Single-side sewing device

A kind of suture equipment and unilateral technology, which is applied in the direction of sewing equipment, sewing machine components, sewing machine housings, etc., can solve the problems such as difficult to complete the sewing operation of large structural parts with complex spatial shapes, flexibility limitations, etc., and achieve simple structure and application Wide-ranging, adaptable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is further described below in conjunction with embodiment and accompanying drawing.

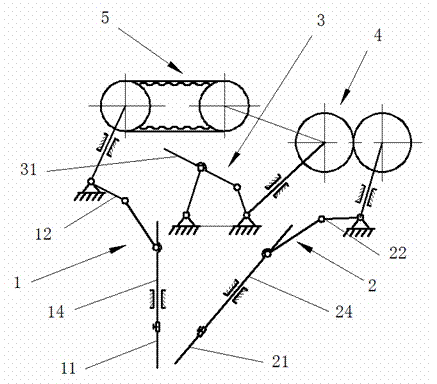

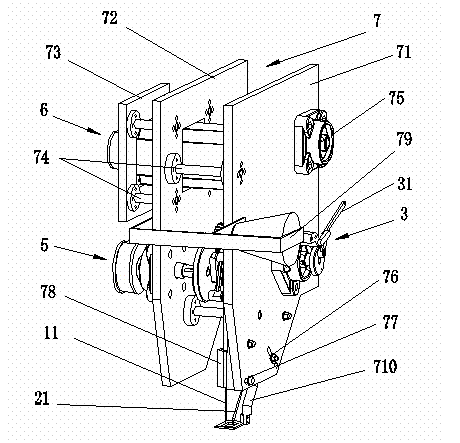

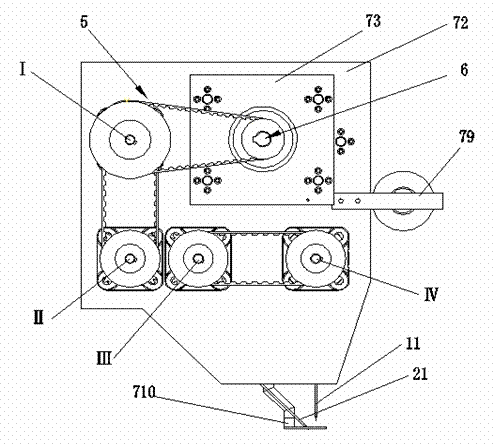

[0025] The unilateral suturing equipment (abbreviation equipment of the present invention's design, see figure 1 —4), the equipment is mainly used for processing three-dimensional composite material prefabricated parts, the main components include hook wire mechanism 1, lead wire mechanism 2, thread take-up mechanism 3, gear transmission mechanism 4, synchronous pulley transmission mechanism 5, servo motor 6 and Box frame 7; the hook wire mechanism 1, lead wire mechanism 2, gear transmission mechanism 4 and servo motor 6 are installed inside the box body type frame 7, and the thread take-up mechanism 3 and the synchronous pulley transmission mechanism 5 are installed in the box body 7 externally (see figure 2 ). The wire lead mechanism 2, the wire hook mechanism 1 and the thread take-up mechanism 3 rely on the servo motor 6, the synchronous pulley transmission ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com