Novel multi-station jacquard needle control device of knitting machinery

A control device and jacquard needle technology, which is applied in knitting, weft knitting, textiles and papermaking, etc., can solve the problems of limited machine speed, jacquard needles not ejected, and production decline, so as to make up for speed limitations and stability. The effect of precise radial and axial movement and light machine running resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

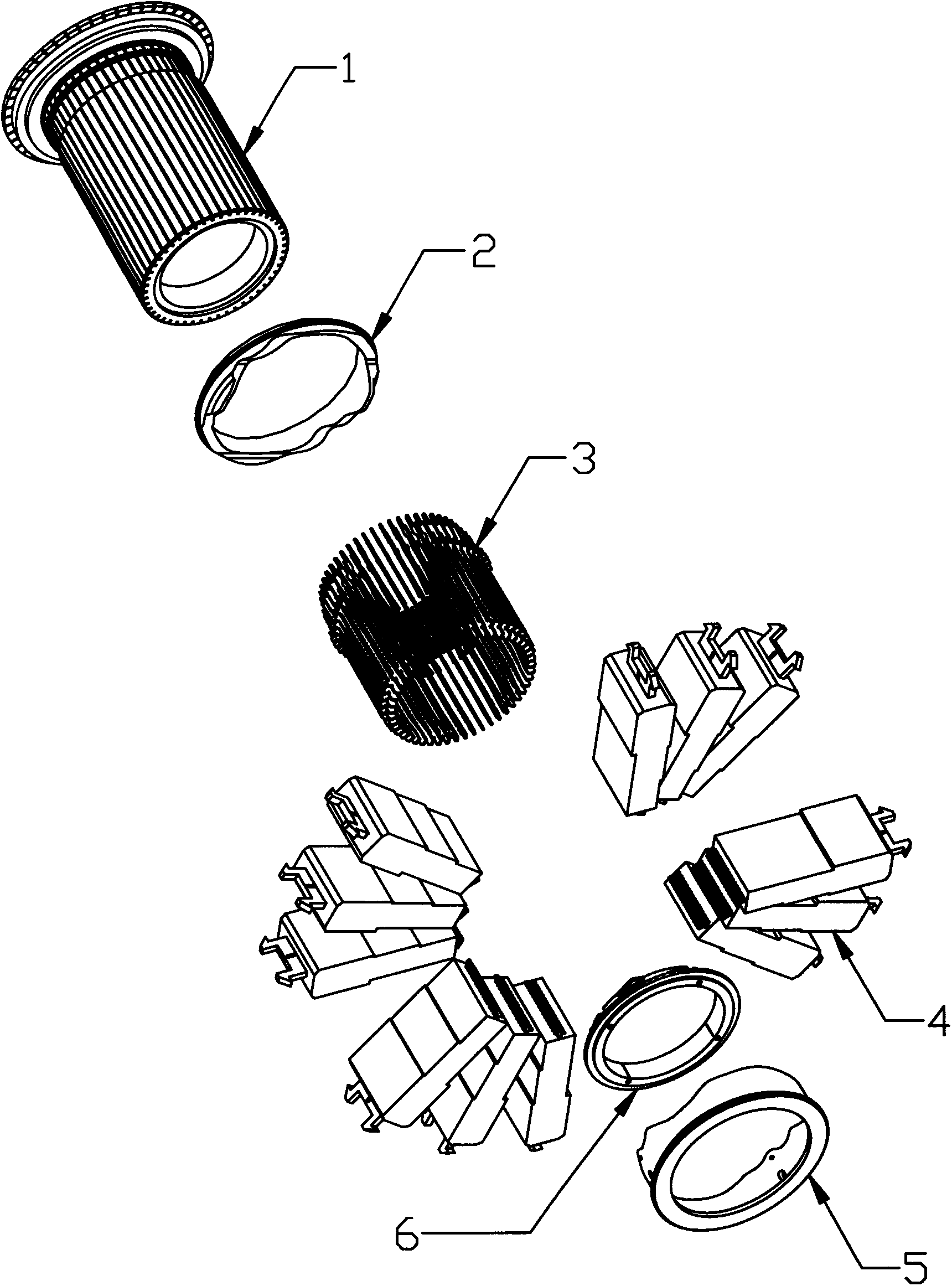

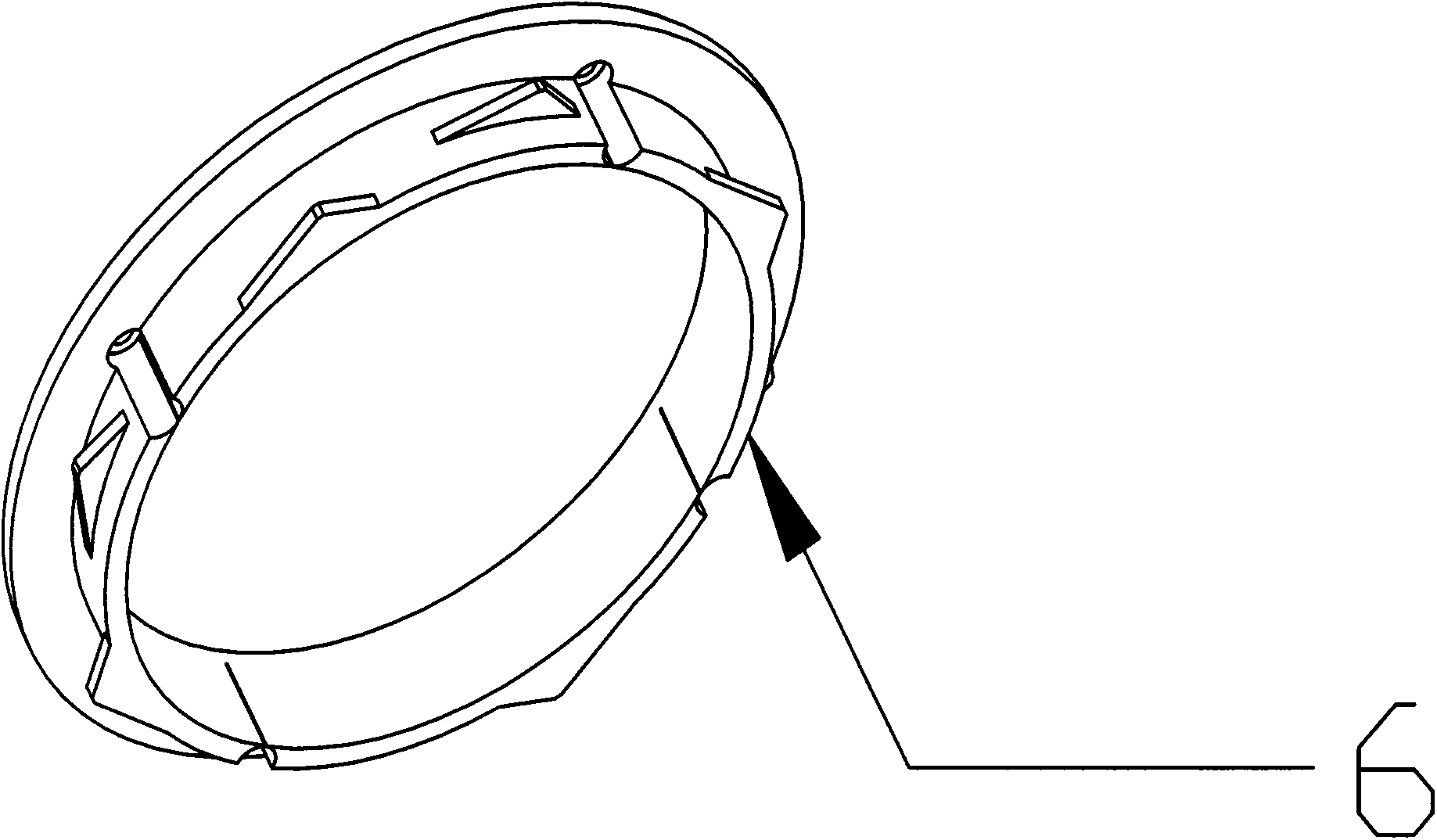

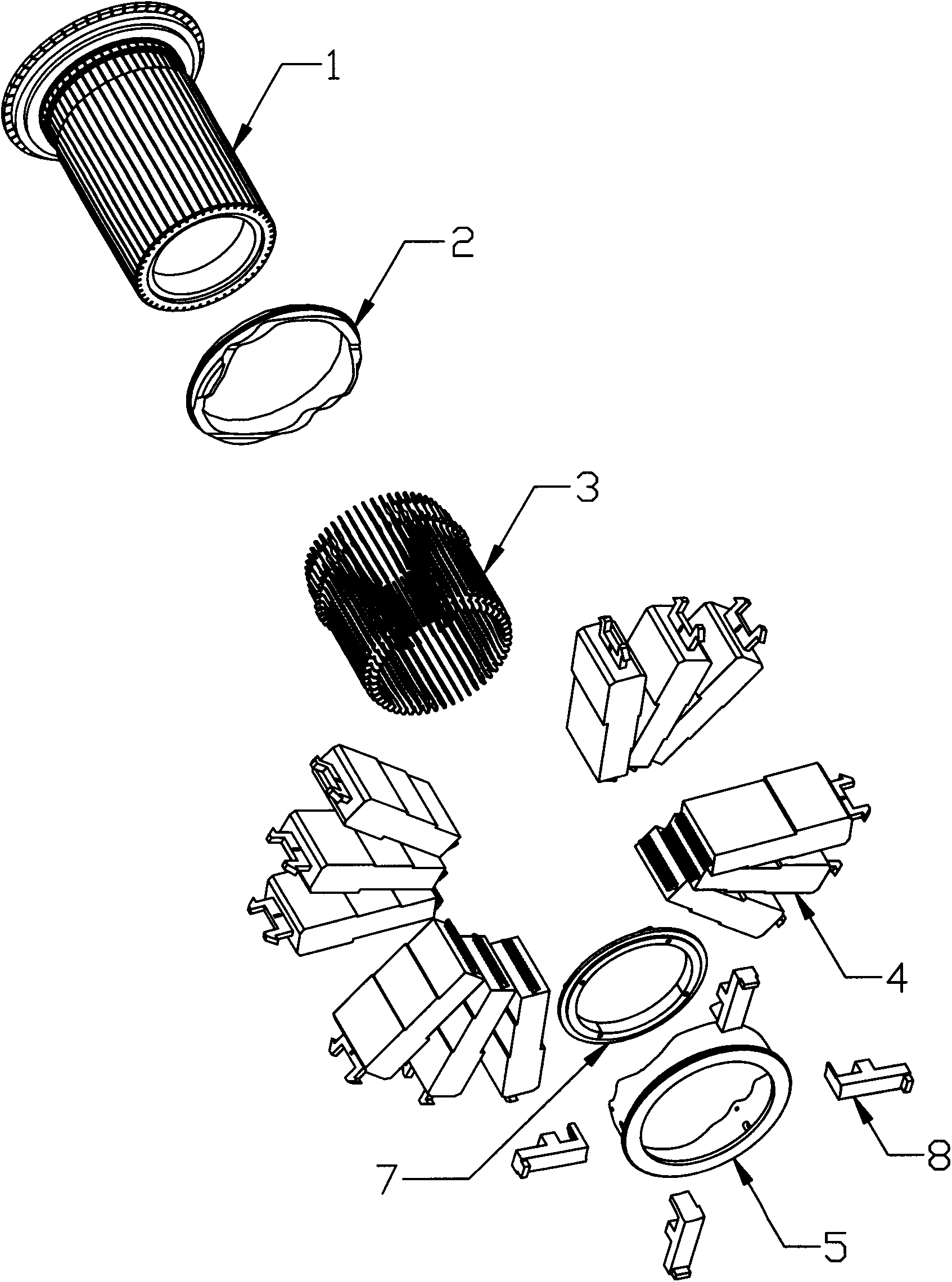

[0021] A new type of multi-station jacquard needle control device for knitting machines, comprising an upper steel ring 2, a lower steel ring 5, a pull-down head, a needle cylinder 1, a needle selector 4 and a jacquard needle 3, and the jacquard needle 3 is placed in the needle cylinder 1 Axial reciprocating movement is made in the axial groove on the outer wall, the upper steel ring 2 is fixed on the upper part of the syringe 1, the upper steel ring 2 is concentric with the syringe 1, the lower steel ring 5 is fixed on the lower part of the syringe 1, and the lower steel ring 5 Concentric with the needle cylinder 1, each needle selector 4 is a group of three, a total of four sets of needle selectors 4 are evenly distributed and fixed on the periphery of the lower steel ring 5, and the center circle formed by the fixing hole for installing the needle selector 4 is in line with the The lower steel ring 5 is concentric, and the jacquard needles 3 are evenly distributed in the axi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com