Bent two-needle sewing machine

A sewing machine, zigzag technology, applied in the direction of sewing machine components, sewing machine needle seat, sewing machine housing, etc., to achieve the effect of easy maintenance and improved precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

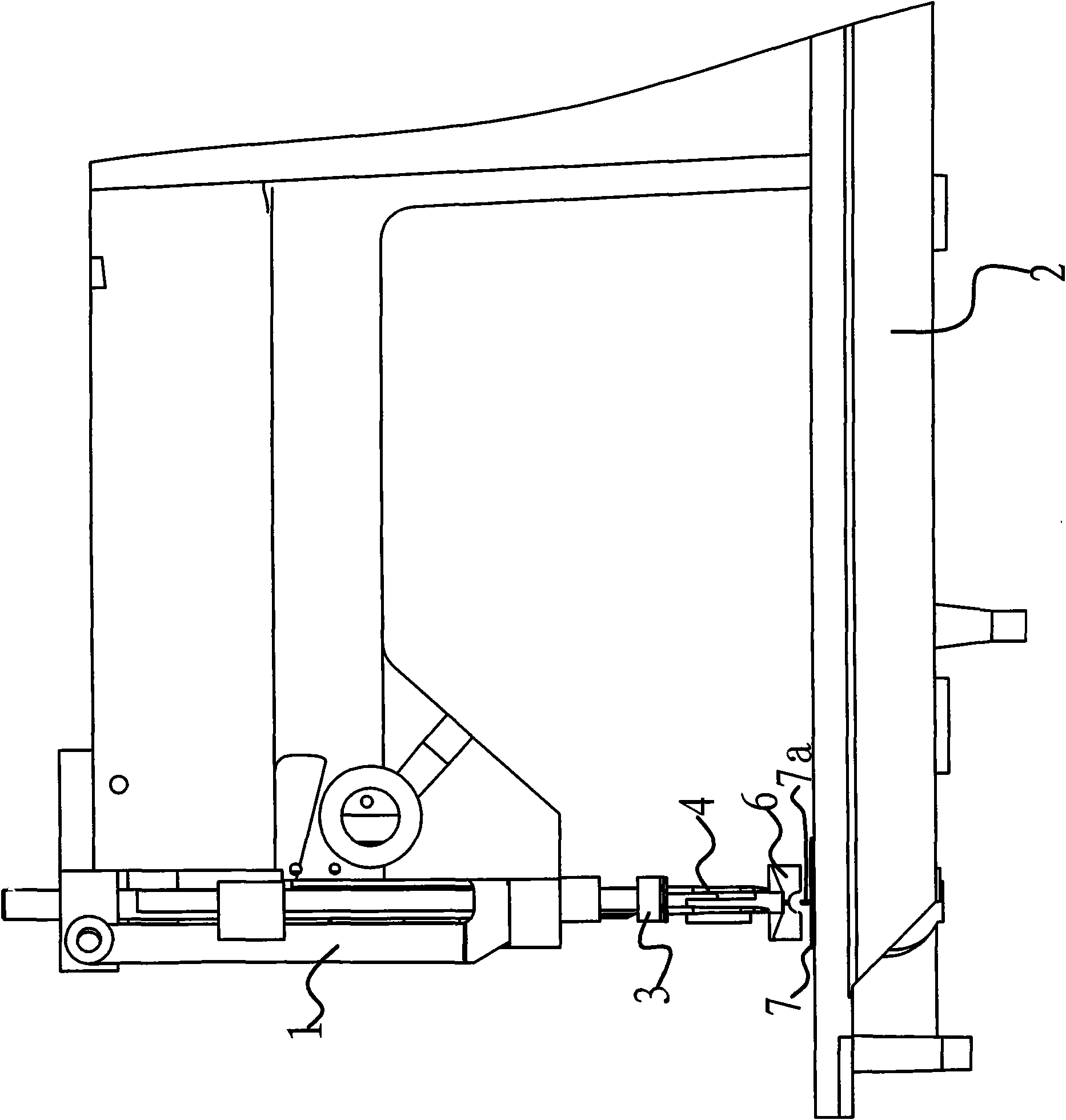

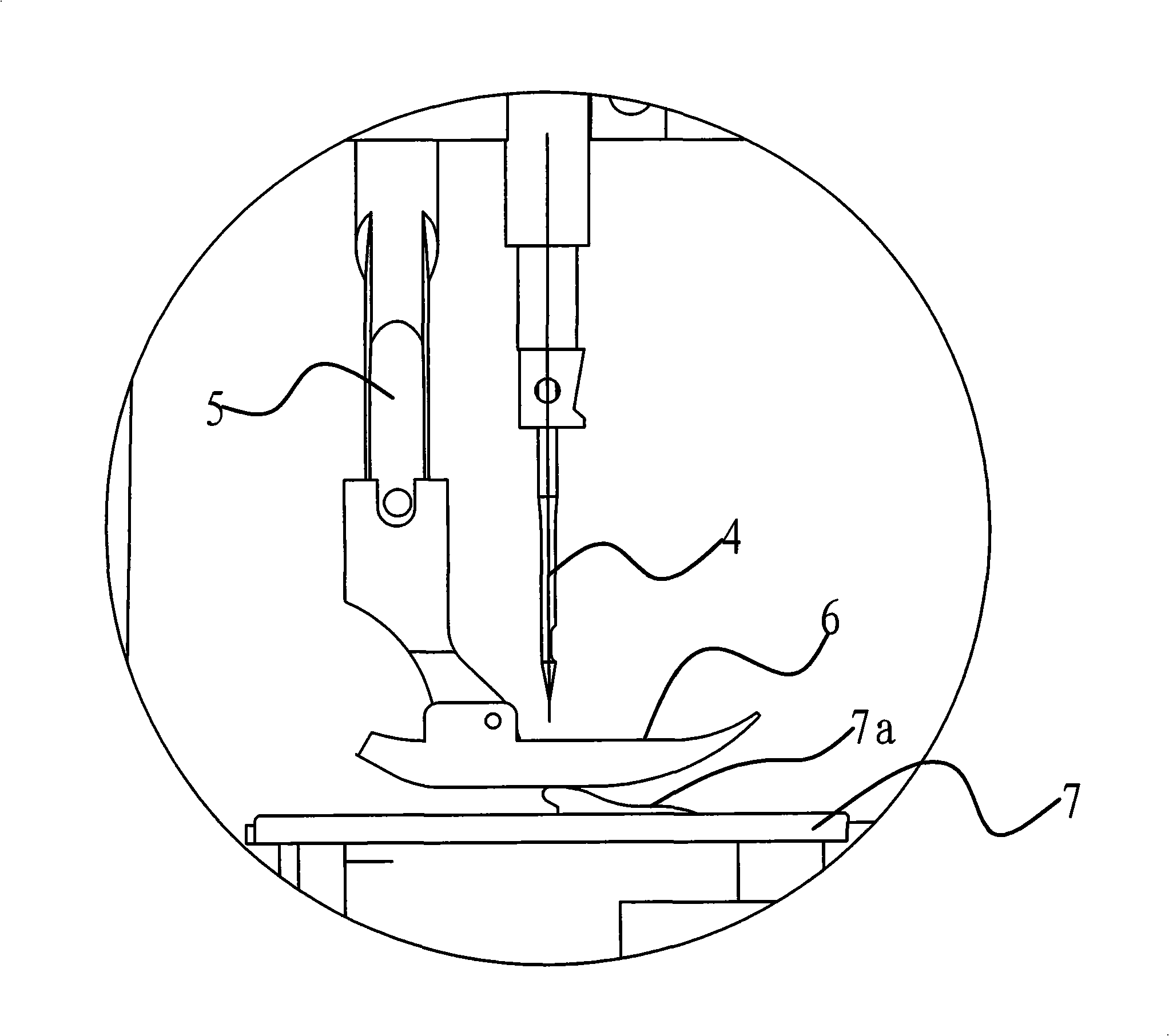

[0020] The present invention is improved on the basis of Singer 20U33 machine, as figure 1 As shown, this zigzag double-needle sewing machine includes a machine head 1, a base plate 2, a presser foot 6, a needle plate 7, a needle clip 3 and two machine needles 4 fixedly connected to the needle clip 3, and the machine head 1 is fixed Connected to the bottom plate 2, the needle clamp 3 is connected with the machine head 1, and a detachable mechanism is arranged between the needle clamp 3 and the machine head 1.

[0021] The detachable mechanism in this embodiment includes a needle bar with an external thread structure fixedly connected to the machine head 1 and a connecting rod with an internal thread structure fixedly connected to the needle clamp 3 . The needle clip 3 is fixedly connected with the machine head 1 through the needle bar. Since the needle clip 3 and the needle bar are threaded together, it is very convenient when the needle clip 3 needs to be replaced.

[0022] ...

Embodiment 2

[0026] The content in the second embodiment is roughly the same as that in the first embodiment, except that the detachable mechanism in the first embodiment includes a needle bar with an external thread structure fixed on the machine head 1 and a needle holder 3 fixed on the A connecting rod with an internal thread structure. However, the detachable mechanism in this embodiment includes an insertion rod arranged on the needle clamp 3 and a slot arranged on the machine head 1, the insertion rod is inserted into the slot, and the two are fixedly connected by a latch .

Embodiment 3

[0028] The content in the third embodiment is roughly the same as that in the first embodiment, except that the detachable mechanism in the first embodiment includes a needle bar with an external thread structure fixed on the machine head 1 and a needle holder 3 fixed on the A connecting rod with an internal thread structure. And the detachable mechanism among the present embodiment comprises bolt, nut, through hole one on the needle clip 3 and through hole two on the machine head 1, and bolt passes through through hole one and through hole two and is connected with nut.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com