Triangular device used for achieving irregular single-face applique

A triangular, single-sided technology, applied in textiles and papermaking, weft knitting, knitting, etc., can solve the problems of knitting jacquard, drop stitch, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

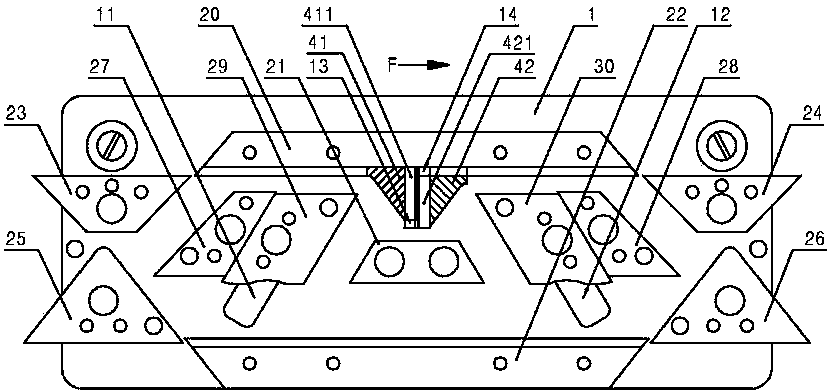

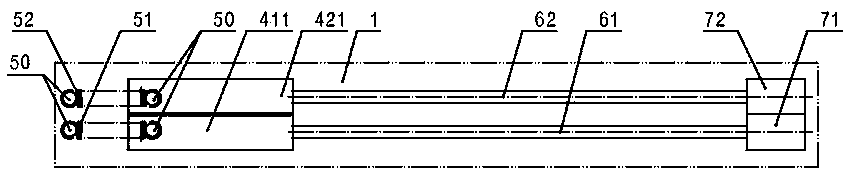

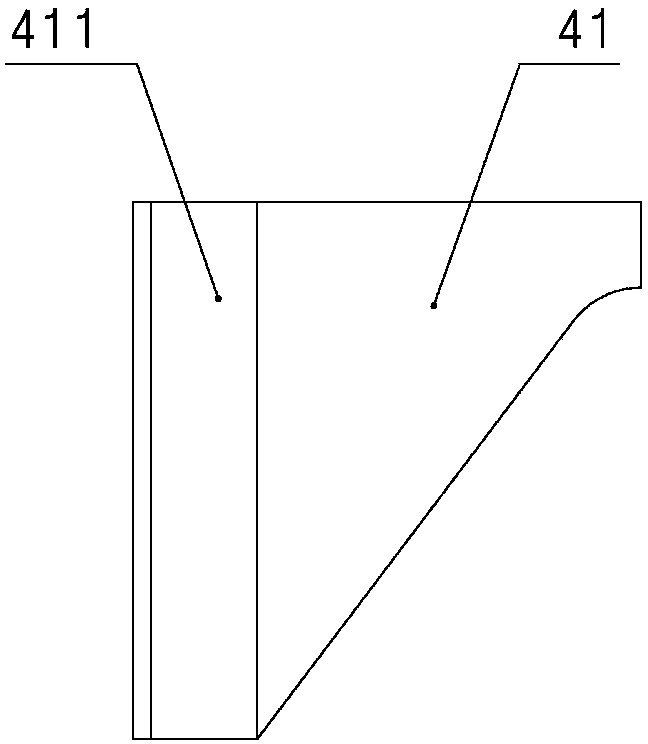

[0019] Such as figure 1 As shown, a cam device for realizing random single-sided intarsia, comprising: a bottom plate 1, a left outer stitching cam 23, a left inner stitching cam 27 and a left Density triangle 29, the right side of the base plate 1 is symmetrically provided with the right outer stitching triangle 24, the right inner stitching triangle 28 and the right density triangle 30 from the outside to the inner axis, that is, the left outer stitching triangle 23 and the right outer stitching triangle 24 Axisymmetric, the needle triangle 27 in the left side is symmetrical to the needle triangle 28 in the right side, the density triangle 29 in the left side is symmetrical to the density triangle 30 in the right side. The left backstitching cam 25 matched with the cam 23 is provided with a right backstitching cam 26 matched with the right outer stitching cam 24 below the right outer stitching cam 24, and the upper and lower sides of the bottom plate 1 are also arranged axia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com