Dropped stitch prevention guide needle block for warp knitting machine

A warp knitting machine anti-yarn guide needle technology, applied in warp knitting, knitting, textiles and papermaking, etc., can solve the problems of limited machine knitting speed, reduced knitting quality, low start-up rate, etc., to reduce the depth of yarn laying , Improve reliability, improve the effect of looping weaving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

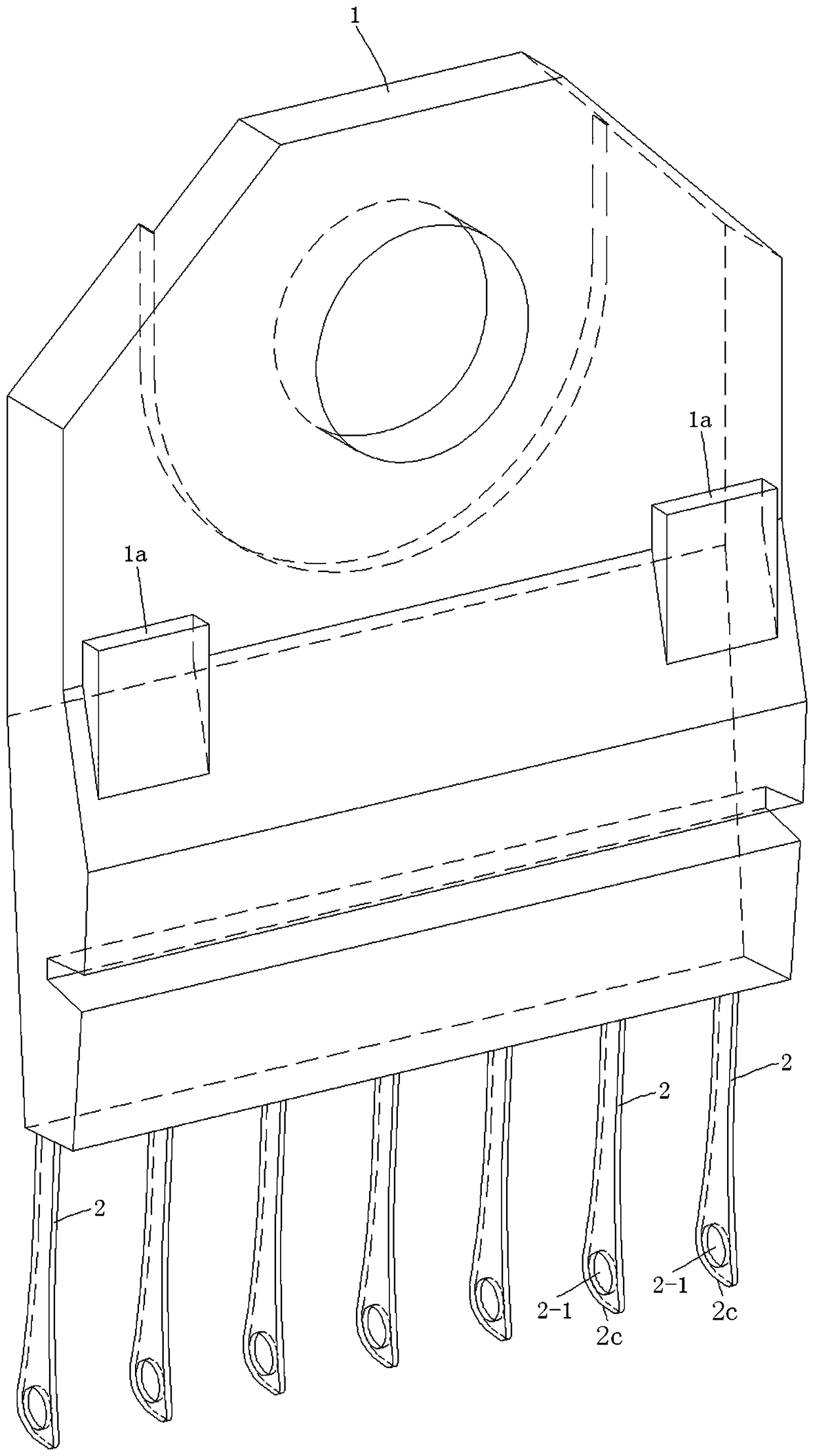

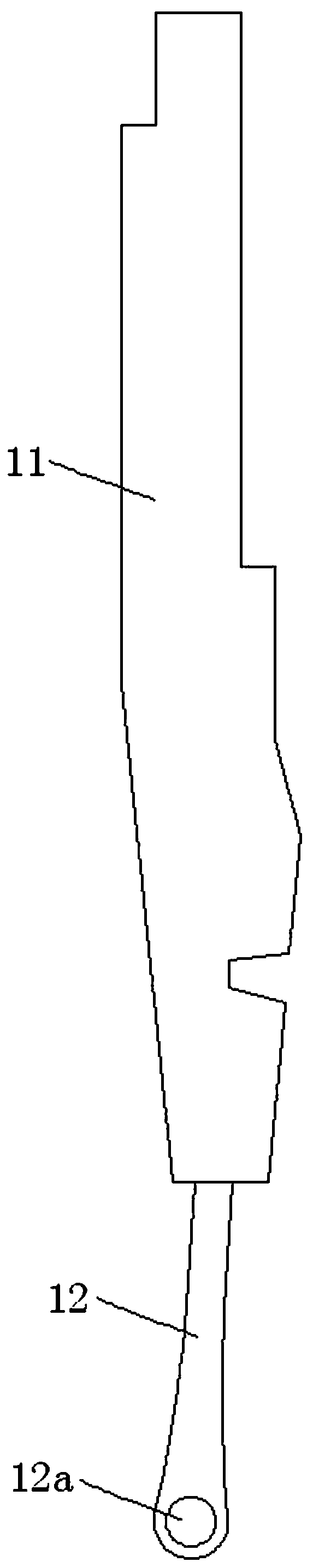

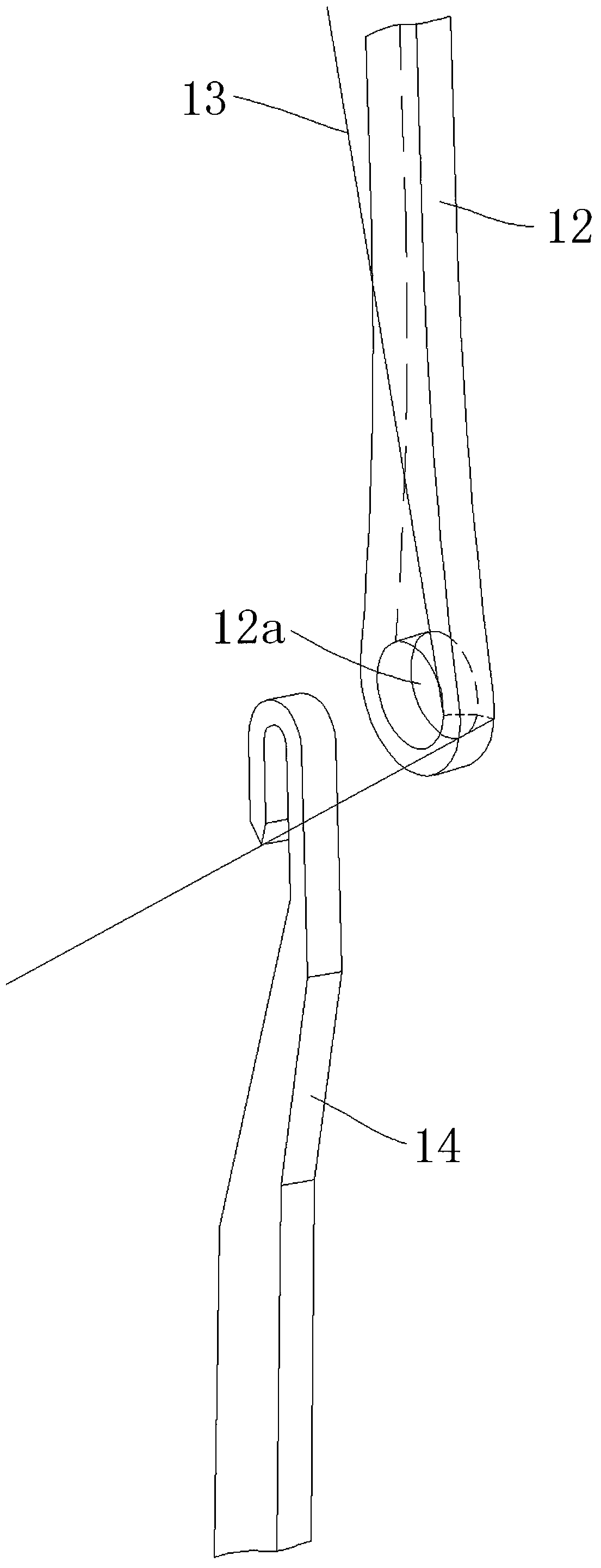

[0026] see Figure 1 to Figure 9 The guide needle block of a leak-proof needle of a warp knitting machine as shown includes a base body 1 and a guide needle 2, the base body 1 adopts a metal part or a plastic part, and the guide needle 2 adopts a metal part such as a steel part. The guide needle 2 is fixedly installed on the base 1 by casting or plugging; the head of the guide needle 2 is provided with a guide hole 2-1 for threading the yarn, and the head of the guide needle 2 There is a groove 2a on the bottom surface of the part, such as image 3 , 4 , 5; or a horizontal surface 2b is provided on the bottom surface of the head of the guide needle 2, as Image 6 shown; or on the bottom surface of the head of the guide needle 2 is provided with a downward slope 2c, as figure 1 , 2 , 8, 9; or the bottom surface of the head of the guide needle 2 is provided with a concave curved surface 2d, such as Figure 7 shown.

[0027] As a preferred embodiment of the present inventi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com