Shoemaking sewing machine

A sewing machine and machine head technology, which is applied in the field of shoemaking sewing machines, can solve problems such as inconsistency, inconvenient operation and control, and affect the appearance of shoes, and achieve the effect of improving sewing efficiency and consistent width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

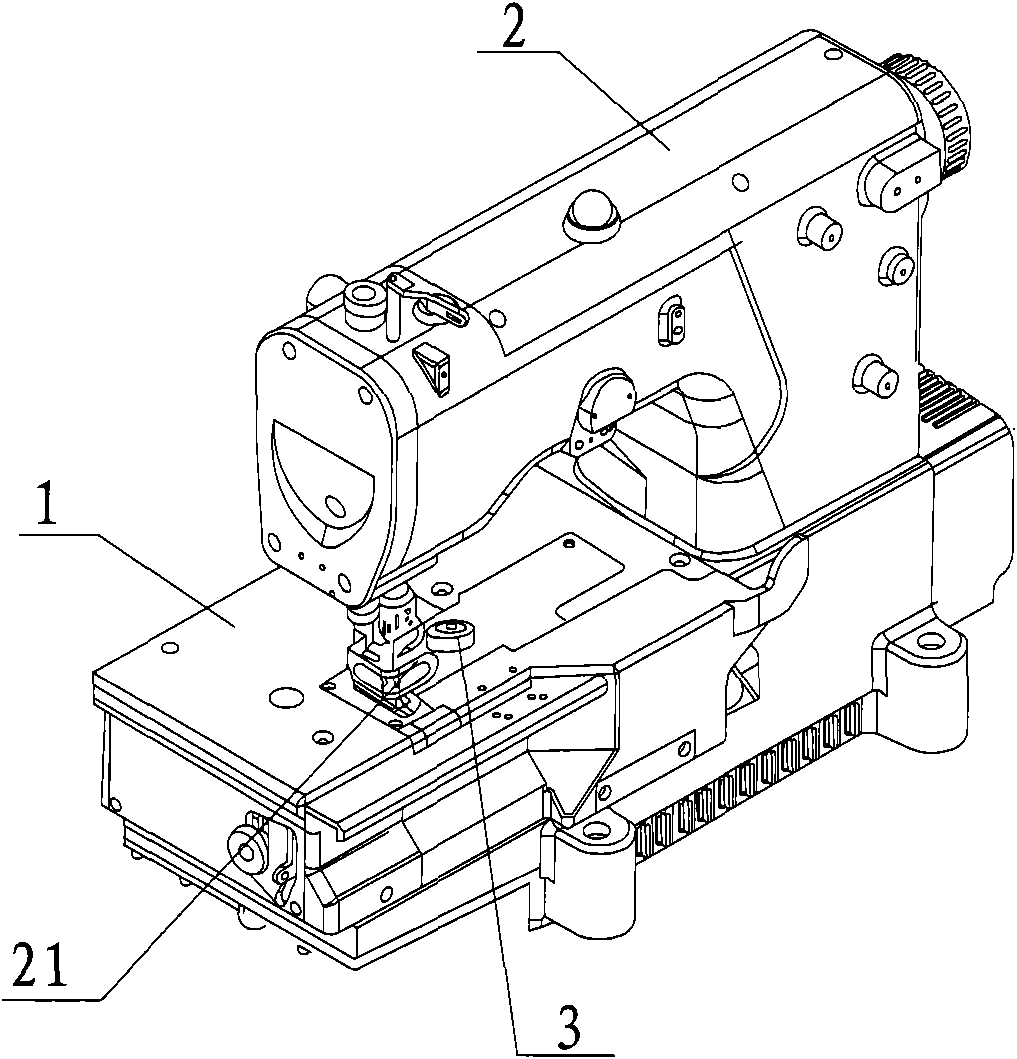

[0010] Such as figure 1 The shown shoe-making sewing machine includes a frame (not shown in the figure), a worktable 1 fixedly arranged on the frame, a machine head 2 installed on the workbench 1, and the machine head 2 includes a sewing needle The presser foot 21 is respectively installed with sewing threads above the machine head 2 and below the work surface 1. When sewing, the upper of the shoe is fitted with the sole at the corresponding place, and the presser foot 21 is pressed on the upper of the shoe upper to drive the sewing machine. Drive mechanism, thereby carry out suturing. The above-mentioned sewing mechanism and its working principle are known technologies, and will not be repeated here.

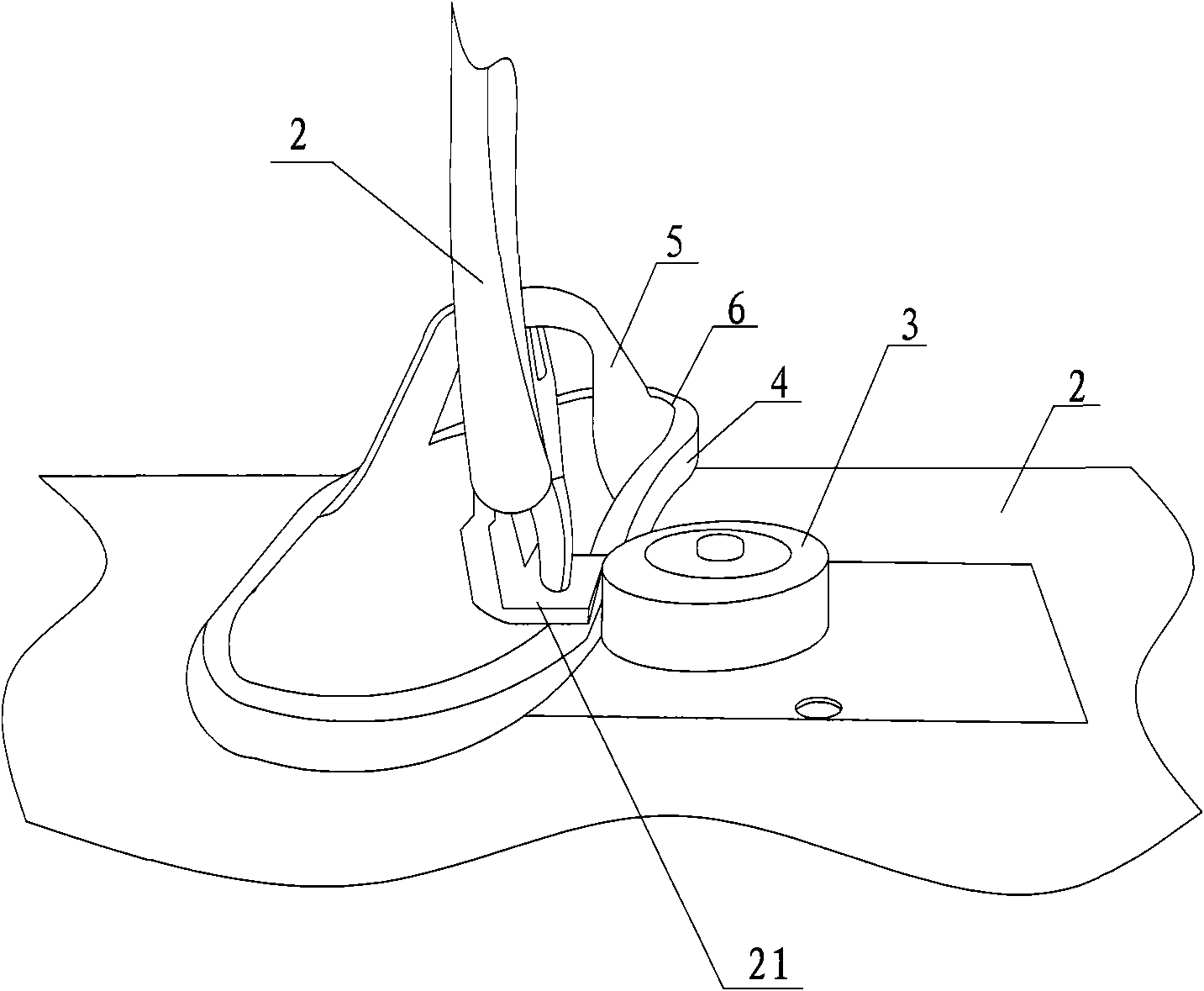

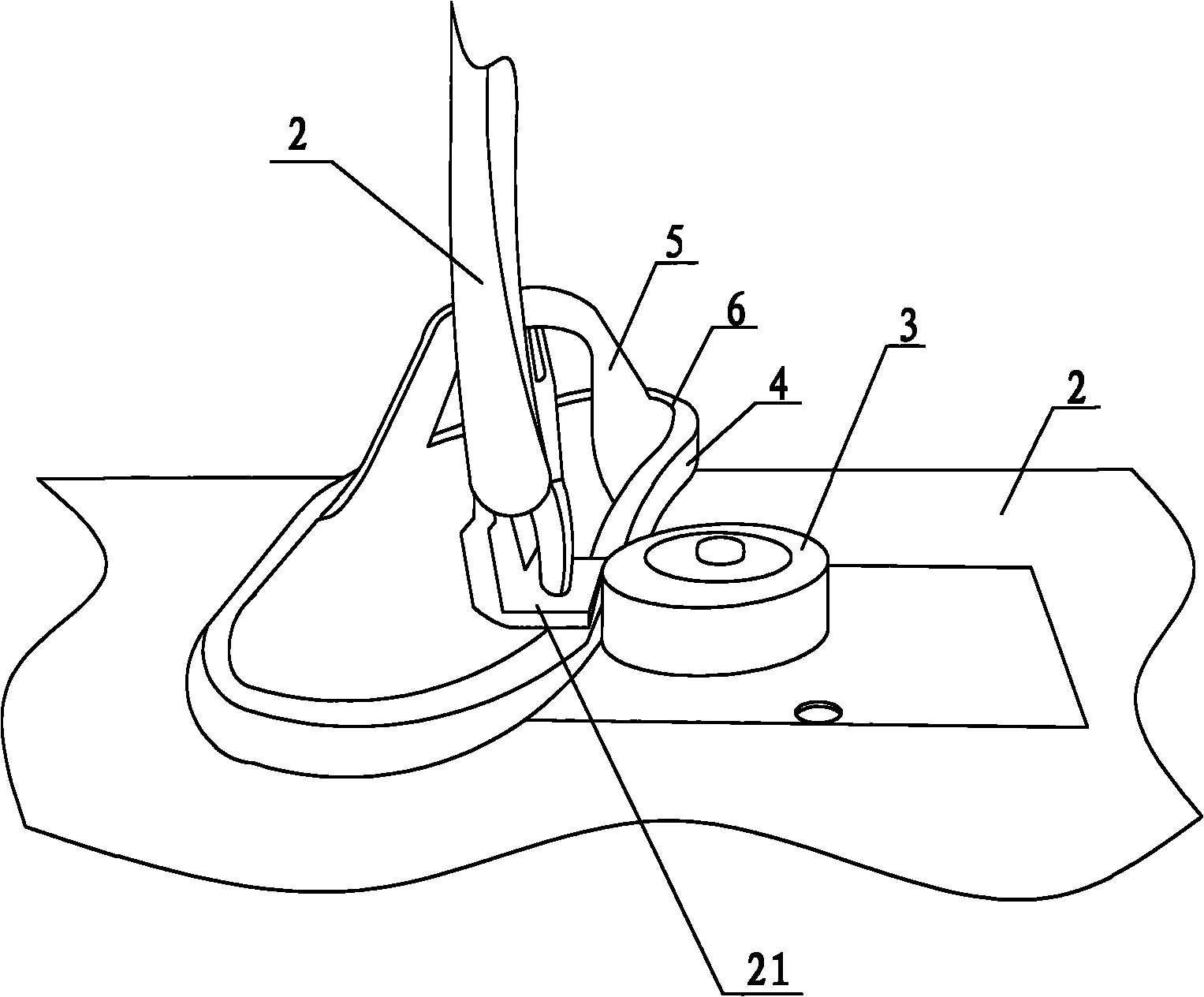

[0011] A fixed column 3 is installed near the inner side of the presser foot 21 on the worktable surface 1, the fixed column 3 can rotate around its axis, and the height of the fixed column 3 can be set between 1 to 3 centimeters.

[0012] figure 2 Shown is a schematic diag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com