Chain automatic running-in oiling machine

A chain transmission mechanism and chain technology, which is applied in the direction of coating, the device for coating liquid on the surface, etc., can solve the problems of poor oiling and deoiling effect, low oiling efficiency and high energy consumption, and achieve good deoiling effect. , The effect of high work efficiency and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

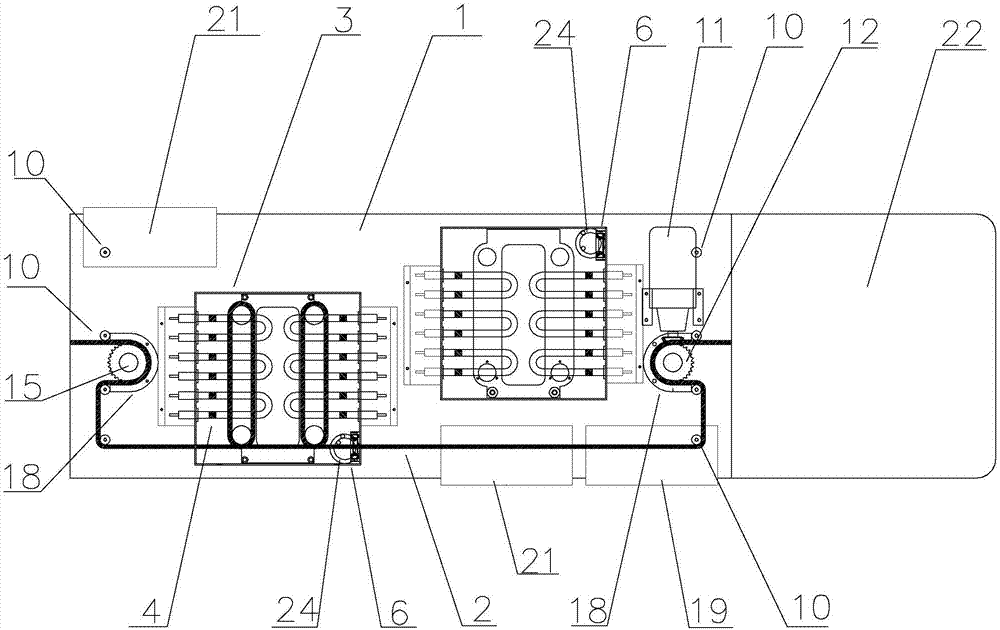

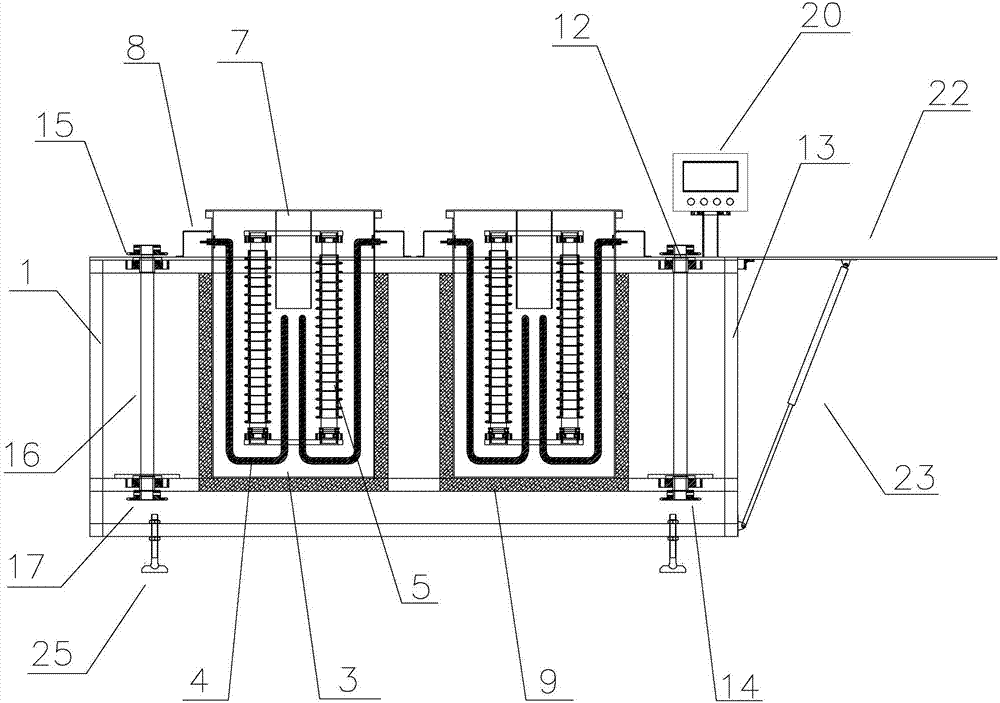

[0030] Such as figure 1 , As shown in 2, a kind of chain automatic run-in oiling machine, comprises frame 1, chain transmission mechanism, two cover oiling mechanisms, control mechanism. The two sets of oiling mechanisms share a set of chain transmission mechanism and control mechanism.

[0031] Such as figure 1 , 2 As shown, the chain transmission mechanism is arranged on the top surface of the frame for leading the chain 2 into and out of the oiling mechanism; it includes a chain driving mechanism, a chain driven transmission mechanism and a plurality of chain guide bearings 10 ; The chain active transmission mechanism and the chain driven transmission mechanism are respectively arranged on the top of the frame and located at the front and rear positions of the oiling mechanism; the chain guide bearings are distributed on the top surface of the frame for leading in and out the chain Oiling mechanism; chain active transmission mechanism includes transmission motor 11, acti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com