360-degree omnibearing additional towel embroidery device

A towel embroidery, all-round technology, applied in auxiliary devices, embroidery machines, embroidery machine mechanisms, etc., can solve the problems of unsatisfactory towel stitch decoration effect, requirements on the direction of patterns, etc., to improve the added value of products, manufacturing Low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

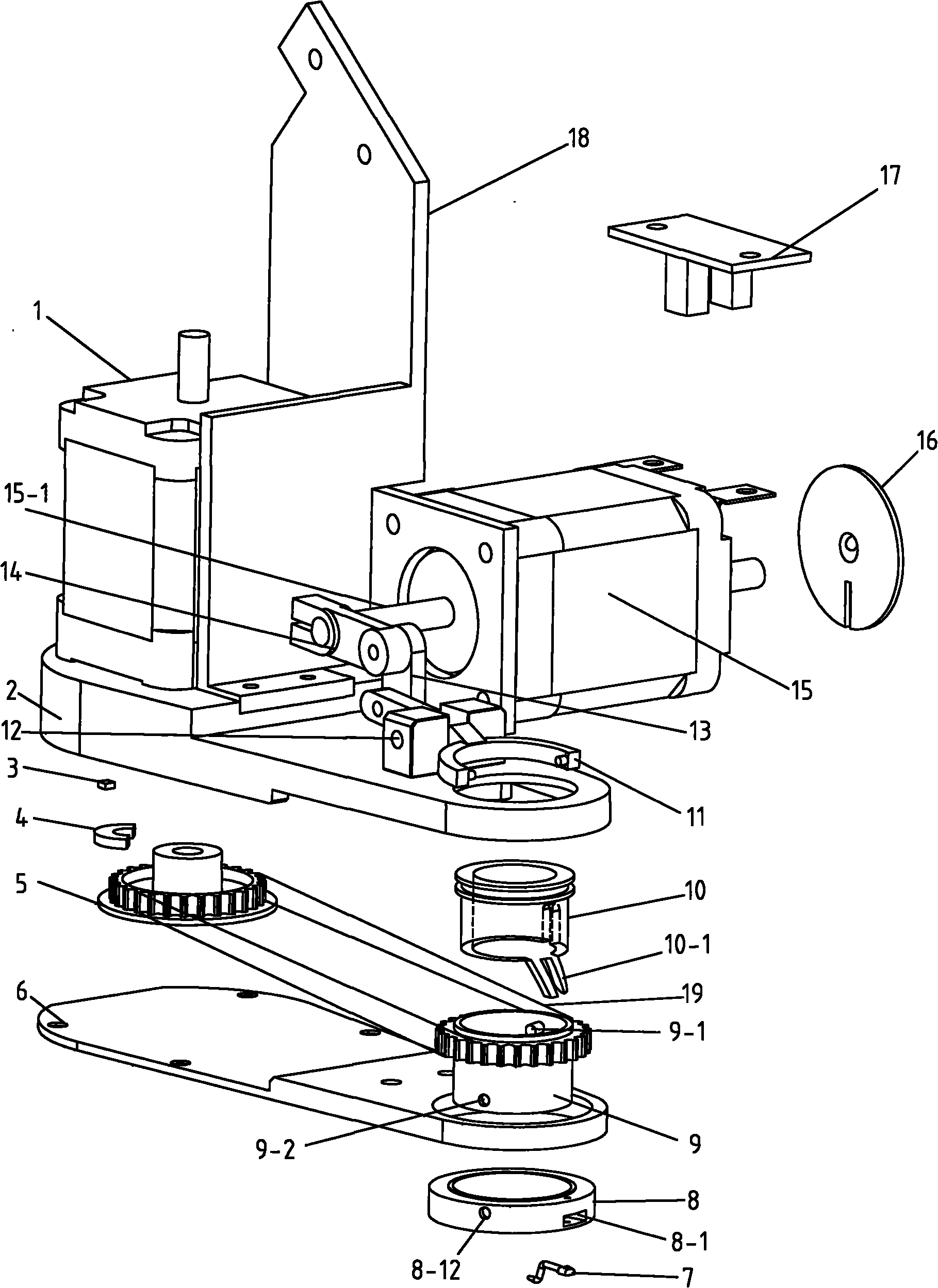

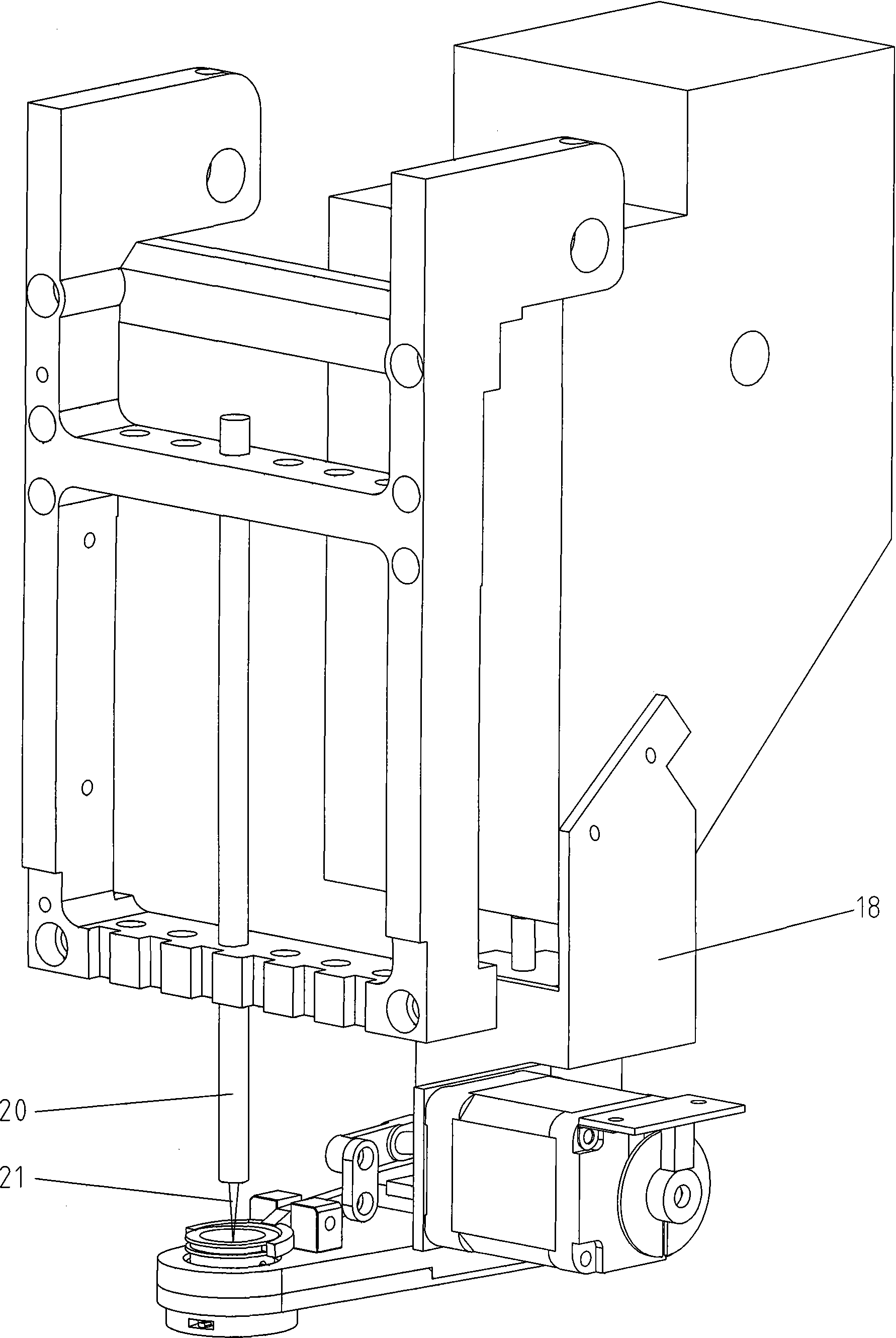

[0027] As shown in the figure, a 360-degree all-round additional towel embroidery device includes a frame 2; a towel lever 7 that can rotate around a vertical axis, a combination sleeve that is installed with the towel lever, and a driving combination The vertical motion mechanism for the vertical reciprocating movement of the sleeve and the rotation mechanism for driving the combined sleeve to rotate around the vertical axis.

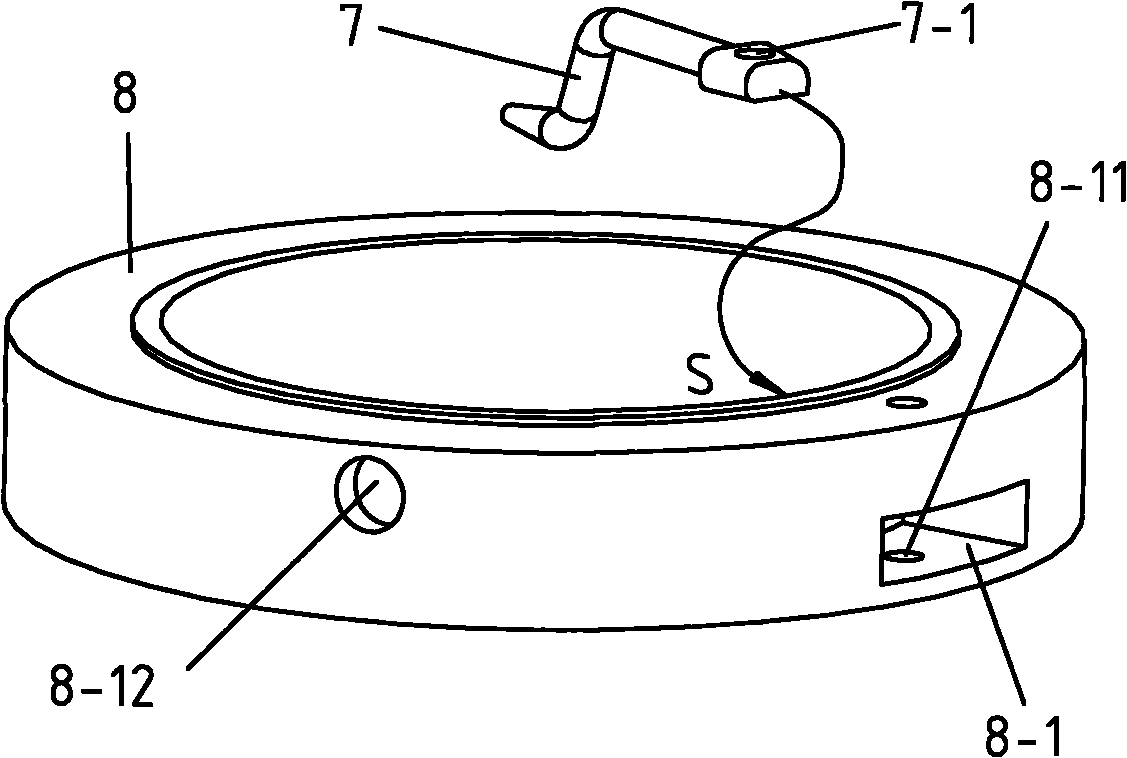

[0028] The fixed ring 8 of the driving rod is sequentially set in the combined sleeve from bottom to top, and the bottom end is inserted into the fixed ring to be hinged with the fixed ring (the hinge point 9-2 of the towel synchronous wheel, the hinge point 8-2 of the fixed ring 12) and the outer peripheral surface is shaped on the tubular towel synchronous wheel 9 (the towel synchronous wheel 9 is inserted in the positioning hole on the frame bottom plate 6, and is supported by the frame bottom plate to realize rotatable positioning) with meshing teet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com