Patch pocket sewing machine

A sewing machine and pocket patching technology, which is applied to pocket sewing machines, sewing machine components, sewing machine casings, etc., can solve the problems of cloth bag and clothing displacement, cloth wrinkles, etc., and achieve the effect of high speed and high accuracy of pocket patching.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

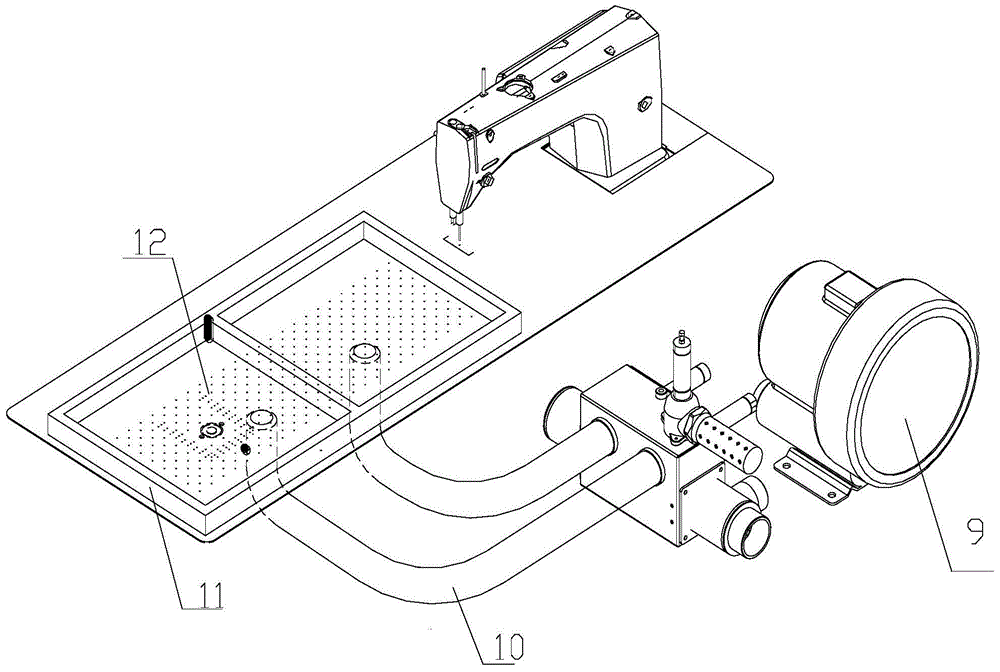

[0021] The present invention relates to a patch pocket sewing machine, comprising a body 1, a bag stacking device 3, a sewing mold 4, a sewing machine 5 and a driving device;

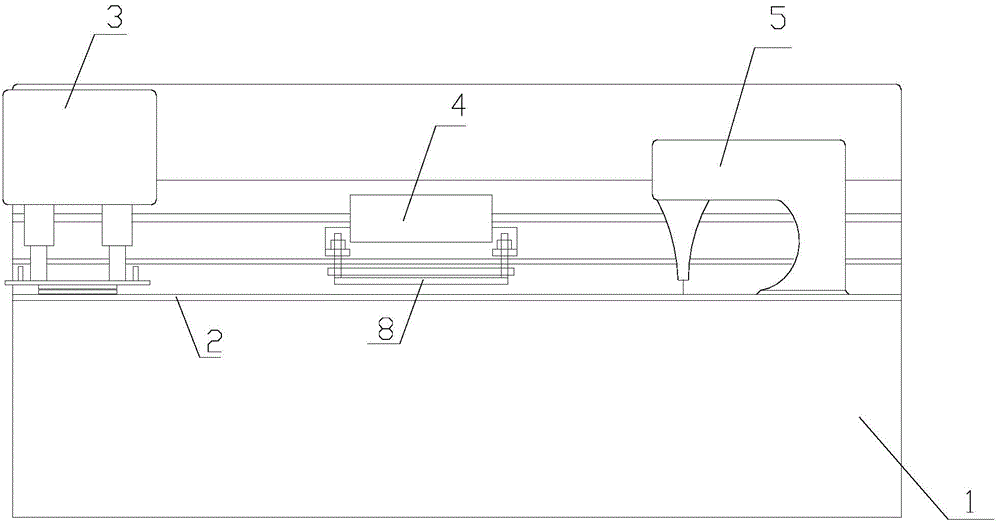

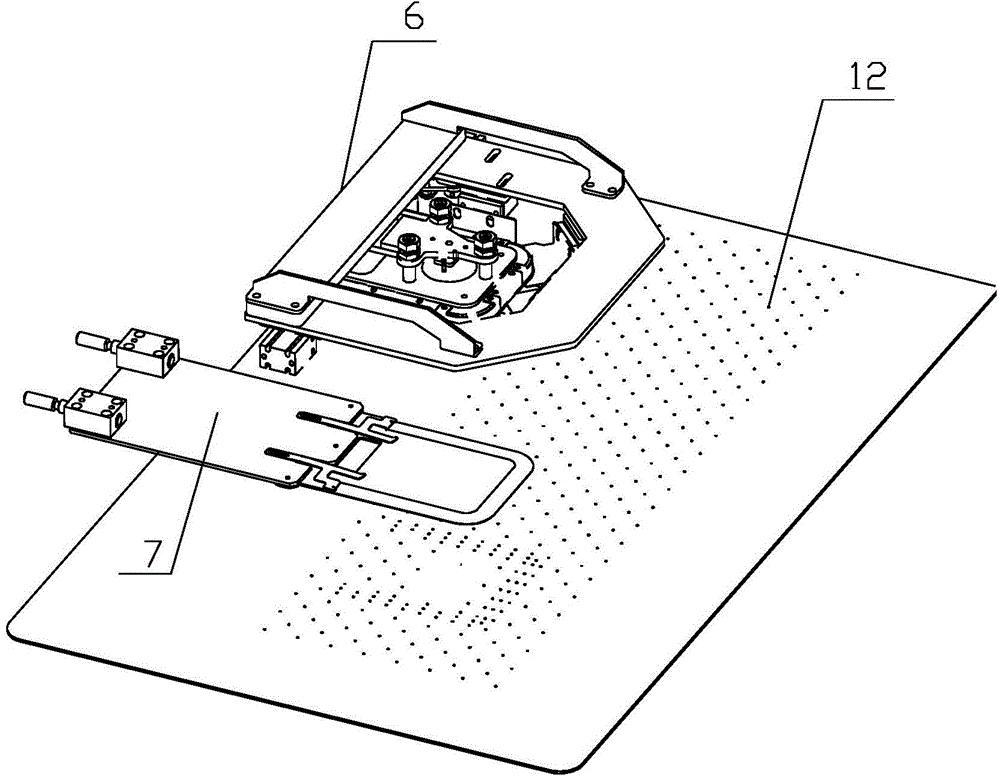

[0022] Fuselage 1 is a rectangular box body, and the upper surface of the fuselage 1 is a working platform 2. The inside of the fuselage 1 is provided with a blower fan 9. The air outlet end of the conversion device is connected to one end of the air pipe 10, and the other end of the air pipe 10 leads into the air chamber 11 under the working platform 2, and the surface of the working platform 2 is provided with a plurality of small air outlets 12;

[0023] Described fuselage 1 body is horizontally fixed with bracket, is provided with two rails between described bracket and fuselage 1, and described rail is horizontally arranged parallel to bracket, and described bag stackin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com