Bead embroidering mechanism of embroidering machine

An embroidery machine and bead embroidery technology, which is applied to the mechanism of the embroidery machine, the embroidery machine, the embroidery machine with automatic control, etc., can solve the problems of low integration, instability, and influence on the work efficiency and stability of the embroidery machine, etc. , to achieve the effect of improving the efficiency of embroidery beads, improving the practicability, and stabilizing the bead body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

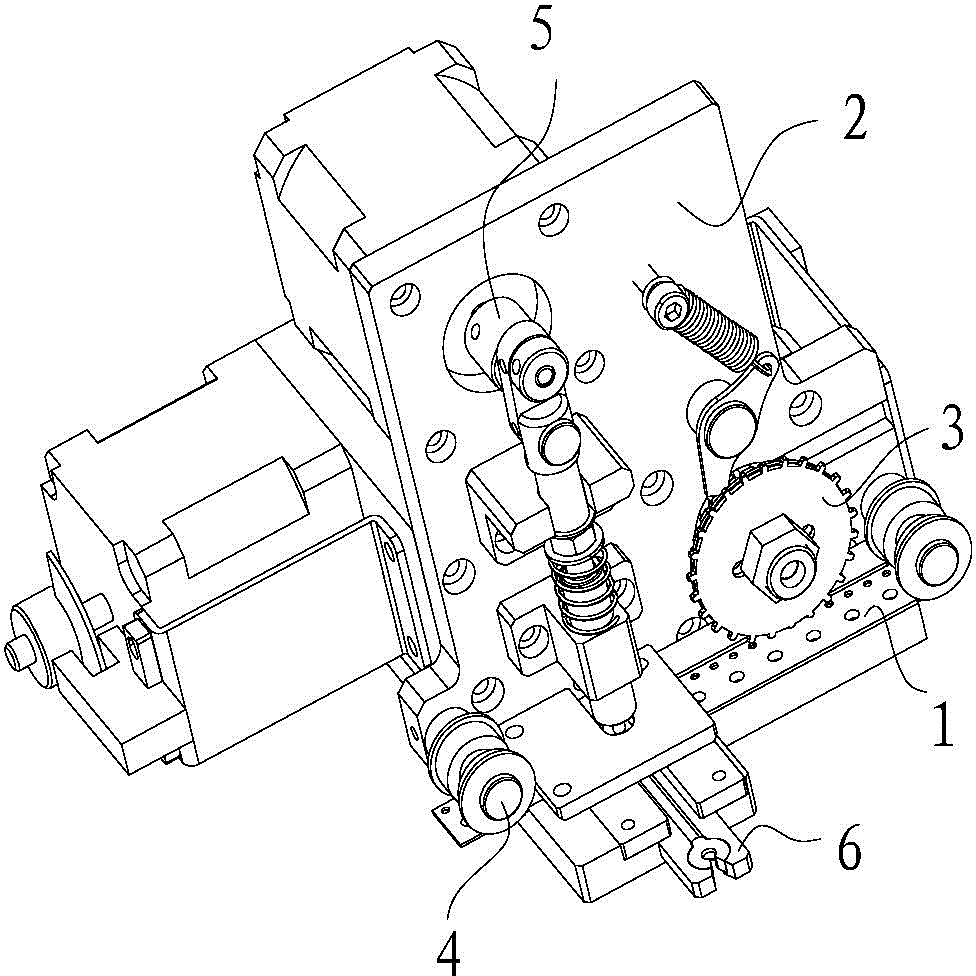

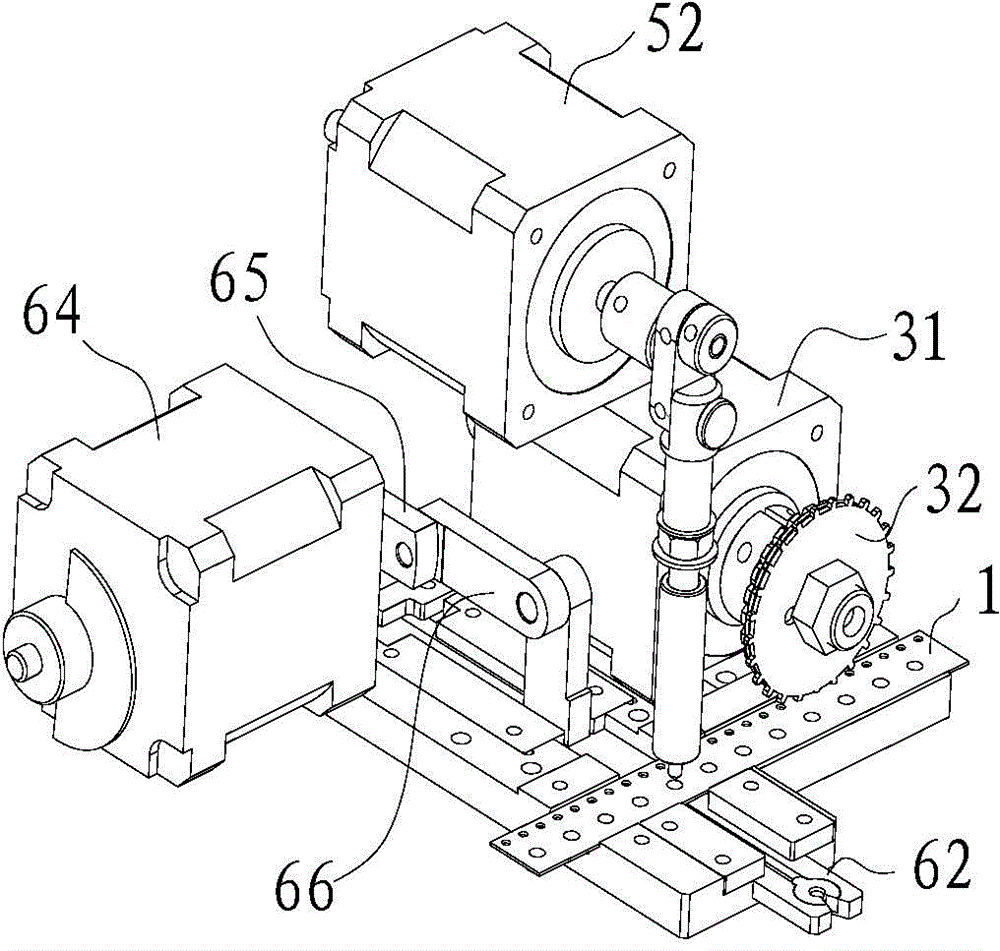

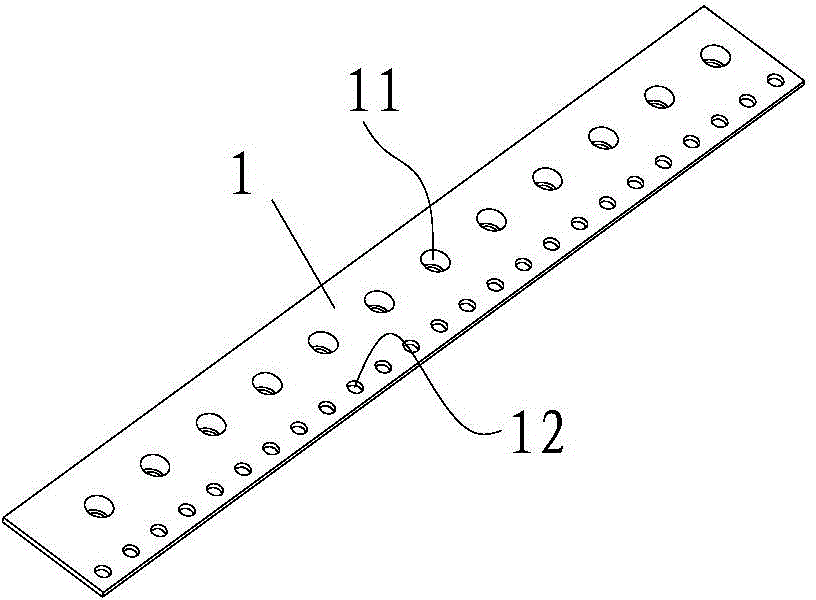

[0045] see figure 1 , figure 2 , Figure 5 , Image 6 and Figure 10 As shown, it is the bead embroidery mechanism of the embroidery machine of the present invention, including the material belt 1, the support 2, the first power unit, the pushing device 5, and the feeding device 6; Arranged and used to place the mounting position of the beads; the first power device is used to drive the material belt 1 to move along its own length; the bracket 2 is provided with a blanking station located on one side of the material belt 1; the pushing device 5 is installed on the On the bracket 2, the pushing device 5 includes a pushing head 51 and a second power device that drives the pushing head 51 to move the beads in the installation position to the blanking station; the feeding device 6 includes a The clamping body 62 of the beads of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com