A multifunctional self-adaptive material guide structure

An adaptive and multi-functional technology, applied in the field of crimping equipment, can solve the problems of high energy consumption and easily damaged materials, and achieve the effects of high adaptability, stability and reliability, crimping quality and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with specific examples.

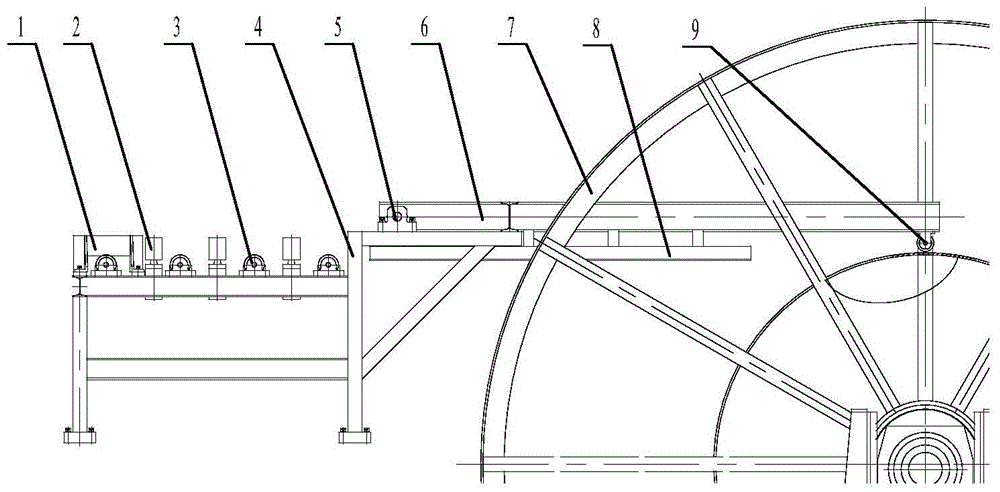

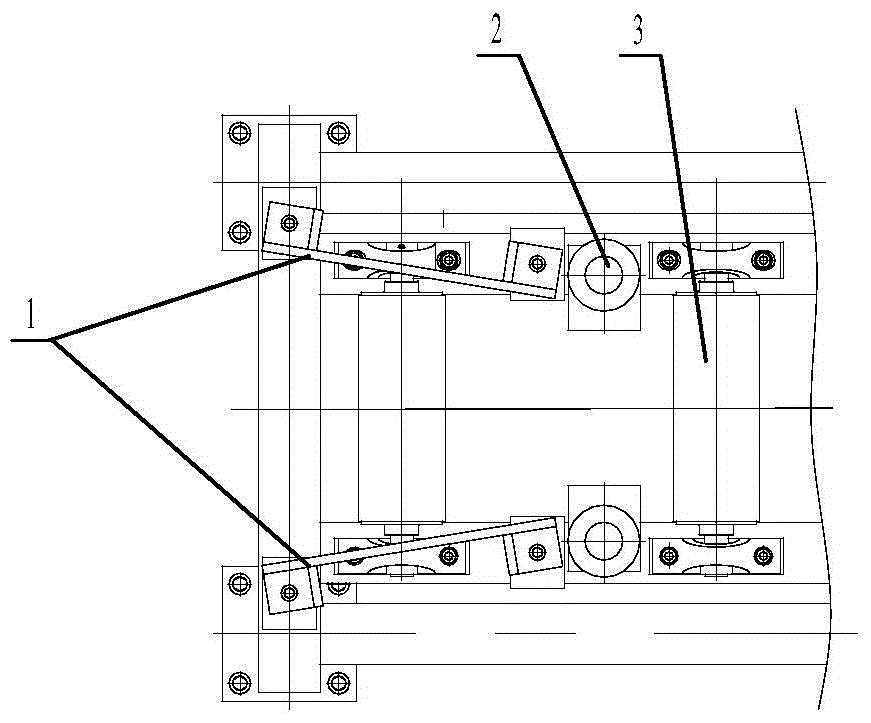

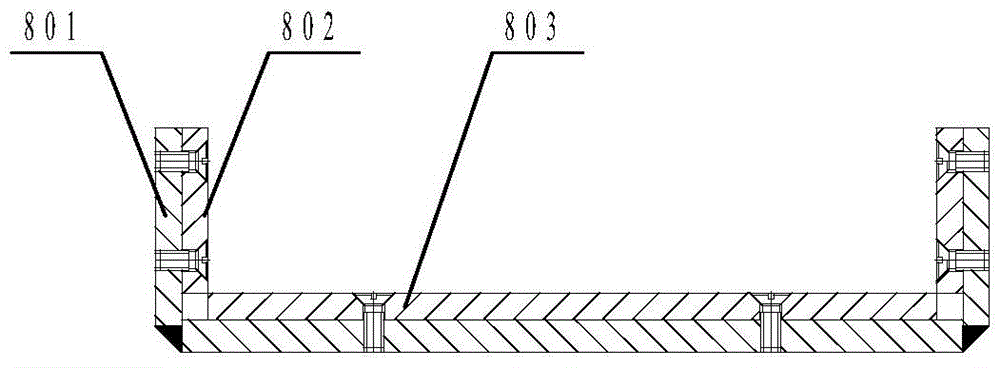

[0014] Such as figure 1 , figure 2 As shown, a multifunctional self-adaptive material guide structure includes a frame 4, the frame 4 is installed on the feeding side of the reel 7, and the side guide plate 1 is connected to the both sides of the feeding port of the frame 4, and the side The side of the frame 4 behind the guide plate 1 is connected with a side roller 2, and the middle part of the frame 4 is connected with a horizontal guide roller 3 along the moving direction of the material to be rolled, and the discharge port of the frame 4 is connected with a hinge shaft 5, and the hinge The shaft 5 is connected with one end of the cantilever 6, and the other end of the cantilever 6 extends into the winding groove of the reel 7, the guide groove 8 is connected under the cantilever 6, the bottom of the cantilever 6 is connected with the pressure roller 9, and the pressure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com