Method and device for fitting angular contact roller bearing

A contact roller and mounting device technology, applied to the field of supporting the crankshaft in the internal combustion engine of a motor vehicle, and installing such an angular contact roller bearing, can solve the problem of flange loosening, adverse effects of production costs, and bearing failure, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

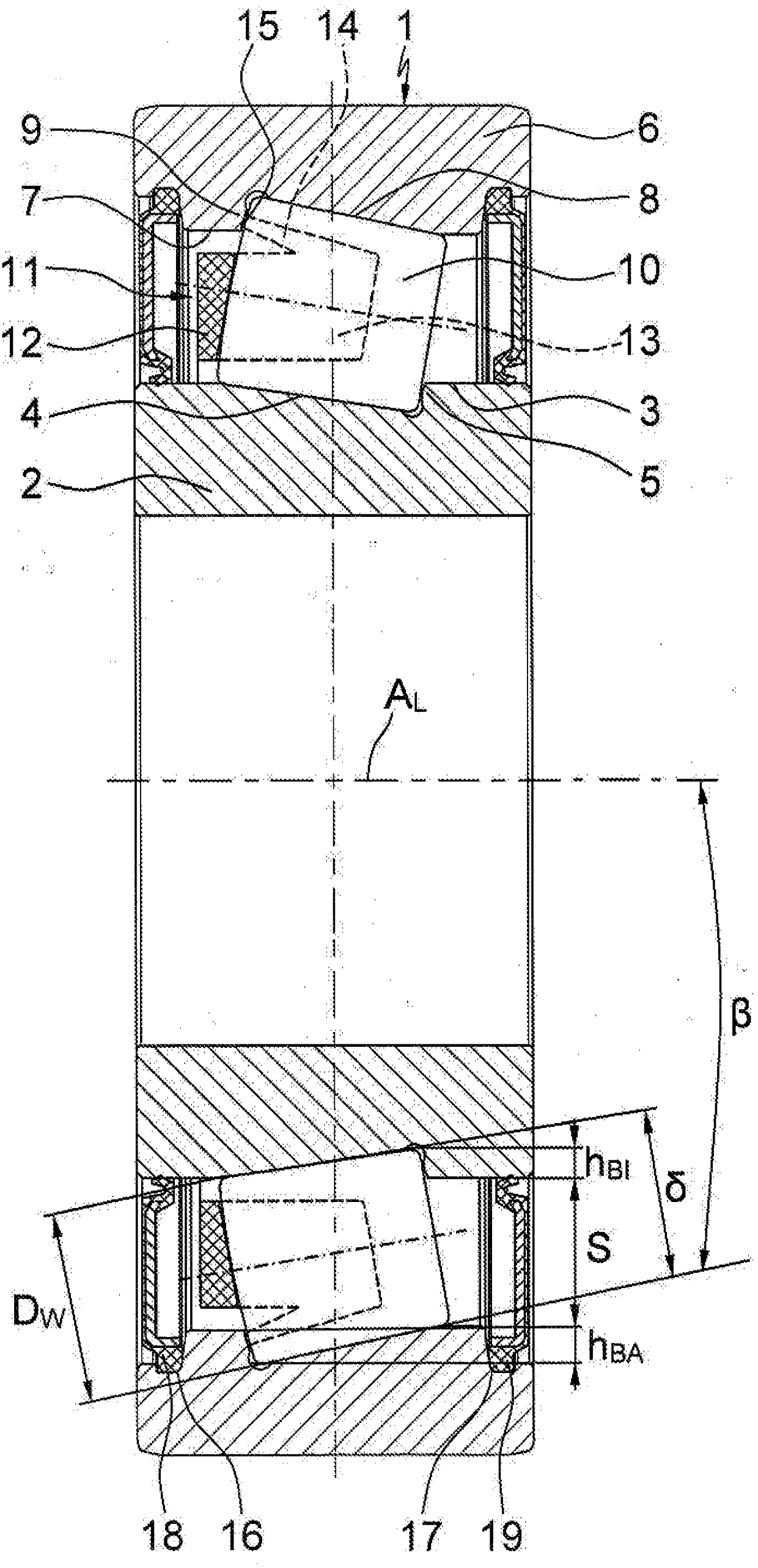

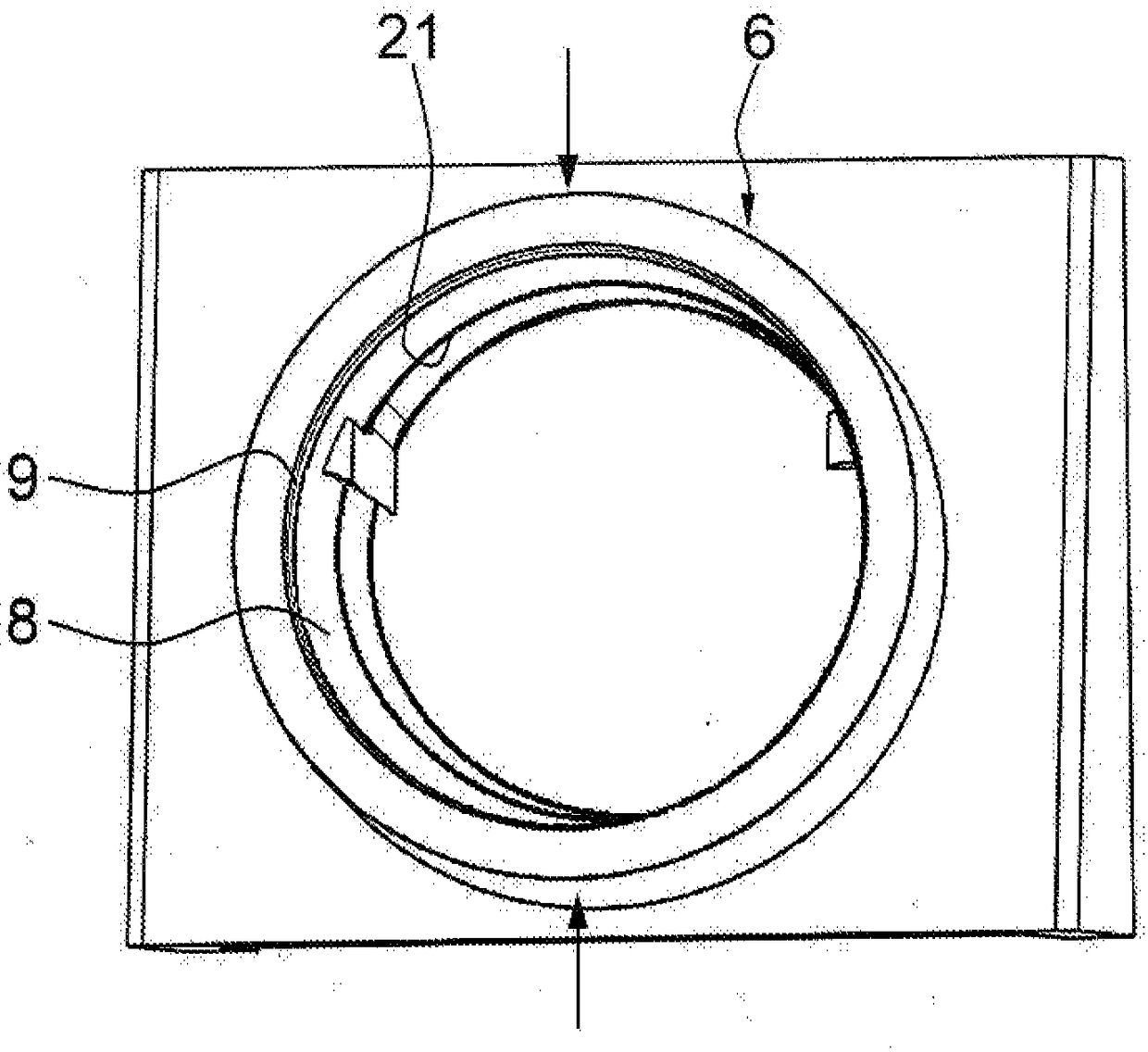

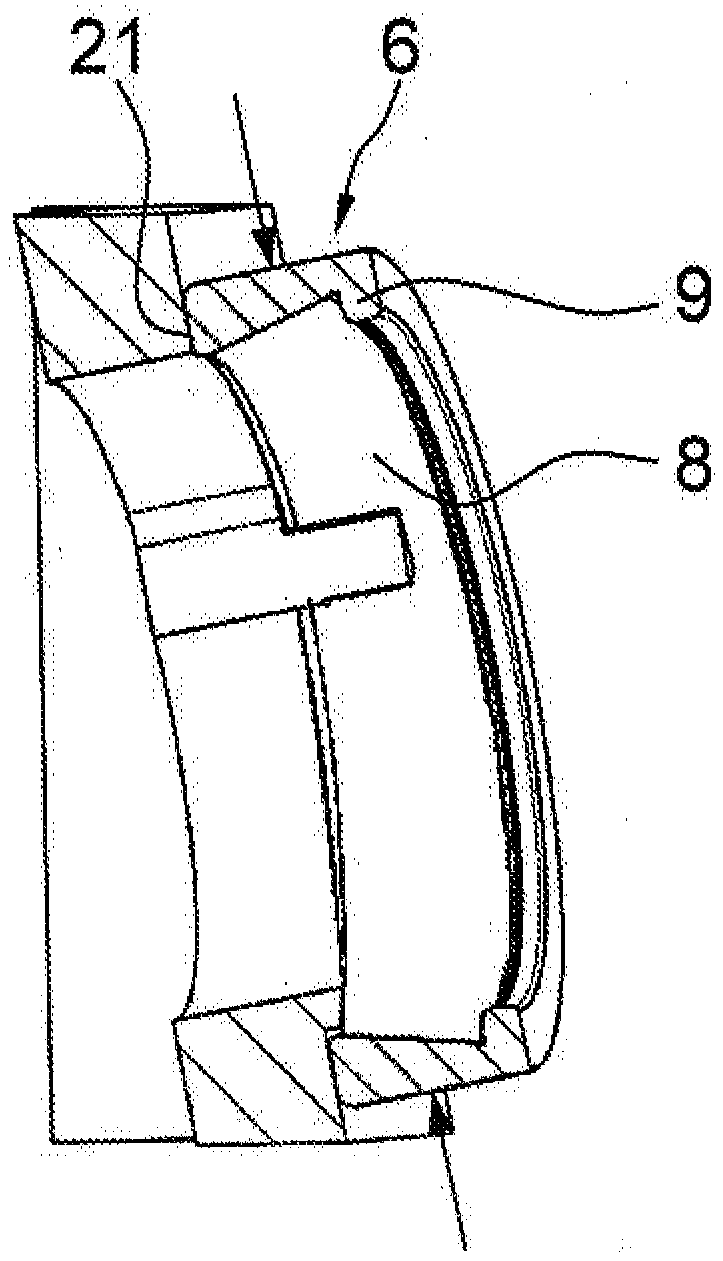

[0040] exist figure 1 shows a cross-section of a single-row angular contact roller bearing 1 which is suitable, for example, to replace the hitherto used deep groove ball bearings for supporting crankshafts in internal combustion engines of motor vehicles. Obviously, this angular contact roller bearing 1 is composed of a bearing inner ring 2 and a bearing outer ring 6. L Arranged inner raceway 4, the minimum diameter of the inner raceway is defined by the flange 5, and the bearing outer ring has a bearing rotation axis A that is also inclined to the radial direction on its inner peripheral surface 7 L The outer raceway 8 is arranged, the maximum diameter of the outer raceway is limited by the flange 9 . Between the bearing rings 2, 6 there are also arranged a plurality of rolling elements 10 rolling on their raceways 4, 8, which are kept at a uniform distance from each other in the circumferential direction by the bearing cage 11 .

[0041] Also in figure 1 It can also be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com