Feeding mechanism for sewing machine

A feeding mechanism and sewing machine technology, applied to sewing machine components, sewing machine housings, sewing machine control devices, etc., can solve problems such as low operating efficiency and troublesome cam replacement operations, and achieve operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

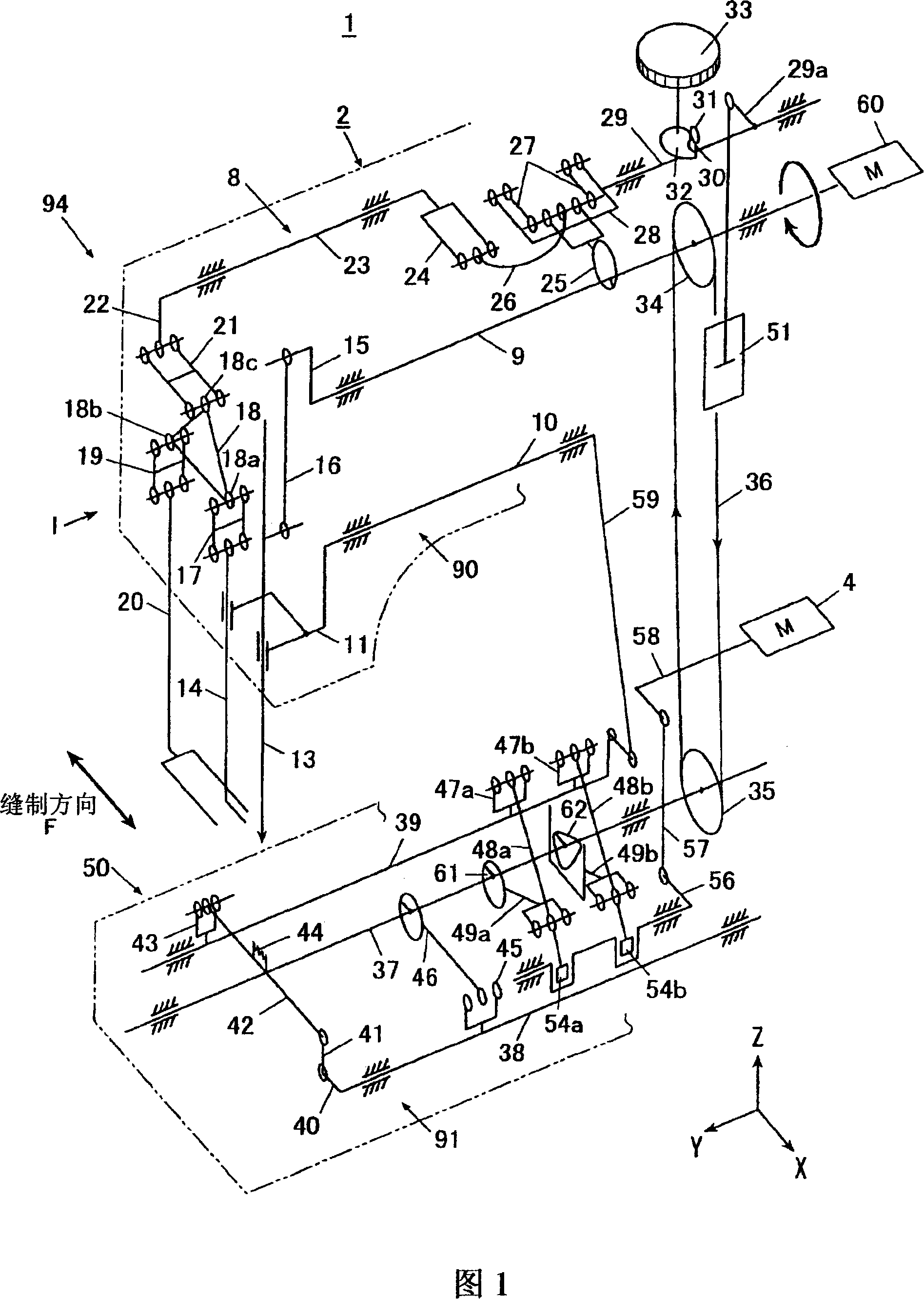

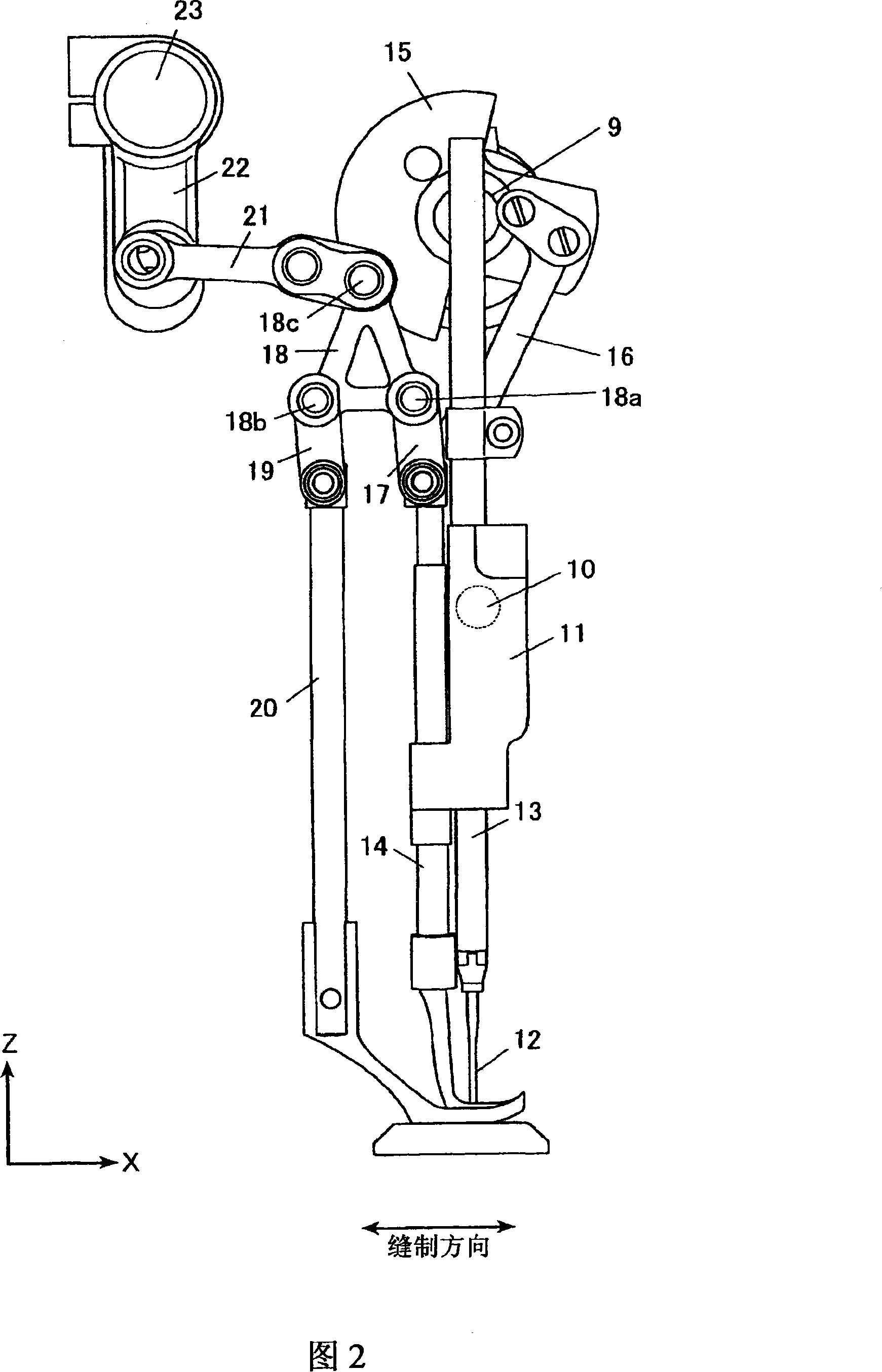

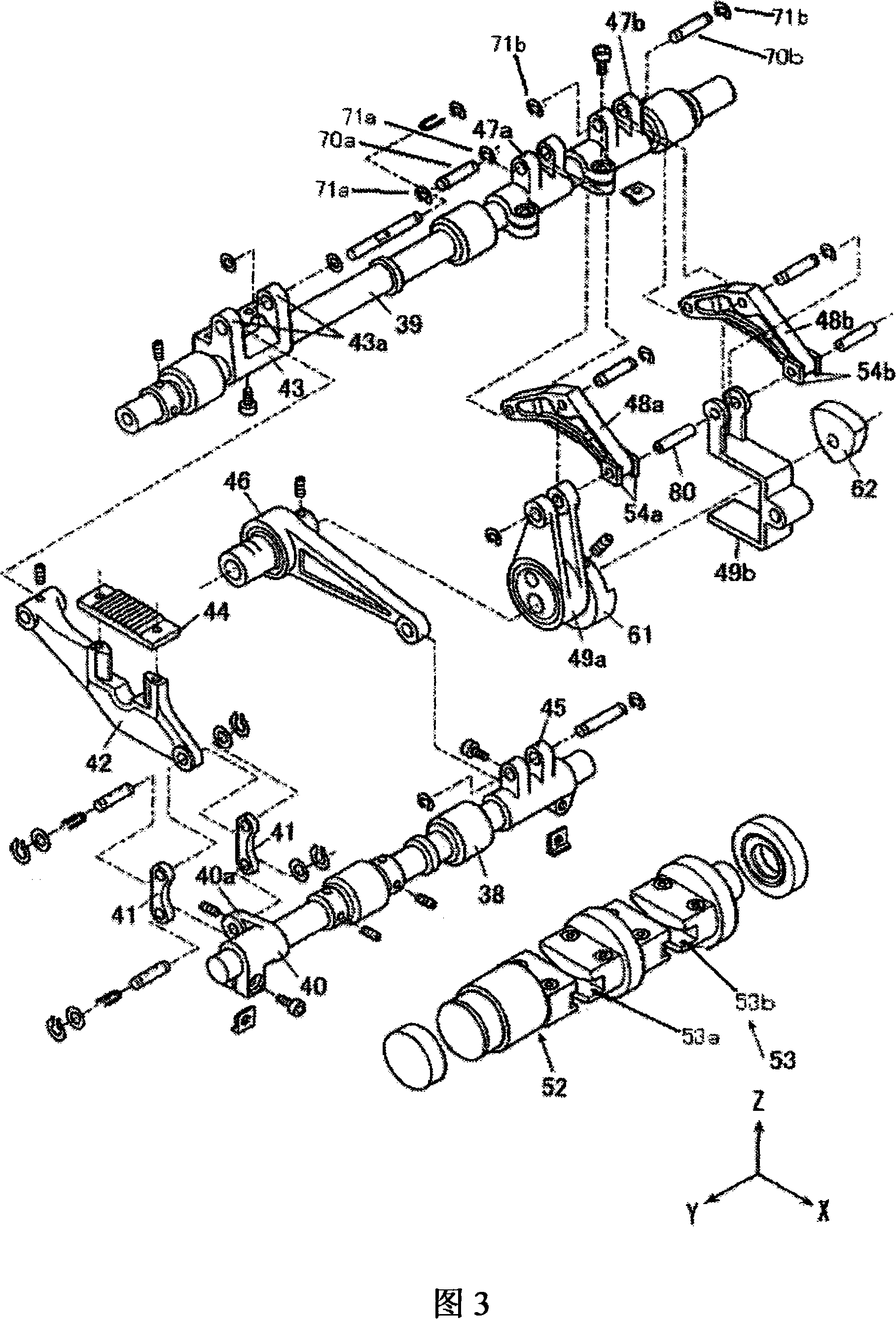

Embodiment approach 1

[0074] (Implementation 1: Effect)

[0075] As described above, according to the combined feed sewing machine 1 according to Embodiment 1, by making the feeding operation of the upper feed leg 14 from the first horizontal feed link 48a into a connected state, the upper feed leg 14 can be moved by eccentricity. The feed action of the ellipse feed obtained by the cam 61, in addition, by making the feed action of the upper feed leg 14 from the second horizontal feed link 48b into a connected state, the upper feed leg 14 can be obtained by the triangular cam 62. The feed action of the rectangular feed. That is, since the eccentric cam 61 and the triangular cam 62 fixed coaxially are selectively used, the elliptical feed and the rectangular feed can be easily switched in one sewing machine, so the improvement of operability and the improvement of productivity can be realized. improve.

Embodiment approach 2

[0077] Next, Embodiment 2 using the present invention will be described based on FIGS. 8 and 9 .

[0078]A sewing machine 101 according to Embodiment 2, as shown in FIG. 8 , is different from Embodiment 1 in that the eccentric cam 161 and the triangular cam 162 are disposed adjacent to each other in the axial direction and can be axially relative to the lower cam. The shaft 37 is moved and positioned, and the switching unit changes its axial position by sliding the eccentric cam 161 and the triangular cam 162 relative to the lower shaft 37 along the axial direction, and the cams engaged with the horizontal feed link 149 as a transmission part , switch to the eccentric cam 161 or the triangular cam 162, thereby switching the movement trajectory of the upper feed foot 14.

[0079] Specifically, as shown in FIG. 8 , a substantially circular eccentric cam 161 and a triangular cam 162 are arranged adjacent to each other in the axial direction, and an integrated cam portion 160 is p...

Embodiment approach 3

[0086] Next, Embodiment 3 using the present invention will be described based on FIGS. 10 and 11 .

[0087] In the sewing machine 201 according to Embodiment 3, the eccentric cam 261 and the triangular cam 262 are adjacent to each other in the axial direction, and the horizontal feed link 249 as a transmission member has a frame portion 255, and within the frame of the frame portion 255, there are: The engaging part 249a engages with the eccentric cam 261; the second engaging part 249b engages with the triangular cam 262; the first engaging escape part 249c engages with the second engaging part 249b on the triangular cam 262 When the eccentric cam 261 is engaged with the horizontal feed link 249; and the second engaging escape portion 249d, when the eccentric cam 261 is engaged with the first engaging portion 249a, it prevents the triangular cam 262 from engaging with the horizontal feed link 249. Engage the connecting rod 249 . The difference between this embodiment 3 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com