Sewing machine needle distance regulating mechanism

A technology of needle distance adjustment and adjustment mechanism, which is applied in the field of sewing machines, can solve the problems such as the inconvenience of needle distance adjustment, and achieve the effect of improving sewing efficiency and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

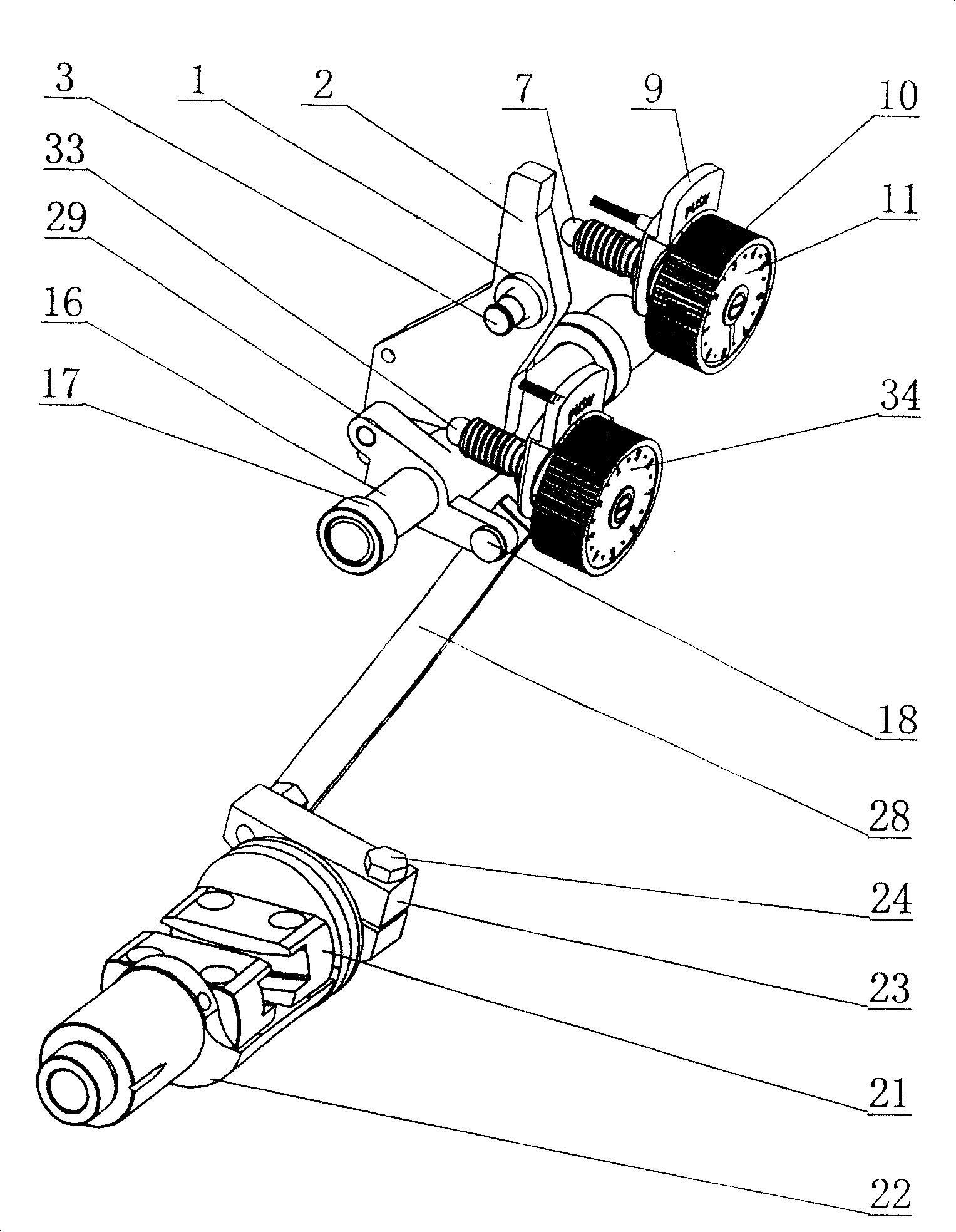

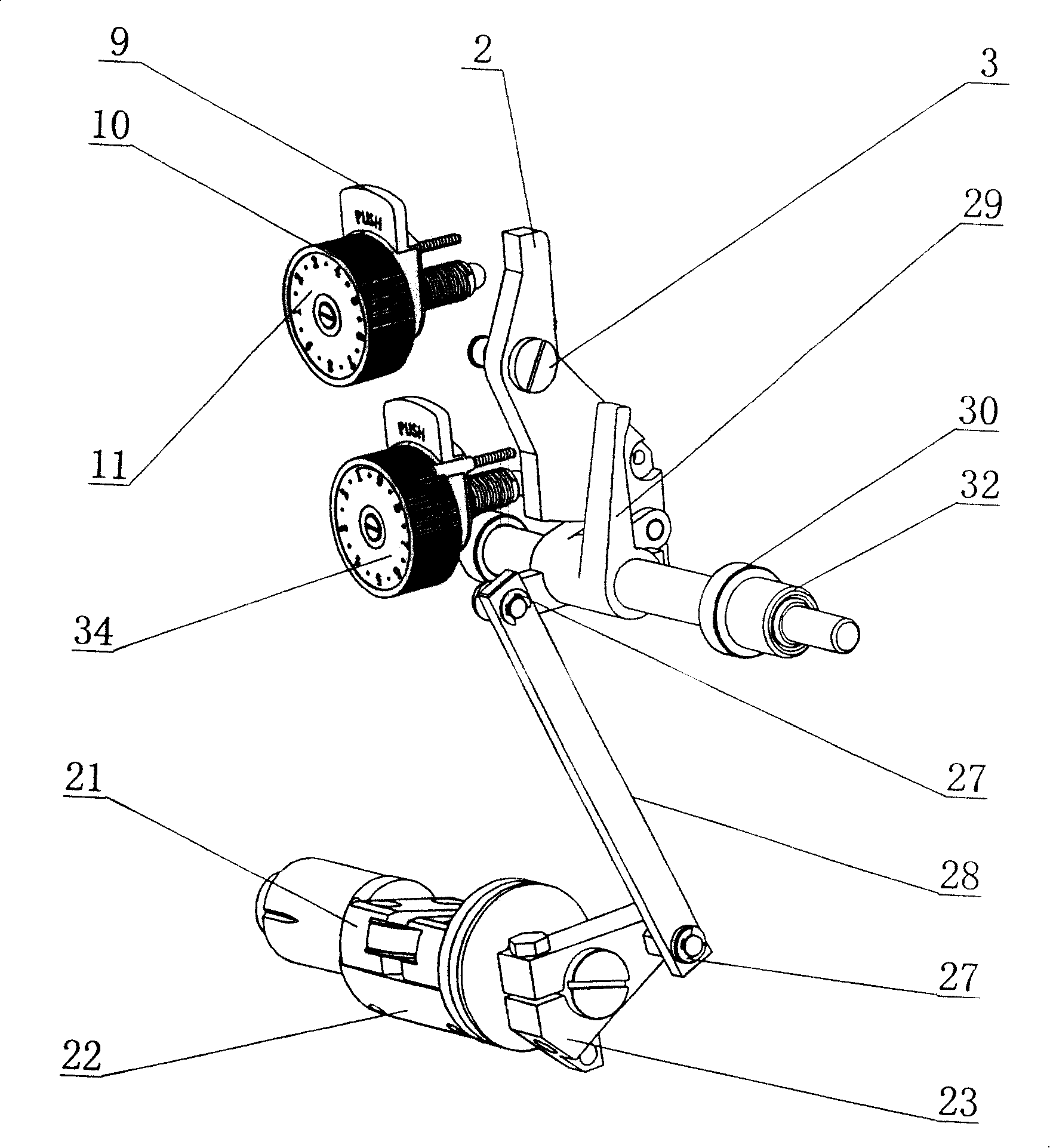

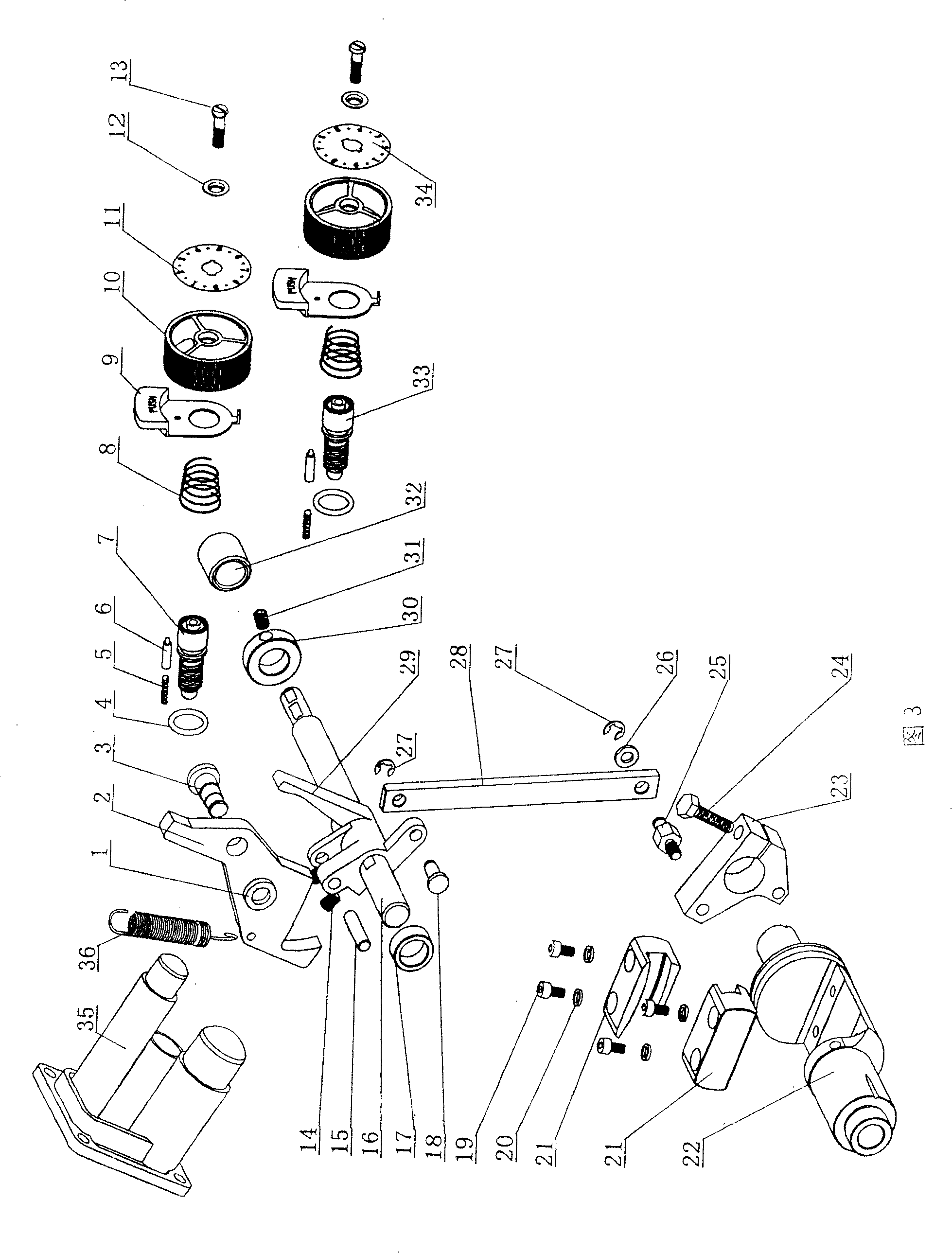

[0027] Such as figure 1 , figure 2 As shown, the stitch length adjustment swing rod 2 is axially fixed on the casing (the casing is not shown in the figure) through the stitch length adjustment swing rod pin 3 and the stitch length adjustment swing rod washer 1 . Backtacking shaft 16 is installed on the casing by backtacking shaft bushing (front) 17 and backtacking shaft bushing (rear) 32, tight ring 30 and tight ring screw 31. As shown in FIG. 3 , the backtack crank (top) 29 is fixed on the backtack shaft 16 by the backtack crank set screw 14 . Back stitching platform 22 is installed on the base plate (base plate is not drawn among the figure), and back stitching crank (down) 23 is connected together with back stitching platform 22 by back stitching crank (down) screw 24.

[0028] The large gauge gauge panel 11 is pasted on the gauge gauge 10, and there is a gauge gauge positioning plate 9 thereafter, and the large gauge gauge panel 11 and the gauge gauge pass through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com