Moisturizing device of wire drawing machine

A wire drawing machine and moisturizing technology, applied in the direction of wire drawing dies, etc., can solve the problems of reducing the service life of wire drawing dies, affecting the quality of steel wire products, affecting the lubrication effect, etc., and achieving the effect of saving manpower, ingenious design and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

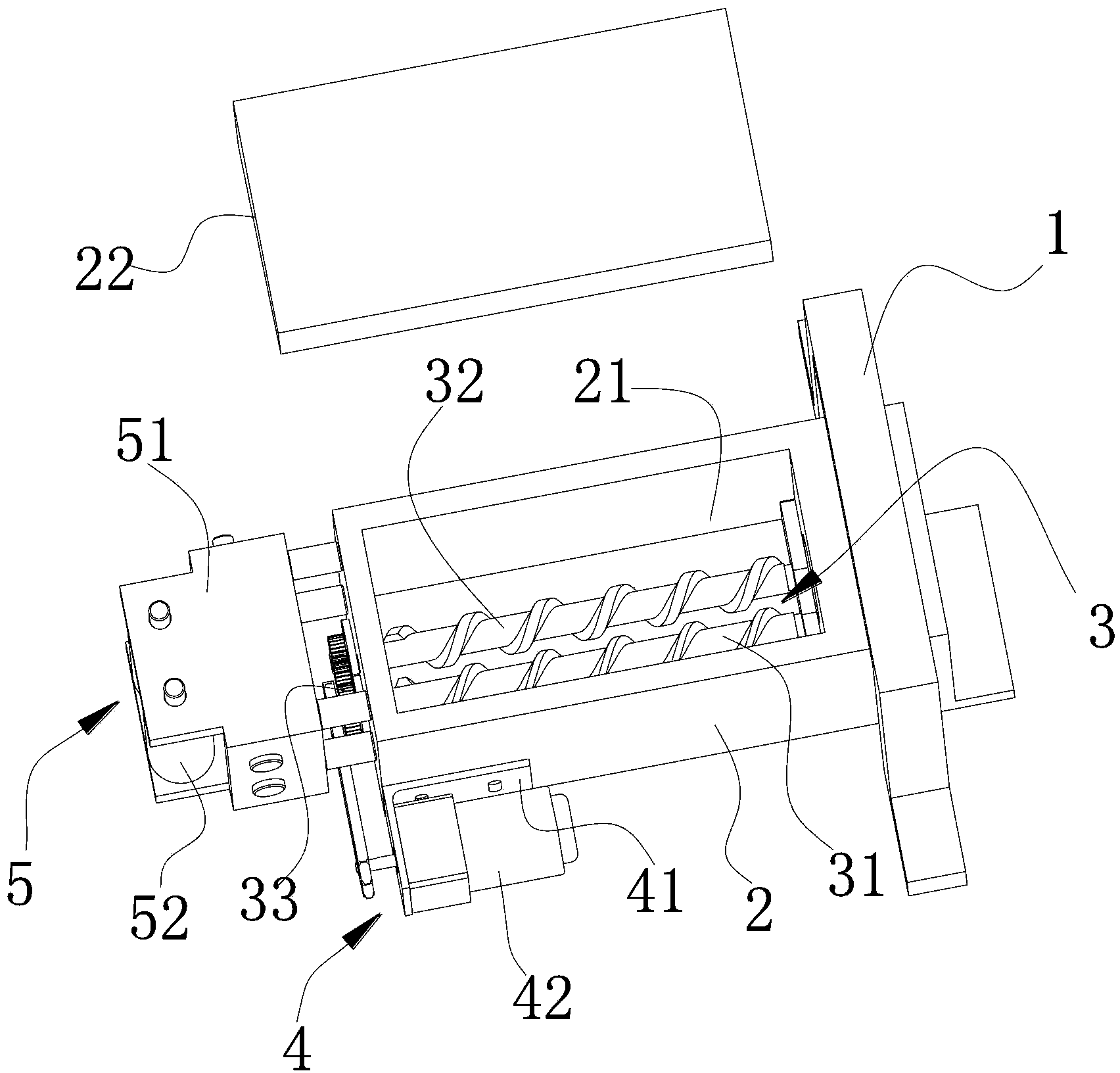

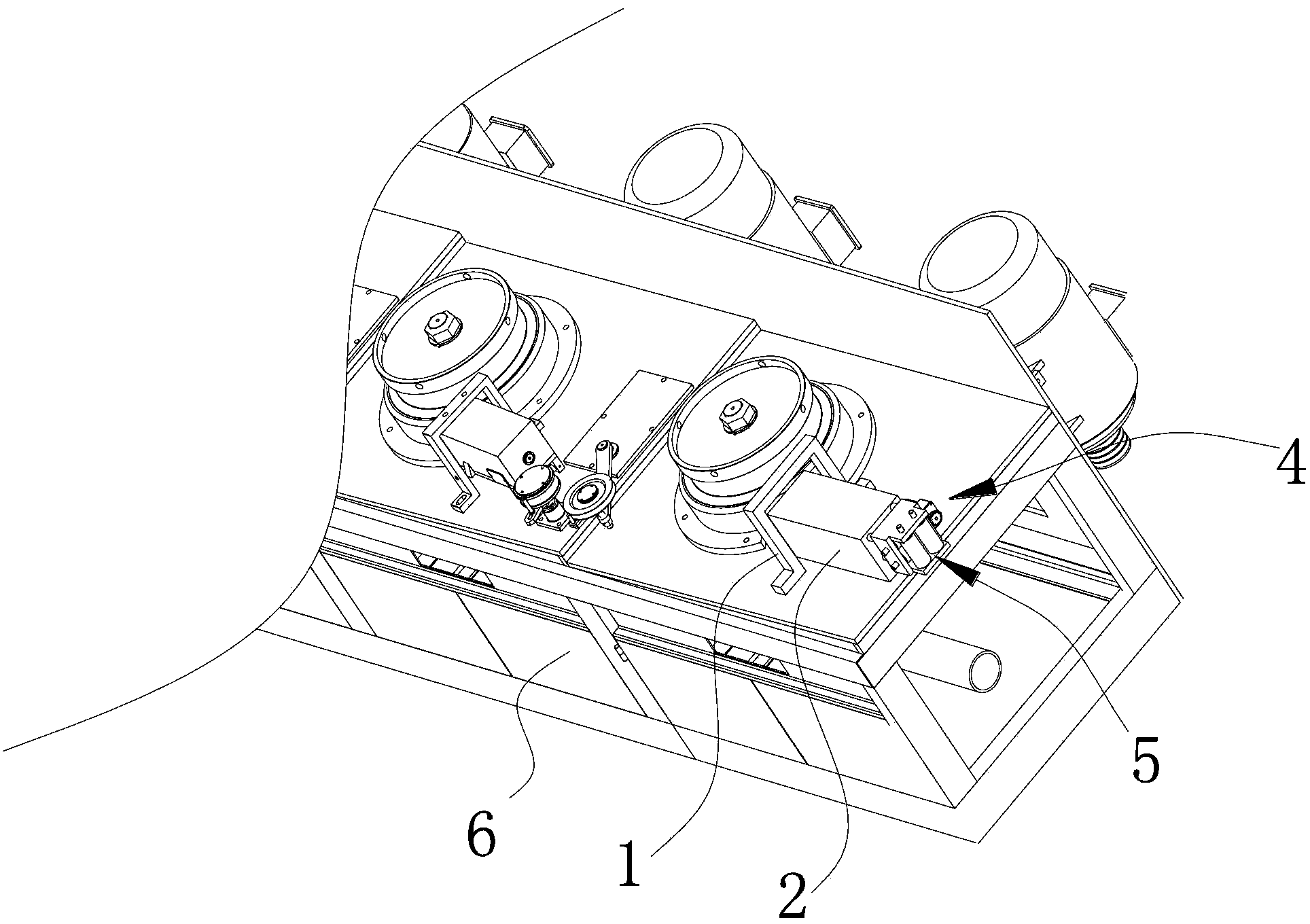

[0020] see figure 1 and figure 2 , a wire drawing machine moisturizing device provided in this embodiment, which includes a gantry bracket 1, a wire passing box 2 provided with a lubricating chamber 21, and a dustproof cover 22 adapted to the wire passing box 2 , the wire passing box 2 is installed on the wire drawing machine 6 through the gantry bracket 1; the dust cover 22 is covered on the wire passing box 2 to prevent the lubricating powder from scattering during stirring, so as not to cause waste and pollute the air. The wire passing box 2 is provided with a wire hole for the steel wire to pass through the lubricating cavity 21, and a pair of stirring mechanisms are arranged in the lubricating cavity 21 of the wire passing box 2 corresponding to the position where the steel wire passes through. 3. A driving device 4 for driving the counter-stirring mechanism 3 is provided on the side wall of the wire passing box 2 . The design is ingenious, the structure is reasonable...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com