Transformer tap changer tool for taking oil sample

A technology for tap changers and transformers, applied in transformers, variable transformers, electric switches, etc., can solve problems such as oil sample pollution, failure to reflect the real situation of tap changer oil quality, and difficulty in controlling the direction of insulating oil outflow, etc., to achieve The effect of reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

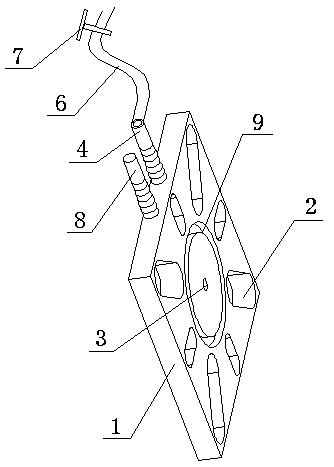

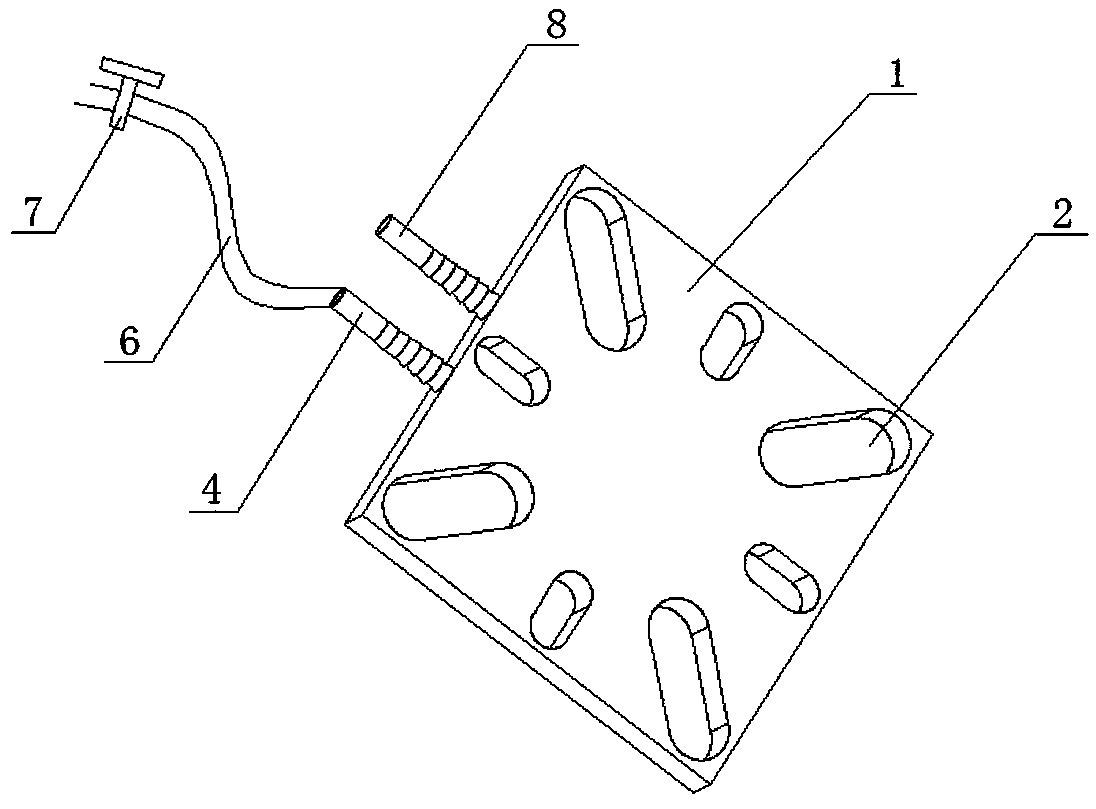

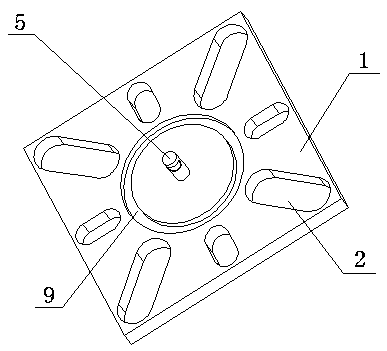

[0029] Such as Figure 1 to Figure 5 Shown is a first embodiment of a transformer tap changer tool for taking oil samples of the present invention, including a bottom plate 1, a connection structure for connecting an oil discharge pipe, a drainage structure and a drainage structure, the connection structure and the drainage structure are both It is arranged on the bottom plate 1, and the drainage structure is connected with the drainage structure. Such as Figure 1 to Figure 5 As shown, the structure of the bottom plate 1 in this embodiment is a quadrilateral structure, the thickness of the bottom plate 1 is between 3 and 12 mm, and the area of the connecting surface of the bottom plate 1 is 300 to 25000 mm 2 between.

[0030] The drainage structure of the present invention has a kind, and a kind of drainage structure comprises drainage hole 3, drainage tube 4 and drainage nozzle 5, and drainage hole 3 is arranged on the bottom plate 1, and drainage nozzle 5 is connected w...

Embodiment 2

[0039] This embodiment is similar to Embodiment 1, the difference is that in this embodiment, the drainage nozzle 5 and the dustproof cap are connected by a buckle, and the setting of the buckle enables quick connection between the dustproof cap and the drainage nozzle 5 or disassembled.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Area | aaaaa | aaaaa |

| Cross-sectional area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com