Transporter for transporting sewing material while operating a sewing machine

A feeder and sewing machine technology, applied in the direction of sewing equipment, sewing machine components, sewing machine needle holders, etc., to achieve the effect of preventing breakage or bending

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

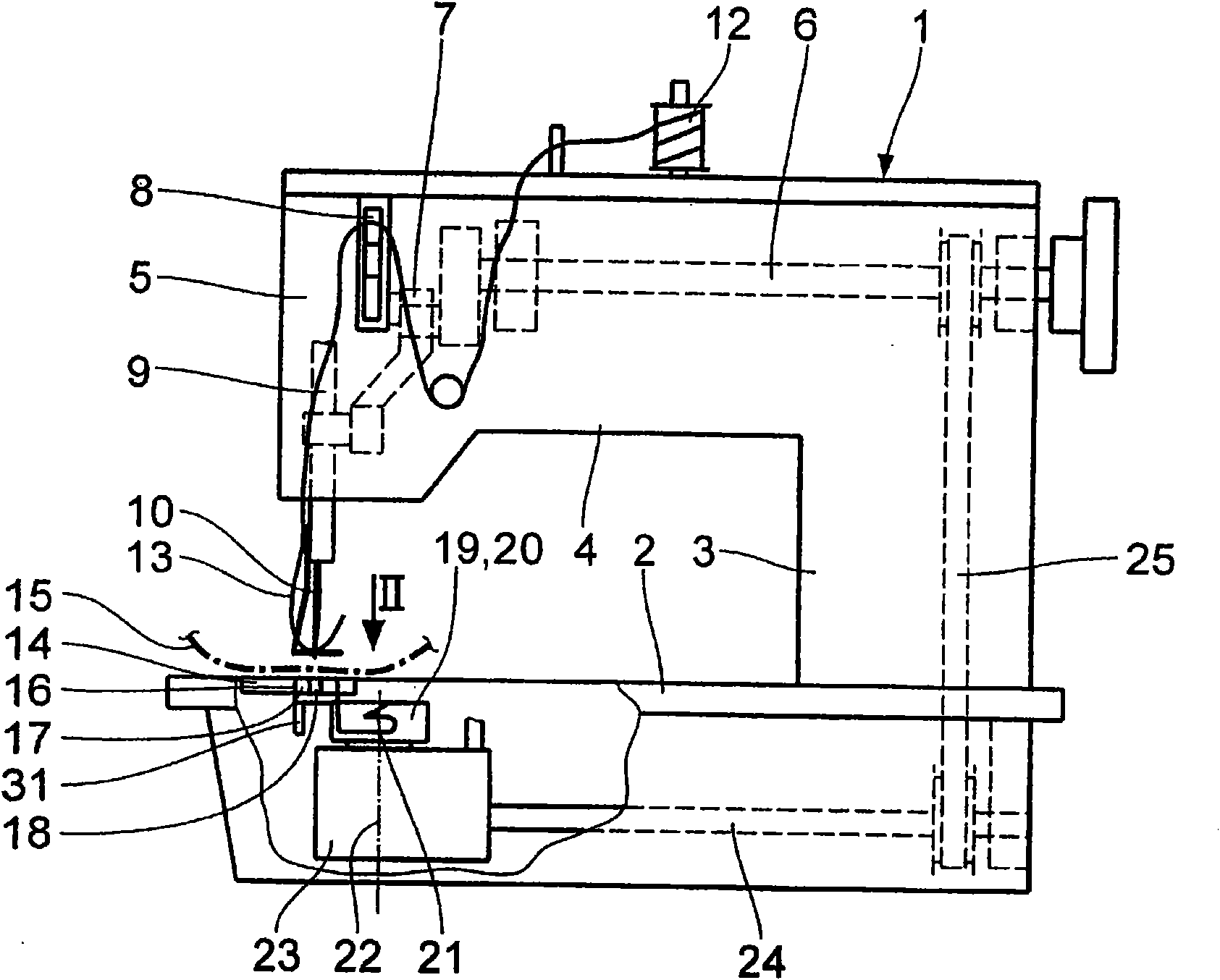

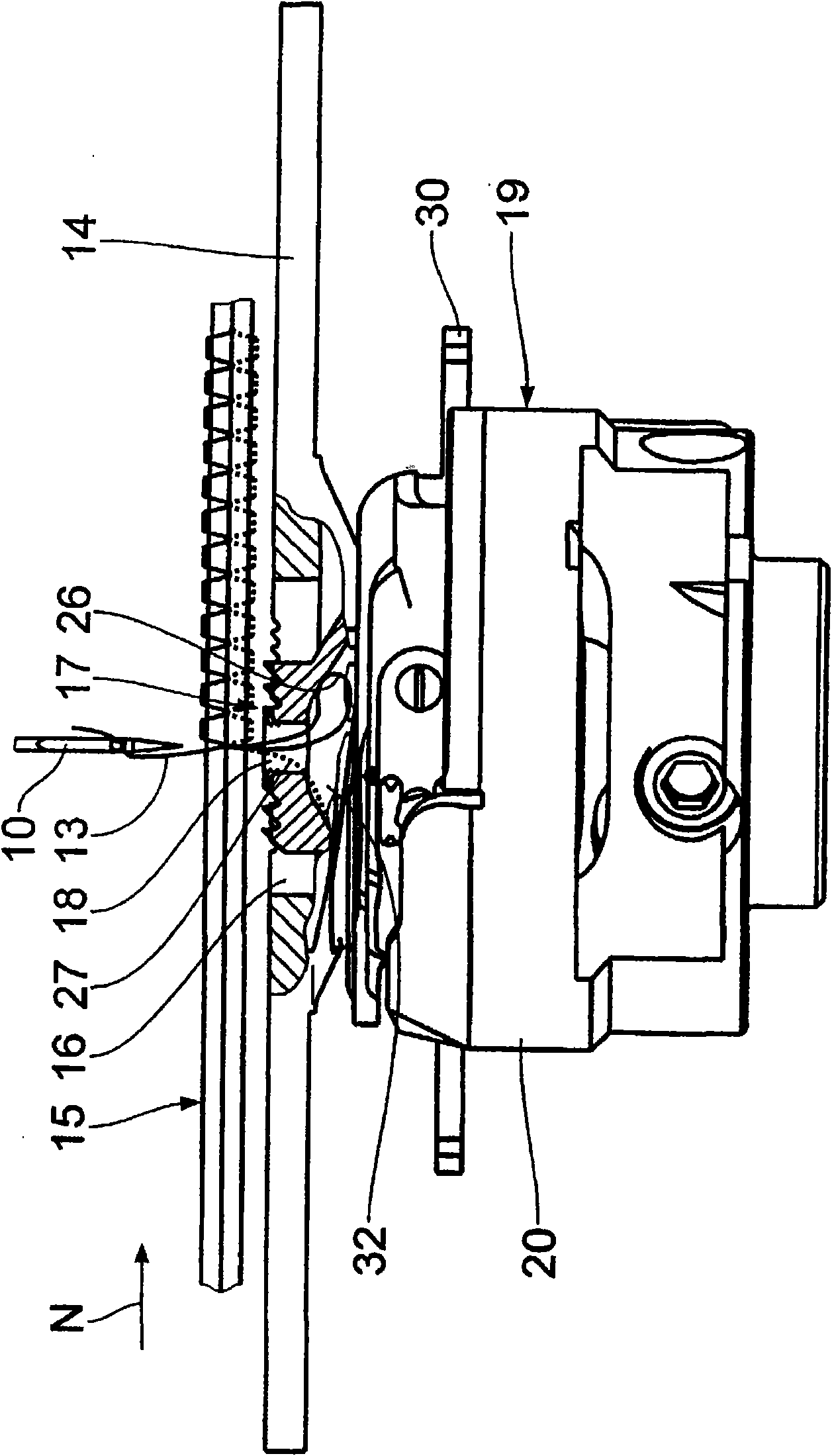

[0023] The sewing machine 1 has a base plate 2 with a column 3 and a curved arm 4 extending upwards from the base plate. The arm 4 terminates in a head 5 . An arm shaft 6 is rotatably arranged in the bending arm 4 , said arm shaft 6 driving a crank drive 7 with a thread take-up lever 8 in the head 5 . The crank drive 7 is drivably connected to a needle bar 9 movably arranged in the head 5 . The lower end of the needle bar 9 has a sewing needle 10 . The sewing needle 10 is driven by the crank driving device 7 to move up and down, whereby the sewing needle 10 passes through the needle movement area, which will be described in detail below. In the eye of the sewing needle 10 the needle thread 13 supplied by the bobbin 12 via the thread take-up device and the thread take-up lever 8 is guided.

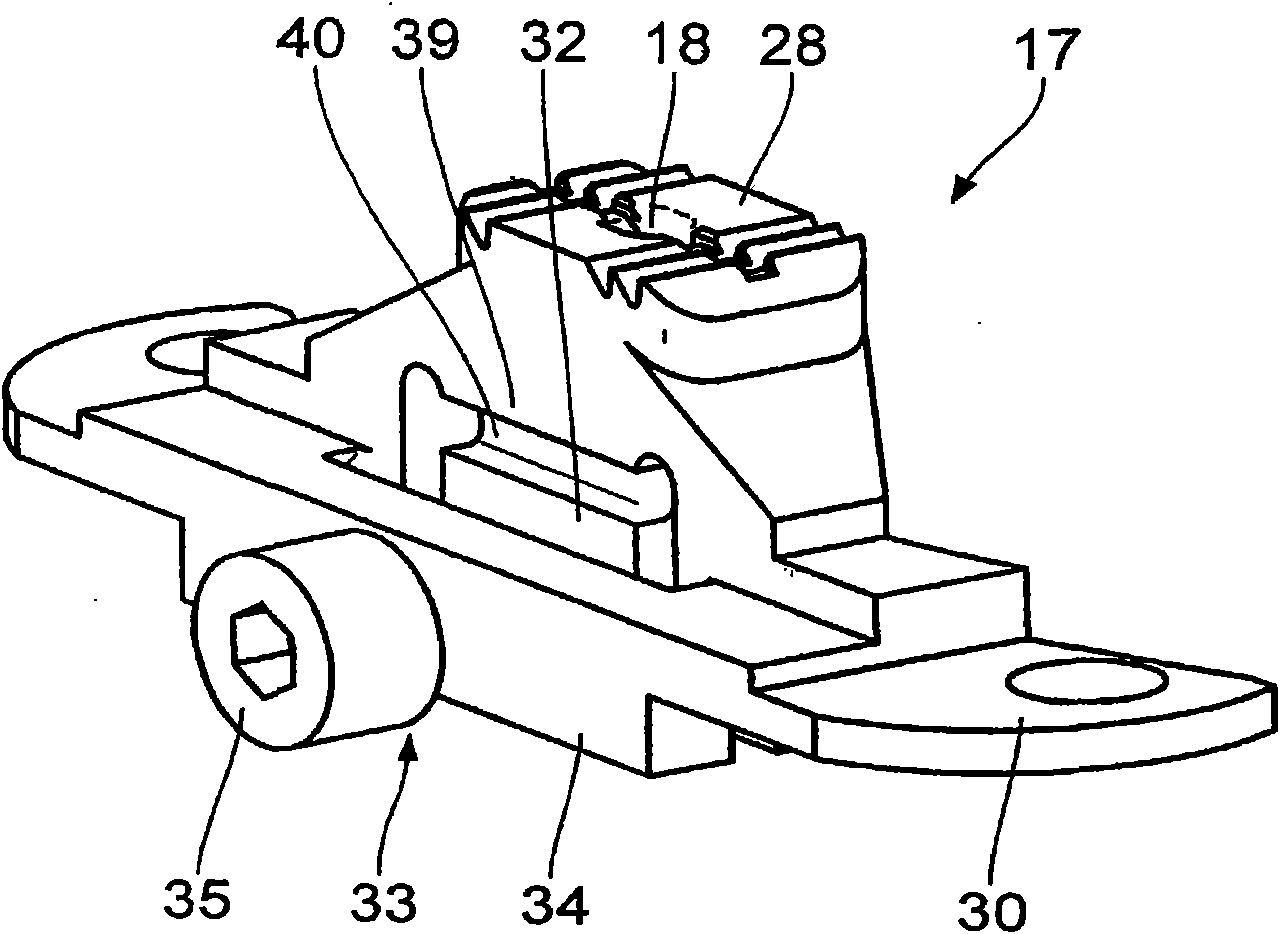

[0024] On the base plate 2 is mounted a support plate or needle plate 14 on which a piece of fabric 15 is placed. The support plate 14 has a dog opening or needle plate recess 16 design...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com