Driving device of industrial sewing machine

A driving device and sewing machine technology, applied in the direction of sewing machine control devices, sewing machine components, sewing machine housings, etc., can solve the problems of complex structure of the tension adjustment unit, increase in the number of assembly processes, and large operating force, etc., to reduce the number of components and The number of parts, the ease of assembly work, and the effect of simplifying the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

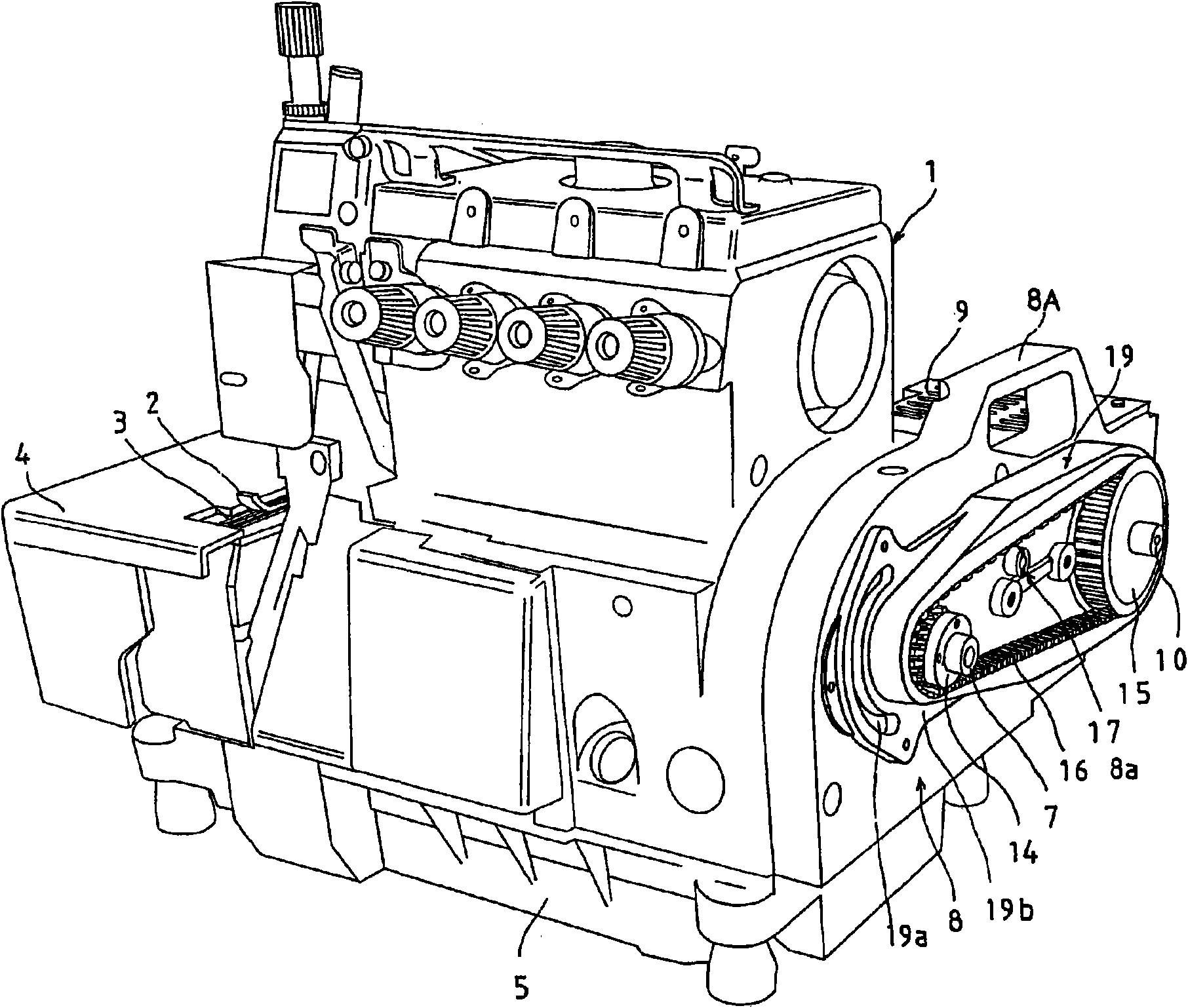

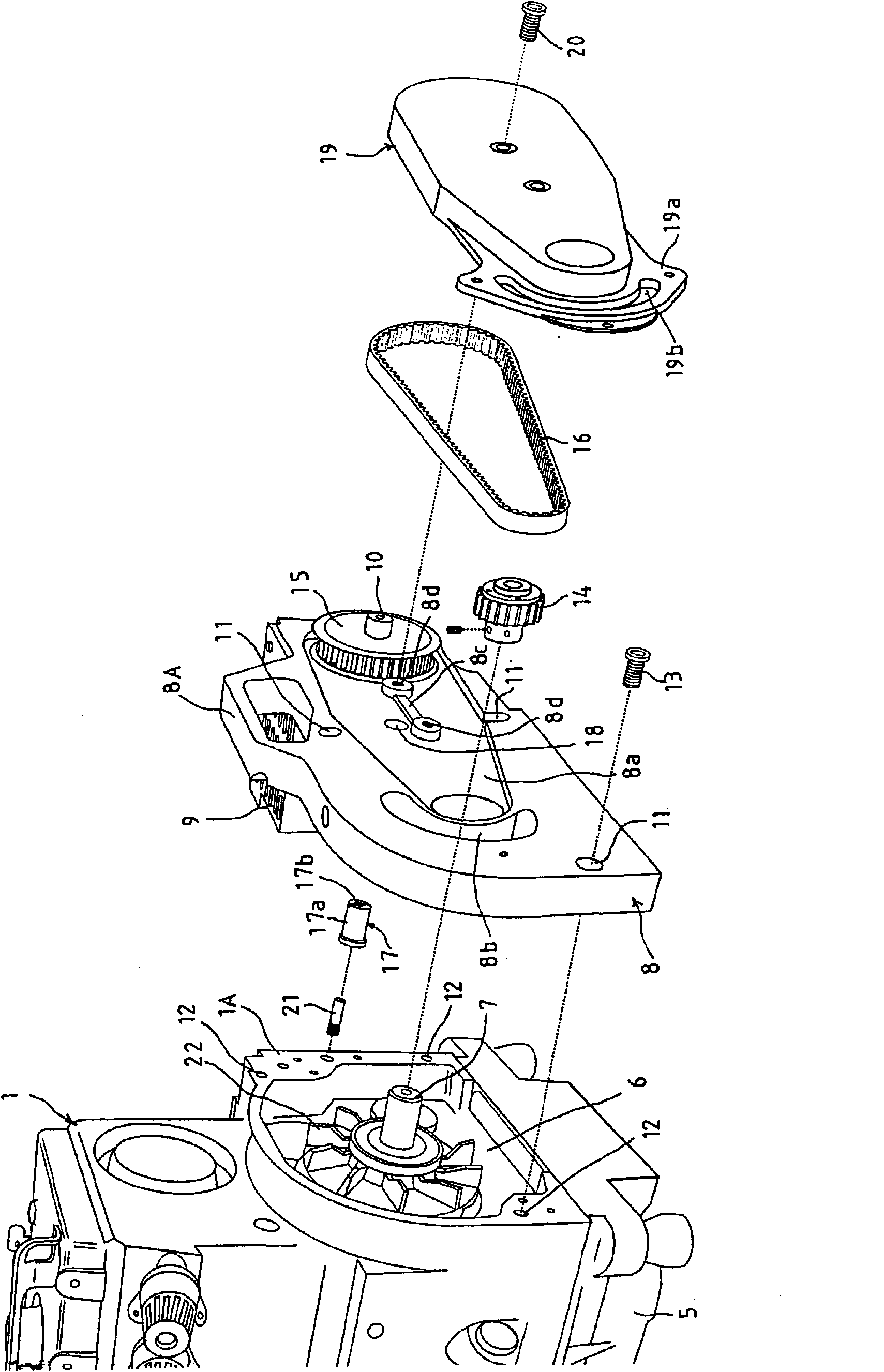

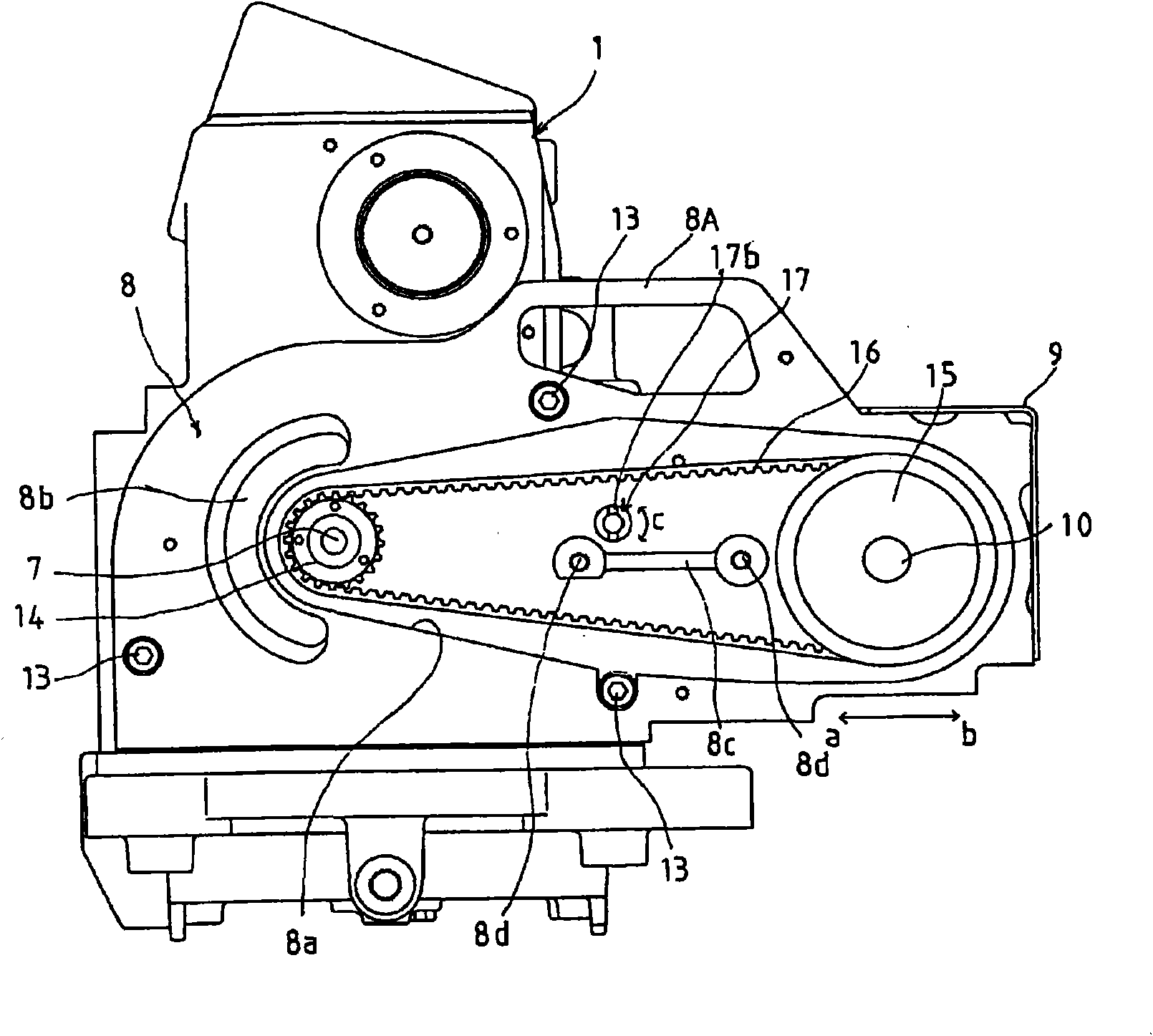

[0017] Embodiments of the present invention will be described below with reference to the drawings.

[0018] figure 1 It is an overall perspective view of an overlock sewing machine to which a driving device for an industrial sewing machine according to the present invention is applied, figure 2 is an exploded perspective view of the main parts, image 3 for the right view. In these Figure 1 ~ Figure 3 Among them, symbol 1 is the main body of the sewing machine, on its left side is provided with a needle (because it is known, so its description is omitted), a presser foot 2, a feed dog 3 and a looper (because it is known, so its description is omitted) on its left side. A sewing platform (clothplate) 4 and the like are installed in the sewing machine body 1, and a lubricating oil storage part 5 called an oil pan is installed at the lower end of the sewing machine body 1.

[0019] A substantially semidome-shaped recessed portion 6 that opens outward is formed at a right e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com