Hemming sewing auxiliary device and hemming sewing method

An auxiliary device and hemming technology, applied in sewing equipment, sewing machine components, textiles and papermaking, etc., can solve problems such as unfavorable work efficiency and complicated procedures, and achieve the effect of improving sewing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Embodiments of the present invention are described in detail below:

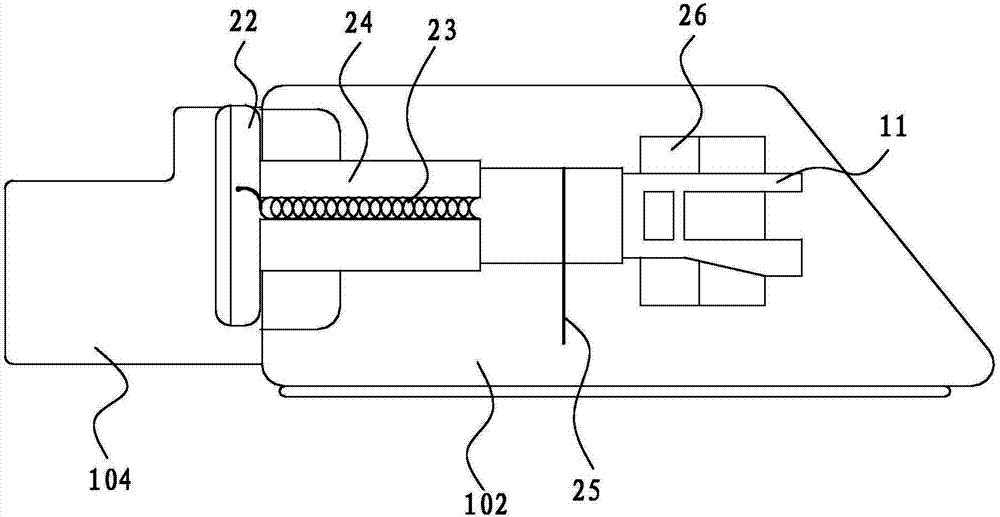

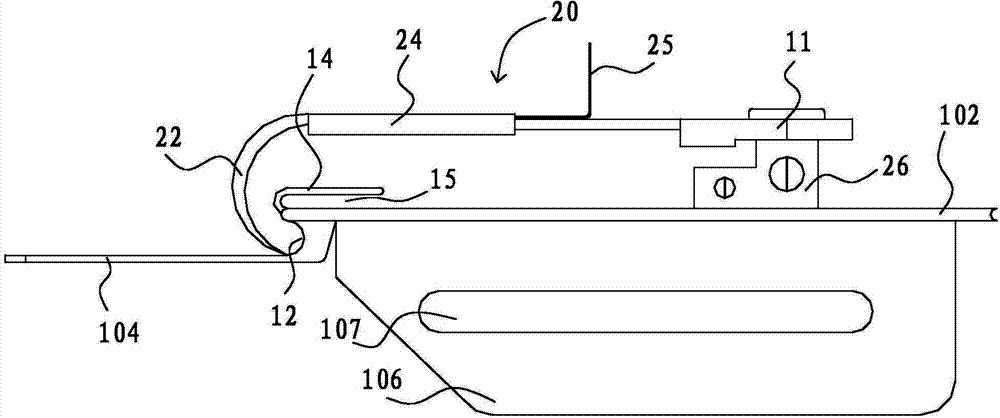

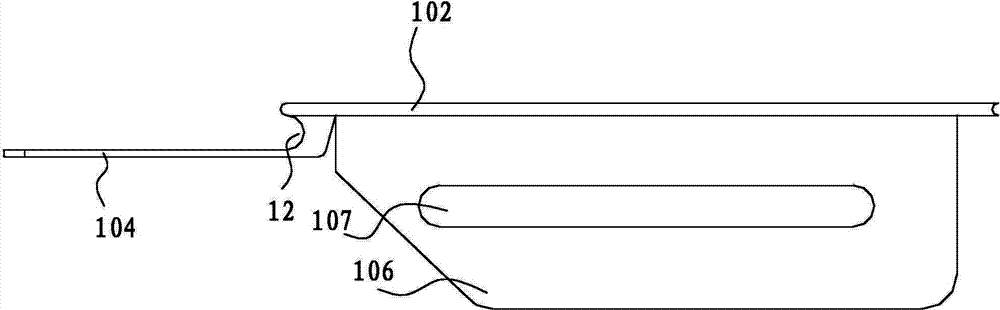

[0029] Such as figure 1 and figure 2 As shown, a hemming sewing auxiliary device includes a base panel 10 and a side mechanism 20; the base panel 10 is provided with a groove 12, and the fixed end 11 of the side mechanism 10 is fixed on the base on the seat panel 10, and the side mechanism 20 can be flipped relative to the base panel 10, and the other end of the side mechanism 10 is provided with a curved side 22 that can be stuck in the groove 12. A paper opening 14 is provided between the groove 12 and the fixed end of the said side mechanism 20, and the paper mouth 14 and the base panel 10 form a strip-shaped accommodation space 15, and the strip-shaped accommodation space 15 The opening faces the fixed end of the side mechanism 20 ; when the side mechanism 20 is overturned so that the curved side 22 matches the groove 12 , the curved side 22 surrounds the outer periphery of the paper mouth side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com