Pavement grooving machine

A technology of slotting machine and cutting wheel, which is applied in the direction of roads, roads, road repairs, etc., can solve the problems of large slotting machine, low system pressure, and inappropriateness, so as to avoid personal health, increase system pressure, reduce The effect of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

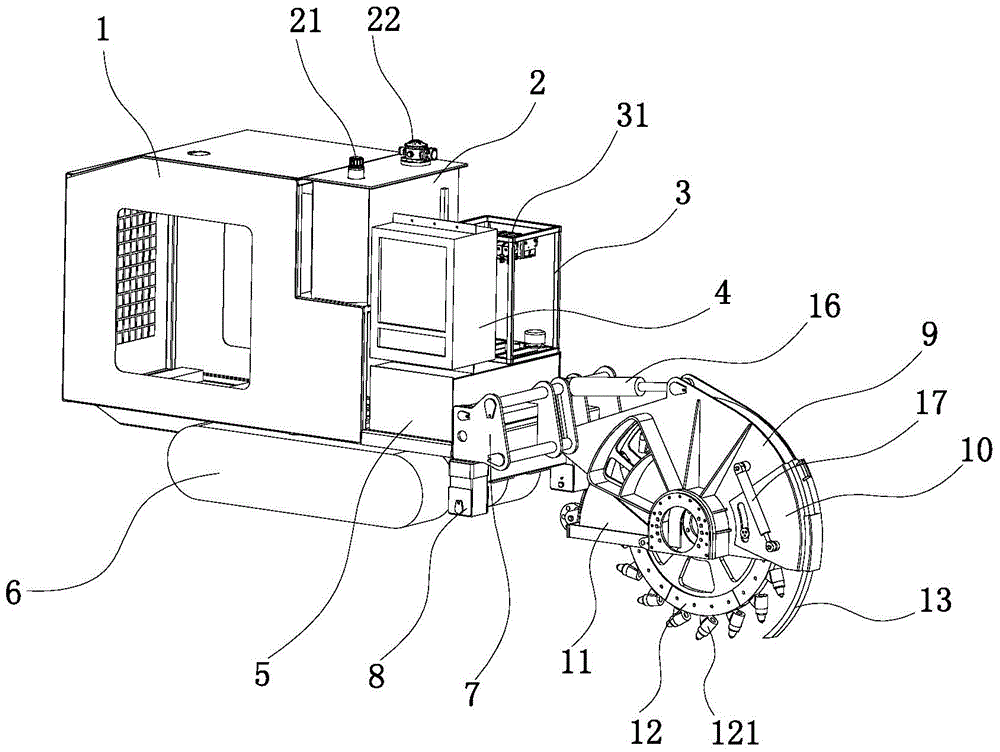

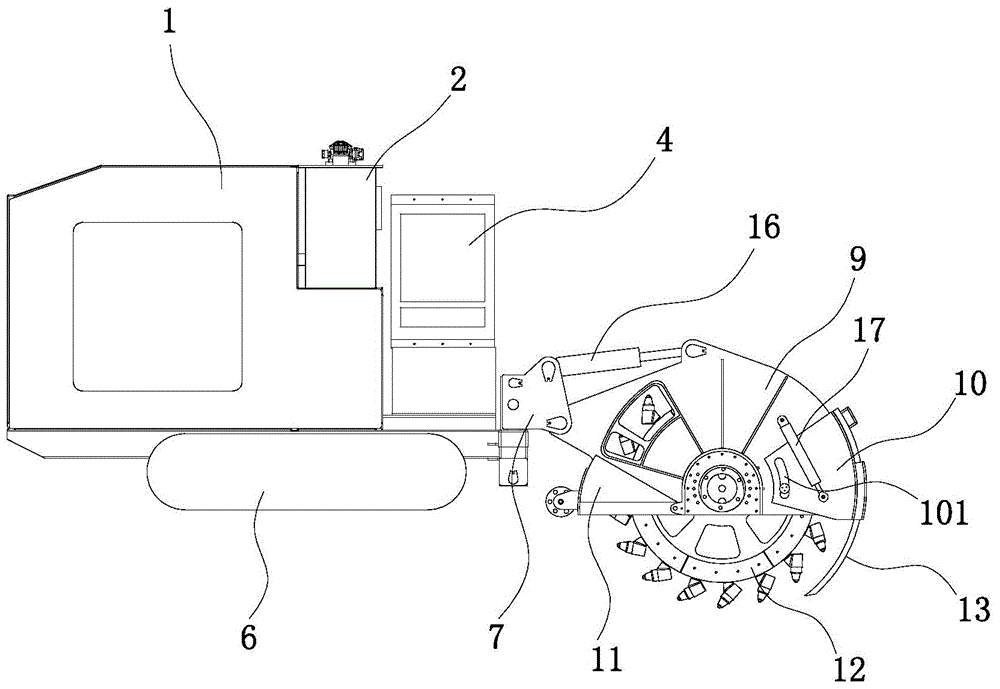

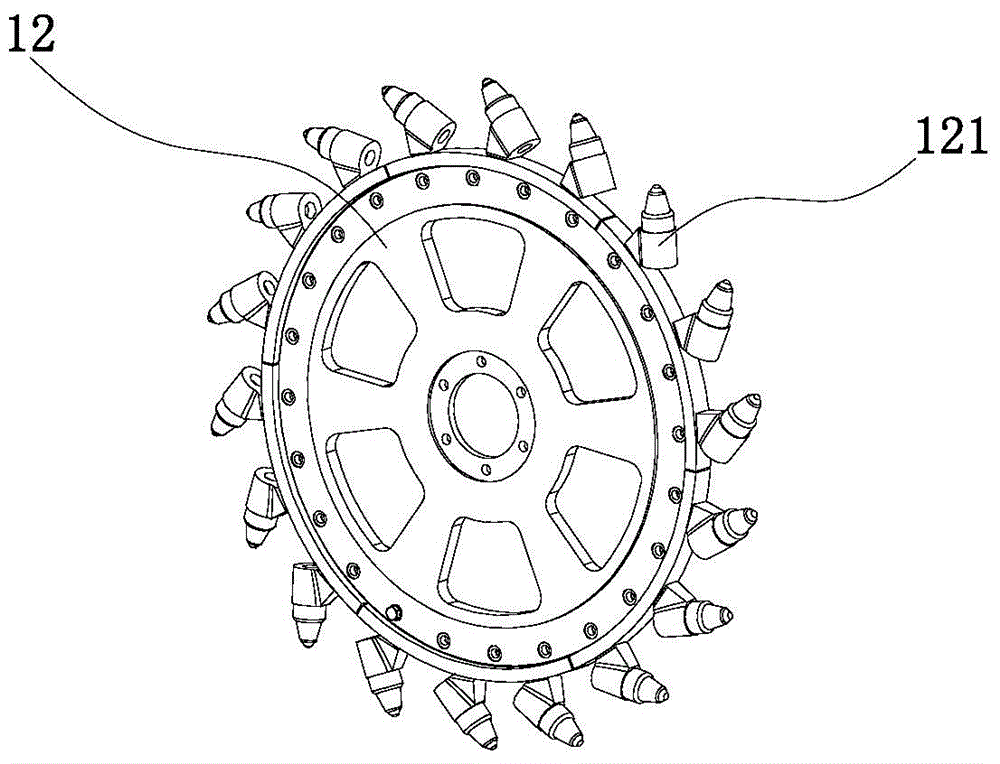

[0029] Such as figure 1 , figure 2 As shown, the road surface grooving machine of the present embodiment includes a slotting device installed at the front end of the driving device, the driving device includes a power station cover 1, and a diesel tank 5, an electric control cabinet 4, a The control cabinet 3 and the hydraulic oil tank 2, the diesel engine and the oil pump are installed in the power station cover 1, and the crawler belt 6 is installed under the power station cover 1, and the crawler belt 6 is driven by a hydraulic motor; Cutting wheel 12, the cutting wheel 12 is driven by a hydraulic motor; the slag cleaning plate 10 positioned at the front of the cutting wheel 12 and the dust cover 11 positioned at the rear of the cutting wheel 12 are installed on the cutting wheel support 9, and the side of the cutting wheel support 9 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com