Integrated-rod type sugarcane harvester

A harvester and rod-type technology, applied in the field of agricultural machinery and whole-rod sugarcane harvesters, can solve the problems of increasing the wheelbase of the front and rear wheels, unable to divide the sugarcane, unreasonable structure, etc., and achieves a small turning radius and a stable center of gravity. , flexible effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0016] detailed description: The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

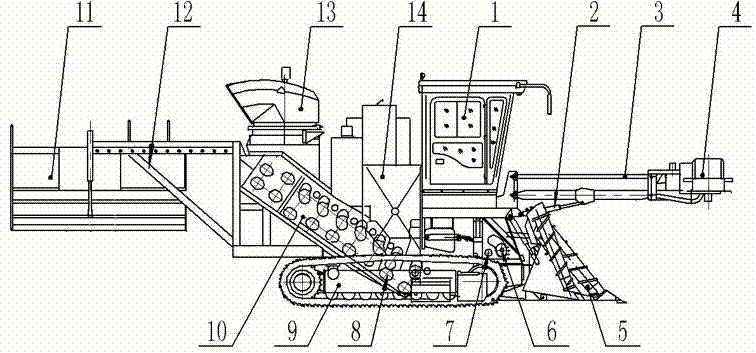

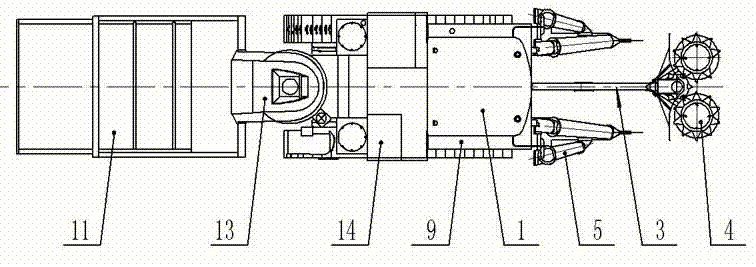

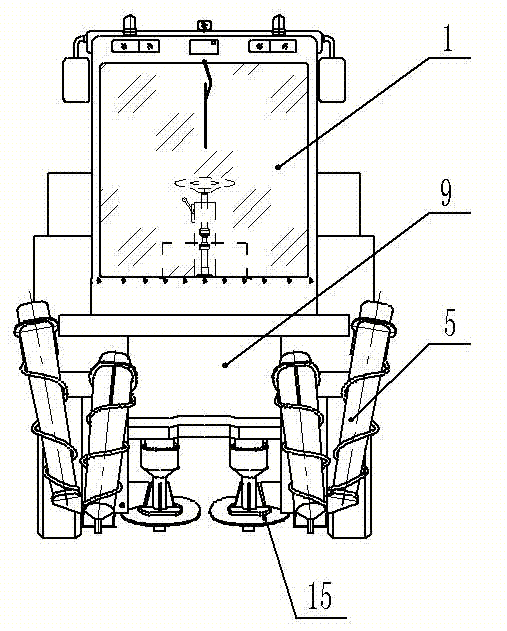

[0017] Such as Figure 1-7 Shown: crawler belt traveling mechanism, engine 14 and driver's cab 1 are fixed on the frame 9; Two cutting slightly cutterheads 4, oil cylinder 2 hinged between frame 9 and support 3 constitute; Oil cylinder 2 can promote support 3 to drive cutting slightly cutterhead 4 to do on-line motion, to adapt to sugarcane slightly of different heights. Below the cutting device are two sets of propping devices which are arranged on the left and right sides of the front end of the frame 9, respectively. It is distributed in a V shape; the helix of the helical roller 5 on the outside in the left-hand support device is left-handed, the helix of the helical roller 5 on the inside is right-handed, and the helix of the helical roller 5 on the outside in the right-hand support device The helix of 5 is right-handed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com