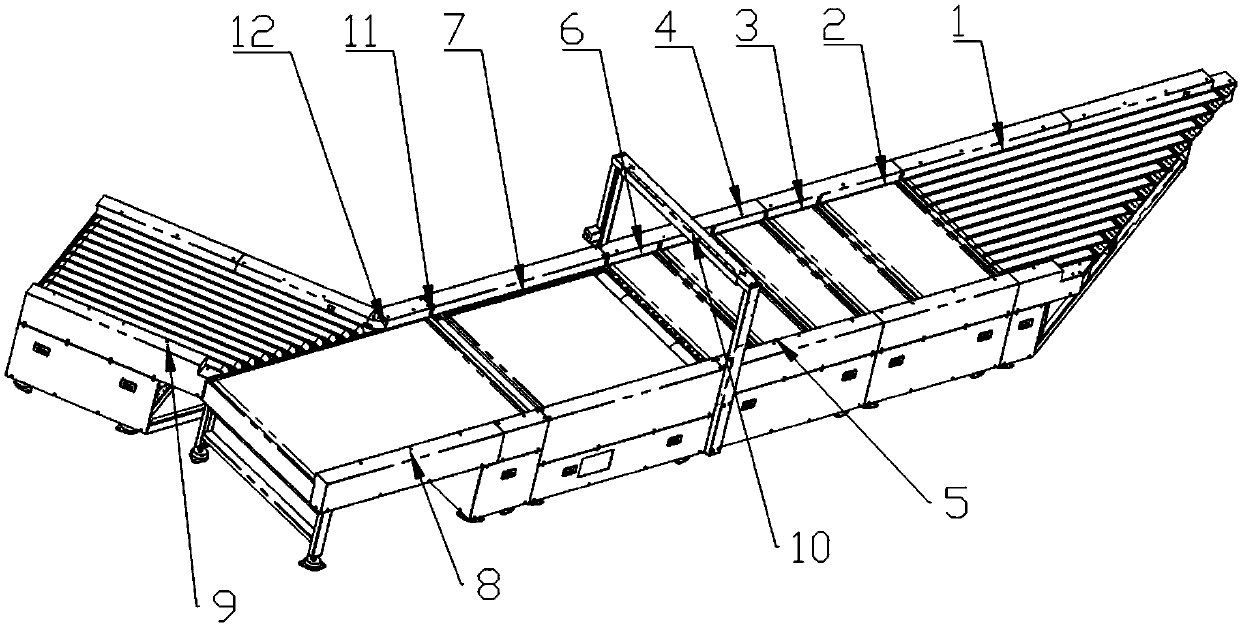

An automatic feeding platform for a cross-belt sorter and its control method

A cross-belt sorting and feeding table technology, applied in the field of automatic feeding table control, can solve problems such as insufficient efficiency, inability to meet large-scale automatic transmission, and placement requirements, and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

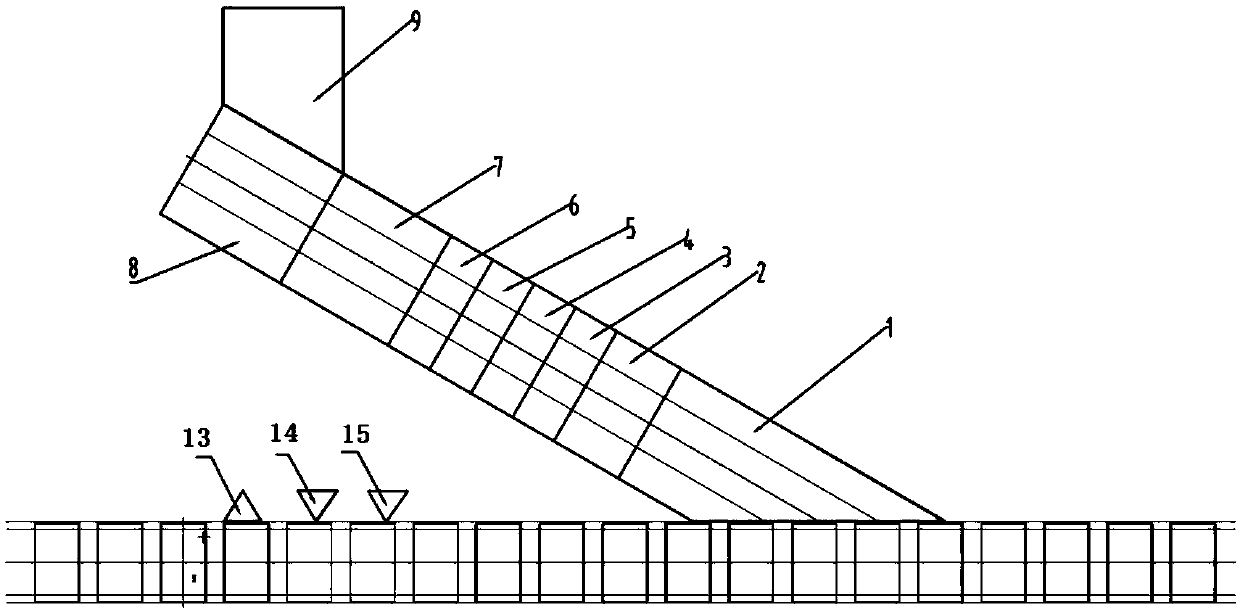

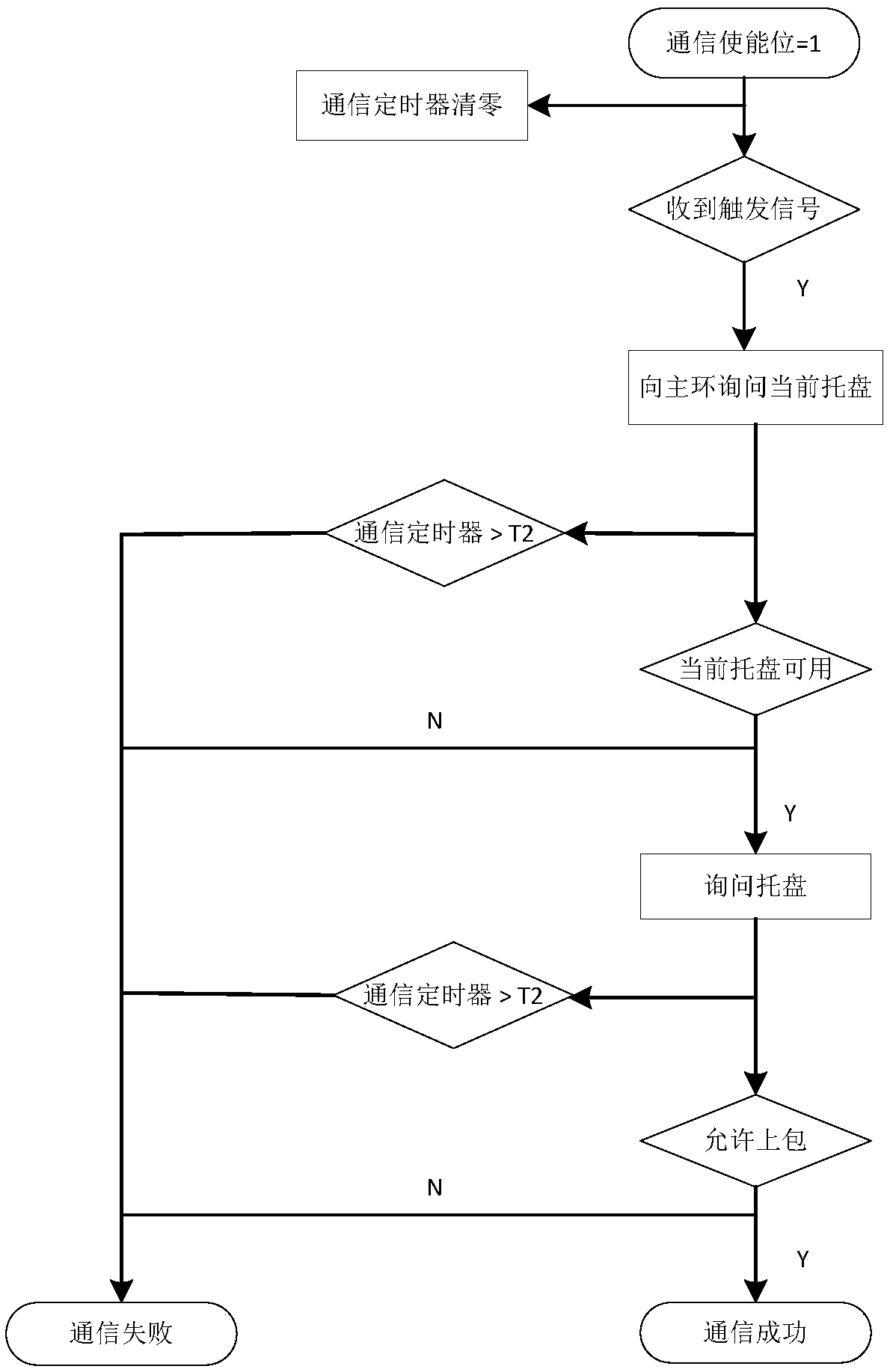

[0033] The control system of the present invention regards the triangular section (upper section) close to the main ring as the first section, and sorts in turn, and the miter section close to the belt conveyor as the ninth section. A measuring photoelectric gantry is set between the sixth section and the seventh section for measuring the size of the mail, and the seventh section is a weighing section. The nine-segment motors are all controlled by frequency converters and connected to the control system through the Profibus-DP bus system. The control system uses a programmable logic controller as the main control CPU, and connects and communicates through the DP module (and the frequency converter), the serial port module (and the upper-package track board), the digital IO module and related peripheral equipment and devices, and through the Profinet interface Communicate with the belt conveyor, the main ring PLC, and the terminal of the supply table. The technical scheme of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com