Cooling structure for internal combustion engine

A technology of cooling structure and internal combustion engine, applied in the direction of engine cooling, liquid cooling, mechanical equipment, etc., can solve problems such as the inability of cooling water to flow, and achieve the effect of reducing pressure loss and friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

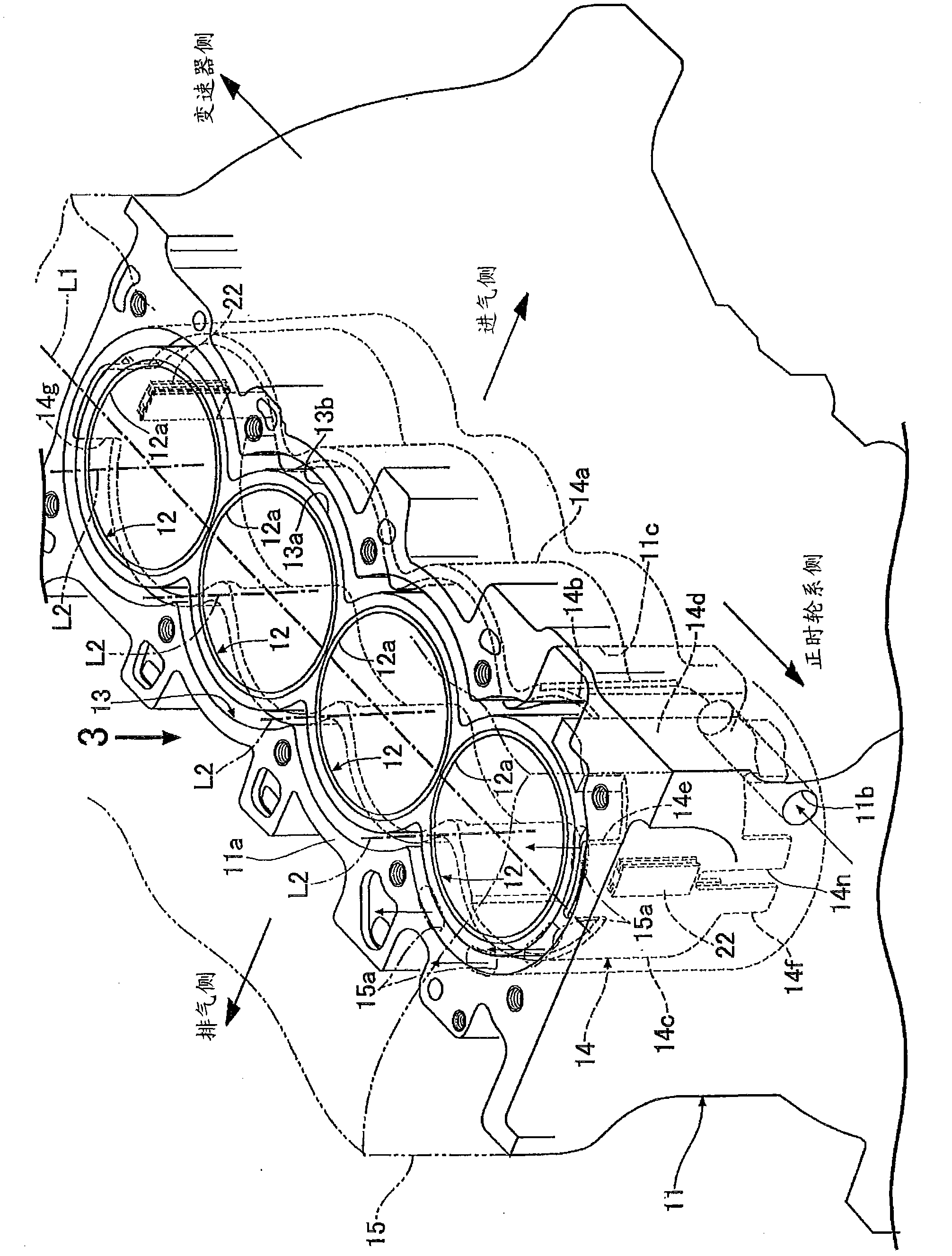

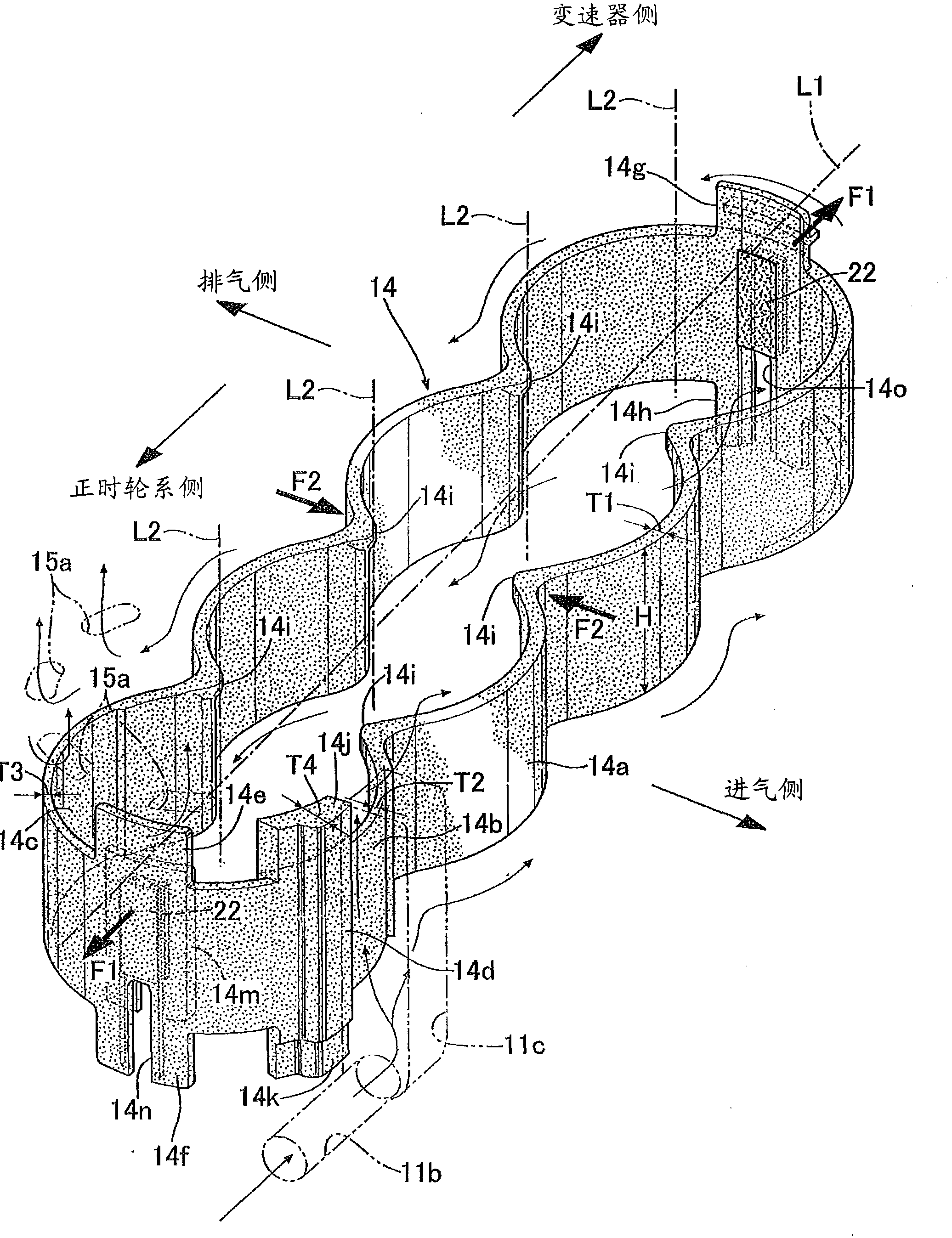

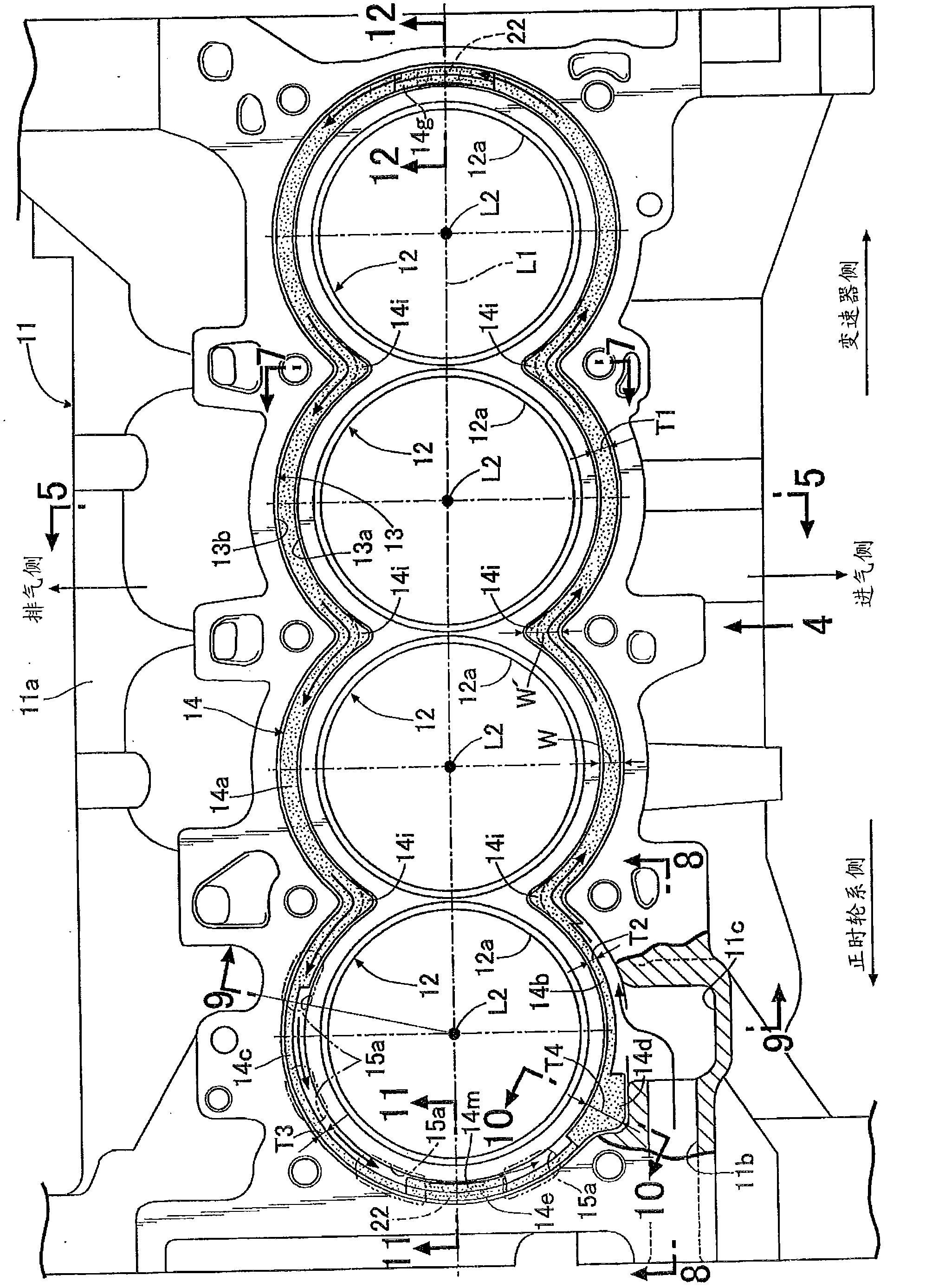

[0031] Below, according to Figure 1 to Figure 12 Embodiments of the present invention will be described.

[0032] Such as figure 1 As shown, in the cylinder block 11 of the in-line 4-cylinder internal combustion engine, four cylinder liners 12... are buried along the cylinder line L1, and the water jacket 13 is formed so as to surround the outer peripheral surfaces of these cylinder liners 12.... The cylinder block 11 of the present embodiment is a Siamese type cylinder block, which does not form a water jacket 13 between adjacent cylinder liners 12 . shorten. A water jacket 13 opened to a deck surface 11a of the cylinder block 11 extends downward at a certain depth from the deck surface 11a toward the crankcase side, and is disposed between an inner wall surface 13a and an outer wall surface 13b of the water jacket 13. There is a spacer 14 made of synthetic resin inserted from the opening side of the plate surface 11 a of the cylinder block 11 .

[0033] In addition, "up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com