Preparation system for deep processing of meat

A preparation system and deep processing technology, which is applied in the field of meat deep processing preparation system, can solve the problems of meat processing, casing folds, casing damage, etc., and achieve the effect of convenient enema work, safe and convenient use, and increased labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

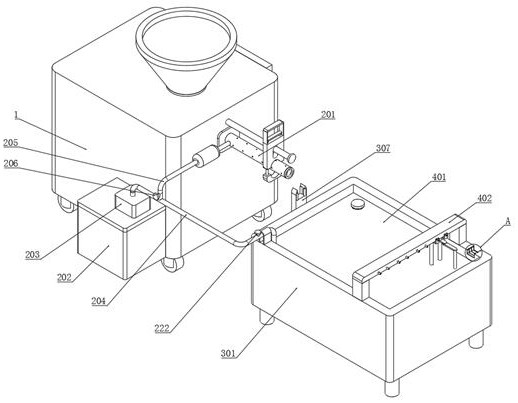

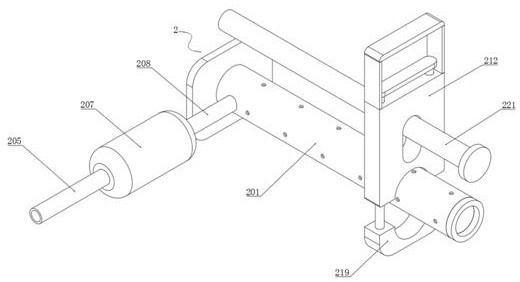

[0042] Example: such as Figure 1-8 As shown, the present invention provides a technical solution, a preparation system for meat deep processing, squeezes the moving mechanism 2, and pulls the sliding plate 212, so that the sliding plate 212 moves on the outer end of the limiting rod 221, so that one end of the casing to stack neatly;

[0043] The swing mechanism 3, because the rubber ball 305 is constantly in contact with the movable plate 307, makes the sausage move back and forth while moving, the operation is simple and convenient, avoiding the need for the staff to manually pull the sausage, which increases the labor intensity;

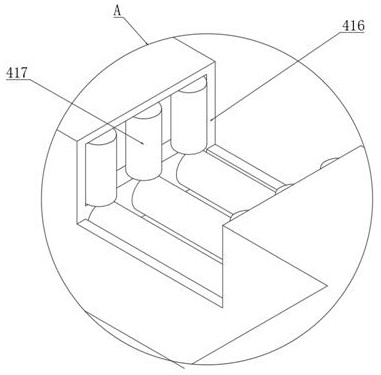

[0044] The conveying mechanism 4 is restricted, and the position of the adjustment plate 414 is adjusted so that the guide roller 415 accurately guides the sausage into the slot 416 , so that the sausage can be exported to the outside of the placement table 301 for processing.

[0045] Including the processing machine body 1, the extrusion movin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com