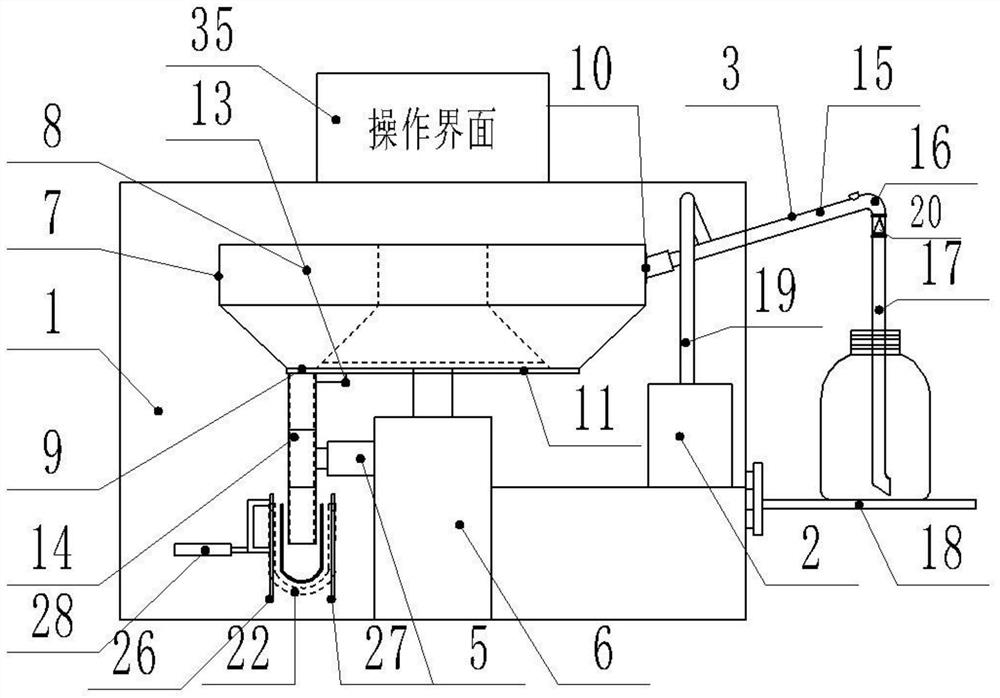

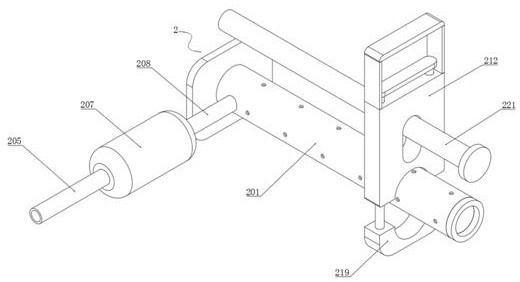

Chain automatic running-in oiling machine

The invention relates to the field of chain production devices and discloses a chain automatic running-in oiling machine. The chain automatic running-in oiling machine comprises a rack (1), a chain transmission mechanism, an oiling mechanism and a control mechanism. The chain transmission mechanism is arranged on the top surface of the rack to guiding a chain (2) into and out of the oiling mechanism. The control mechanism is used for controlling operation of the chain transmission mechanism and the oiling mechanism. The oiling mechanism comprises an oil tank (3), electric heat couplings (4), oil tank rollers (5) and an air knife. The oil tank is arranged in the rack and is internally provided with the multiple vertical oil tank rollers used for transporting the chain and electric heat couplings. The air knife is arranged at a chain outlet in the oil tank, and after being guided out of the oil tank, the chain penetrates through the air knife. According to the chain automatic running-in oiling machine, automatic oiling of the chain can be achieved, the working efficiency is high, the oiling and deoiling effects are good, energy consumption is low, and the cost can be reduced.

Owner:浙江东亿自动化科技有限公司

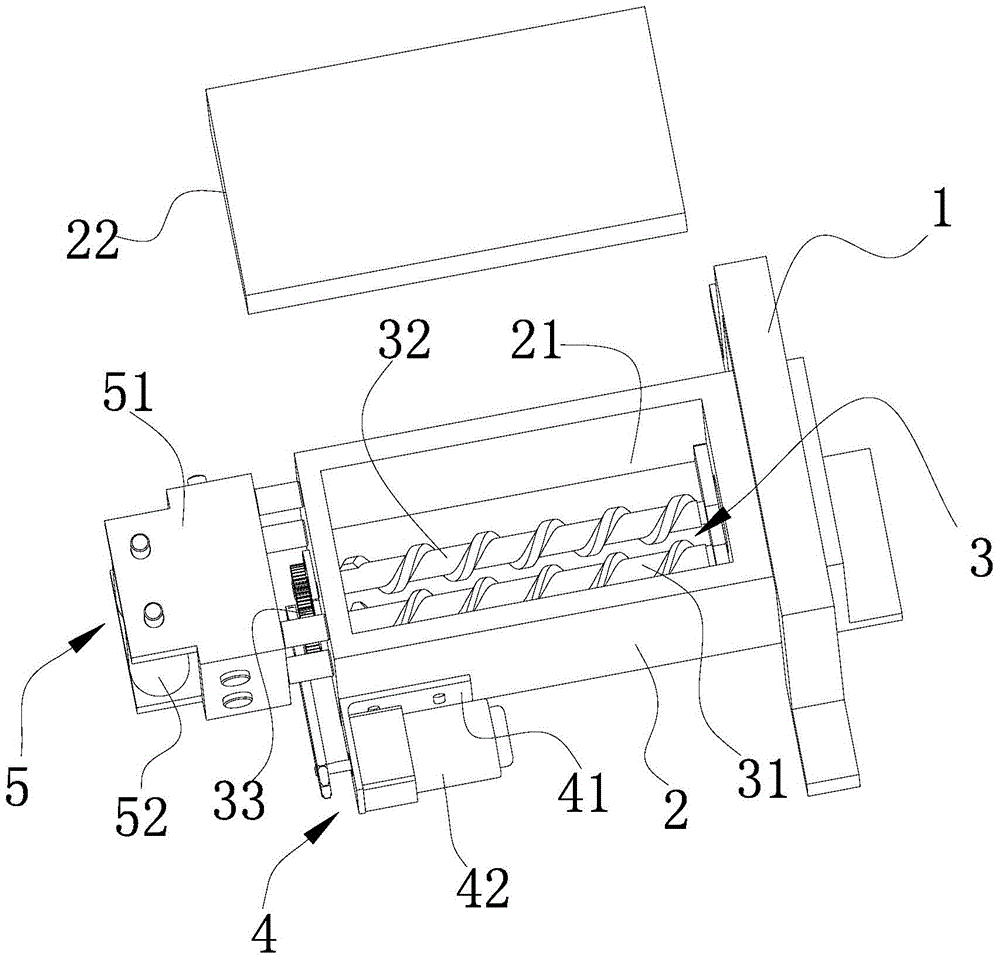

Moisturizing device of wire drawing machine

InactiveCN103831311AUniform coatingQuality improvementDrawing diesUltimate tensile strengthLubrication

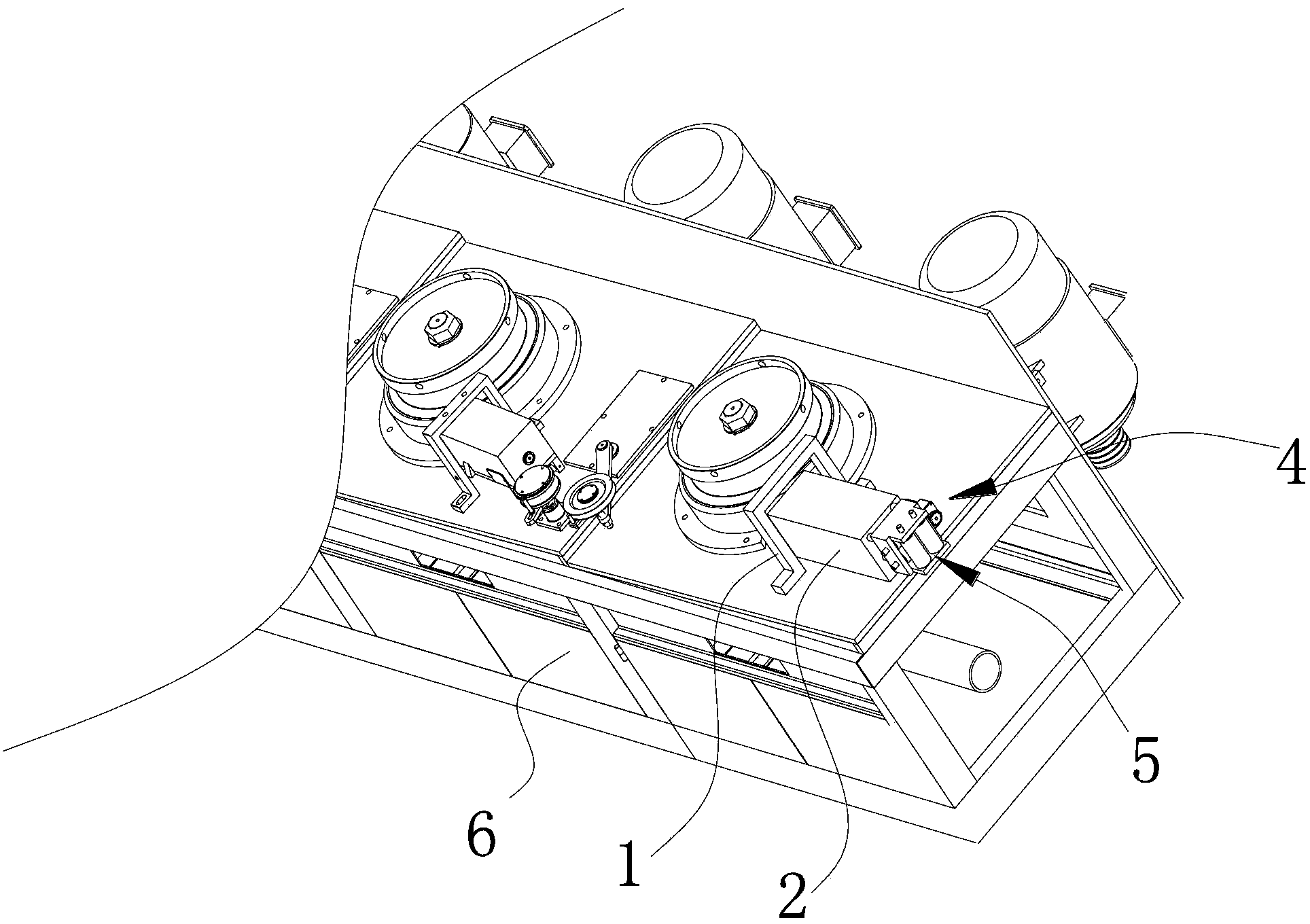

The invention discloses a moisturizing device of a wire drawing machine. The moisturizing device comprises a wire passing box body, an opposite mixing mechanism and a drive device, wherein the opposite mixing mechanism comprises a drive spiral mixing shaft and a driven spiral mixing shaft rotating oppositely to the drive spiral mixing shaft, the driven spiral mixing shaft and the driven spiral stirring shaft are symmetrically arranged at two sides of a position through which a steel wire passes, and are parallel with the steel wire, a transmission gear is arranged at one end of the drive spiral mixing shaft and is connected with the driven spiral mixing shaft. The moisturizing device is provided with the opposite mixing mechanism which is capable of fully turning and mixing lubrication powder and enabling the lubrication powder to generate an extruding force to the steel wire, and thus the lubrication powder is uniformly coated on the steel wire, and the lubrication effect is enhanced, and thus the non-uniform deformation and drawing heat during drawing are reduced, the quality and the performance of the steel wire are effectively improved, the service life of the wire passing box body is prolonged, and the production cost is lowered; and meanwhile, a drive device is used for driving the opposite mixing mechanism to work, thus the moisturizing device is convenient to operate so that the labor intensity of a worker is reduced, and the manufacturing cost is low so that the requirement of a continuous and automatic production line can be completely met.

Owner:黄壮明

A kind of ash lifting device for cement preparation

ActiveCN113526017BPersistent loadingTurnaround docking is effectiveConveyorsLoading/unloadingClassical mechanicsEngineering

The invention relates to the technical field of cement preparation, in particular to a lifting device for ash materials used in cement preparation, which includes a lifting frame on which: a lifting transmission component is erected on the lifting frame in an inclined manner; parts, used to carry ash; the material carrier is installed on the lifting transmission assembly and reciprocates with the lifting transmission assembly from a low level to a high level; the turnover bracket is erected on the top of the lifting frame; the turnover component is adjusted The component is installed on the turnover bracket; the material conveying bearing part is installed on the turnover component in a movable manner, and is used for docking the material with the connecting material bearing part and introducing the material into the cement preparation kettle. This application uses the lifting transmission component as the medium tool for material lifting, and is equipped with a fully automatic material turnover docking device, which can effectively carry out material lifting docking with different types of cement preparation kettles.

Owner:江苏新喜地新材料科技有限公司

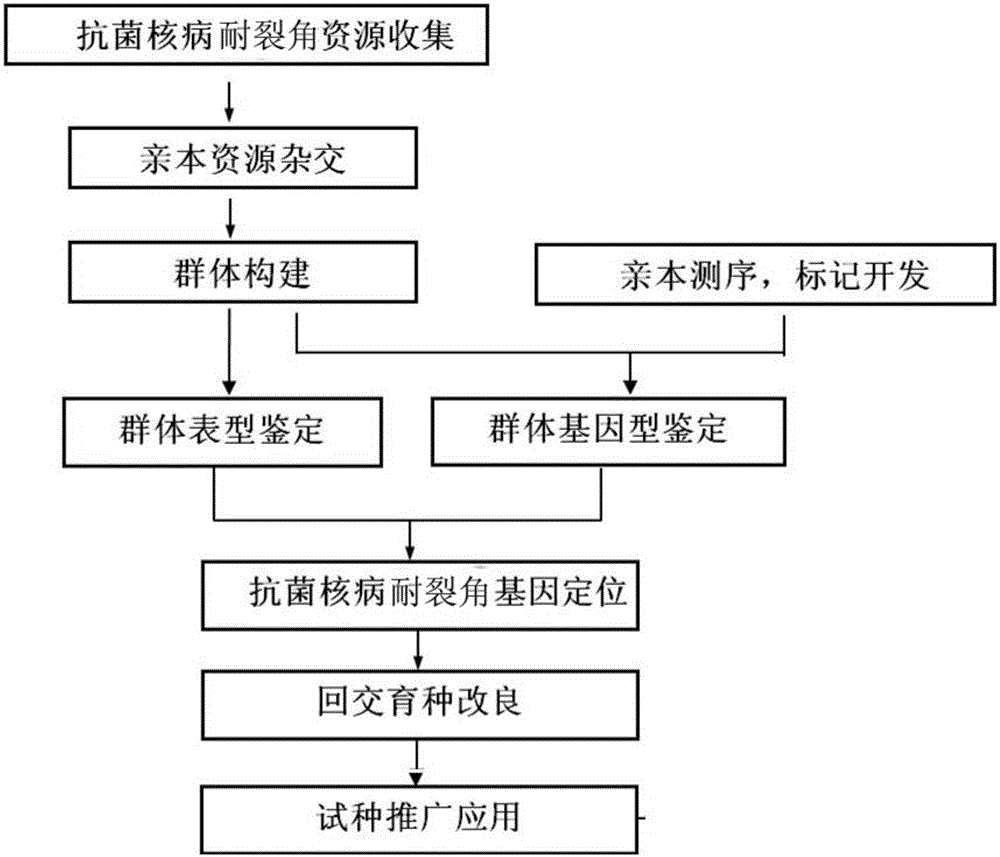

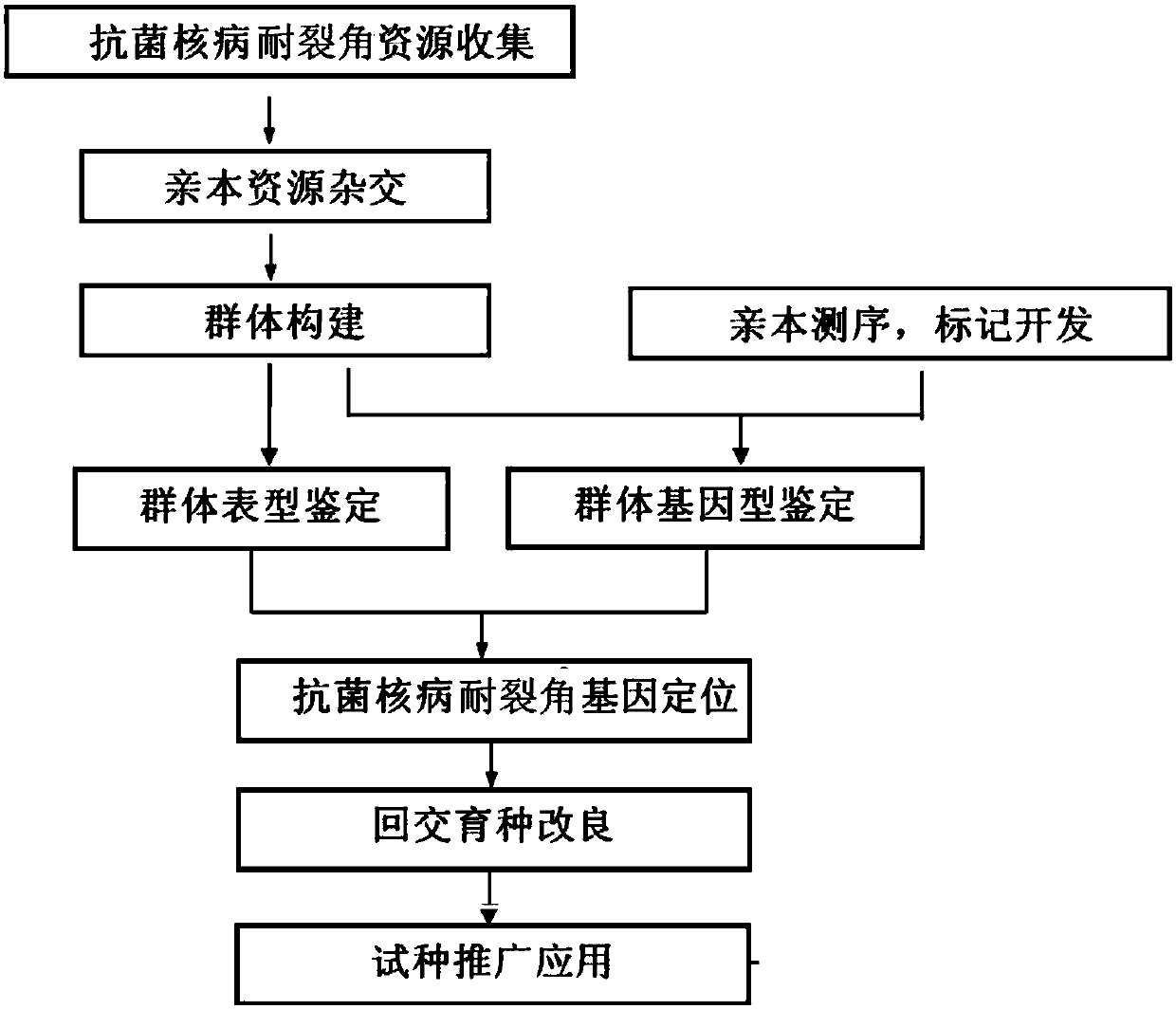

Rapeseed breeding method adopting gene mapping technology

ActiveCN105815209AAccurate importBreed fastPlant genotype modificationGene mappingAgricultural science

The invention provides a rapeseed breeding method adopting a gene mapping technology.A representative hybrid female parent with outstanding comprehensive characters is selected as a parent 1, a sclerotinia sclerotiorum resisting resource material is selected as a parent 2, a pod split resisting resource material is selected as a parent 3, the parent 1 is crossbred with the parent 2 and the parent 3 to obtain F1 generations, and the F1 generations are subjected to selfing to obtain two F2 colonies; a character survey, gene mapping and a back cross breeding improvement are carried out to obtain a female parent with two improved characters, namely sclerotinia sclerotiorum resistance and pod split resistance.The method breaks through the bottlenecks of a long cycle, poor predictability, low selection efficiency and the like of traditional seed breeding, and is faster, controllable and efficient.

Owner:SICHUAN FANGPAI SEED CO LTD

Transformer tap changer tool for taking oil sample

PendingCN109637859AReduce wasteAccurate importVariable inductancesElectric switchesTap changerBall valve

The invention belongs to the technical field of transformer equipment and more particularly to a transformer tap changer tool for taking an oil sample. The transformer tap changer tool comprises a bottom plate, a connection structure connected to an oil drain pipe, a drainage structure and a guiding structure. The connection structure and the drainage structure are disposed on the bottom plate. The guiding structure is connected to the drainage structure. The transformer tap changer tool is simple in structure and convenient to operate. The oil sample can be taken by removing the dustproof plate of the original ball valve of the oil drain pipe and then installing the transformer tap changer tool. The transformer tap changer tool has a good sealing property and can prevent the oil sample from contact with outside air to improve sample extraction accuracy and sampling efficiency.

Owner:GUANGDONG POWER GRID CO LTD +1

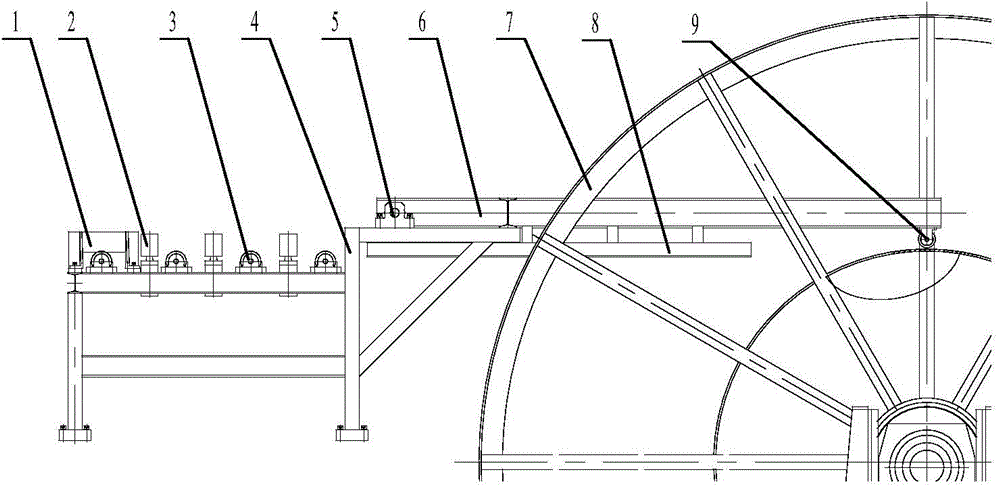

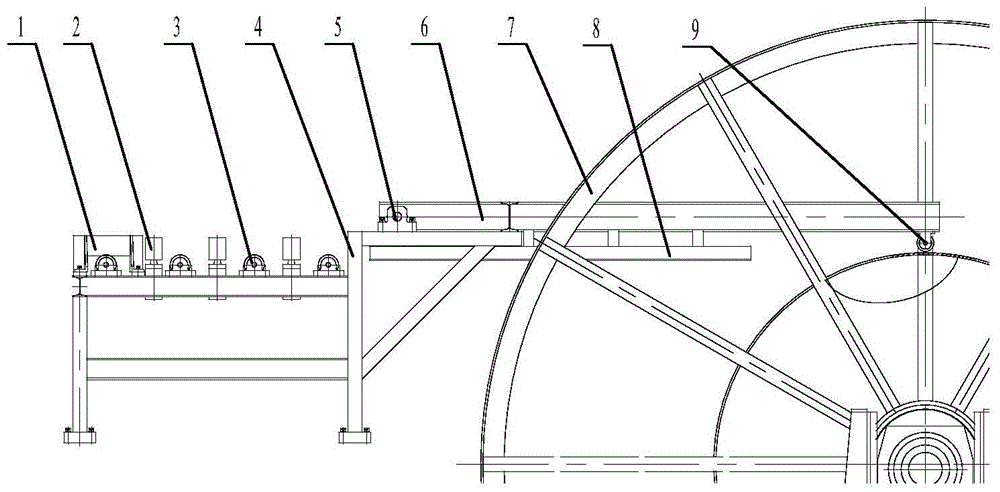

Multifunctional auto-adaptable material guide structure

A multifunctional auto-adaptable material guide structure includes a rack which is installed at a material feeding side of a rolling disk. Side guide plates are connected to the two side surfaces of a material inlet on the rack. A side roller is connected to the side surface of the rack at the back side of the side guide plates. A horizontal guide roller is connected to the middle of the rack in the moving direction of a to-be-rolled material. A hinge shaft is connected to a material outlet of the rack and is connected to one end of a cantilever. The other end of the cantilever is stretched in a rolling-up trough of the rolling disk. A guide trough is connected under the cantilever. The lower parts of the ends of the cantilever are connected to a press roller which is arranged right above the rolling disk. During operation, the press roller is pressed on the to-be-rolled material. The multifunctional auto-adaptable material guide structure can accurately guide the to-be-rolled material on the rolling disk, and by means of the press roller, the to-be-rolled material is subjected to uniform bending deformation and the layers of the to-be-rolled material are tightly attached to each other, thereby ensuring rolling quality and rolling efficiency. The structure has an auto-adaptable property and a high fault tolerance, so that stability and reliability of the structure are ensured under various work situations.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

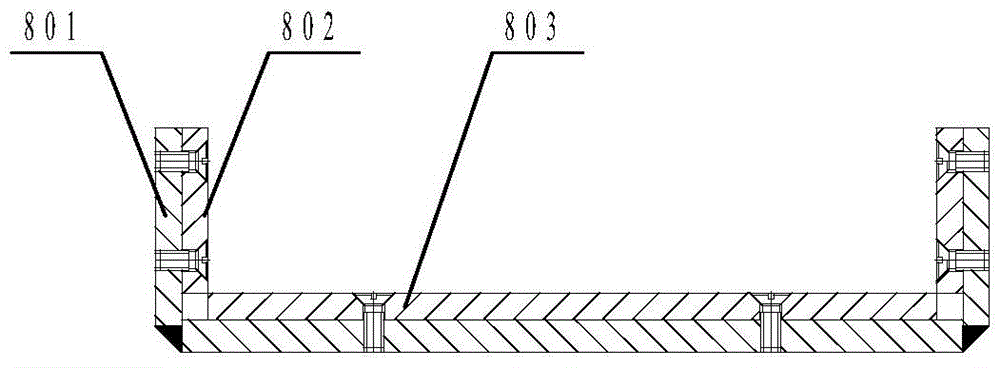

Loader hopper and loader

PendingCN111411653AImprove work efficiencyEasy to controlMechanical machines/dredgersStructural engineeringMechanical engineering

The invention discloses a loader hopper and a loader. The loader hopper comprises a hopper body, wherein discharging holes are formed in the two ends of the hopper body, and the discharging holes areconnected with the inner bottom surface of the hopper body; a gate is arranged at the discharging holes, the gate is hinged to the hopper body, and the gate is used for blocking materials in the hopper body; and a locking mechanism is further arranged on the hopper body, and the locking mechanism is used for controlling opening and closing of the gate. According to the loader, during discharging,automatic discharging of the loader can be achieved, secondary participation of constructors is not needed, safety and health risks caused by manual discharging are eliminated, and the influence of aconstruction site on the construction progress is reduced.

Owner:中国葛洲坝集团第三工程有限公司

Opposite-stirring lubricating device for wire rod

The invention discloses an opposite-stirring lubricating device for a wire rod, which comprises a wire passing box body, an opposite-stirring mechanism and a driving device, wherein the opposite-stirring mechanism comprises a driving spiral stirring shaft and a driven spiral stirring shaft rotating opposite to the driving spiral stirring shaft; the driven spiral stirring shaft and the driving spiral stirring shaft are symmetrically arranged on the two sides of the position through which a steel wire penetrate and are parallel to the steel wire; a transmission gear connected with the driven spiral stirring shaft is arranged at one end of the driving spiral stirring shaft. By the arrangement of the opposite-stirring lubricating device, lubricating powder can be fully turned and stirred, and the lubricating powder can generate extruding force on the steel wire, so that the steel wire can be uniformly coated with the lubricating powder, and the lubricating effect is enhanced; therefore, non-uniform deformation during drawing and drawing heat are reduced, the quality and the performance of the steel wire are effectively improved, the service life of the wire passing box body is prolonged, and the production cost is reduced.

Owner:陈训宏

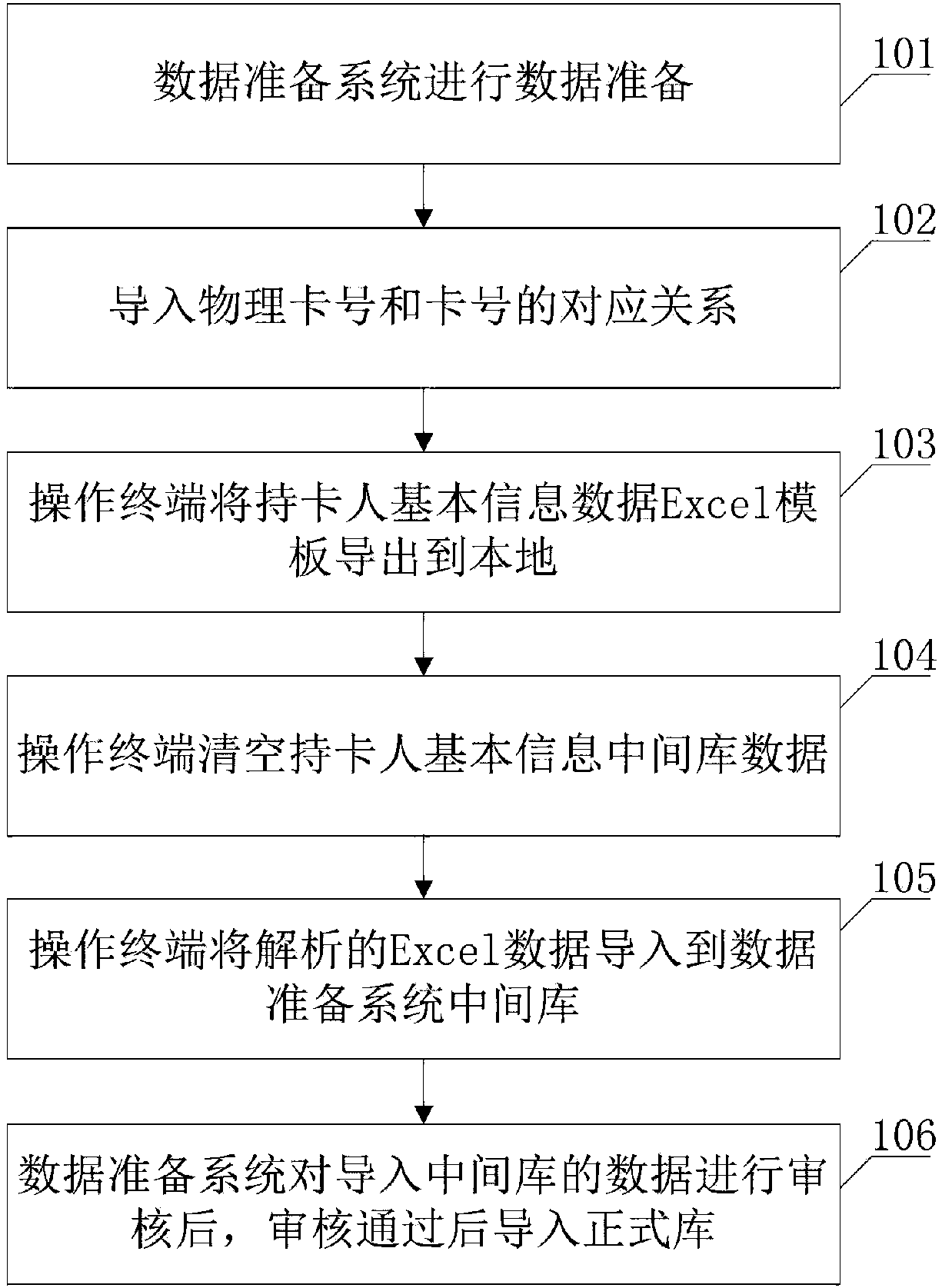

Method for Importing Basic Information of Cardholders

ActiveCN108121818AOptimize processReduce error rateSpecial data processing applicationsData preparationSoftware engineering

The invention provides a method for importing basic information of a cardholder, which includes: operating terminal exports a basic information data Excel template of a cardholder to a local area; theoperation terminal parses the selected Excel data into a data preparation system, and imports the analyzed Excel data into a data preparation system middle library; after the data preparation systemverifies the data imported into the intermediate library, the data enters the official library after passing through. The process is more optimized, so that the information is rapidly and accurately imported into the data preparation system, the error rate is low, the repeated rework error correction is not needed, and the recording efficiency is improved.

Owner:NEWCAPEC ELECTRONICS CO LTD

A multifunctional self-adaptive material guide structure

A multifunctional auto-adaptable material guide structure includes a rack which is installed at a material feeding side of a rolling disk. Side guide plates are connected to the two side surfaces of a material inlet on the rack. A side roller is connected to the side surface of the rack at the back side of the side guide plates. A horizontal guide roller is connected to the middle of the rack in the moving direction of a to-be-rolled material. A hinge shaft is connected to a material outlet of the rack and is connected to one end of a cantilever. The other end of the cantilever is stretched in a rolling-up trough of the rolling disk. A guide trough is connected under the cantilever. The lower parts of the ends of the cantilever are connected to a press roller which is arranged right above the rolling disk. During operation, the press roller is pressed on the to-be-rolled material. The multifunctional auto-adaptable material guide structure can accurately guide the to-be-rolled material on the rolling disk, and by means of the press roller, the to-be-rolled material is subjected to uniform bending deformation and the layers of the to-be-rolled material are tightly attached to each other, thereby ensuring rolling quality and rolling efficiency. The structure has an auto-adaptable property and a high fault tolerance, so that stability and reliability of the structure are ensured under various work situations.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

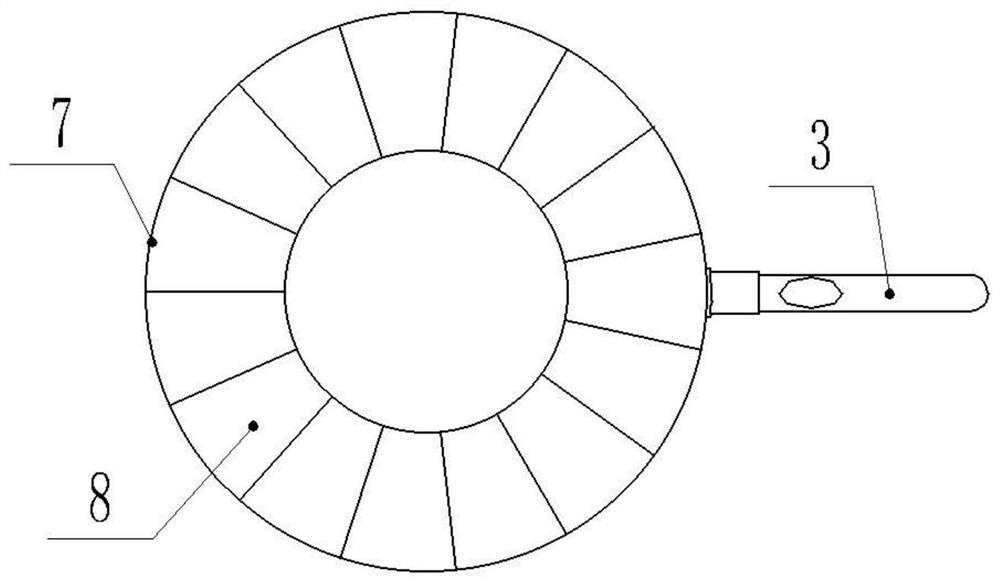

Full-automatic intelligent tablet subpackaging device

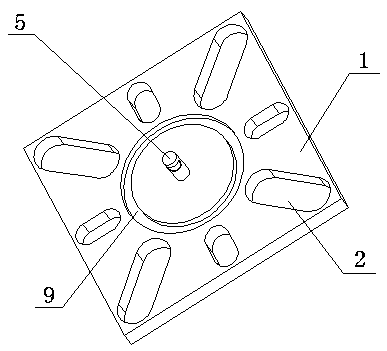

ActiveCN113247327AAccurate countAvoid false countsWrapping material feeding apparatusWrapper twisting/gatheringMechanical engineeringFully automated

The invention discloses a full-automatic intelligent tablet subpackaging device. A tablet containing disc servo motor is longitudinally arranged in a subpackaging box body, a rotating shaft of the tablet containing disc servo motor is provided with a tablet containing disc, a plurality of tablet containing bins are evenly distributed on the tablet containing disc in a surrounding mode, a tablet outlet is formed in the bottom of each tablet containing bin, a tablet inlet is formed in the outer ring face of each tablet containing bin, a bottom sealing plate is fixedly arranged at the bottom of the tablet containing disc, and a rotating shaft of a tablet guiding servo motor is connected to the middle of a tablet guiding-out pipe; the upper end of a tablet suction guide pipe is inserted into the subpackaging box body in a downward inclined mode, the upper end of the tablet suction guide pipe is in sealed butt joint with the outer ring face of the tablet containing disc, the lower end of the tablet suction guide pipe is vertically arranged, and a tablet bottle tray is arranged at the position, corresponding to the lower end of the tablet suction guide pipe, of the subpackaging box body; and a suction pump is arranged in the subpackaging box body, a suction pipe of the suction pump is connected to the upper end part of the tablet suction guide pipe, a counting sensor is arranged at the joint of the upper end part of the tablet suction guide pipe and an elbow part, and a tablet blocking separator is arranged at the joint of the lower end part of the tablet suction guide pipe and the elbow part.

Owner:QINGDAO CITY CHENGYANG DISTRICT PEOPLES HOSPITAL

Double-edge ball

The invention discloses a double-edge ball. The double-edge ball comprises a rod body, chip grooves, cutting edges, a ball, a chip guiding groove, a knife edge, a hand-holding part, a base, a fixed groove and a limiting hole. The double-edge ball disclosed by the invention has the beneficial effects that the rod body is connected with an installation seat through the limiting hole formed in the base, and the rod body is fixed through the fixed groove formed in the side wall of the rod body, so that the rod body is prevented from tilting during installation of the double-edge ball; the chip grooves are spirally surrounded on the rod body, so that scrap cut off by the ball can be conveniently discharged through the chip grooves; the inner surface of the chip guiding groove is a smooth arc-shaped surface, and the tail end of the chip guiding groove is connected with the chip grooves, so that the cut scrap can be accurately guided into the chip grooves; the ball is made by adopting a hardalloy material, and the knife edge on the top end of the ball is coated with a composite coating layer, so that abrasion of the knife edge is reduced; the hand-holding part is provided with strip-shaped bands, and the strip-shaped bands are uniformly distributed on the outer wall of the hand-holding part, so that the friction coefficient between the hand-holding part and fingers can be increased,and the rod body can be conveniently screwed.

Owner:CHANGZHOU BOLU INSTR SCI & TECH

A Rapeseed Breeding Method Using Gene Mapping Technology

The invention provides a rapeseed breeding method adopting a gene mapping technology.A representative hybrid female parent with outstanding comprehensive characters is selected as a parent 1, a sclerotinia sclerotiorum resisting resource material is selected as a parent 2, a pod split resisting resource material is selected as a parent 3, the parent 1 is crossbred with the parent 2 and the parent 3 to obtain F1 generations, and the F1 generations are subjected to selfing to obtain two F2 colonies; a character survey, gene mapping and a back cross breeding improvement are carried out to obtain a female parent with two improved characters, namely sclerotinia sclerotiorum resistance and pod split resistance.The method breaks through the bottlenecks of a long cycle, poor predictability, low selection efficiency and the like of traditional seed breeding, and is faster, controllable and efficient.

Owner:SICHUAN FANGPAI SEED CO LTD

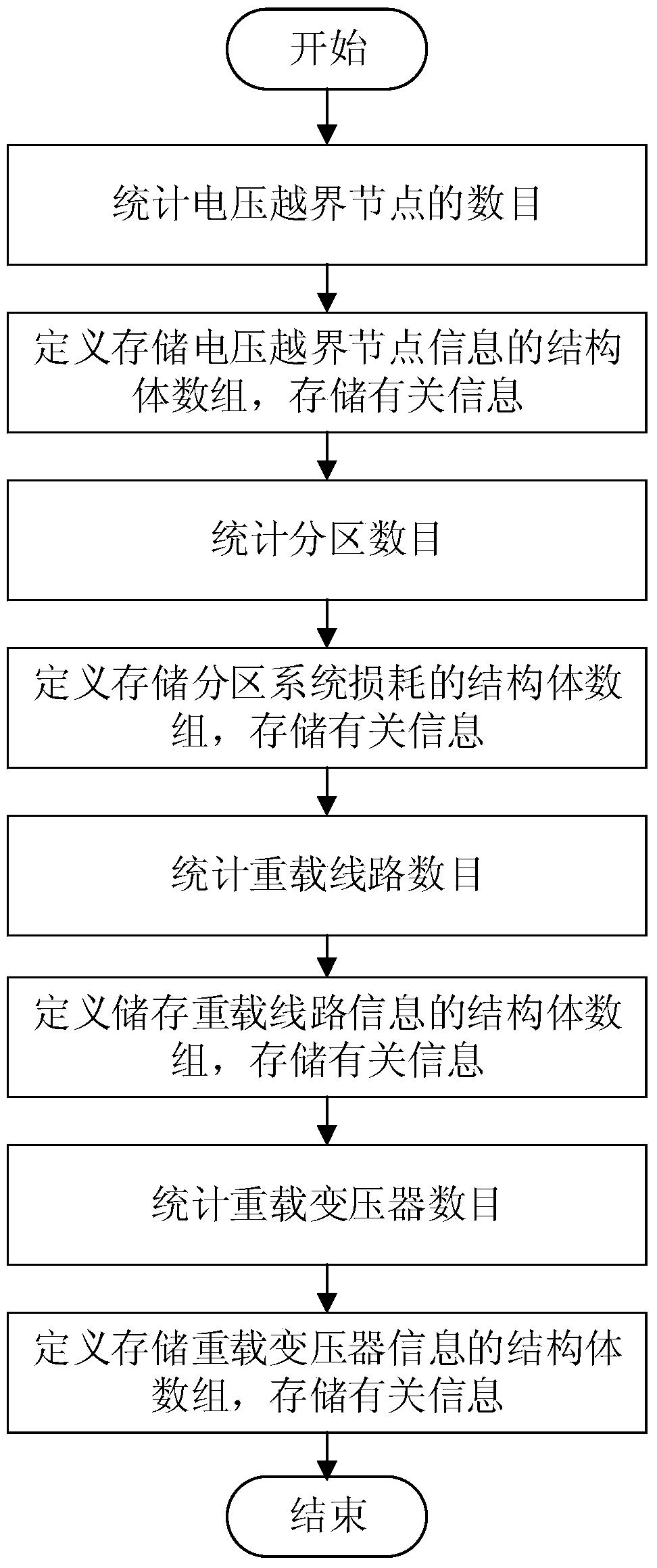

A method of interface conversion between pfo data format and xls

ActiveCN105718583BEasy to calculateHas engineering practical valueDigital data information retrievalResourcesElectric power systemSoftware engineering

The invention provides an interface conversion method for the PFO data format and XLS.A PFO format file exported through BPA software is read in a program, and the load flow calculation result of BPA is positioned, rearranged and exported to an XLS file.The problems that after the electric power system analysis software BPA is generally applied in an electric power system, the information amount in the load flow calculation result is large and required key information can hardly be visually obtained are solved, and high engineering practicability is achieved.

Owner:STATE GRID CORP OF CHINA +2

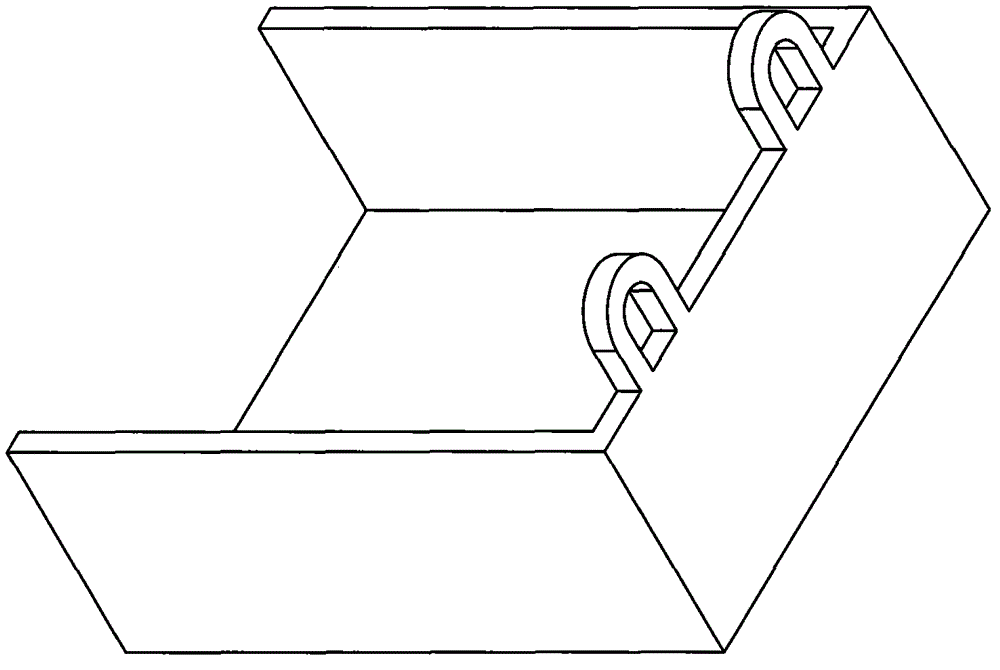

Efficient and environment-friendly electric furnace iron chip feeding barrel

InactiveCN104803122AReduce manufacturing costStable structureLarge containersMaintainance and safety accessoriesIsosceles trapezoidDischarge efficiency

The invention discloses an efficient and environment-friendly electric furnace iron chip feeding barrel, which comprises a base, foot pads, a barrel body, reinforcing bars, a cross beam, a hanging ring, a pull rod, a guide rod and a barrel plug, wherein four foot pads are arranged under the base, the barrel body is in a funnel shape, and comprises four isosceles-trapezoid-shaped side surfaces with the same sizes, the four side surfaces form one upper end feeding opening and one lower end discharging opening, the reinforcing bars are respectively arranged between each side surface and the bottom surface, a cross beam is fixedly arranged between two opposite side surfaces of the four side surfaces, a first installing hole is formed in the middle position of the cross beam, a pull rod capable of vertically ascending and descending is arranged in the installing hole, one end, positioned above the cross beam, of the pull rod is fixedly connected with a pull ring, one end, positioned under the cross beam, of the pull rod is fixedly connected with the barrel plug, the barrel plug is in clearance fit arrangement with the discharging opening, and in addition, the dimension of the lower end surface of the barrel plug is greater than the dimension of the discharging opening arranged at the lower end. The efficient and environment-friendly electric furnace iron chip feeding barrel has the characteristics that the cost is low, the structure is stable and firm, the discharging is convenient, the discharging efficiency is high, the chip leakage is avoided, the water discharge is easy, and the environment is protected.

Owner:ZHEJIANG SUN STOCK

Preparation system for deep processing of meat

ActiveCN114468014AScientific and reasonable structureEasy to useClimate change adaptationSausage filling/stuffing machinesWater storage tankEngineering

The preparation system comprises a processing machine body, and an extrusion moving mechanism is installed at the top position of one end of the processing machine body; and the extrusion moving mechanism comprises a discharging pipe, a water storage tank, a booster pump, a water outlet pipe, a connecting pipe, a connecting valve, an air bag, a guide pipe, a convergence cavity, a guide hole, a moving hole, a sliding plate, a placement hole, a storage hole, a connecting frame, a tensioning spring, a moving plate, a limiting plate, an extrusion plate, a clamping hole, a limiting rod and a water outlet valve. Water can be conveniently guided into the air bag and sprayed to the outer end of the connecting pipe from the guide hole through the air bag and the gathering cavity, so that a worker can conveniently sleeve the casing, the outer end of the casing can be conveniently extruded by an extrusion plate through a tensioning spring and a moving plate, and a sliding plate can be conveniently moved by matching with a limiting rod. Therefore, one end of the casing is stacked neatly, and the casing filling work is facilitated.

Owner:广东亚北农副产品有限公司

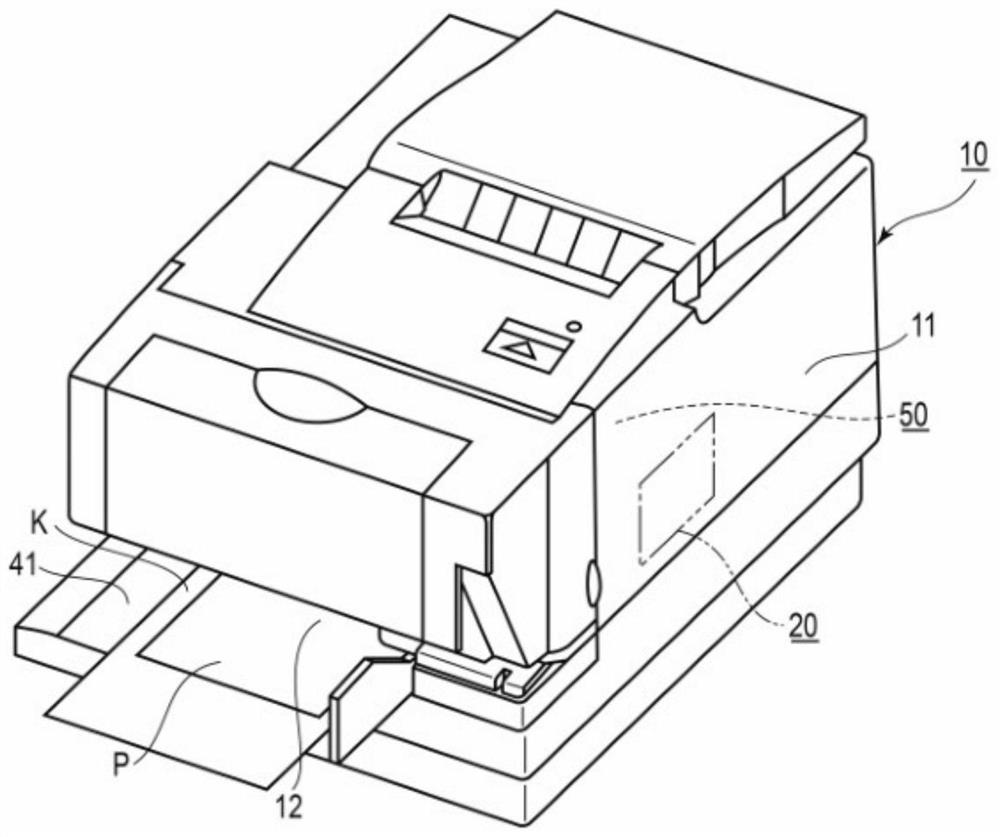

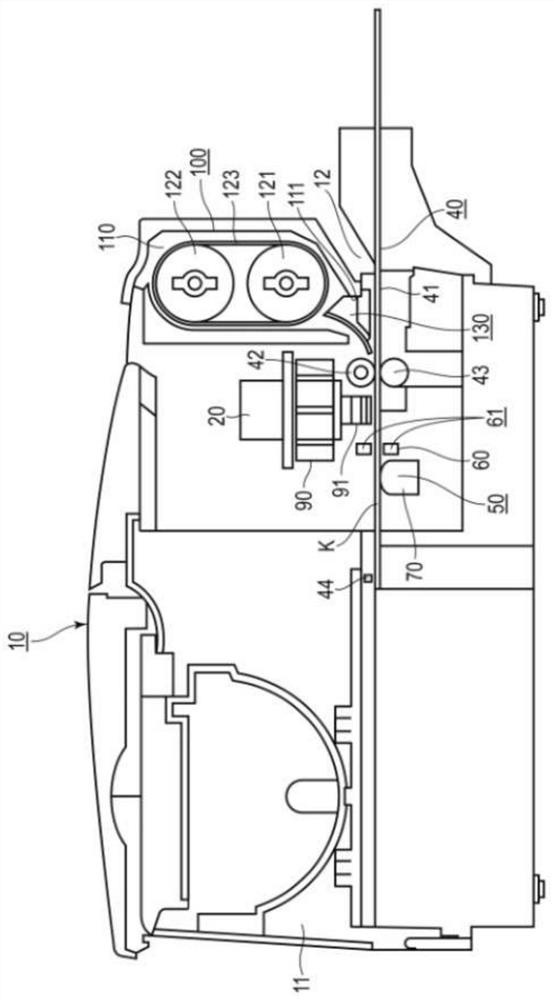

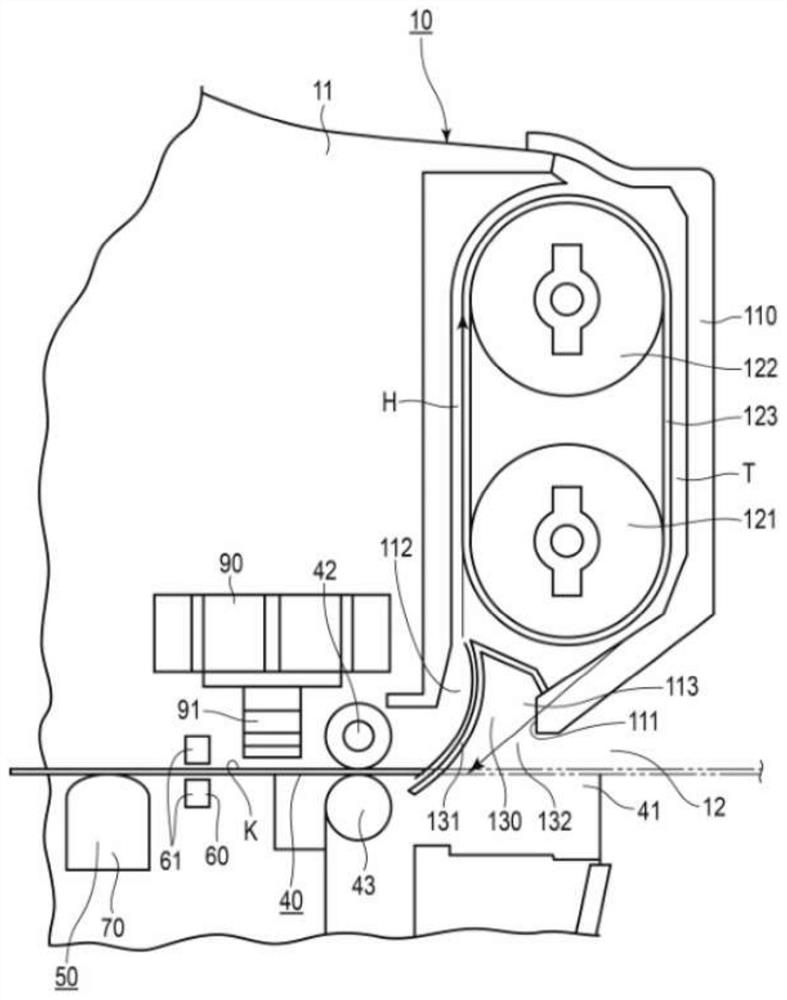

Magnetic ink reading device and printer

ActiveCN110014733BAccurate importPaper-money testing devicesCoin/currency accepting devicesComputer printingEngineering

The invention discloses a magnetic ink reading device and a printer, which can prevent the user from taking out the magnetic ink by mistake when reading the magnetic ink printed on the medium, and simplify the structure and miniaturize the device. The fetching device includes: a case and a conveying mechanism arranged in the case. The chassis is provided with a media access port for entering and exiting media printed with magnetic ink. The conveying mechanism has a magnetizing mechanism for conveying the medium along the conveying path and magnetizing the magnetic ink of the medium on the conveying path, and is arranged near the magnetizing mechanism along the conveying path for reading the magnetic force of the magnetized magnetic ink. Magnetic detection head. Moreover, the magnetic ink reading device also has a medium inlet and outlet side that is arranged on the conveying path, and a turning mechanism that makes the inside and outside of the medium turn over in the inner turning path. Evacuation path to temporarily evacuate the media.

Owner:TOSHIBA TEC KK

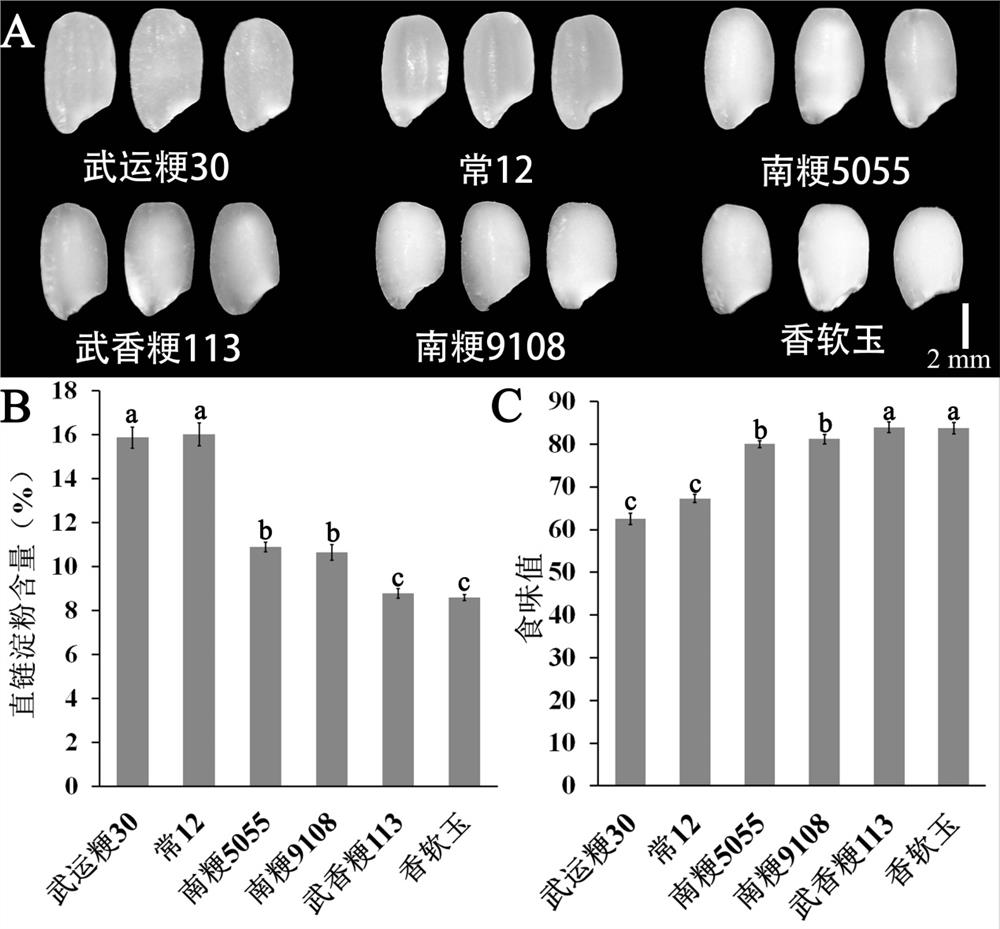

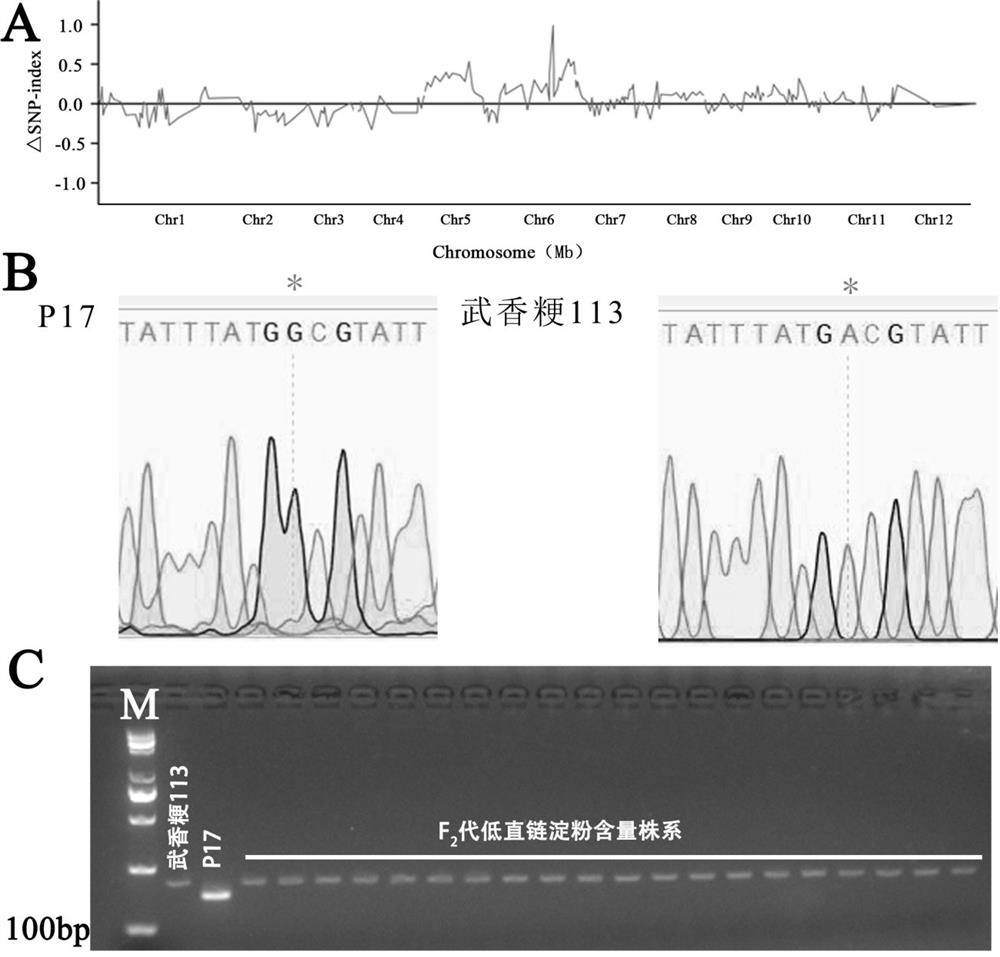

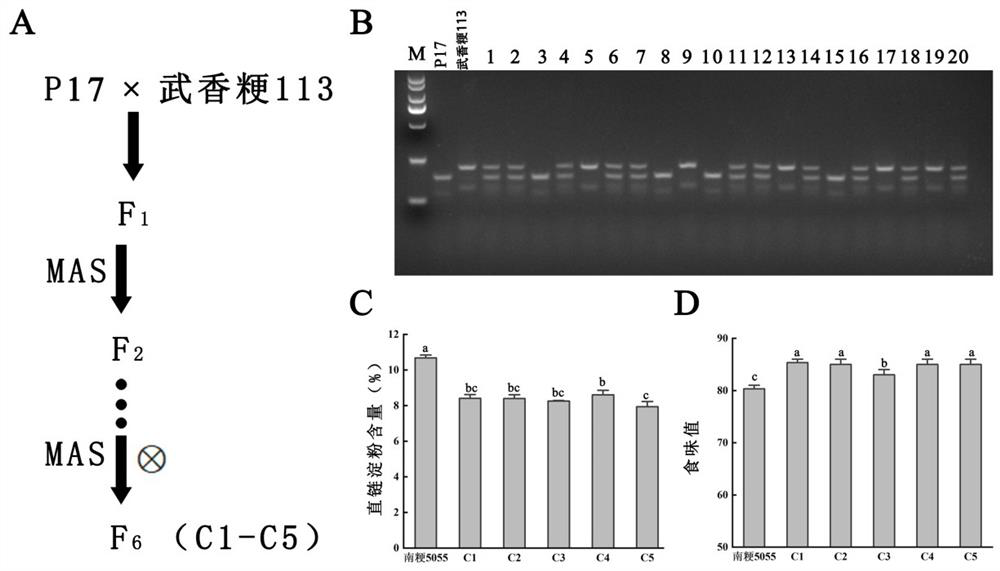

DNA (Deoxyribonucleic Acid) molecular marker and method for cultivating low-amylose-content excellent-taste rice by utilizing DNA molecular marker

ActiveCN114525359ARich varietyAccurate importMicrobiological testing/measurementDNA/RNA fragmentationBiotechnologyGermplasm

The invention discloses a DNA (Deoxyribonucleic Acid) molecular marker and a method for cultivating low-amylose-content excellent-taste rice by utilizing the DNA molecular marker. A variety A with low amylose content and excellent-taste performance is selected and hybridized with a conventional variety B; the molecular marker closely linked with the low amylose content is used for rapid selection of the low amylose content character of the offspring, the amylose content of the rice bred through the method is remarkably lower than that of conventional japonica soft rice in Jiangsu areas at present, and the soft rice of the type has better taste quality and is suitable for large-scale production. The method provides an important technical route for widening soft rice germplasm resources and cultivating a new rice variety with excellent taste quality; meanwhile, the method also has important significance for improving the taste quality of the rice.

Owner:YANGZHOU UNIV +1

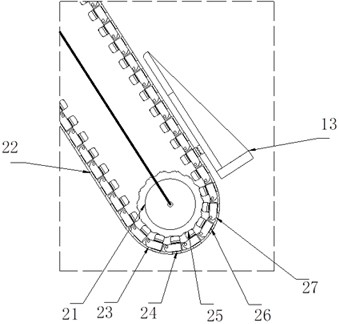

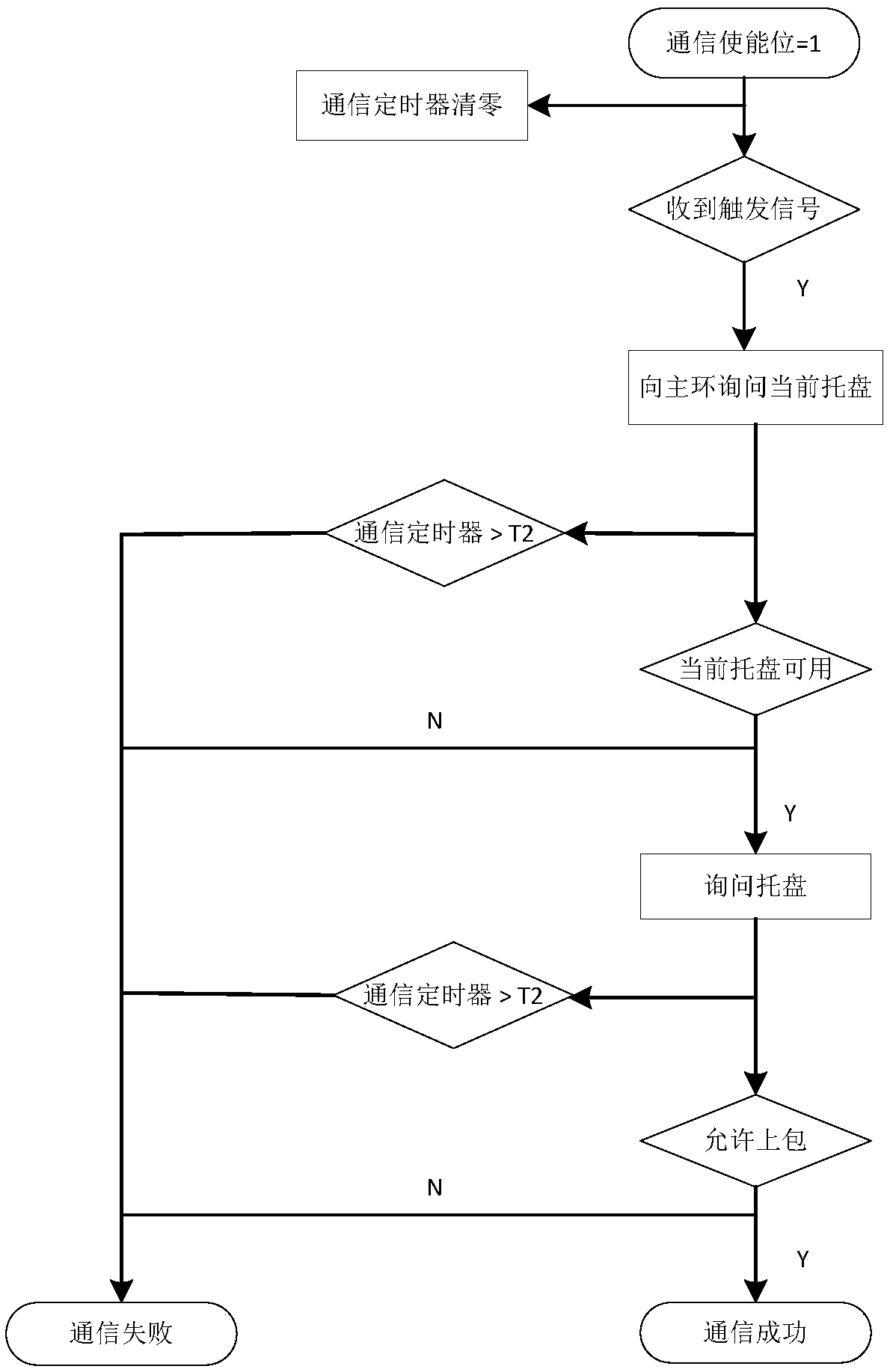

An automatic feeding platform for a cross-belt sorter and its control method

An automatic piece supplying table for a cross-belt sorting machine adopts a nine-section type structure. A piece feeding section closest to a main ring is arranged to be the first section. Sections are successively sequenced. The chamfered joint section close to a belt conveyor is arranged to be the ninth section. A measurement photoelectric portal frame is arranged between the sixth section and the seventh section and used for measuring the size of a parcel. The seventh section serves as the weighing section. Drive motors of all the nine sections are connected with a control system through a bus. The control system comprises a master controller which is connected with a frequency converter, a parcel feeding rail plate, a digital IO module, the belt conveyor, a main ring PLC and a piece supplying table terminal.

Owner:CHINA POST SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com