Efficient and environment-friendly electric furnace iron chip feeding barrel

A feeding barrel, environmentally friendly technology, applied in metal processing equipment, metal processing machinery parts, maintenance and safety accessories, etc., can solve the problems of low blanking efficiency, inability to discharge, complicated maintenance, etc., and achieve low manufacturing cost and blanking efficiency. High, structurally stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

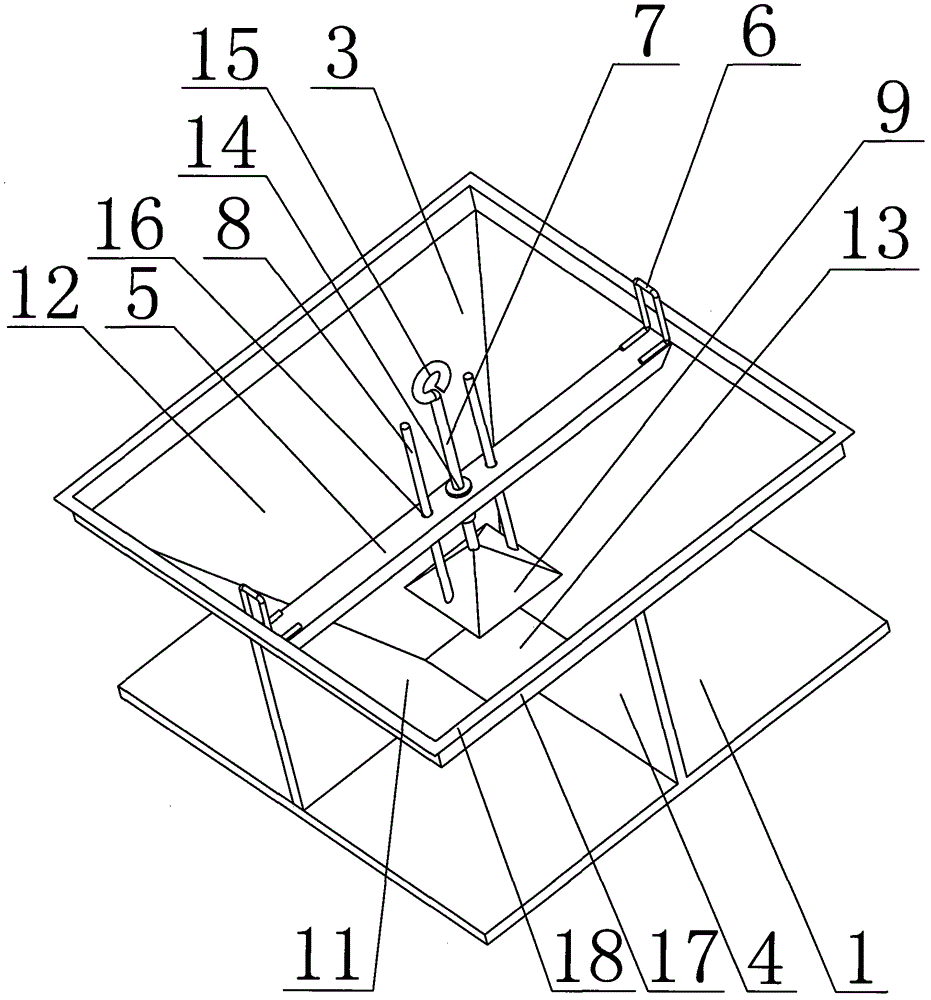

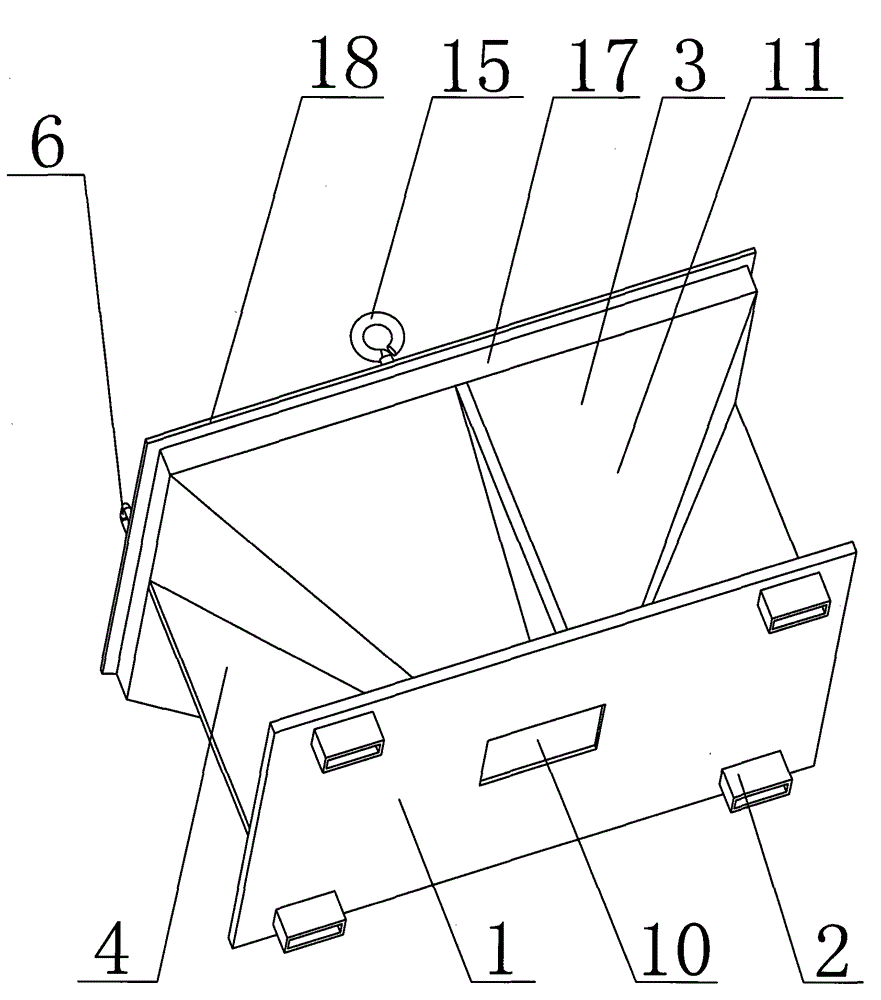

[0017] In order to enable those skilled in the art to better understand the solutions of the present invention, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments.

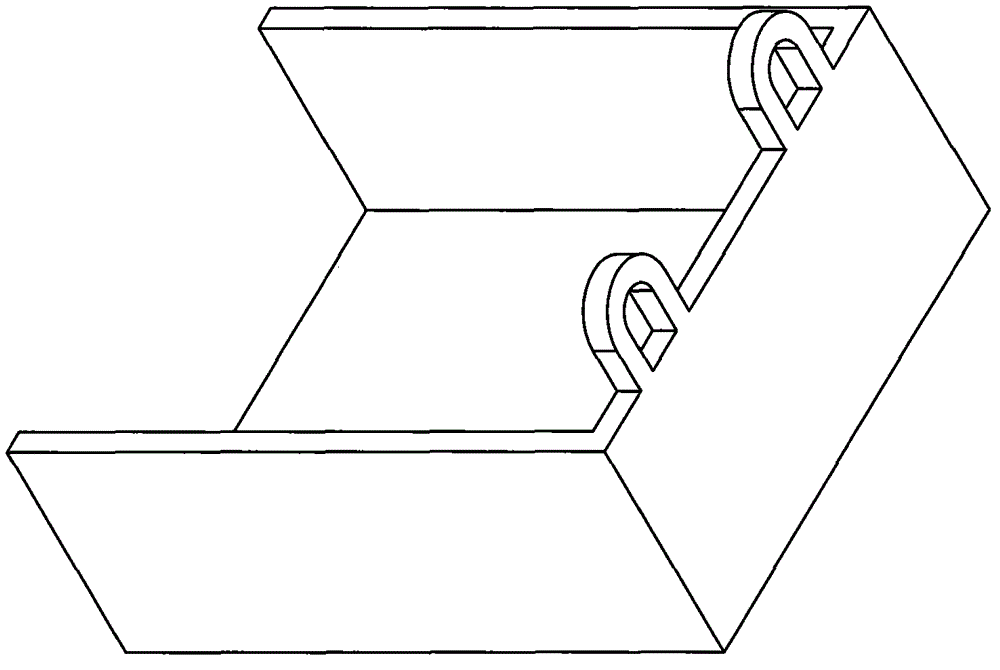

[0018] like figure 2 , image 3 As shown, the present invention discloses a high-efficiency and environment-friendly electric furnace scrap feeding barrel, which includes a base 1, a foot pad 2, a barrel body 3, a reinforcing rib 4, a beam 5, a lifting ring 6, a pull rod 7, a guide rod 8 and a barrel plug 9 The shape of the base 1 is square, four feet pads 2 are arranged under the base 1, and a square through hole 10 is provided at the center of the base 1; the barrel body 3 is funnel-shaped, and the barrel body 3 includes four equal in size and shape. Waist trapezoidal side 11, four sides 11 constitute an upper end feed port 12 and a lower end discharge port 13, the shapes of the upper end feed po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com