Device for creating a reactionable flowable compound

A mixture, reactive technology, applied in the direction of fluid mixer, mixer, mechanical equipment, etc., can solve the problems of production downtime, time-consuming, high cost, cleaning operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

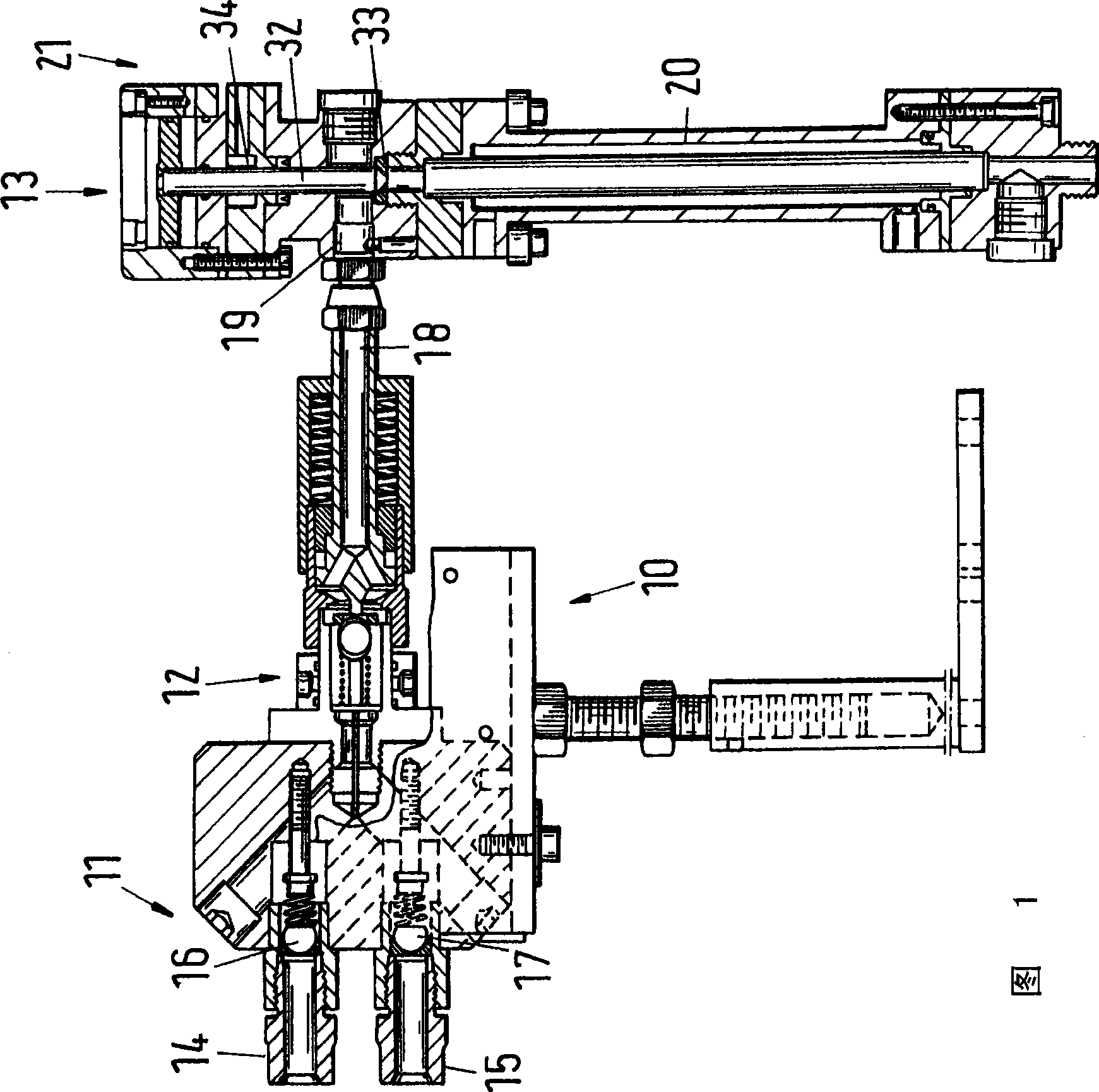

[0018] FIG. 1 shows a device 10 for delivering reactive flowable mixtures according to the prior art. The apparatus comprises a supply device 11 , a collection arrangement 12 and a mixing device 13 . The supply means comprise a first supply line 14 for the first component 3 and a second supply line 15 for the second component 5 . The first supply line contains a first non-return valve 16 and the second supply line 15 contains a second non-return valve 17 . Both components lead together into a collection device 12 downstream of the non-return valves 16 , 17 . Both components leave the collection device 12 through the collection channel 18 . Collection channel 18 contains the first and second components. Hardly any mixing of the components takes place as they pass through the collection channel 18 if they are high viscosity fluids. The collecting channel 18 leads to the actual mixing device 13 , in which an inlet channel 19 is arranged which leads to a mixing channel 20 whic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com