Patents

Literature

52results about How to "Solve the lack of pressure resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

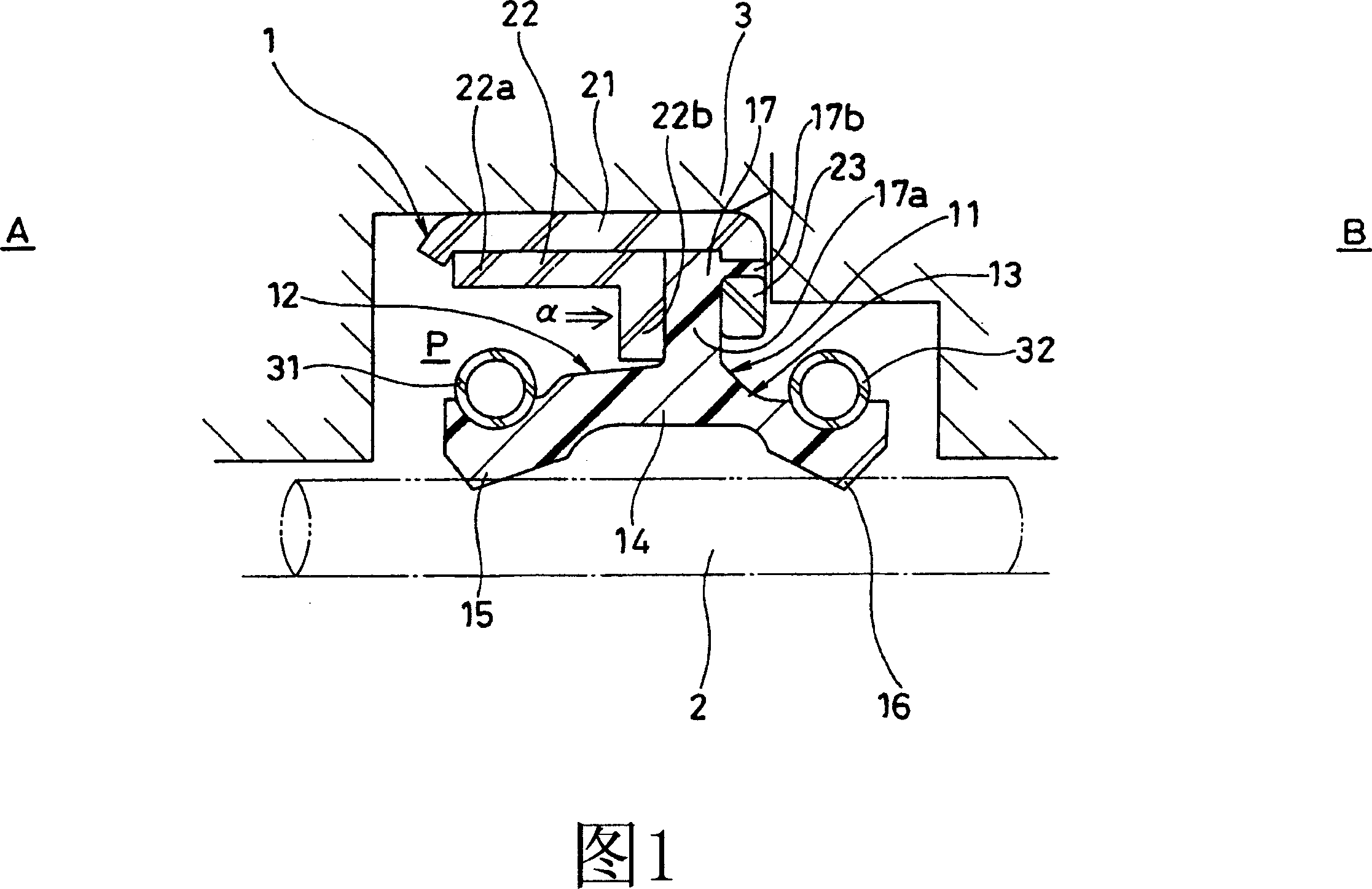

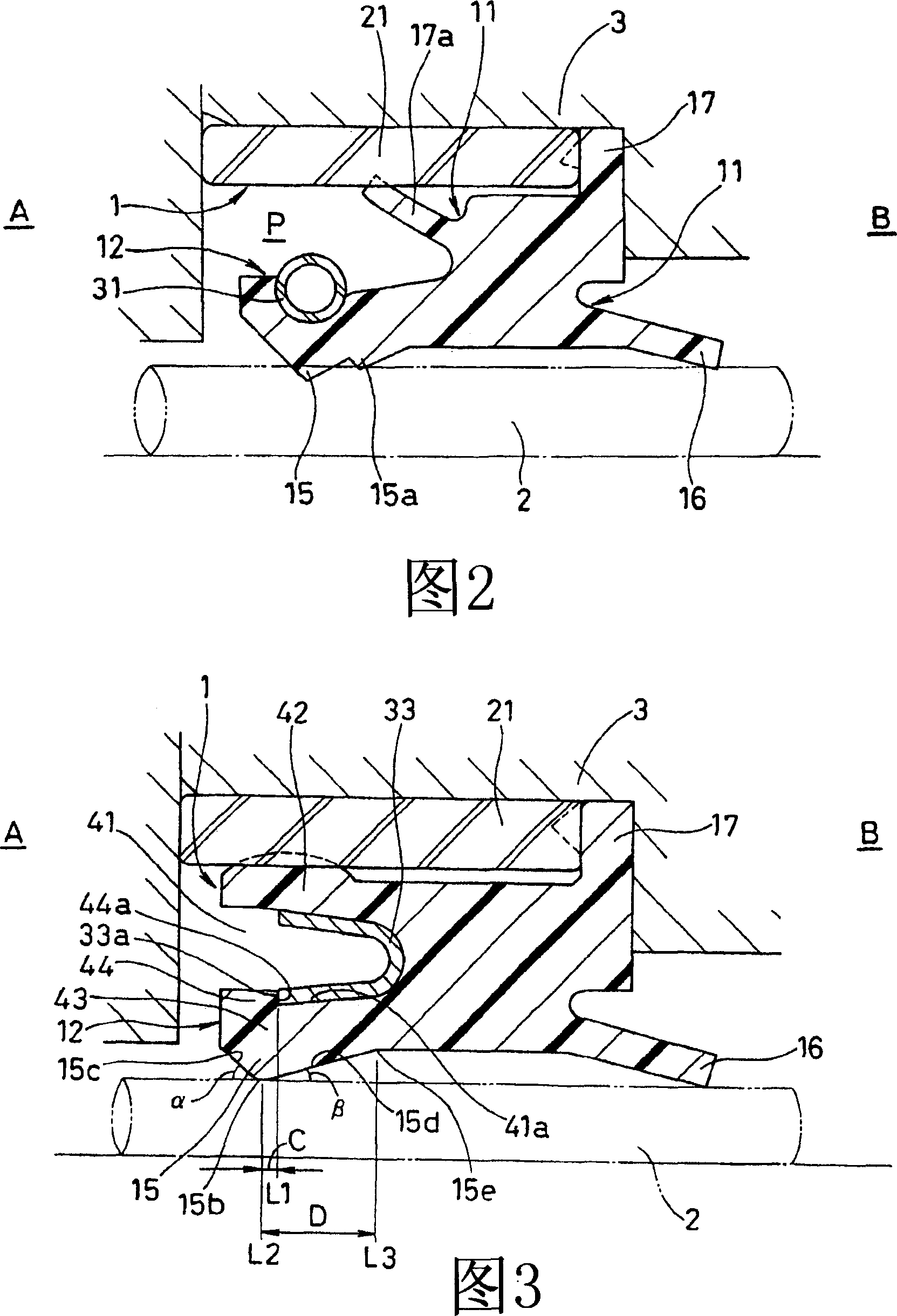

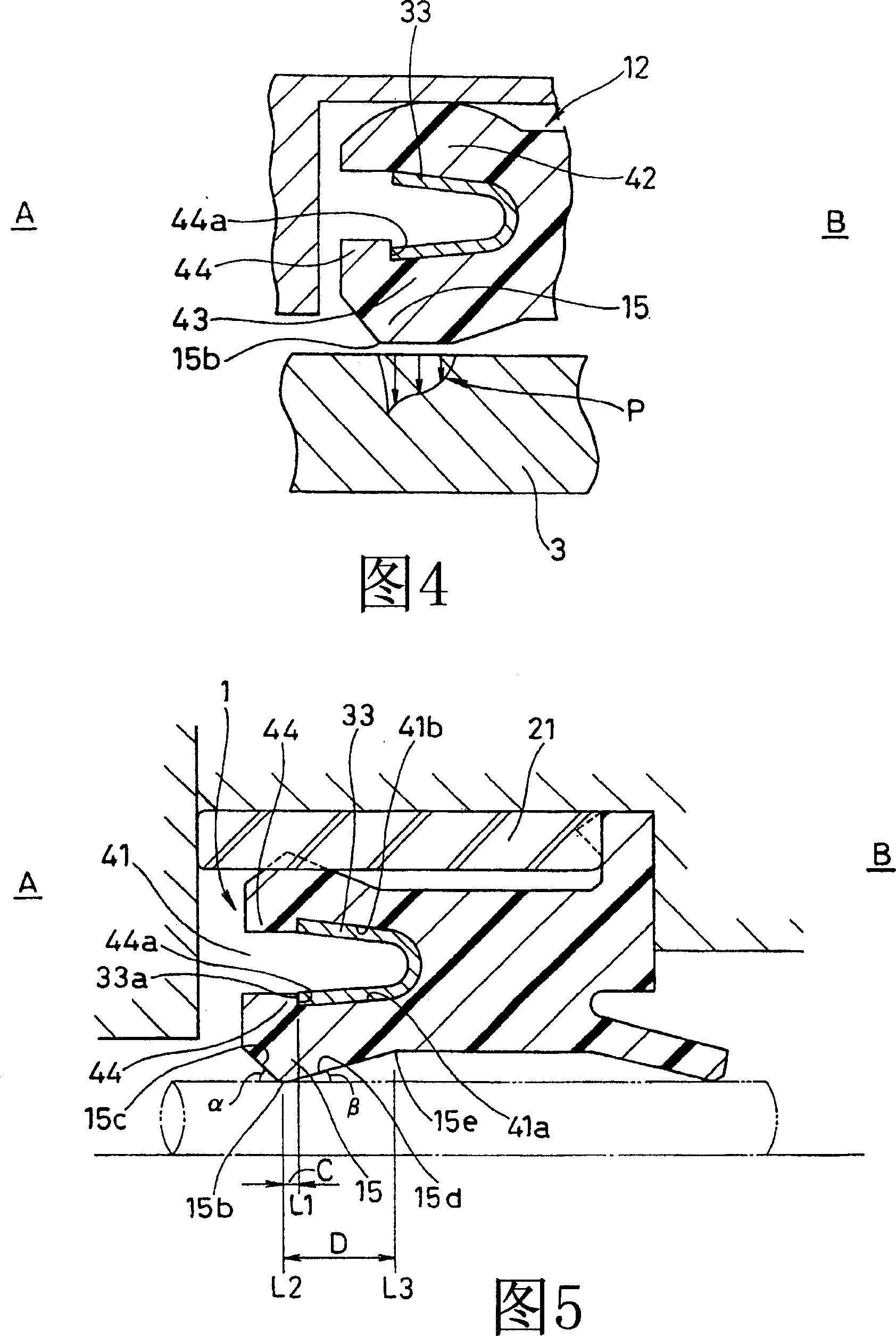

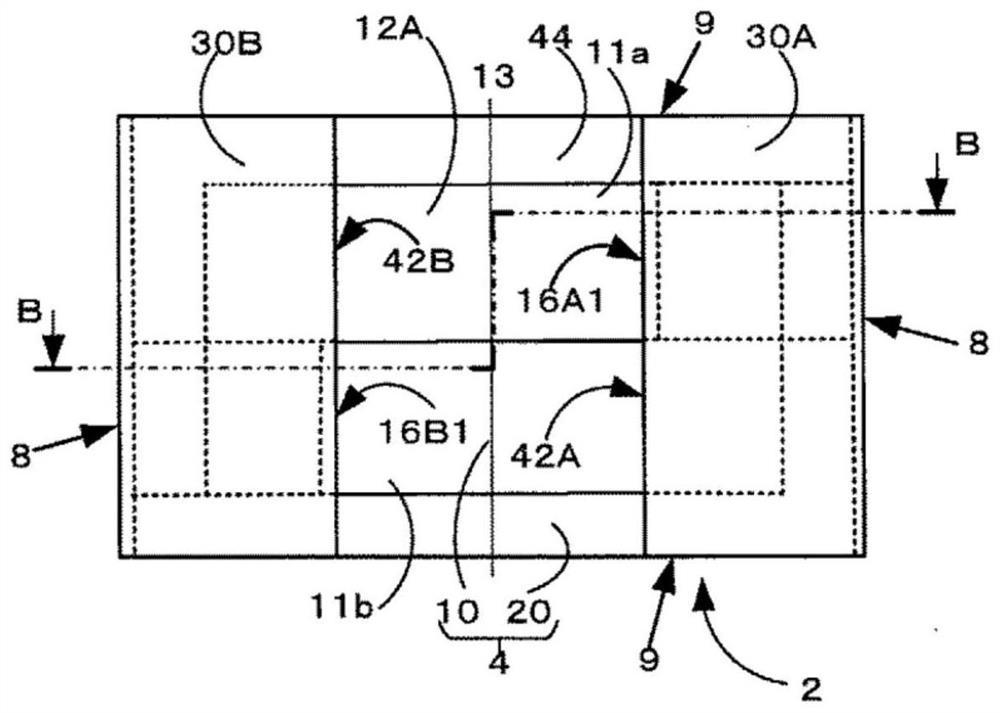

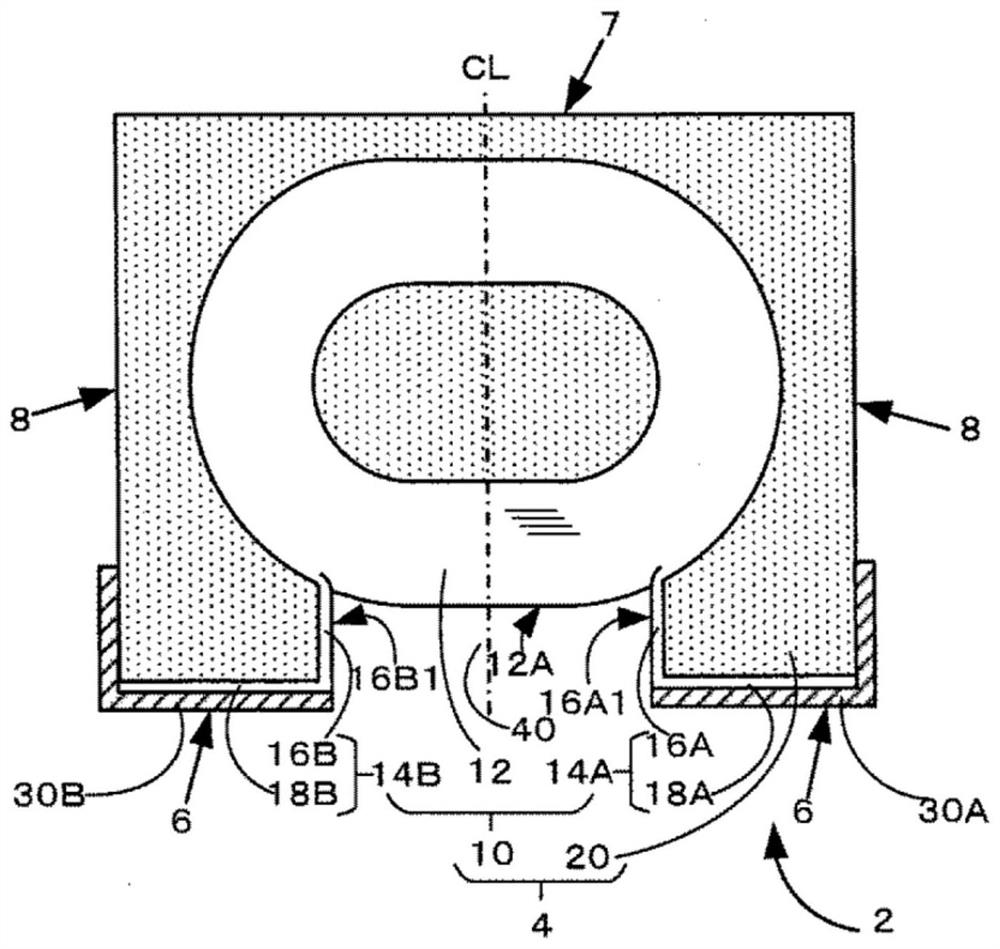

Seal for pump

InactiveCN1954149AImprove sealingAchieve compactnessEngine sealsPositive displacement pump componentsMan-hourGasoline

A plunger seal (1) for a pump, which is used for a fuel injection pump for a direct-injection gasoline engine, in which, even if a resin material is used as a fuel seal member (12), the plunger seal can be made compact, sealing ability is increased, and assembling man-hours can be reduced, and in which set sealing performance can be achieved when a U-shaped elastic member (33) for applying an urging force is used in a groove (41) formed in the fuel seal member (12). The resin fuel seal member (12) and an oil seal member (13) are assembled to form one seal system. Further, when the U-shaped elastic member (33) is installed in the groove (41), the axial position (L1) of an end surface (44a) that is on the side opposite the side to be sealed and belongs to a flange (44) for fixation formed on the inner peripheral surface of the groove (41) is positioned more on the side (B) opposite the side to be sealed than the axial position (L2) of a head section (15b) of a seal lip (15) of the fuel seal member (12).

Owner:NOK CORP

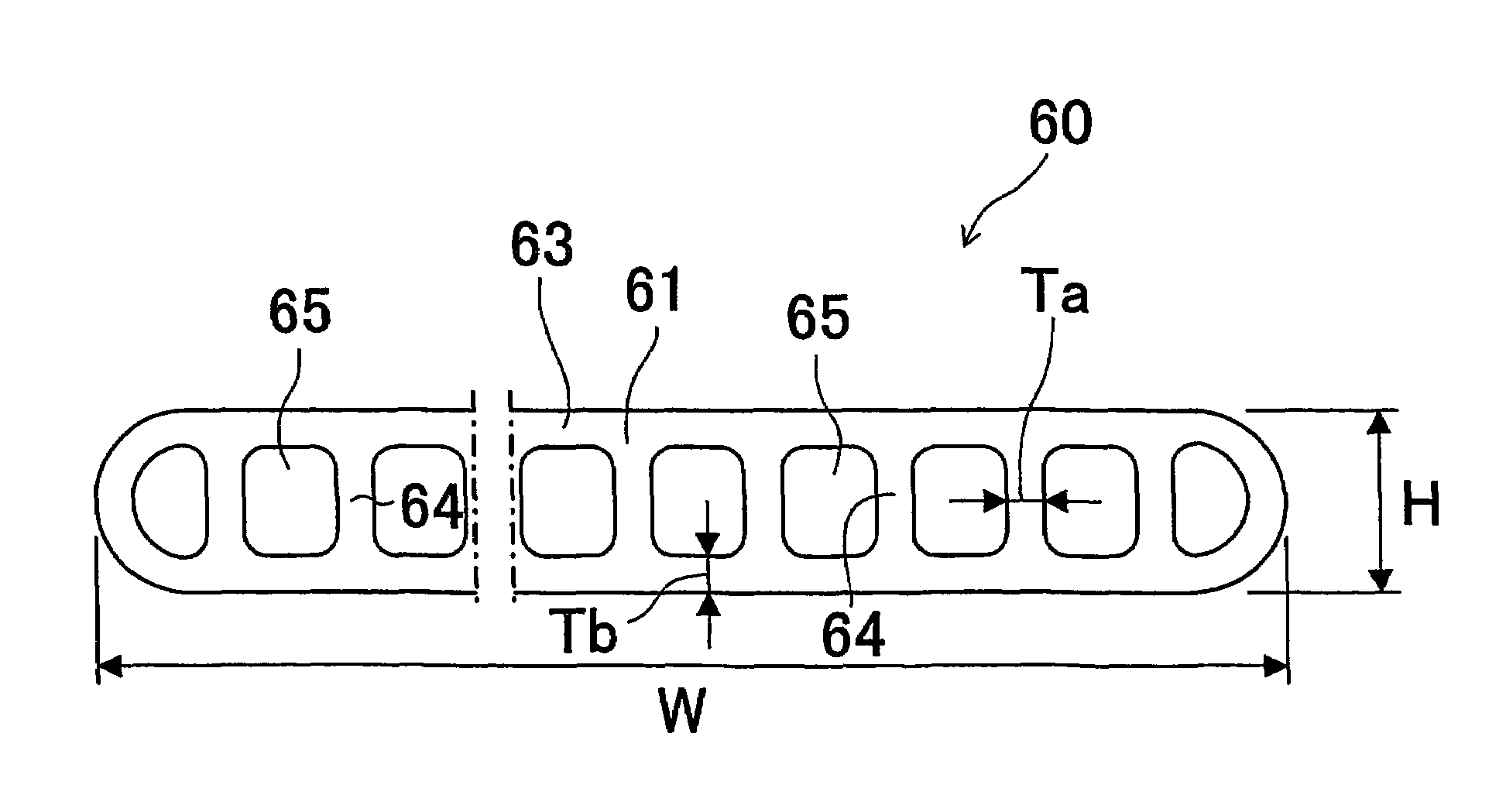

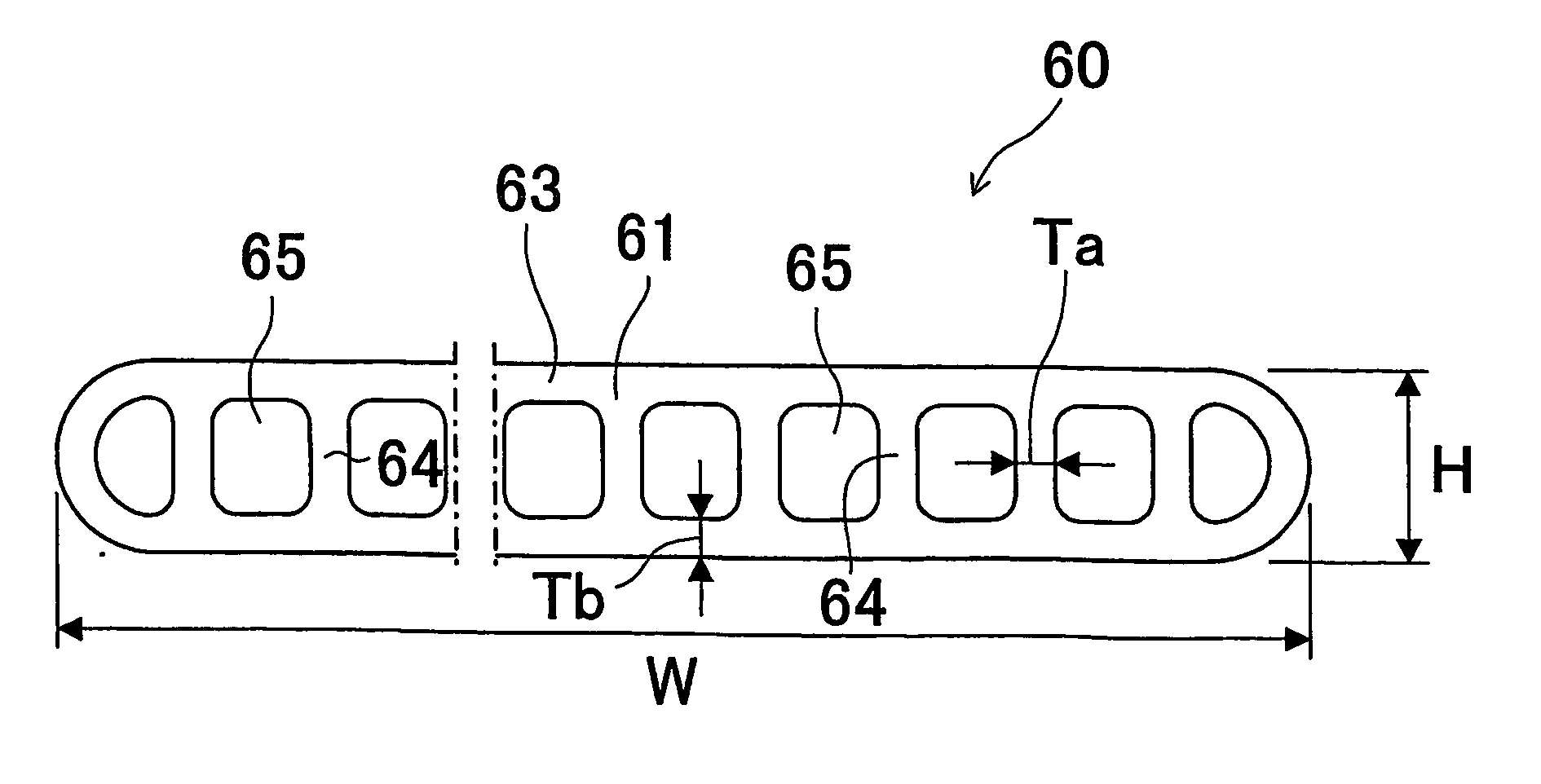

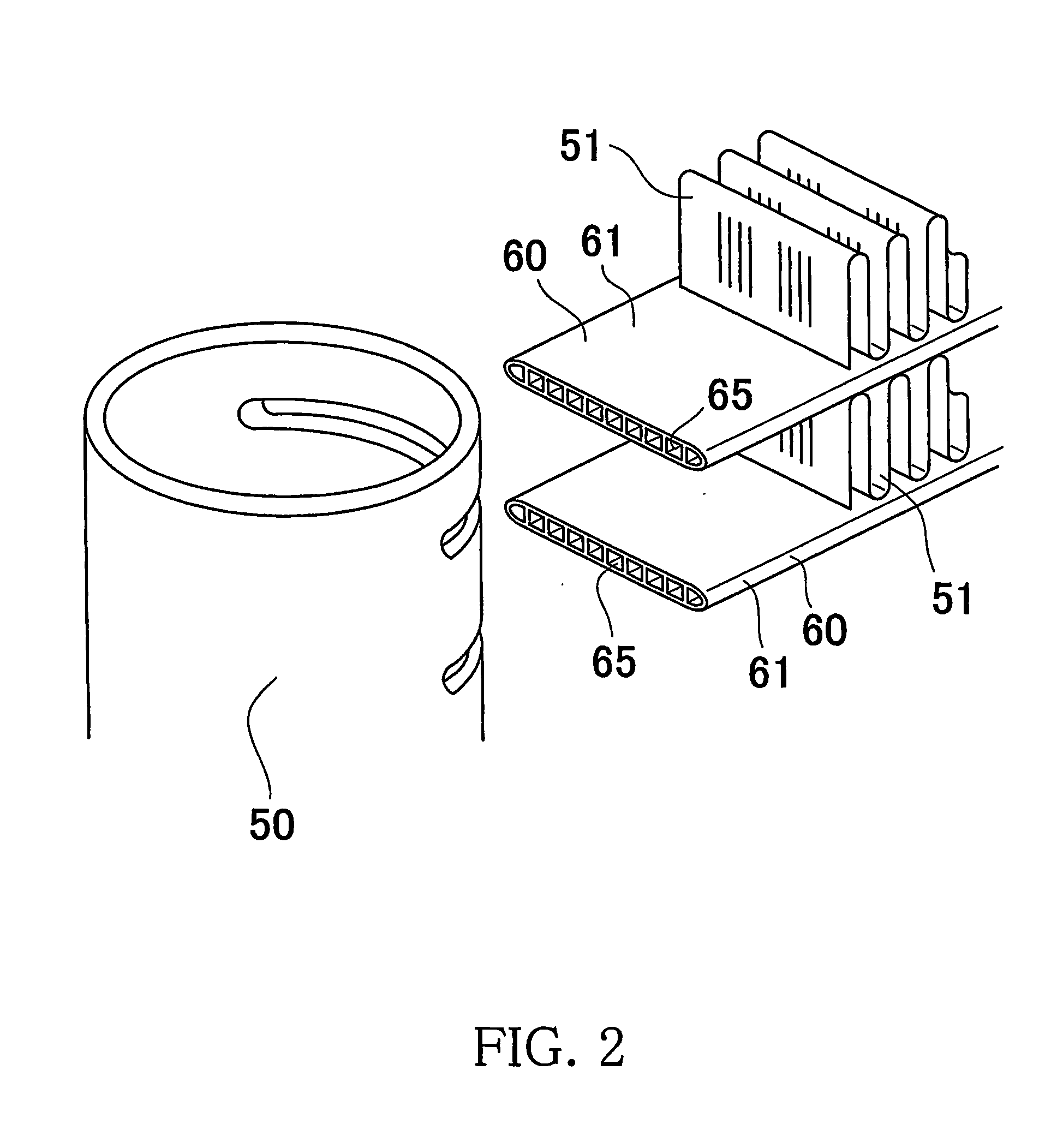

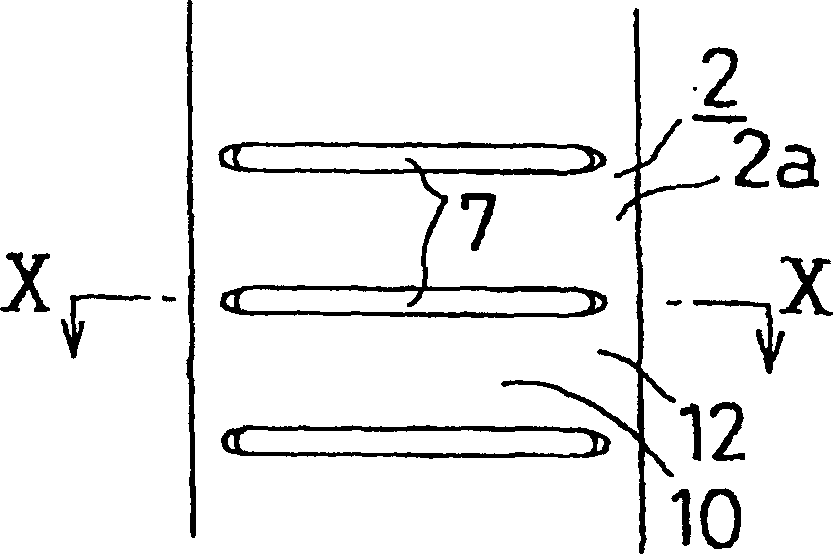

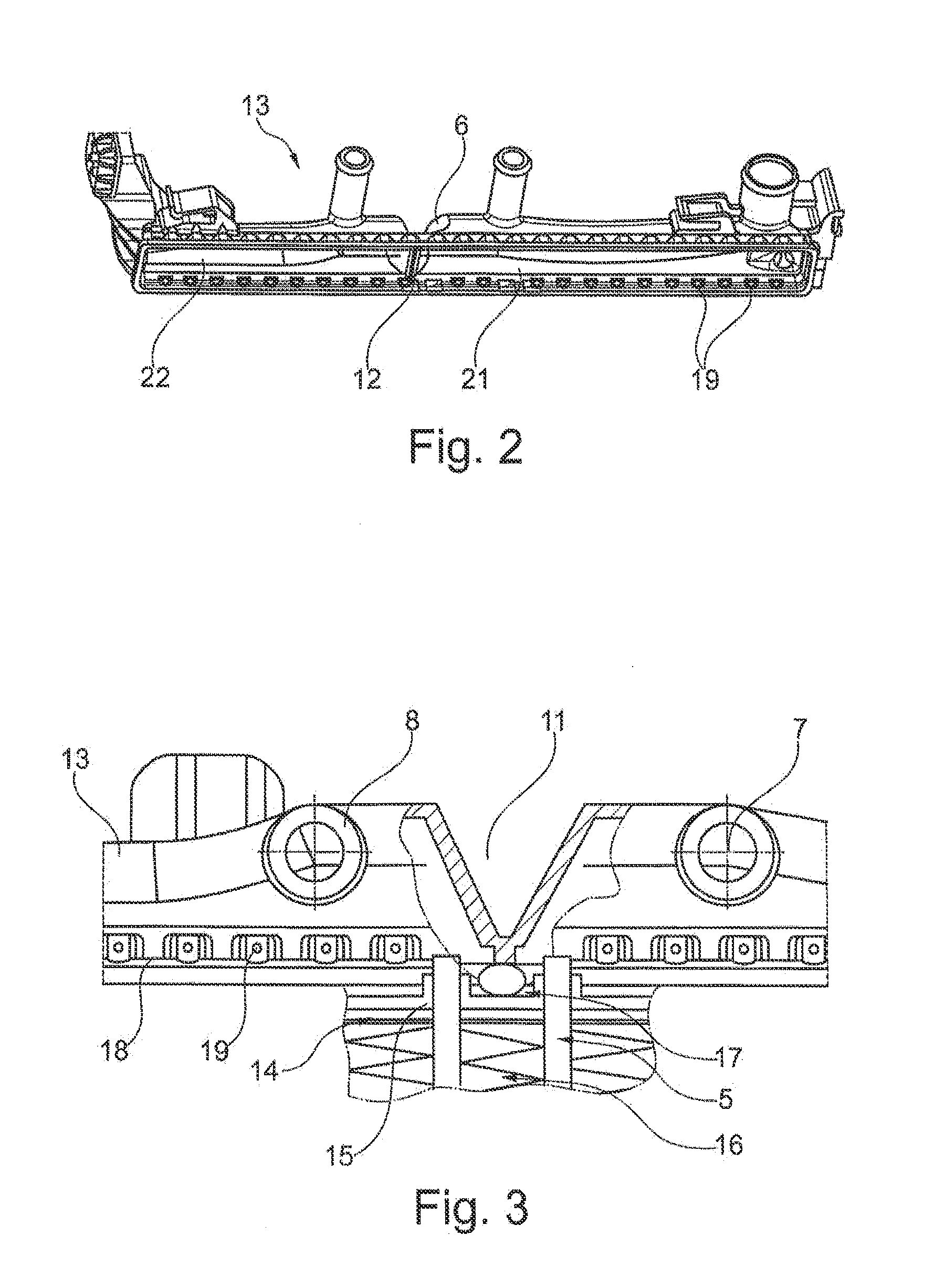

Heat exchanging tube and heat exchanger

InactiveUS7165606B2Improve performanceReduce channel resistanceEvaporators/condensersStationary conduit assembliesTO-18Plate heat exchanger

A heat exchanging tube is provided with a flat tube main body having a predetermined length and a plurality of refrigerant passages extending in a tube longitudinal direction and arranged in a tube widthwise direction. The following relational equations (a) to (c) are satisfied: W=6 to 18 mm . . . (a); Ac / At×100=50 to 70% . . . (b) and P / L×100=350 to 450% . . . (c), where “W” is a width of the tube main body, “Ac” is a total cross-sectional area of the refrigerant passages, “At” is a total cross-sectional area of the tube main body ( including the refrigerant passages), “L” is an external perimeter of the tube main body and “P” is a total inner perimeter of the refrigerant passages. With this tube, enough pressure strength can be obtained and the passage resistance can be decreased while keeping the light weight, and further the heat exchanging performance can be improved.

Owner:KEIHIN THERMAL TECH CORP

Heat exchanging tube and heat exchanger

InactiveUS20060151160A1Improve performanceReduce channel resistanceEvaporators/condensersSteam/vapor condensersTO-18Engineering

A heat exchanging tube is provided with a flat tube main body having a predetermined length and a plurality of refrigerant passages extending in a tube longitudinal direction and arranged in a tube widthwise direction. The following relational equations (a) to (c) are satisfied: W=6 to 18 mm . . . (a); Ac / At×100=50 to 70% . . . (b) and P / L×100=350 to 450% . . . (c), where “W” is a width of the tube main body, “Ac” is a total cross-sectional area of the refrigerant passages, “At” is a total cross-sectional area of the tube main body ( including the refrigerant passages), “L” is an external perimeter of the tube main body and “P” is a total inner perimeter of the refrigerant passages. With this tube, enough pressure strength can be obtained and the passage resistance can be decreased while keeping the light weight, and further the heat exchanging performance can be improved.

Owner:KEIHIN THERMAL TECH CORP

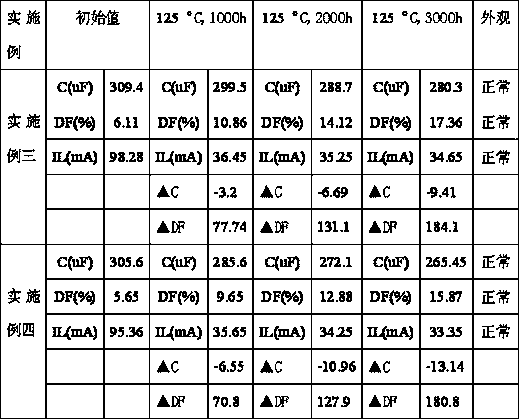

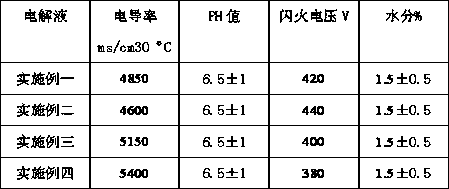

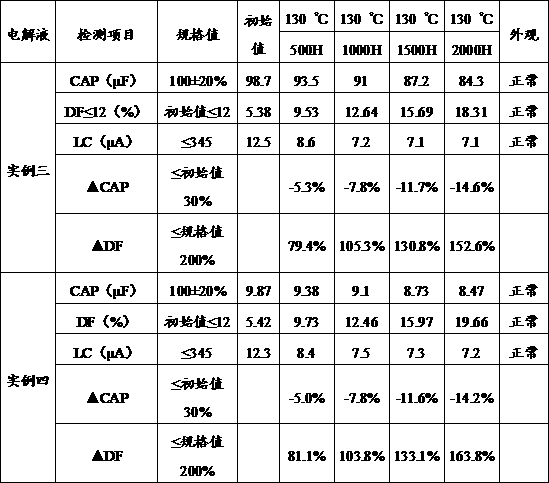

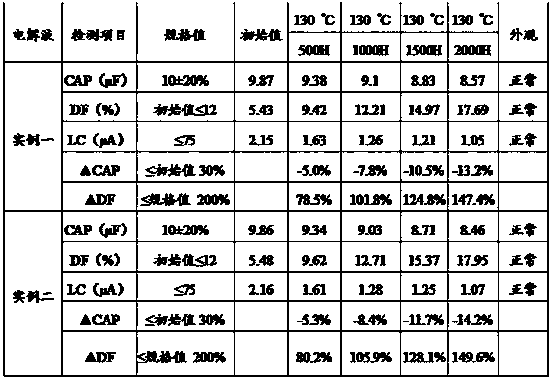

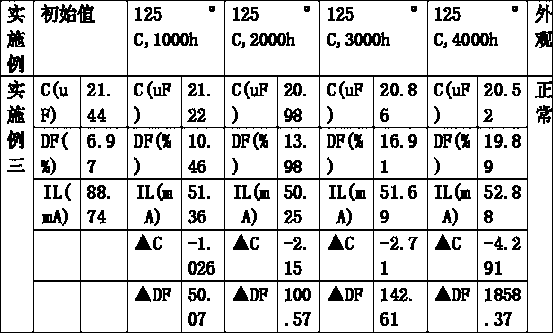

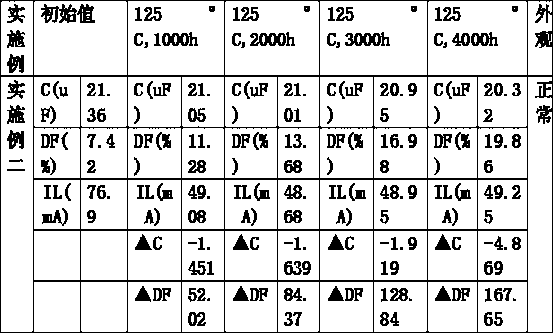

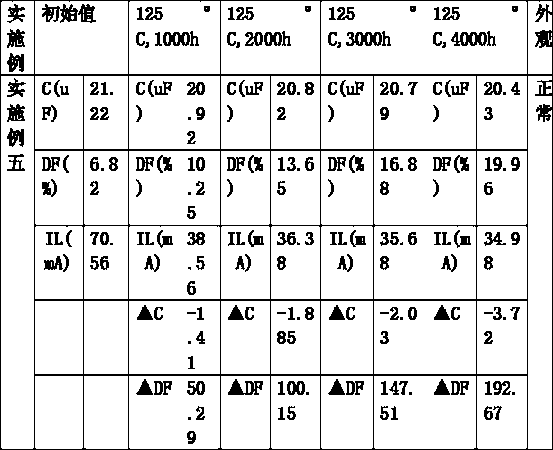

Medium-voltage working electrolyte of aluminum electrolytic capacitor and preparation method of medium-voltage working electrolyte

InactiveCN107863252AGuaranteed high temperature characteristicsGuaranteed lifeElectrolytic capacitorsElectrolysisMedium pressure

The invention discloses a medium-voltage working electrolyte of an aluminum electrolytic capacitor. The electrolyte comprises constituents based on ratio by mass: 36.5-78% of main solvent, 3-20% of auxiliary solvent, 8-15% of main solute, 6-17% of auxiliary solute, 0.05-0.3% of waterproof mixture, 2-7% of voltage-resistant promoter, 1.5-3% of formation special modifier and 0.6-1.5% of hydrogen elimination agent, wherein the main solvent is ethylene glycol. A mixed solvent system is employed, high-temperature characteristic is ensured, and low-temperature characteristic is also compatible; theboiling point (245 DEG C) of diethylene glycol is high, the condensation point (-44 DEG C) of Gamma-butyrolactone is low, an appropriate amount of voltage resistant promoter is added, U<flash>=alg Rho+b (V), Rho is resistivity (ohm. cm) of the electrolyte, a and b are relevant constants of the electrolyte, thus, the electrical conductivity of the medium-voltage electrolyte is high to cause that the flash voltage is low, and enough voltage resistant capability can be ensured under the condition of high electrical conductivity by the introduction of the voltage resistant promoter; and moreover,with the addition of a corrosion resistant agent, the corrosion probability during long-term working is reduced, and the lifetime of a product is ensured.

Owner:NANTONG SUNION ELECTRONICS

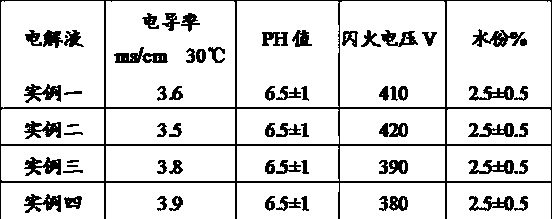

Low leakage current working electrolyte for medium-voltage aluminum electrolytic capacitor and preparation method thereof

InactiveCN110047656AImprove oxidation efficiencyReduce hydrationElectrolytic capacitorsElectrolysisLow leakage

The invention discloses a low leakage current working electrolyte for medium-voltage aluminum electrolytic capacitor and a preparation method thereof, wherein the working electrolyte comprises the following components in parts by weight: 40-80% of main solvent, 4-15% of auxiliary solvent, 7-20% of main solute, 5-15% of auxiliary solute, 0.05-2% of water-inhibiting agent, 0.5-5% of pressure-resistant promoting agent, 0.5-1.5% of oxidant, 0.5-1.5% of preservative and 0.5-1.5% of hydrogen-eliminating agent, wherein the main solvent is glycol. The invention has the advantages that sufficient voltage capacity is still ensured under the condition of high conductivity; the hydration of the aluminum foil during long-time work is reduced, the oxide film is more stable, the saturated vapor pressureof the oxide film is reduced, and the flash fire voltage is improved; the electrolyte oxidation efficiency is improved, and the corrosion probability of the anode lead of the capacitor is reduced; theleakage current is reduced, the hydrogen is eliminated, the capacitor bulge is prevented, and the service life of the product is prolonged.

Owner:益阳市开元电子有限公司

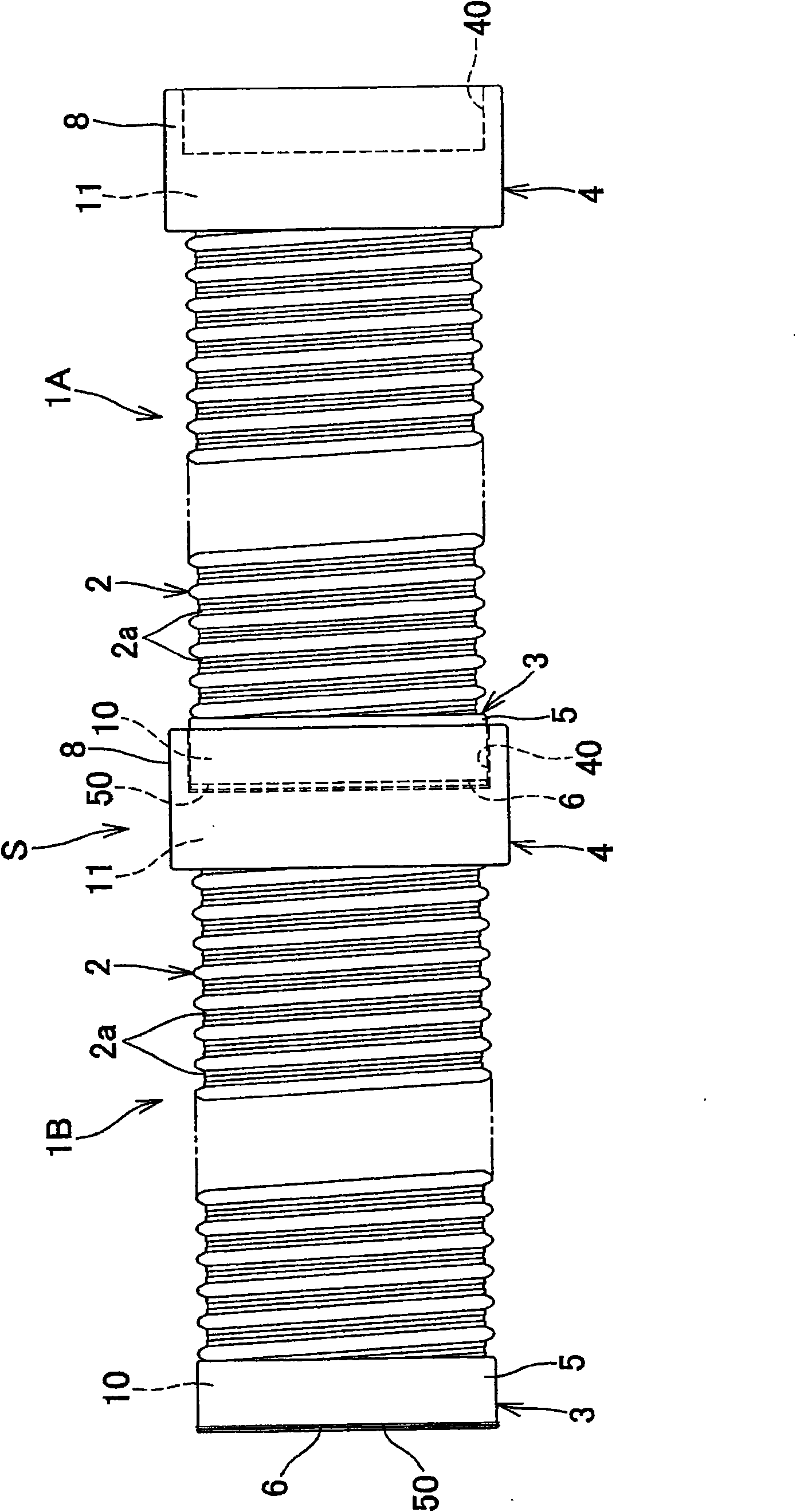

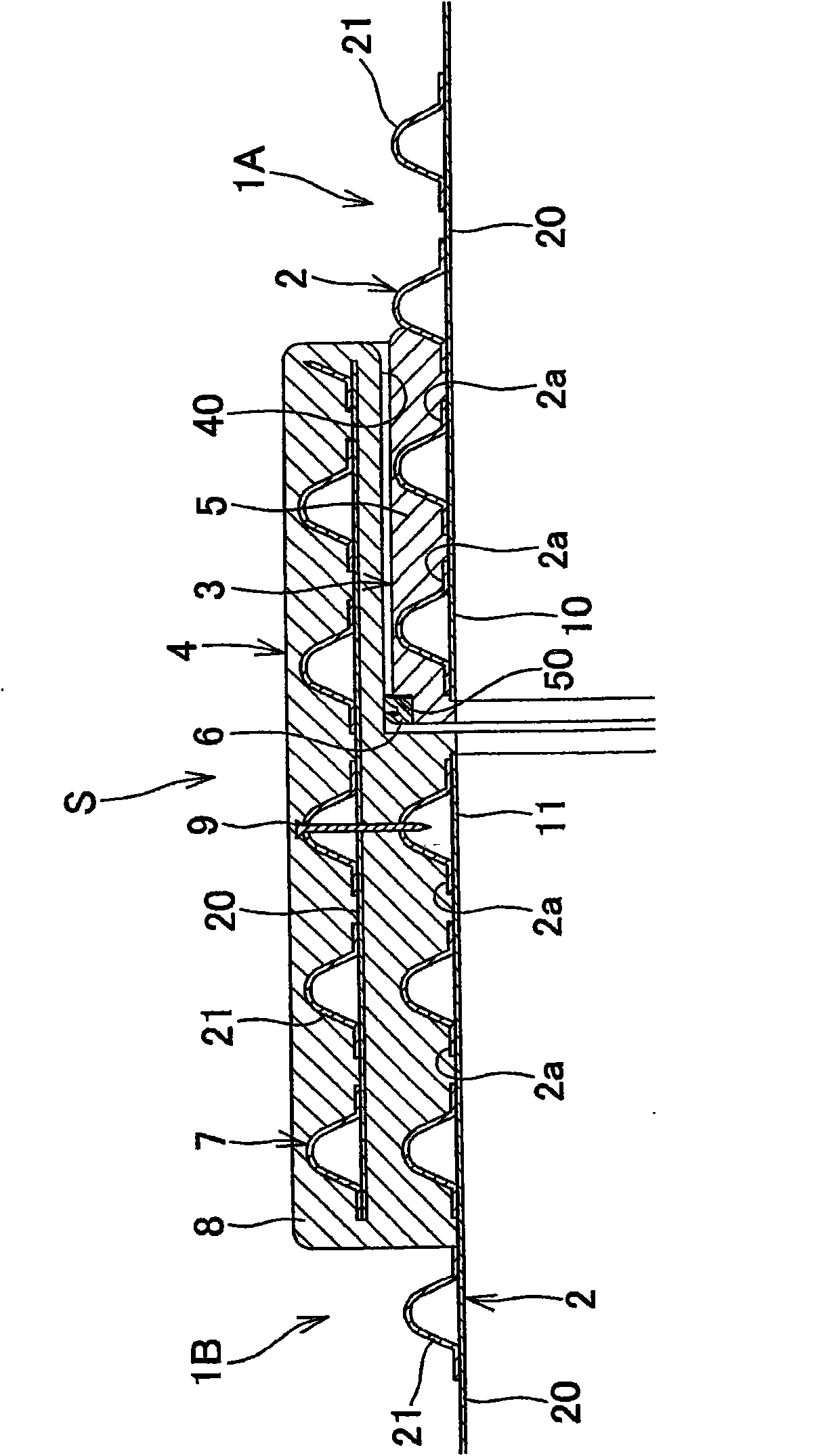

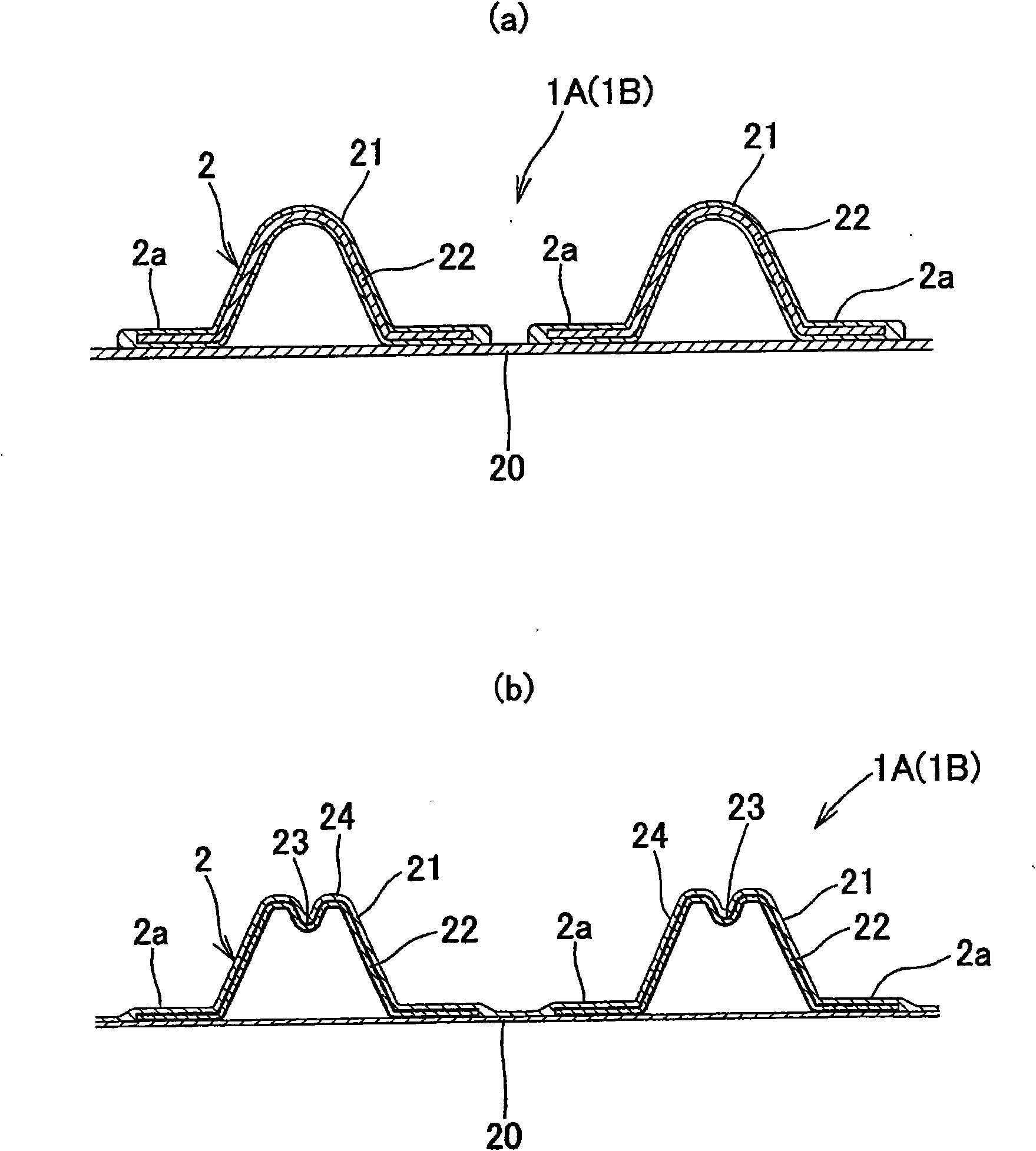

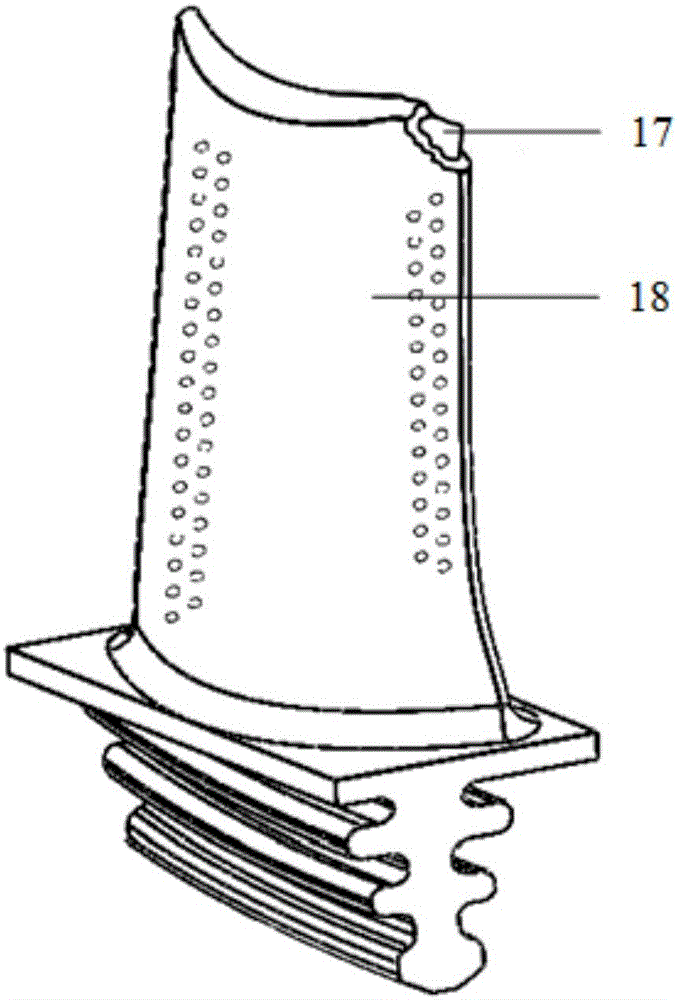

Connection structure of waveform plastic conduit, a waveform plastic conduit used by the connection structure and manufacture method thereof

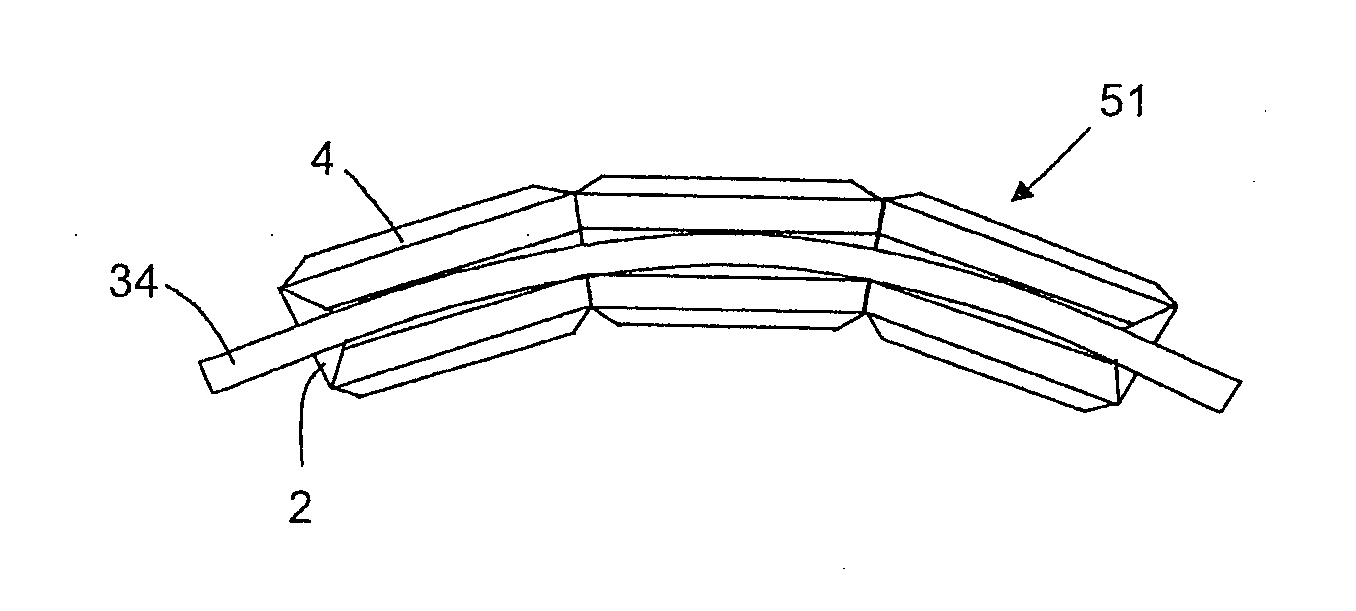

ActiveCN101551043AFirmly connectedImprove work efficiencyFlexible pipesPipe-jointsWave shapeStructural engineering

The invention provides a connection structure of waveform plastic conduit, a waveform plastic conduit used by the connection structure and manufacture method thereof. A tubular insertion part (3) is set on the opposite end (10) of a first waveform plastic conduit (1A) by covering at least burying the synthetic resin layer (5) for forming the waveform cove (2a) of the end outer-surface side. A pipesocket part (4) is set on the opposite end (11) of a second waveform plastic conduit (1B) and composed of synthetic resin, which is covered on the end outer-surface side and extends in outside tubular shape along the axle direction and the tubular insertion part (3) of the first waveform plastic conduit (1A) is inserted into the pipe socket part (4) of the second waveform plastic conduit (1B) andconnected with each other.

Owner:KANA FURETSUKUSU KOOHOREESHON

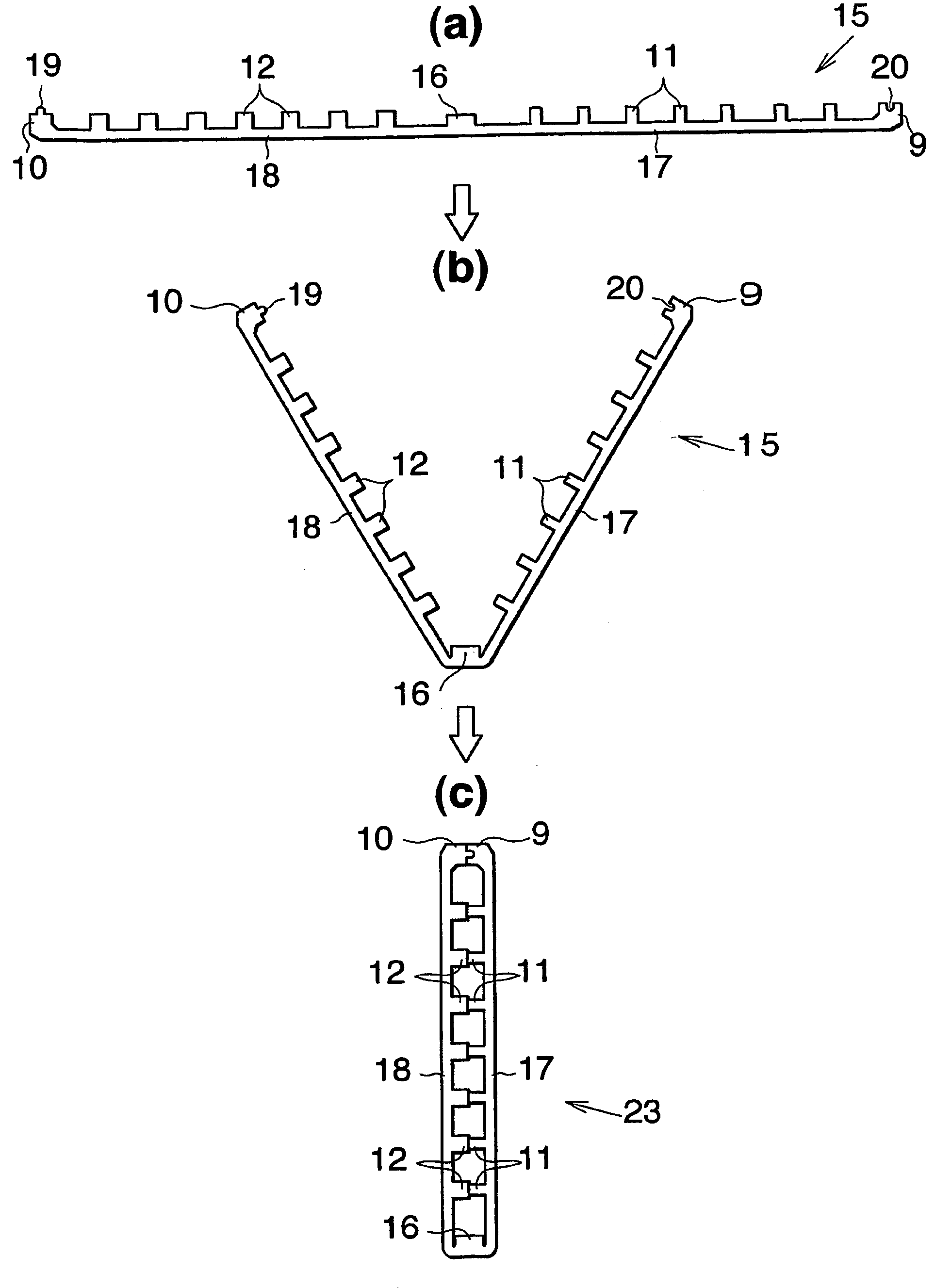

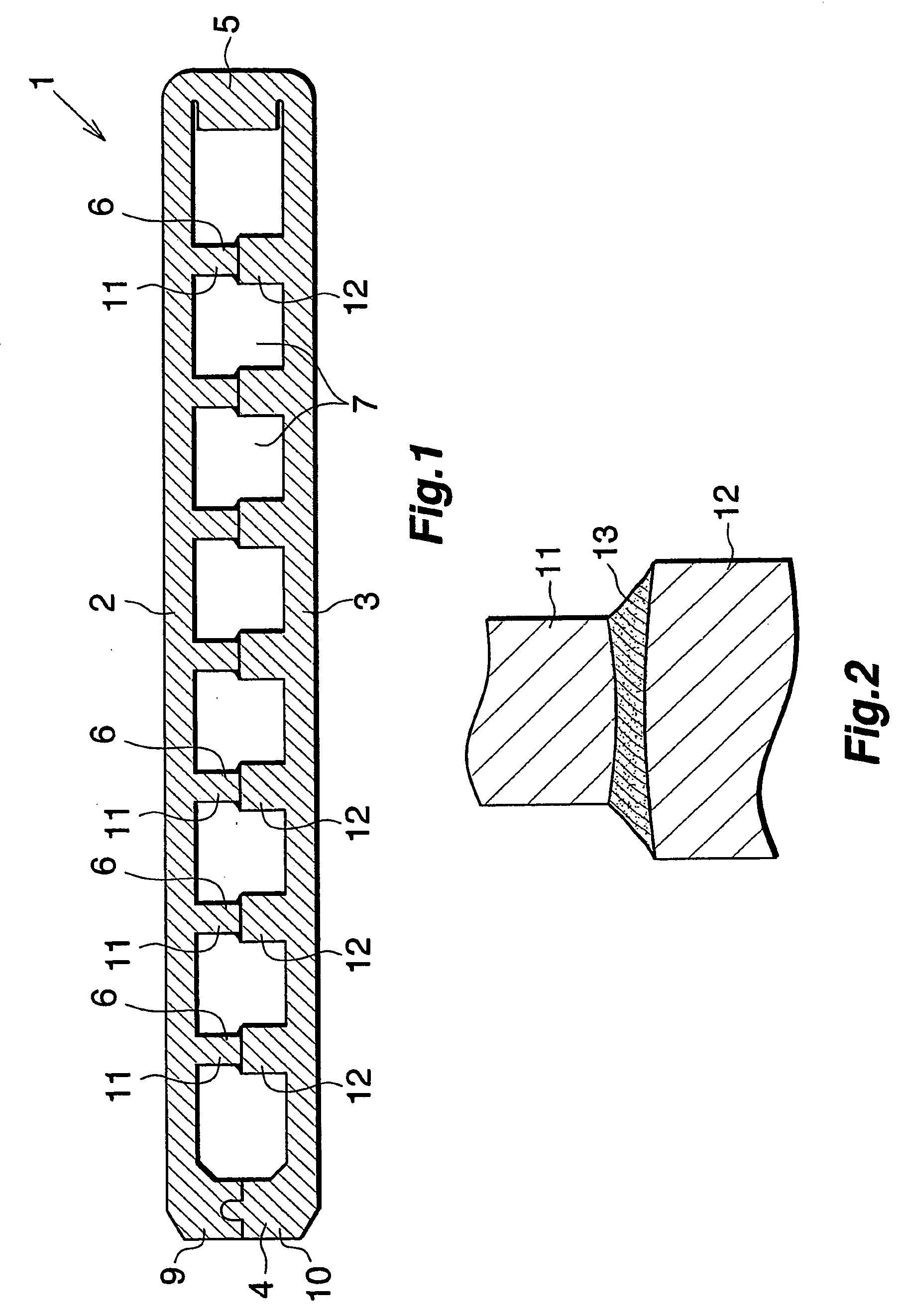

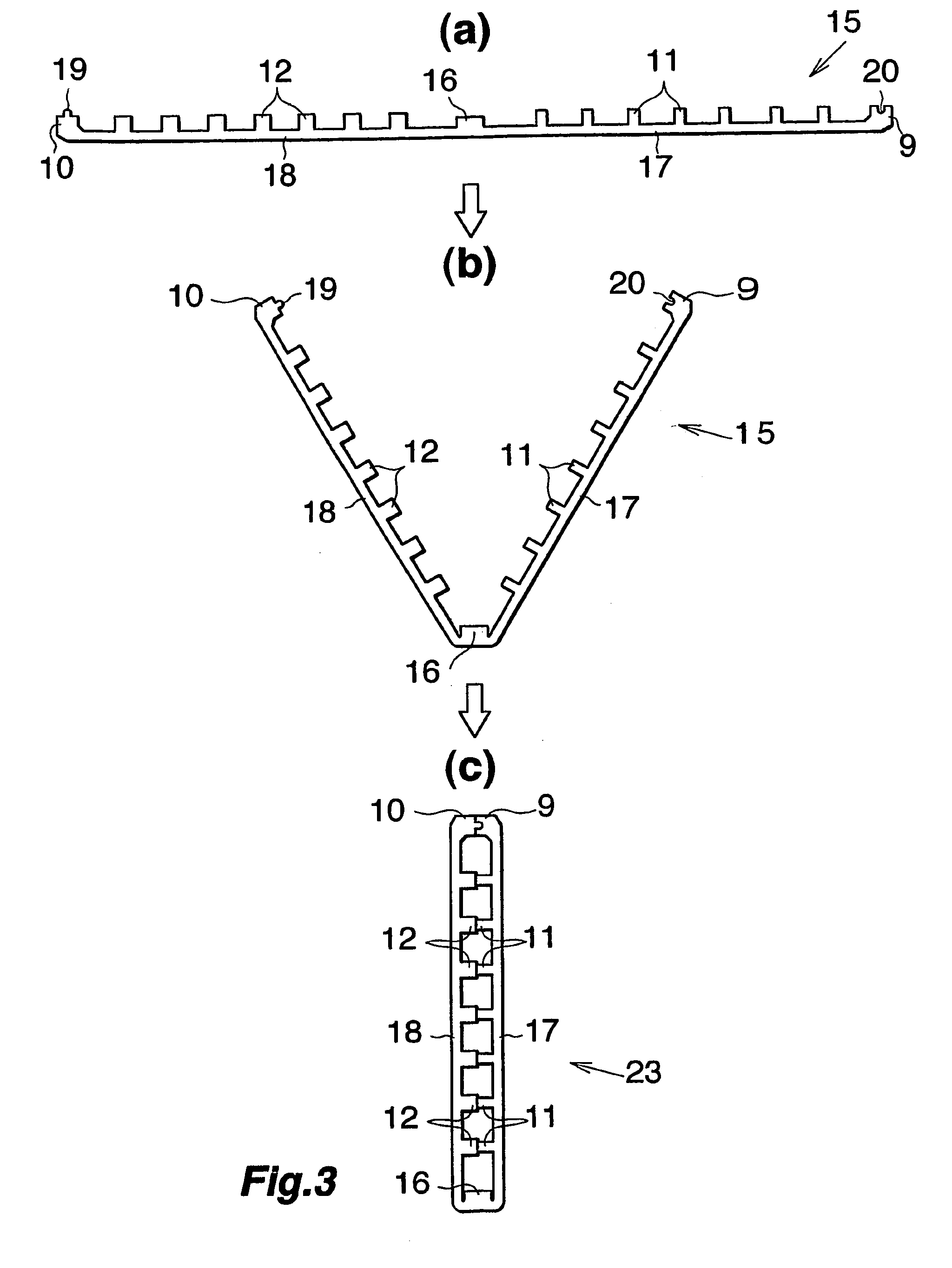

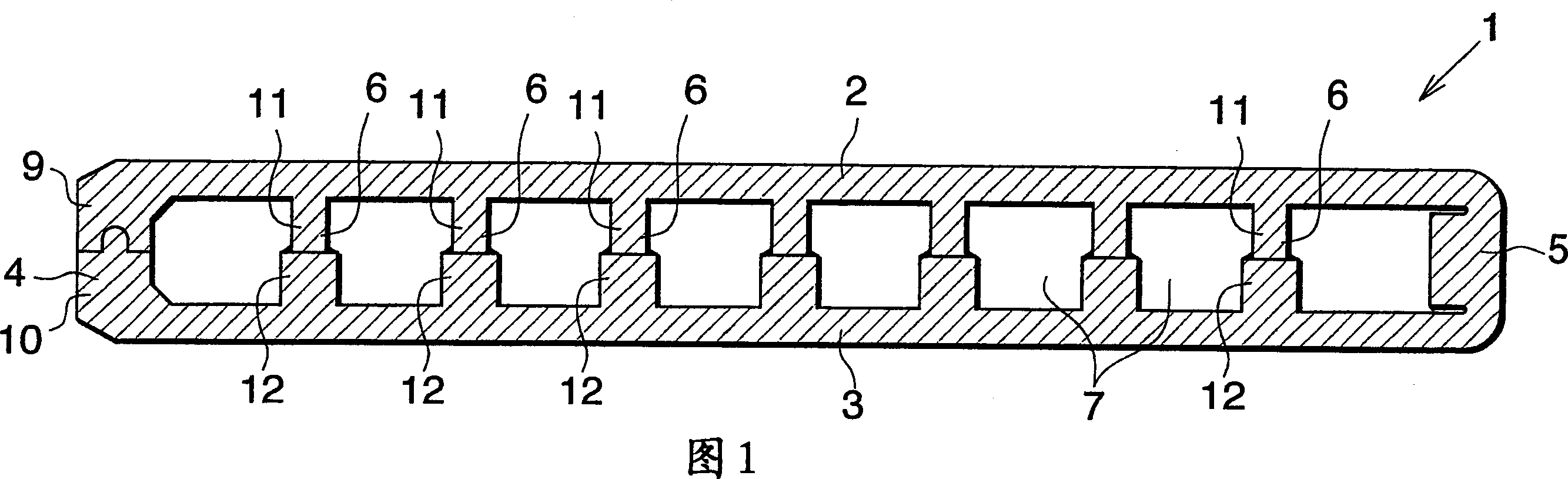

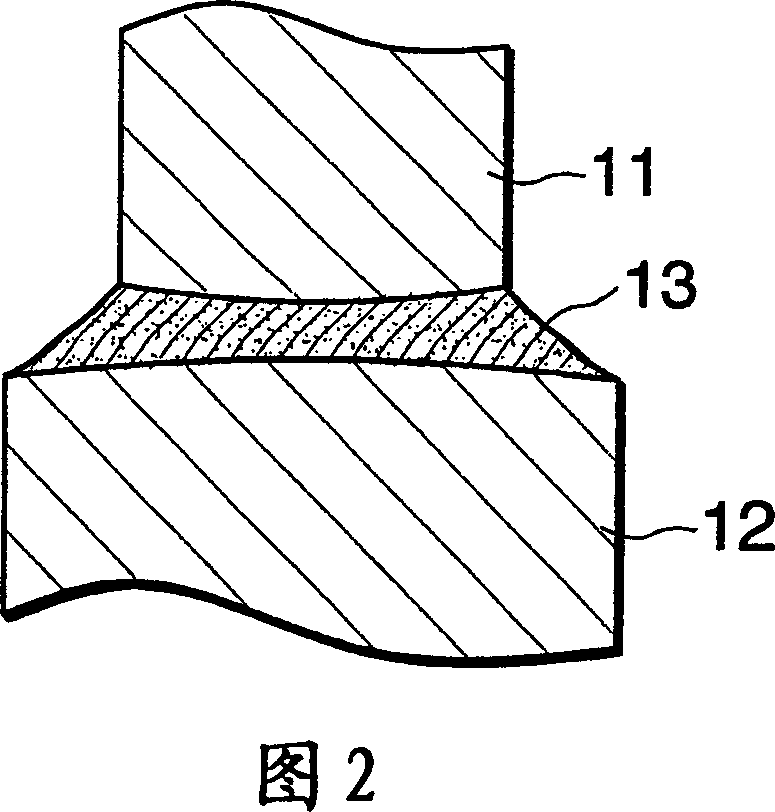

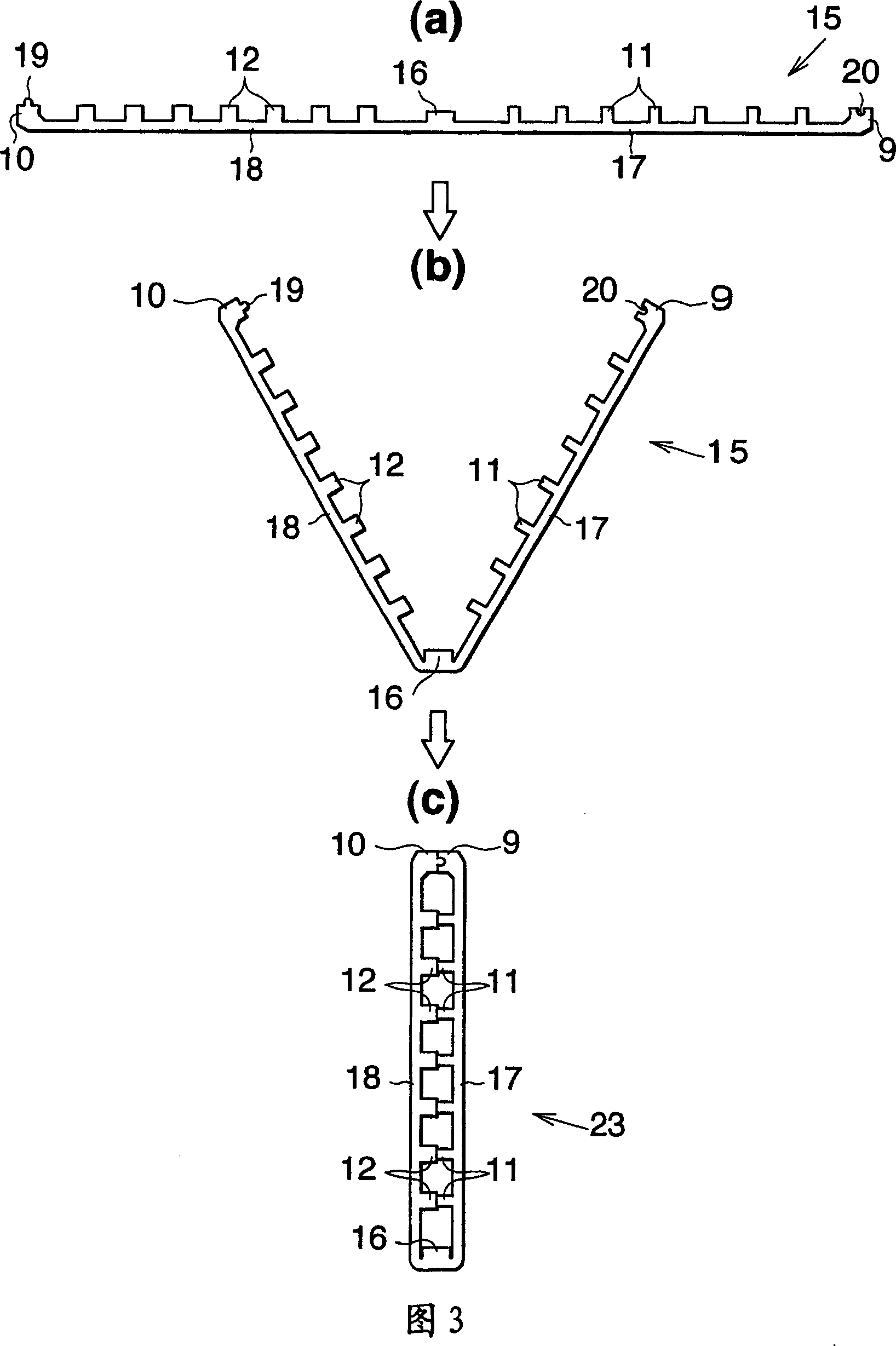

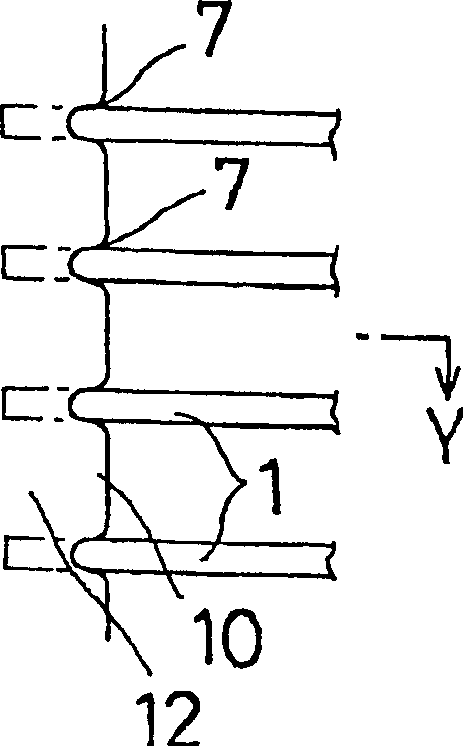

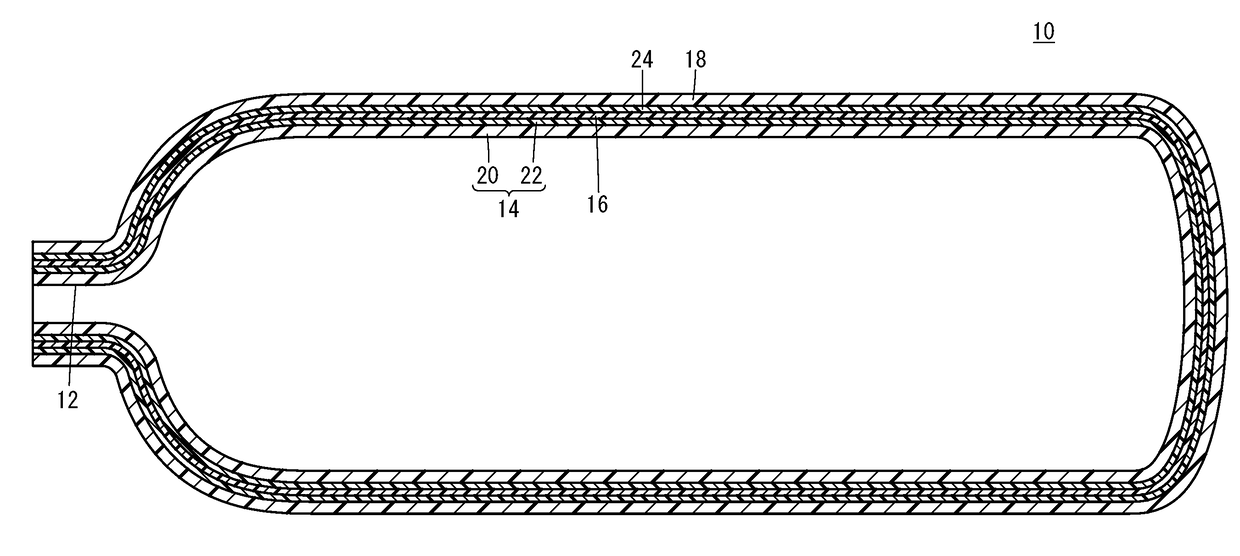

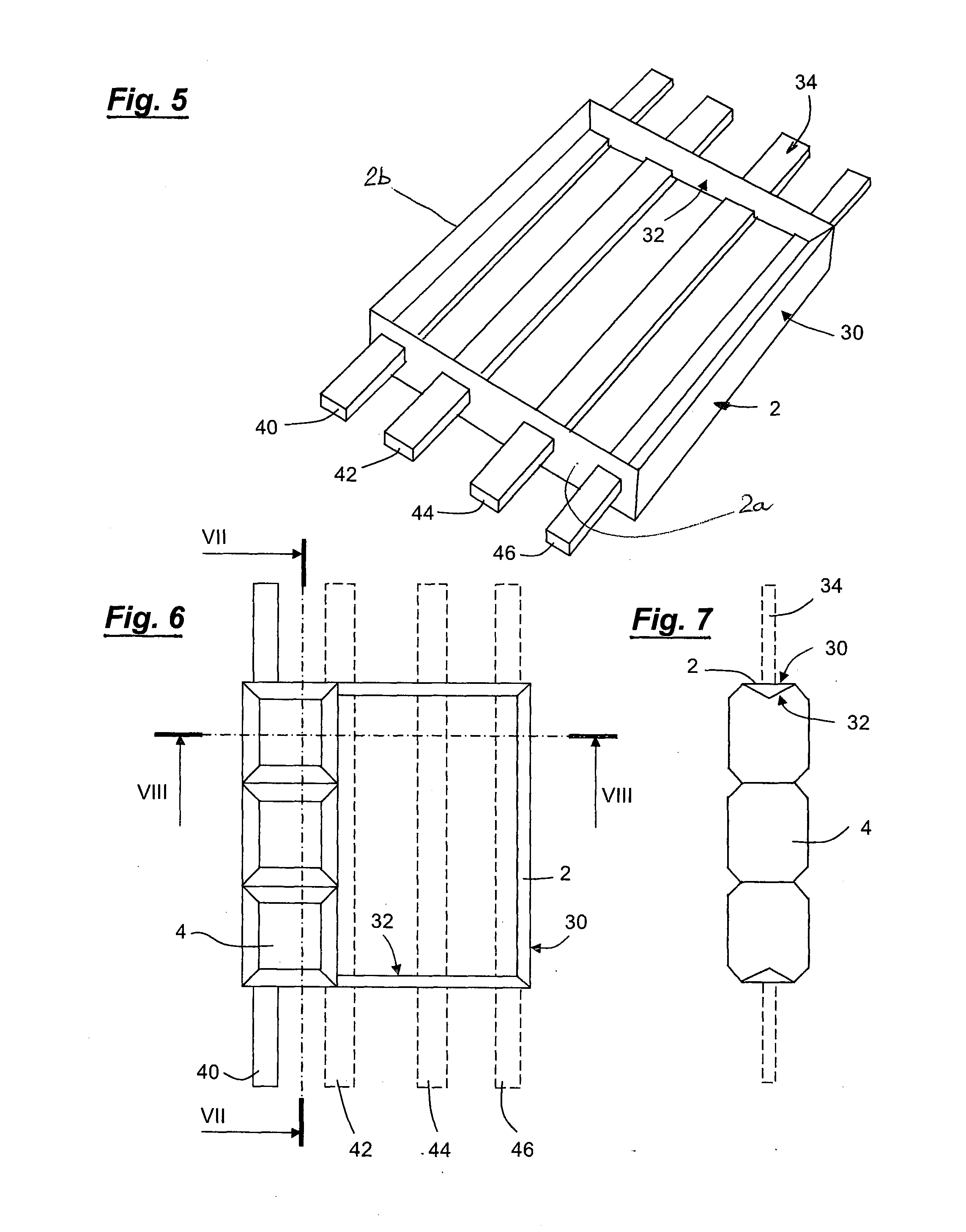

Flat Tube Making Platelike Body, Flat Tube, Heat Exchanger and Process for Fabricating Heat Exchanger

InactiveUS20080245518A1Increase the brazing areaImprove stress resistanceReinforcing meansStationary conduit assembliesStructural engineeringMetal

A flat tube making platelike body 15 is in the form of a single metal plate in its entirety and comprises two flat wall forming portions 17, 18 having the same width, a connecting portion 16 for interconnecting these portions 17, 18, side wall forming portions 9, 10 projecting from the respective flat wall forming portions 17, 18 and each formed integrally with one side edge of the flat wall forming portion opposite to the connecting portion 16, and first and second reinforcing wall forming portions 11, 12 integrally formed on each of the flat wall forming portions 9, 10. The first reinforcing wall forming portions 11 are butted against the respective second reinforcing wall forming portions 12 in pairs when the metal plate is folded into a hairpin form at the connecting portion 16. The first reinforcing wall forming portions 11 are given a smaller thickness than the second reinforcing wall forming portions 12 on the other flat wall forming portion 18 butted against the respective portions 11. The platelike body 15 gives an enhanced brazing joint strength to the reinforcing wall forming portions in fabricating a flat tube, and improved pressure resistance to the flat tube to be fabricated.

Owner:SHOWA DENKO KK

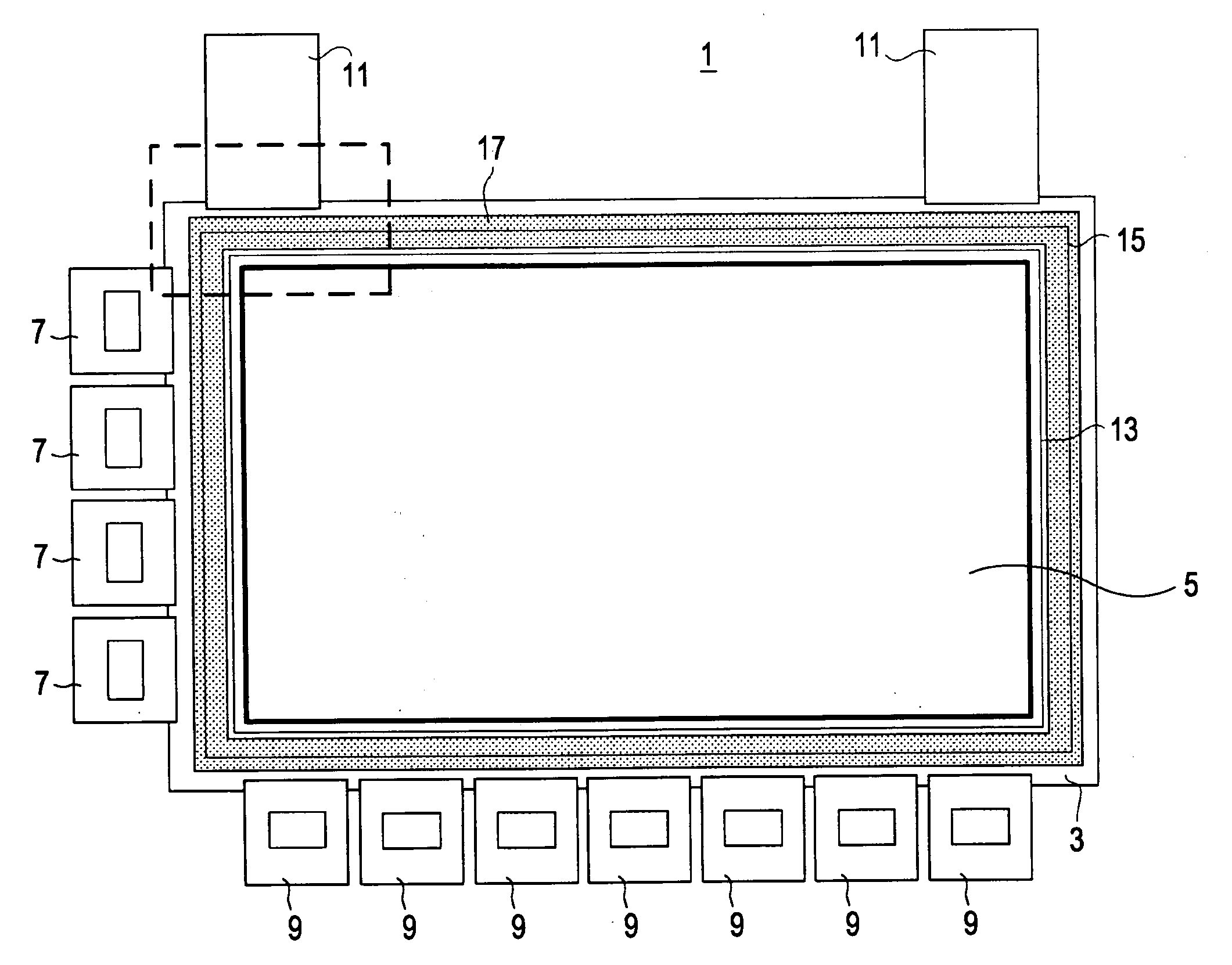

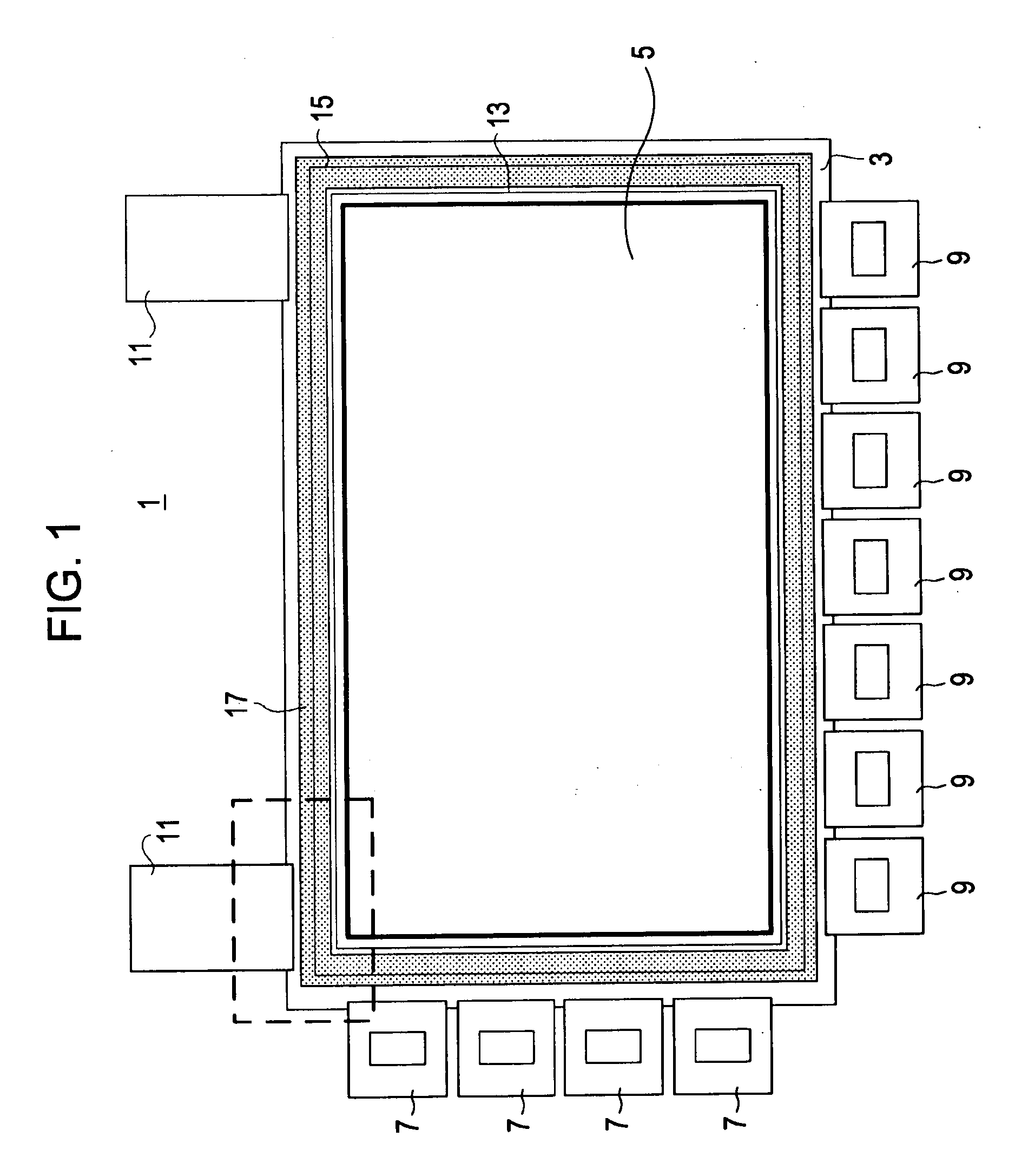

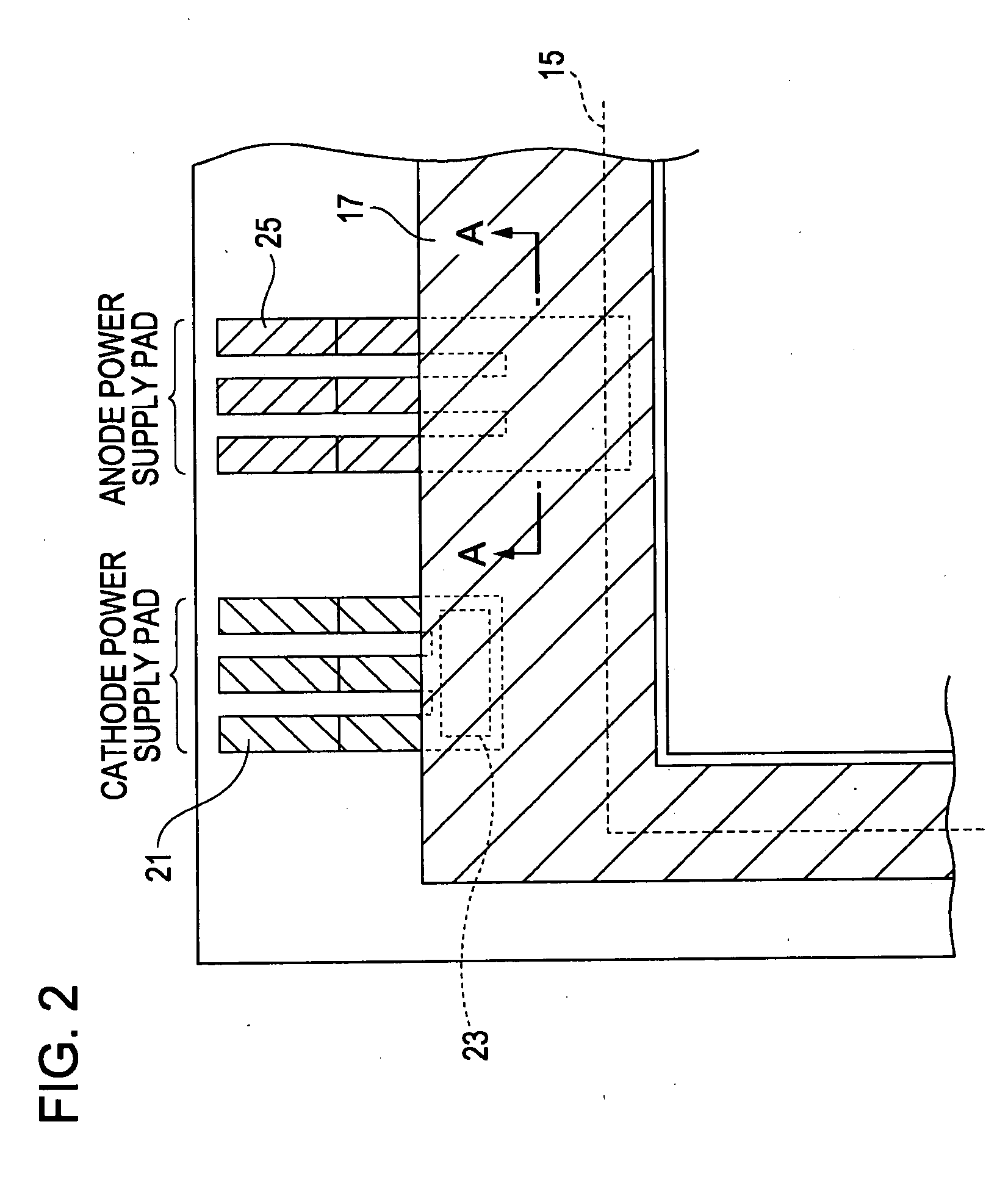

Display panel, electronic device, and mehtod of making display panel

ActiveUS20080265783A1Minimizes overlapping areaSolve the lack of pressure resistanceStatic indicating devicesSolid-state devicesEngineeringElectrical and Electronics engineering

Disclosed is a display panel having a display area with a matrix array of display pixels. The display panel includes an electrode arranged so as to cover the whole of the display area, and a common electrode electrically connected to the electrode. The common electrode is frame-shaped and is arranged along the periphery of the display area. The common electrode has a notch that is opposed to a power supply lead pattern to which a potential different from that applied to the common electrode is applied.

Owner:JOLED INC

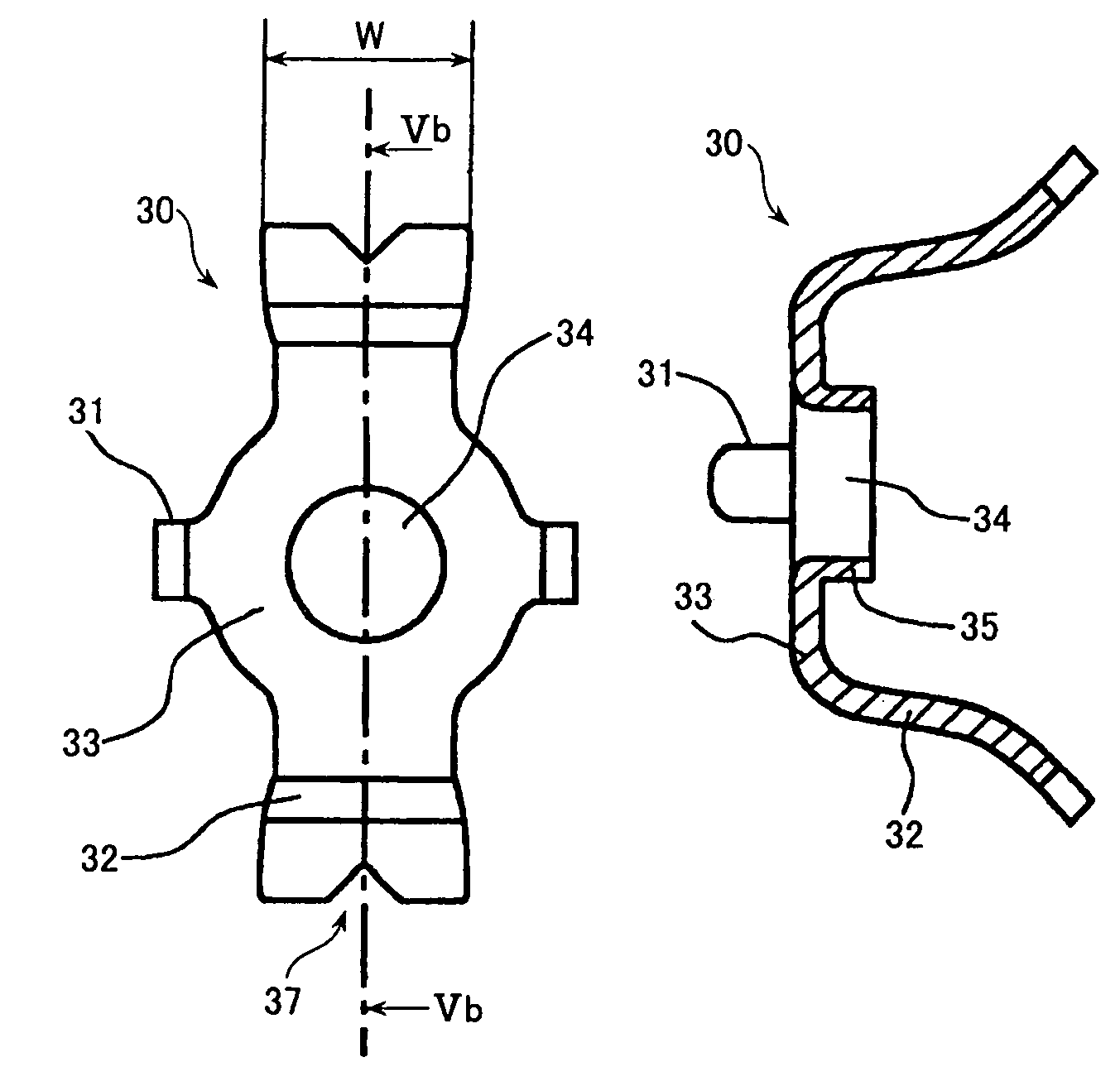

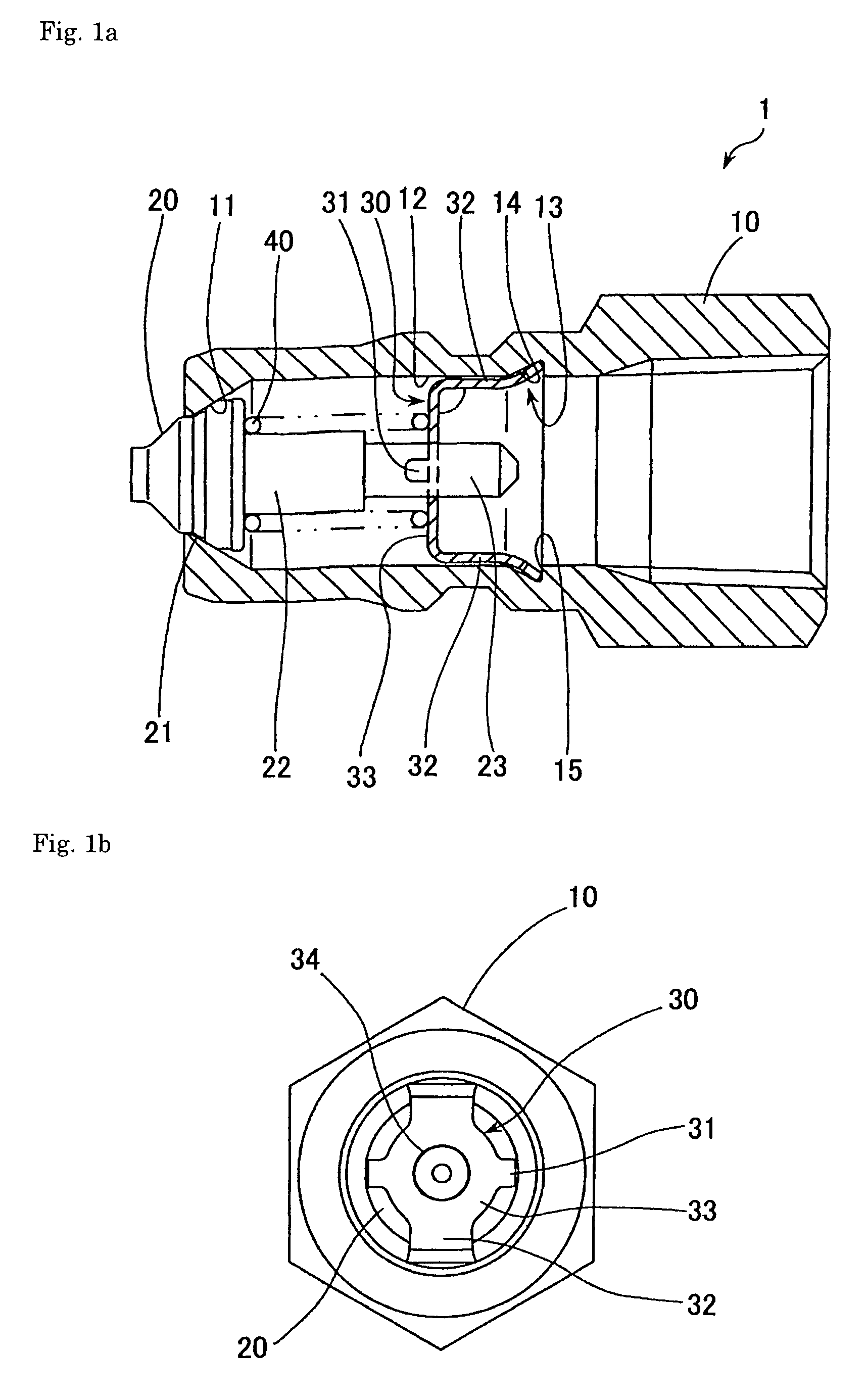

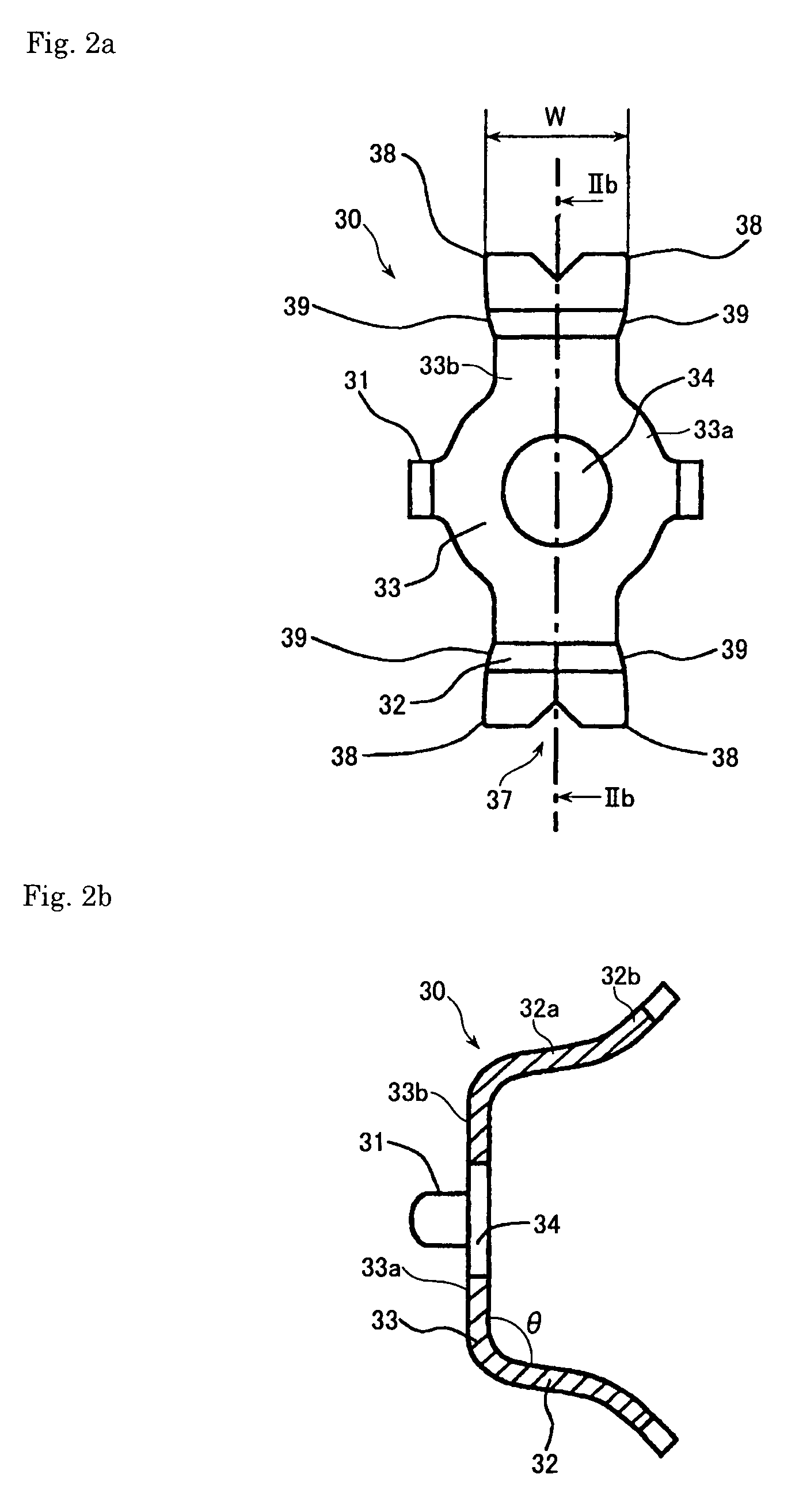

Valve holding member

ActiveUS7472888B2Hold steadyReduce areaMachines/enginesJoints with fluid cut-off meansCouplingEngineering

There is provided a valve holding member for holding a valve of a pipe coupling. The valve holding member includes a hub part 33 having a guide hole 34 for a valve stem, two arm parts 32 diametrically opposing each other on the peripheral edge of the hub part, and spring holding parts 31 formed at the peripheral edge.

Owner:NITTO KOHKI CO LTD

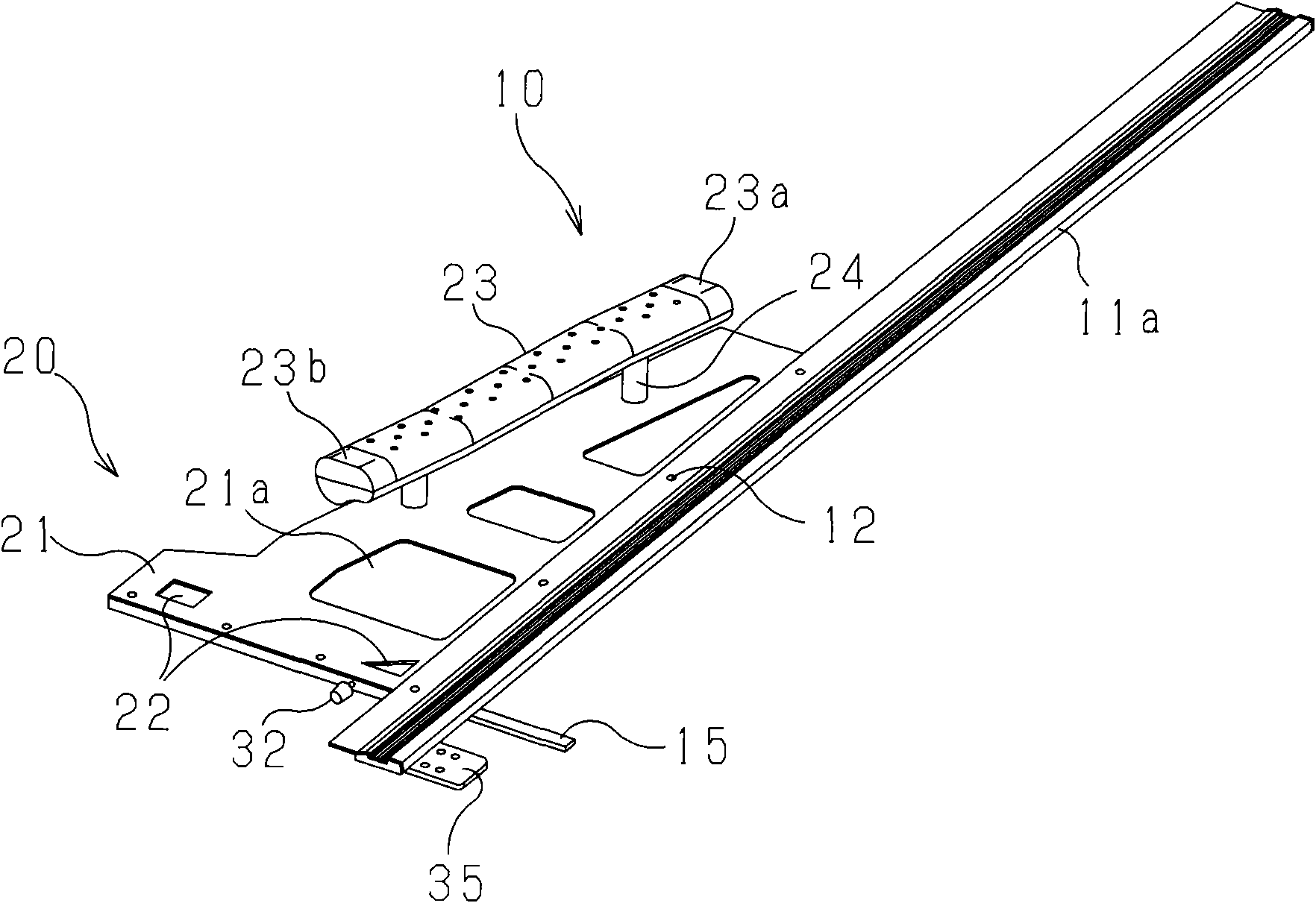

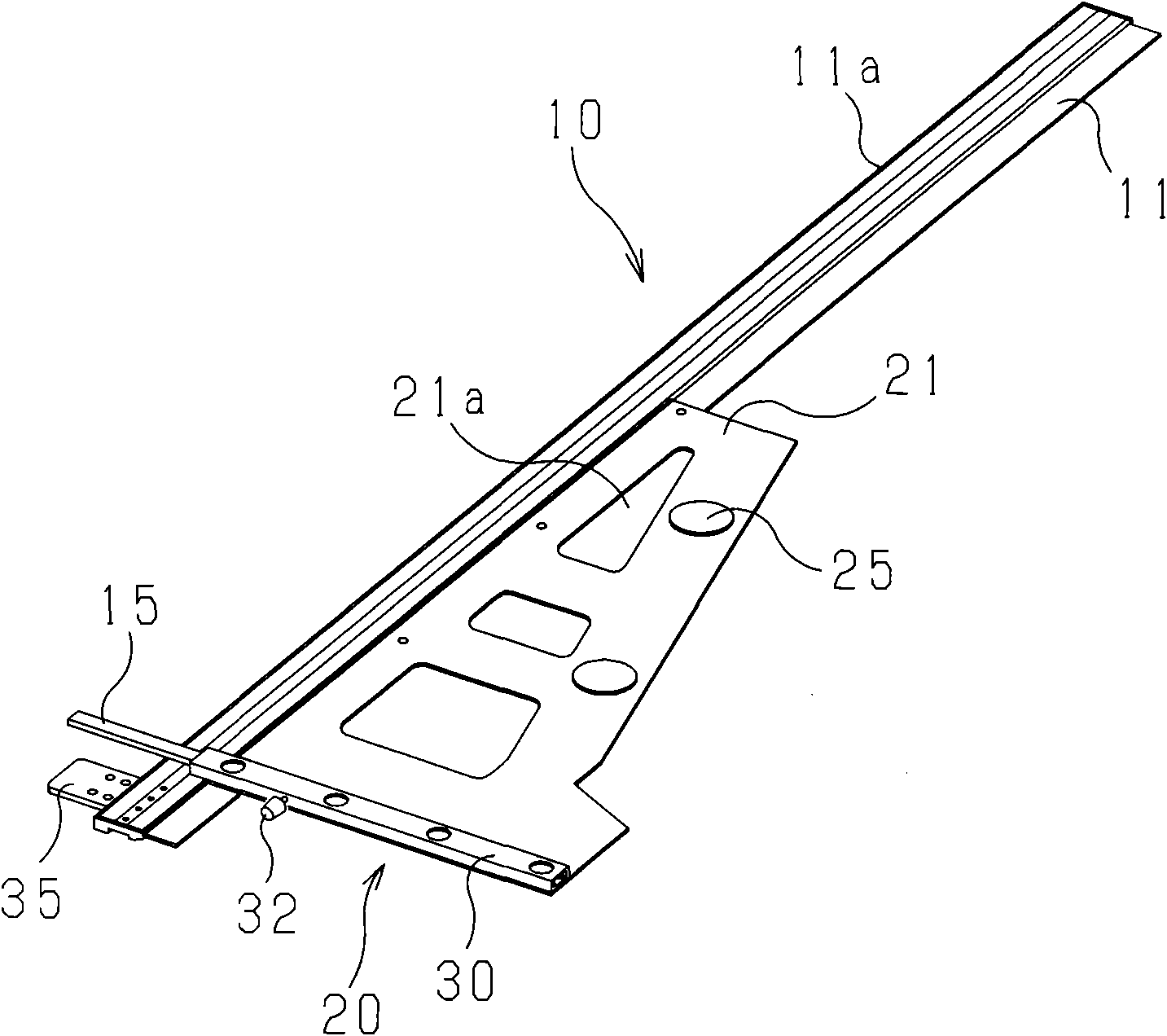

Circular saw guiding device

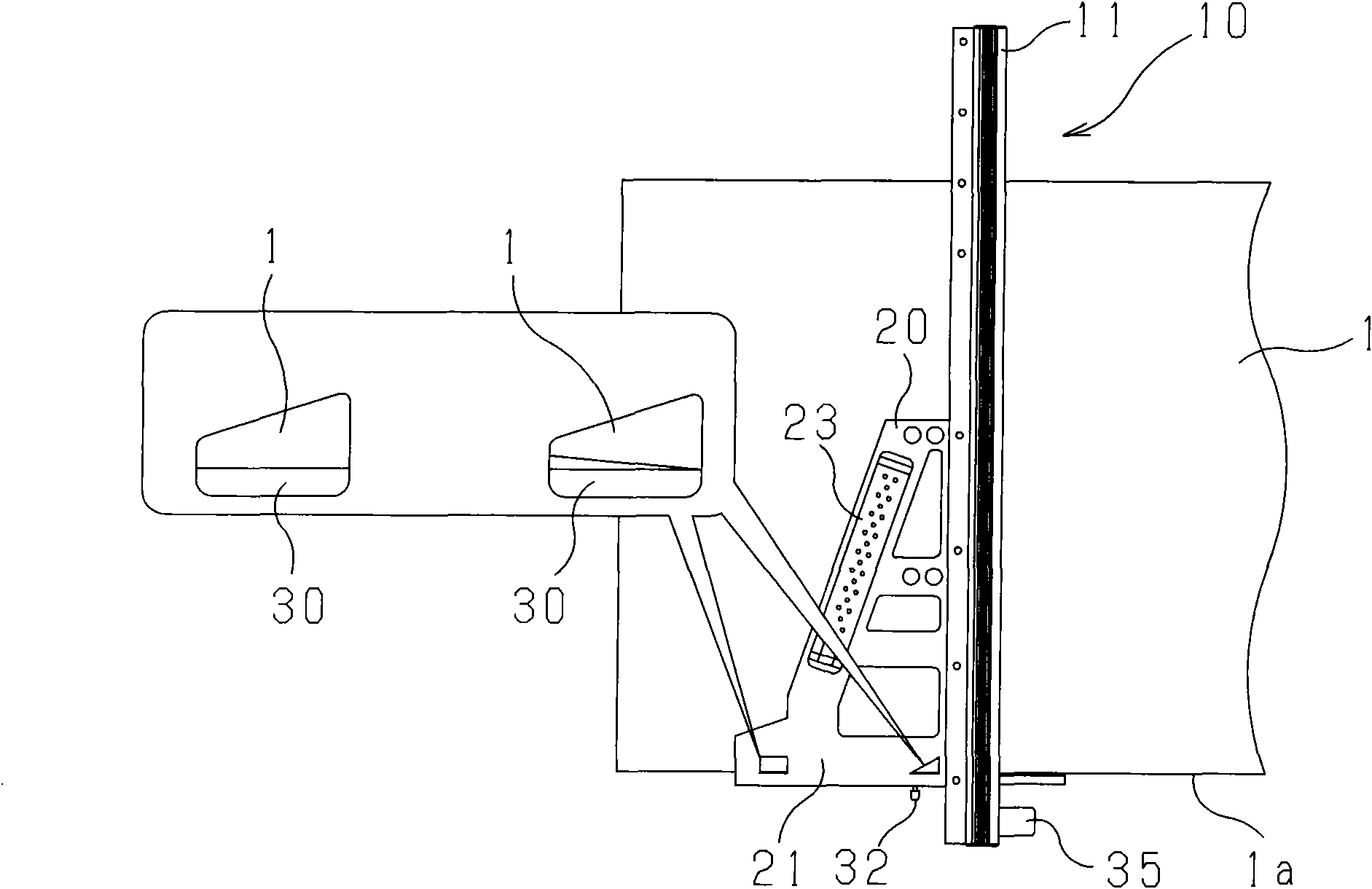

InactiveCN102039637APrecise and correct orientationSufficient pressure resistanceStone-like material working toolsCircular saw

The invention provides a circular saw guiding device which can precisely and correctly guide a dynamoelectric circular saw. The circular saw guiding device 10 is provided with a guide plate 11 and a handle device 20, wherein the guide plate 11 guides the dynamoelectric circular saw 5, and the handle device 20 is connected to the guide plate 11; the handle device 20 is provided with a handle substrate 21 and a knob 23, wherein the handle substrate 21 is arranged on a processed object, and the knob 23 is supported by a pair of struts 24a and 24b on the handle substrate 21 and is arranged in a lifting mode from a rear end part 23 b to a front end part 23a; the front end part 23a extrudes to the front end side from the strut 24a at the front end; and the rear end part 23b extrudes to the rear end side from the strut 24b at the rear end. When the dynamoelectric circular saw is used, the circular saw guiding device can simply and easily apply the pressure to the dynamoelectric circular saw, has enough pressure-bearing performance on strong force pressure and can precisely and correctly guide the dynamoelectric circular saw.

Owner:LEIYU SHANGHAI PACKAGING PROD +2

Flat tube making platelike body, flat tube, heat exchanger and process for fabricating heat exchanger

InactiveCN1926398AReduce weightImprove pressure resistanceTubular elementsStructural engineeringMetal

A flat tube making platelike body 15 is in the form of a single metal plate in its entirety and comprises two flat wall forming portions 17, 18 having the same width, a connecting portion 16 for interconnecting these portions 17, 18, side wall forming portions 9, 10 projecting from the respective flat wall forming portions 17, 18 and each formed integrally with one side edge of the flat wall forming portion opposite to the connecting portion 16, and first and second reinforcing wall forming portions 11, 12 integrally formed on each of the flat wall forming portions 9, 10. The first reinforcing wall forming portions 11 are butted against the respective second reinforcing wall forming portions 12 in pairs when the metal plate is folded into a hairpin form at the connecting portion 16. The first reinforcing wall forming portions 11 are given a smaller thickness than the second reinforcing wall forming portions 12 on the other flat wall forming portion 18 butted against the respective portions 11. The platelike body 15 gives an enhanced brazing joint strength to the reinforcing wall forming portions in fabricating a flat tube, and improved pressure resistance to the flat tube to be fabricated.

Owner:SHOWA DENKO KK

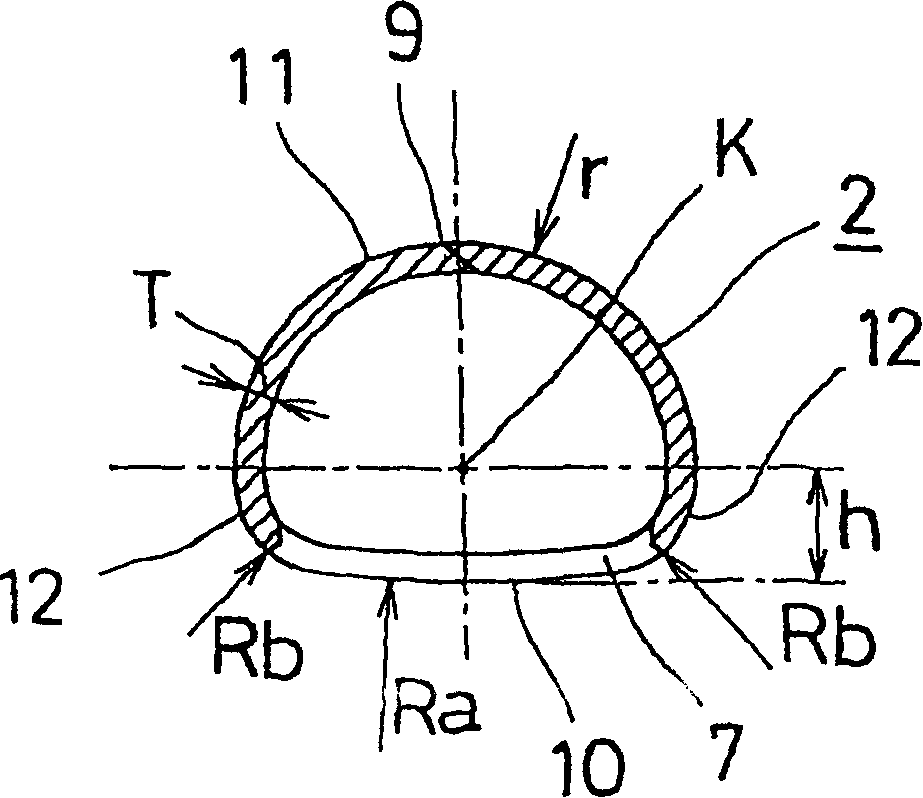

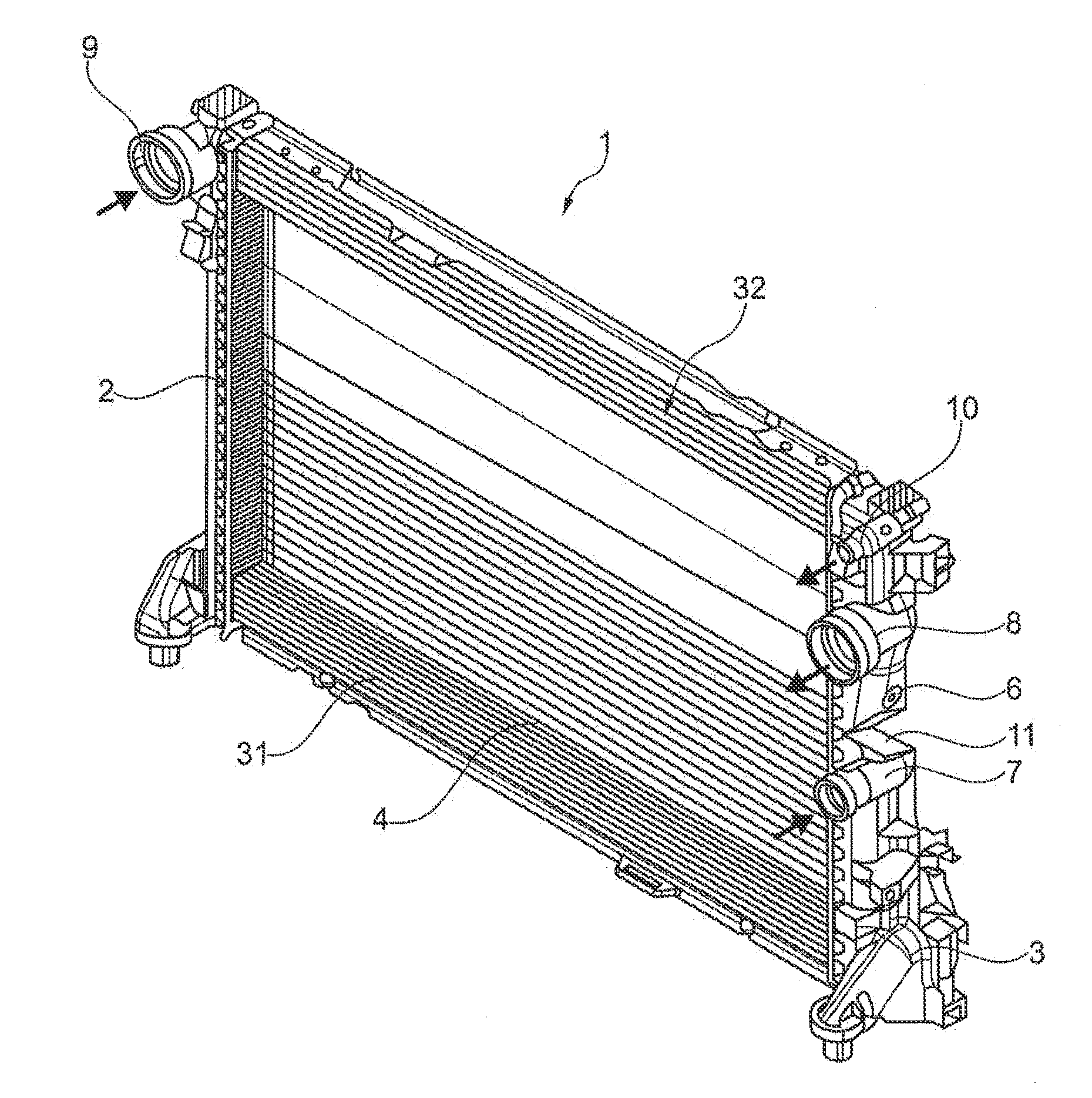

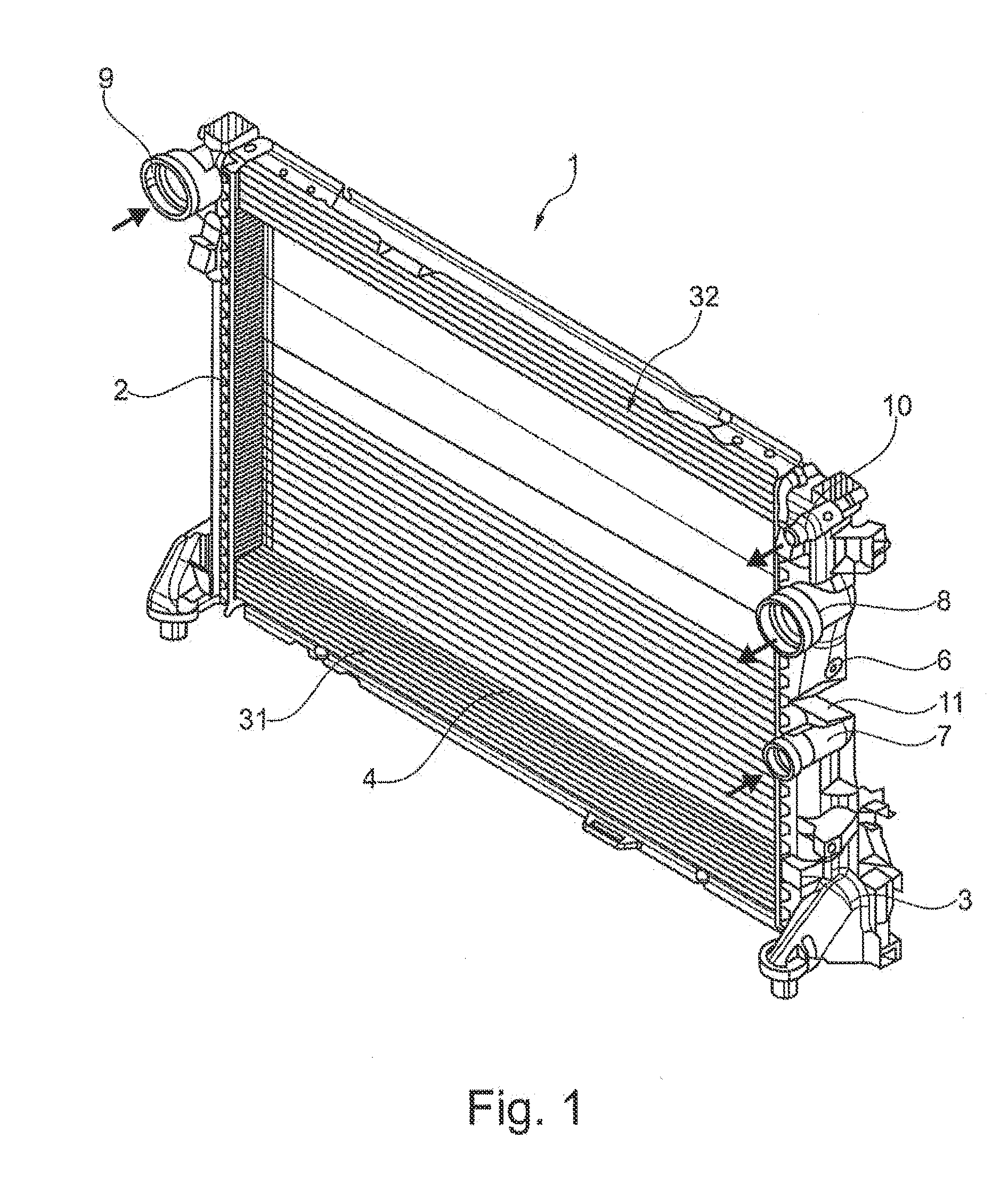

Heat exchanger

InactiveCN1447900AReduce internal volumeReduce dead spaceStationary conduit assembliesHeat exchanger casingsEngineeringHeat exchanger

A heat exchanger comprises a header (2) and a plurality of tubes (1) connected to the header. The manifold (2) comprises: an inner peripheral wall portion (10) having a generally flat arcuate cross-sectional shape to which the tube (1) is connected; an outer peripheral wall portion (11), the outer peripheral wall portion (11) has a substantially semicircular cross-sectional shape, the outer peripheral wall portion (11) faces the inner peripheral wall portion (10); and the inner peripheral wall portion (10) and the The curved peripheral wall portion (12) connected to the peripheral wall portion (11) is connected. The parameters of the header (2) such as the outer radius of curvature Ra of the inner peripheral wall portion (10), the outer curvature radius Rb of the connecting curved peripheral wall portion (12), and the outer curvature radius of the outer peripheral wall portion (11) fall within a specific range, This reduces the header volume and weight while ensuring sufficient pressure resistance.

Owner:KEIHIN THERMAL TECH CORP

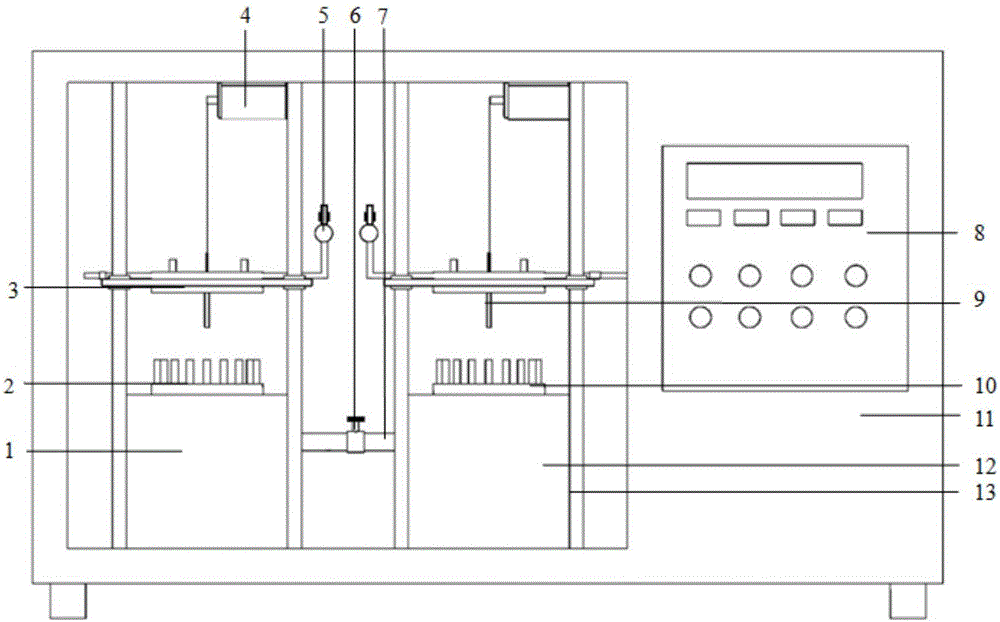

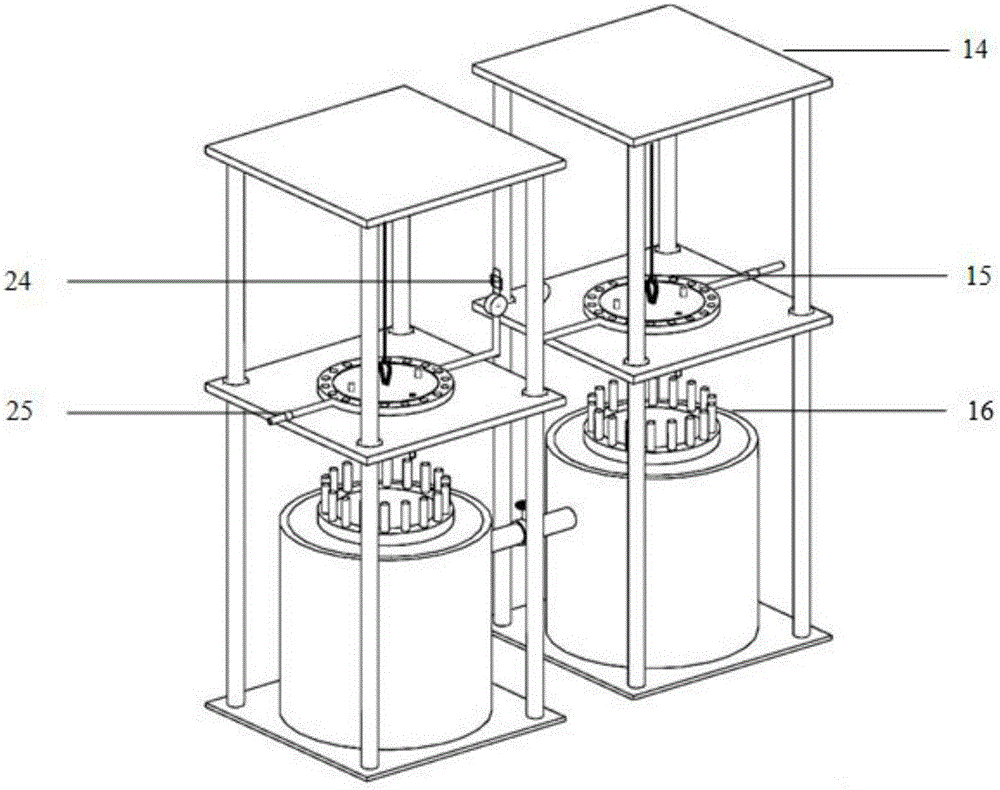

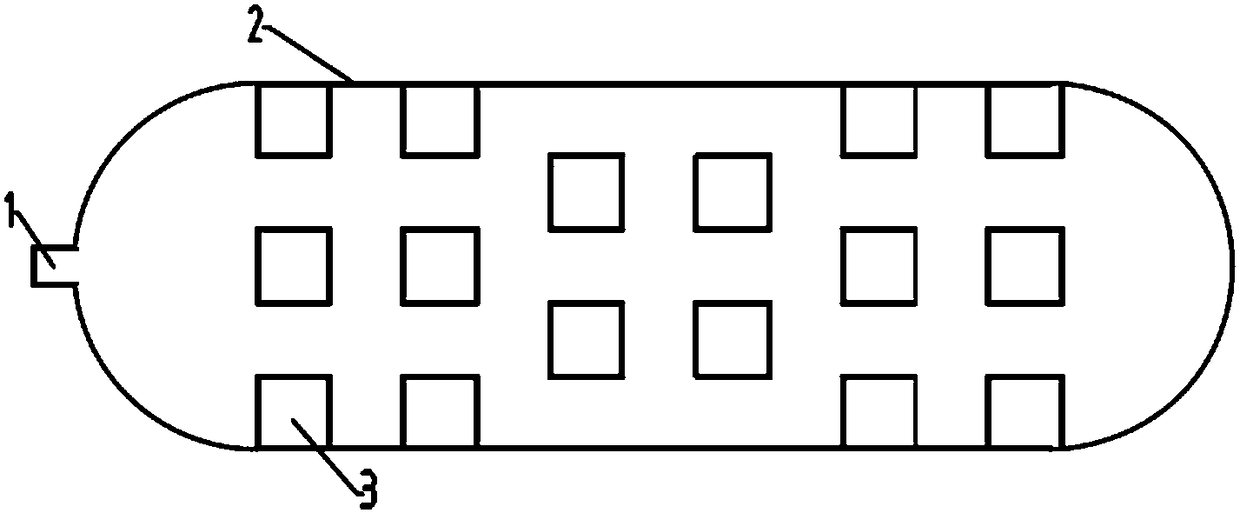

Hollow turbine blade ceramic core removal device based on heat convection principle

ActiveCN105964937AEasy to removeIncrease internal pressureFoundry mouldsFoundry coresTurbine bladeMetal

The invention discloses a hollow turbine blade ceramic core removal device based on the heat convection principle and belongs to the field of aircraft engine hollow turbine blade manufacturing equipment. The device comprises an autoclave assembly, a buffer still assembly and a controller. The autoclave assembly and the buffer still assembly are each internally provided with a heating device. The autoclave assembly is connected with the buffer still assembly through a convection channel. The convection channel is provided with a valve. The temperatures of the autoclave assembly and the buffer still assembly, the power of the heating devices and the on / off state of the valve are all controlled through the controller. The removal device is reasonable in structural design, easy and convenient to use and capable of effectively solving the problem that it is difficult to remove a residual ceramic core in an aluminum-based metal blade body of a hollow turbine blade; and the device can be widely applied to the field of hollow turbine blade manufacturing.

Owner:XI AN JIAOTONG UNIV

Heat exchanger

ActiveUS20150159963A1Increase in costRelieve stressThermal insulationSafety devices for heat exchange apparatusInterior spaceTemperature induced

A heat exchanger having a tube-fin block that is closed by two collecting tanks, whereby the ends of the tubes engage in a bottom of the particular collecting tank and the bottom is closed with a cover. A partition wall secured to the cover is formed transverse to a longitudinal extension of the collecting tank and divides an interior space of the collecting tank into two subchambers. The heat exchanger, which prevents great structural changes for compensating temperature-induced stresses, a first stress decoupling device is formed in the bottom and / or a second stress decoupling device in the area of the partition wall in the cover of at least one collecting tank.

Owner:MAHLE INT GMBH

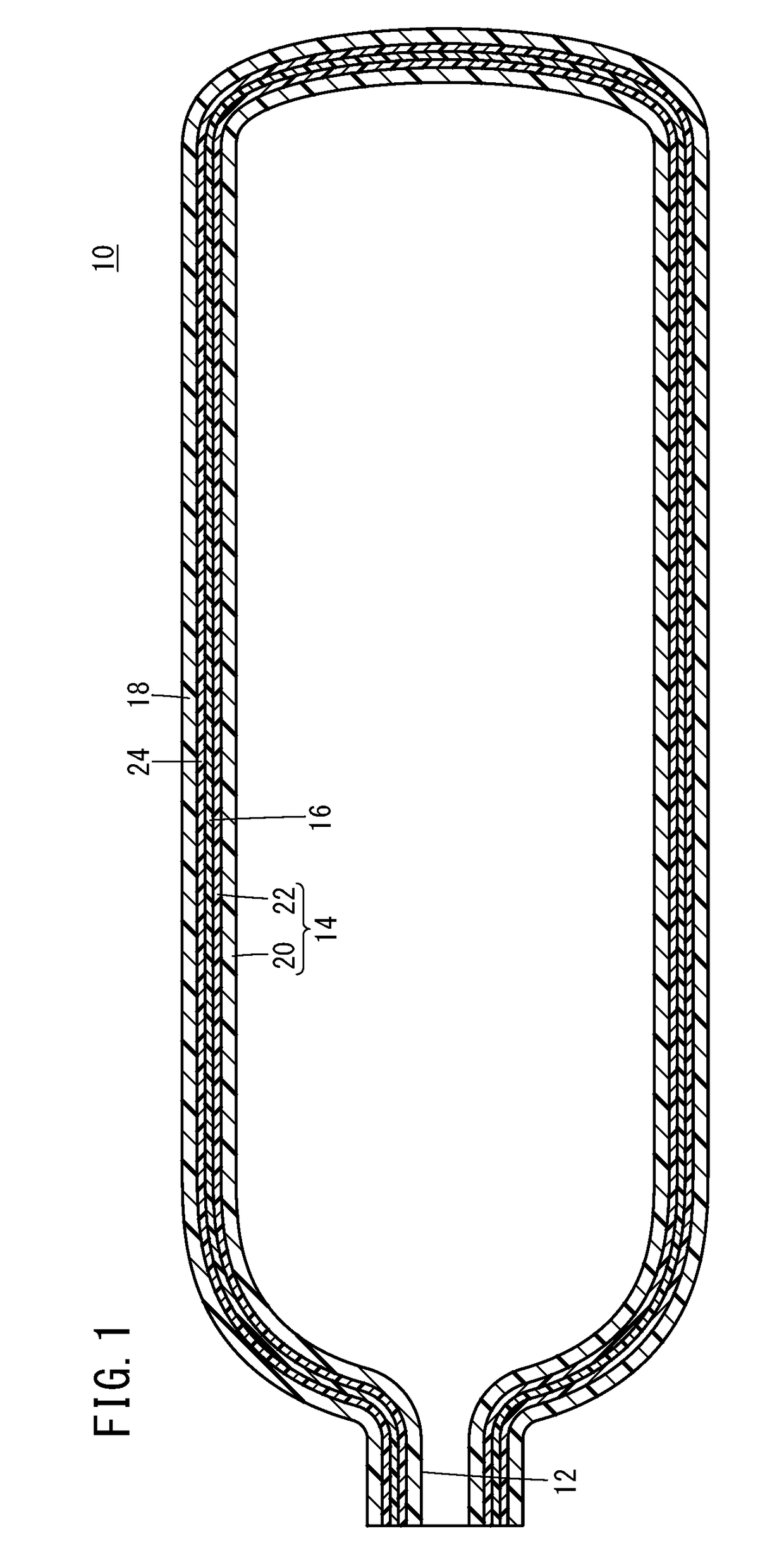

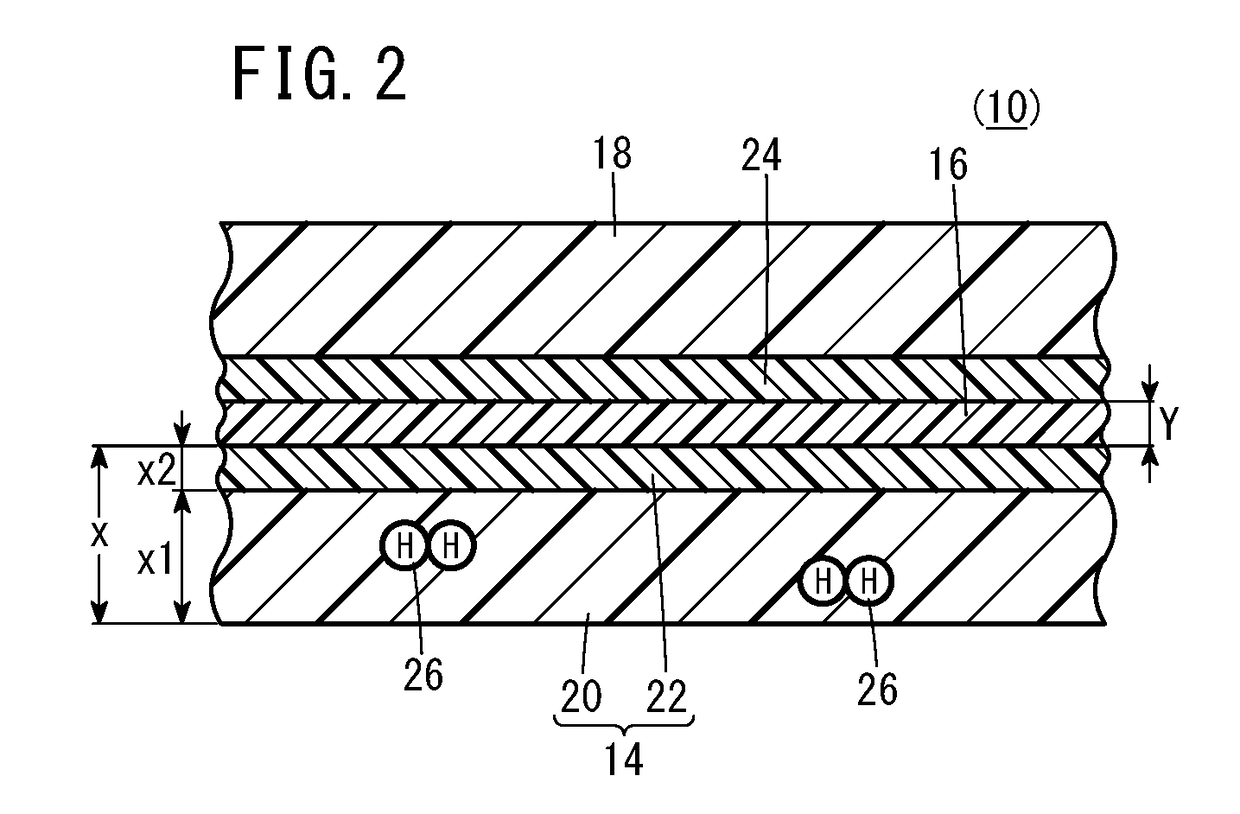

Hydrogen storage container

InactiveUS20180048001A1Avoid residuePrevent peelingReactant parameters controlVessel geometry/arrangement/sizeDifferential pressurePermeation

A hydrogen storage container has an inner side resin layer that comes into contact with hydrogen gas that is introduced into the container, a barrier layer which is disposed on the outside of the inner side resin layer and which prevents permeation of hydrogen gas, and an outer side resin layer comprising a resin. Among these layers, the inner side resin layer comprises a polyethylene-based resin, and if the thickness of the barrier layer is denoted by Y and the thickness of the inner side resin layer is denoted by X, the thickness X satisfies formula (1). Moreover, D in formula (1) is the diffusion coefficient of the polyethylene-based resin, as determined by means of a differential pressure method at 50° C.

Owner:HONDA MOTOR CO LTD

Working electrolyte of lead aluminum electrolytic capacitor and preparation method thereof

ActiveCN111524708AFree from hydrationGuaranteed high temperature characteristicsElectrolytic capacitorsElectrolytic agentHydration reaction

The invention relates to a working electrolyte of a lead aluminum electrolytic capacitor. The working electrolyte is composed of the following raw materials in percentage, by mass of 30-50% of solventI, 10-20% of solvent II, 6-9% of solute I, 2-4% of solute II, 1-3% of antifouling agent, 5-20% of additive and 8-20% of pressure-resistant improver. The preparation method comprises the following steps of adding the solvent I and the solvent II into a reaction kettle, heating while stirring, adding the additive when the temperature rises to 120 DEG C, and continuously heating to 140 DEG C, addingthe solute I and the solute II, keeping the temperature of 140 DEG C for 45 minutes, cooling the kettle to 130 DEG C, adding the pressure-resistant improver, stirring and keeping the temperature for30 minutes, and finally, cooling the kettle to 110 DEG C, adding the antifouling agent, fully stirring, and naturally cooling to room temperature after 45 minutes to obtain the finished product electrolyte. The method is advantaged in that the enough voltage endurance capability can be guaranteed under the condition of high conductivity, the aluminum foil is prevented from hydration reaction, andthe service life of the product is prolonged.

Owner:南通新三能电容器有限公司

PLugging device for shieLd tunneL

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD +1

Magnetic liquid sealing device

ActiveCN112728111AReduce axial sizeAvoid Insufficient Pressure CapabilityEngine sealsMagnetic liquidsEngineering

Owner:TSINGHUA UNIV

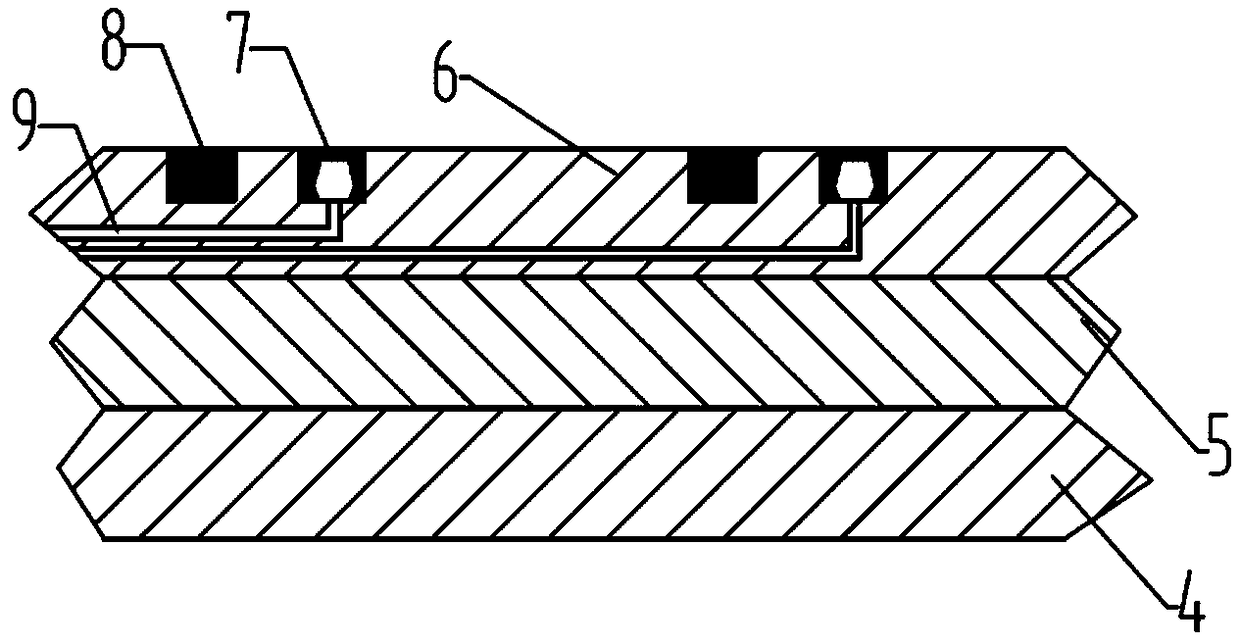

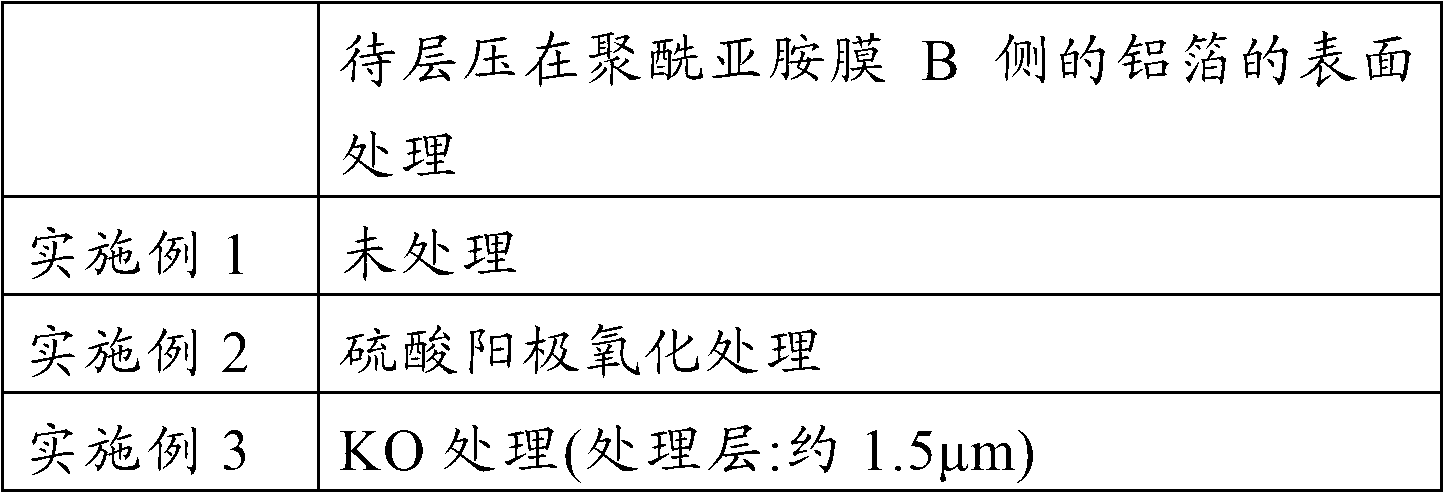

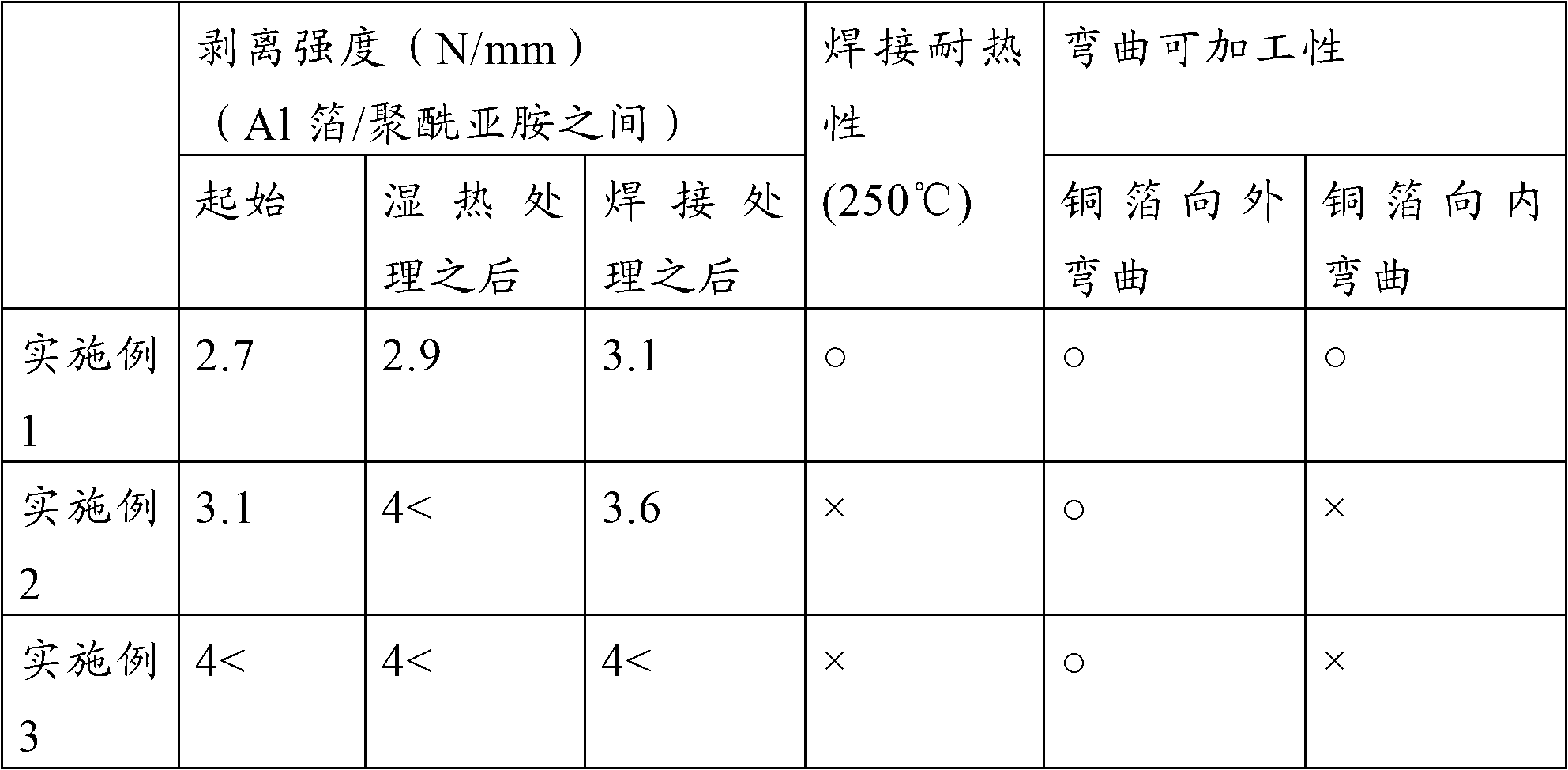

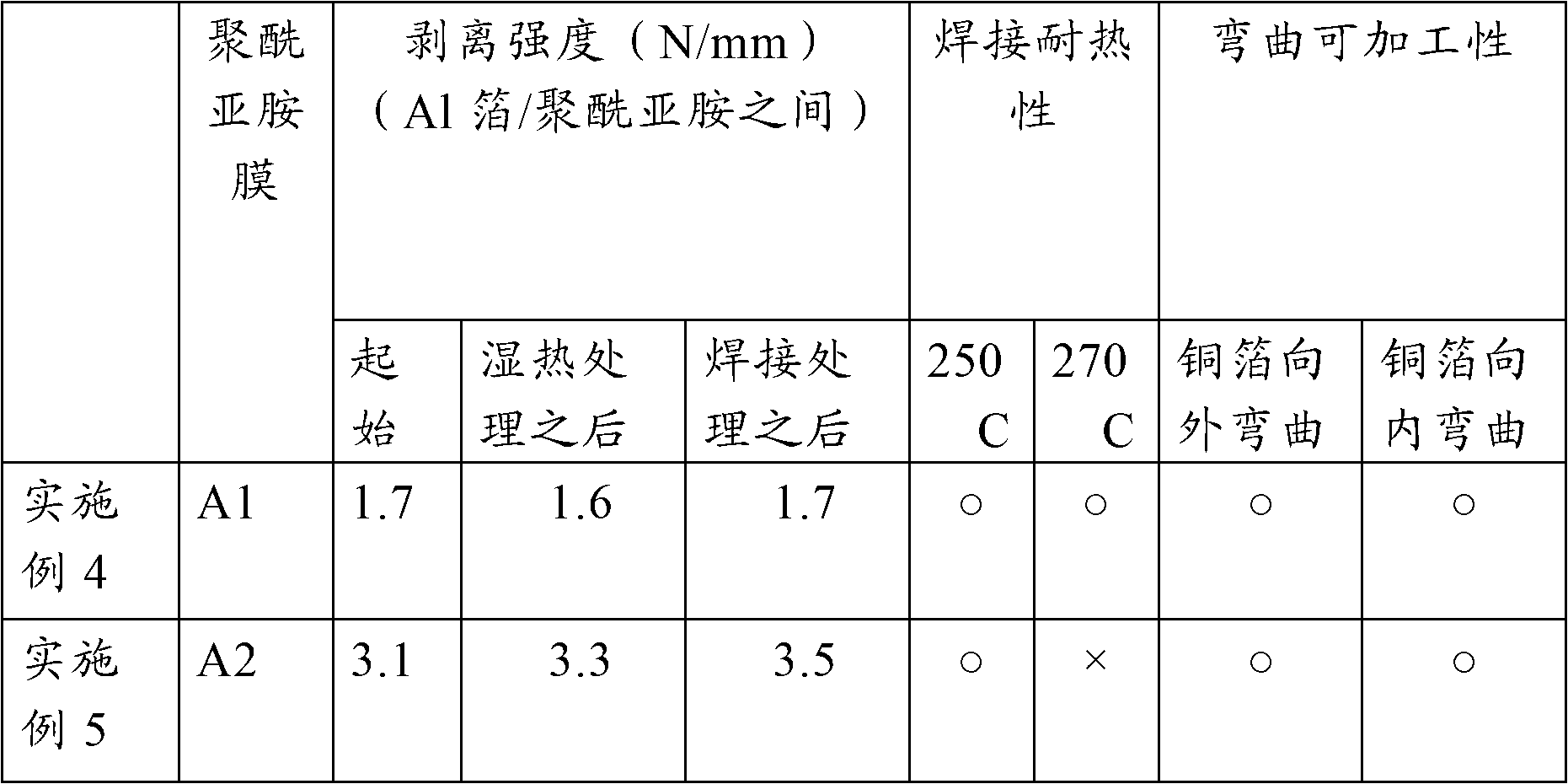

Heat dissipation substrate for led

InactiveCN102939671AImprove flexibilityImprove cooling effectPrinted circuit aspectsHeat exchange apparatusCopper foilPolyimide membrane

A heat dissipation substrate for an LED has copper foil or copper alloy foil layered on one side of a polyimide film and also has aluminum foil or aluminum alloy foil layered on the other side thereof. The thermal resistance between the surface of the copper foil or the copper alloy foil and the surface of the aluminum foil or the aluminum alloy foil is 1.8 DEG C / W or less.

Owner:UBE IND LTD

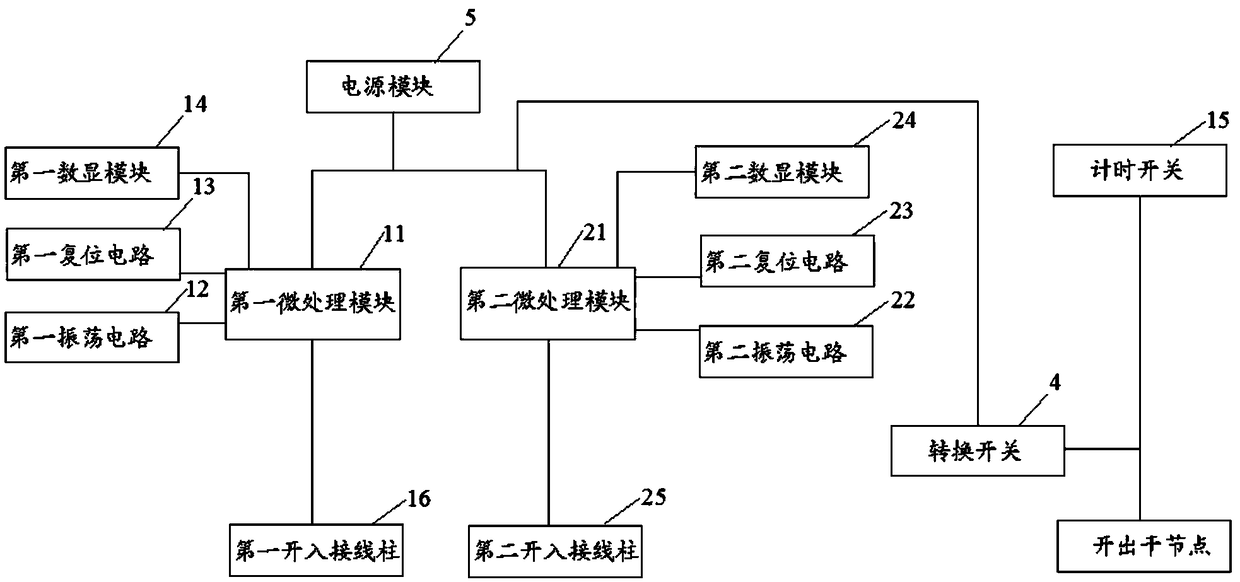

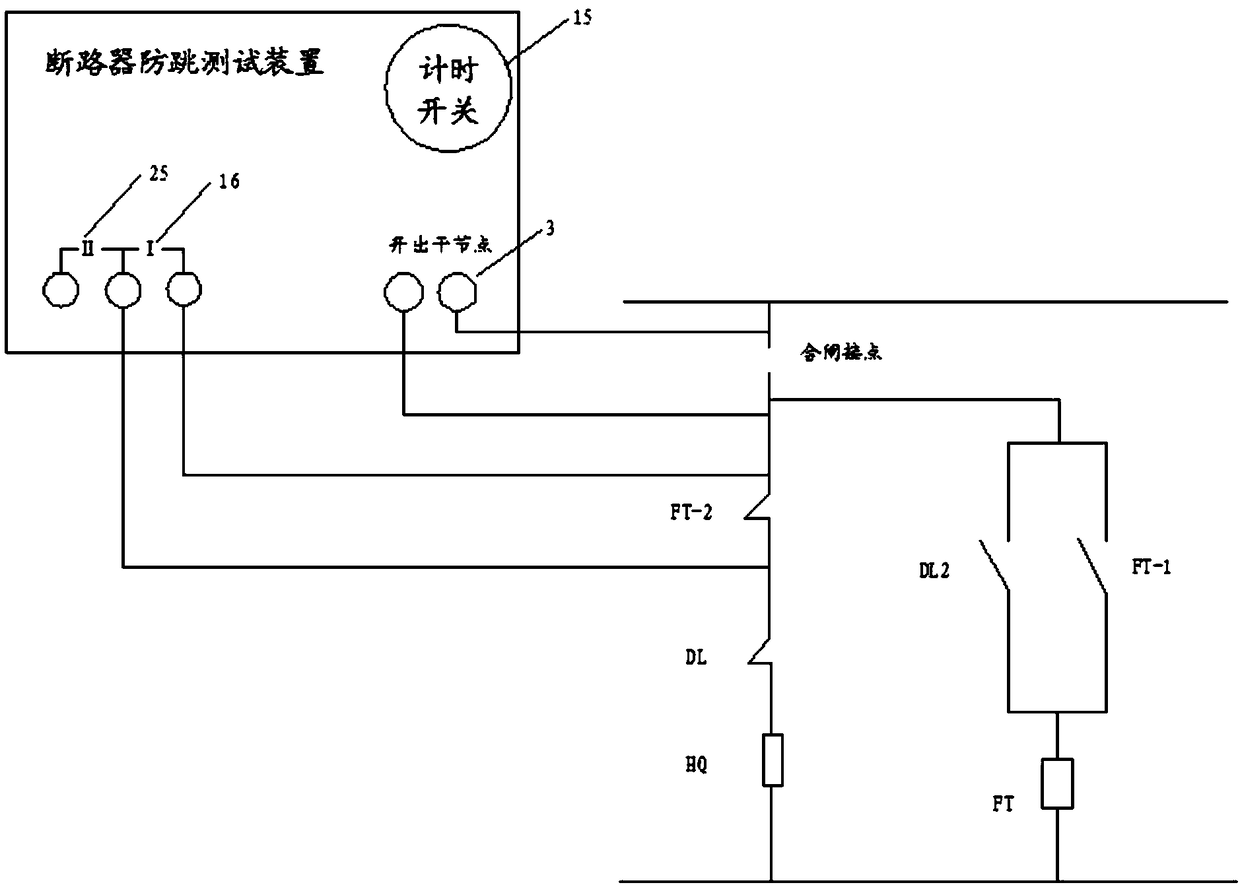

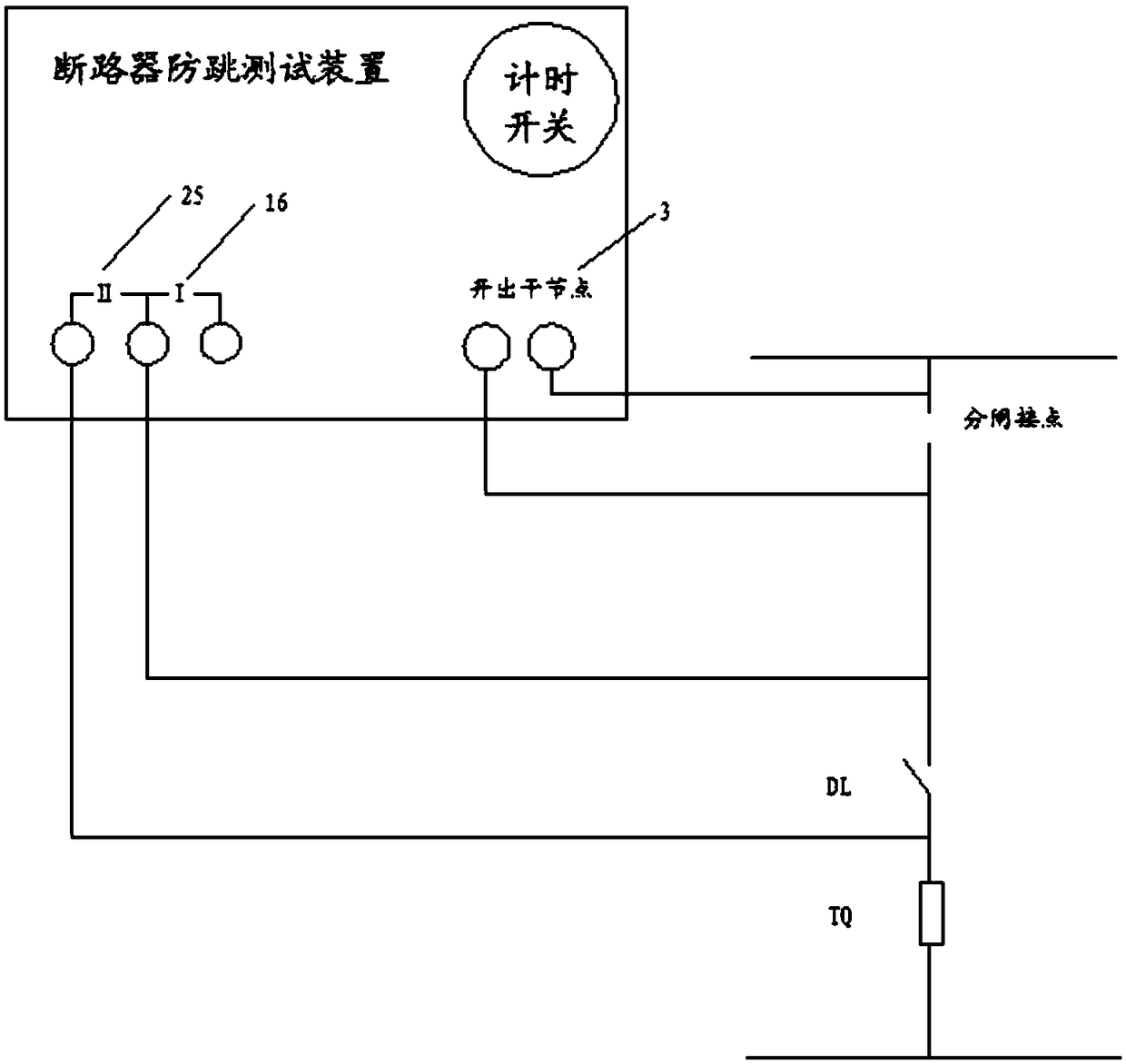

Circuit breaker anti-trip test device

Owner:国网宁夏电力有限公司中卫供电公司

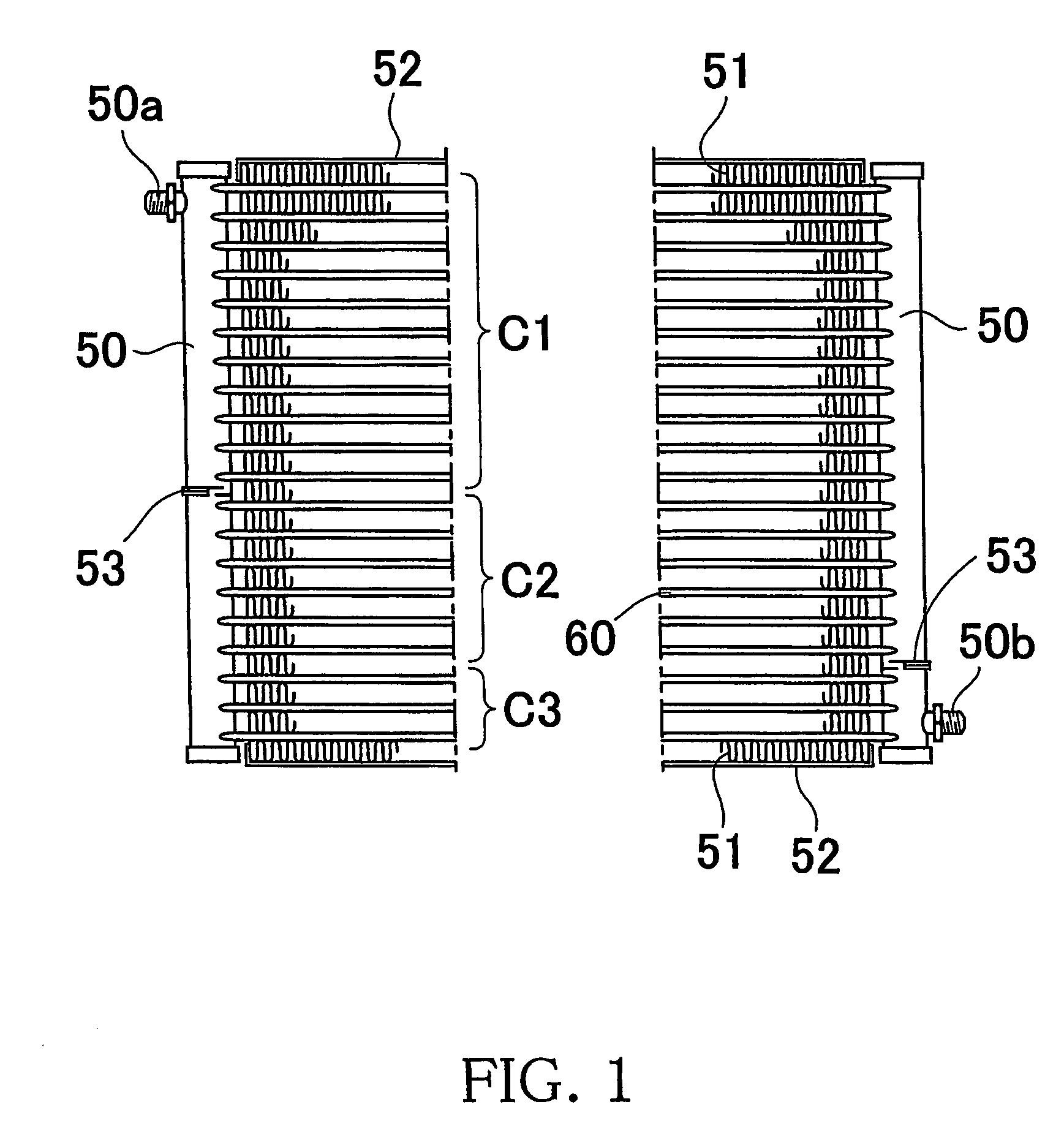

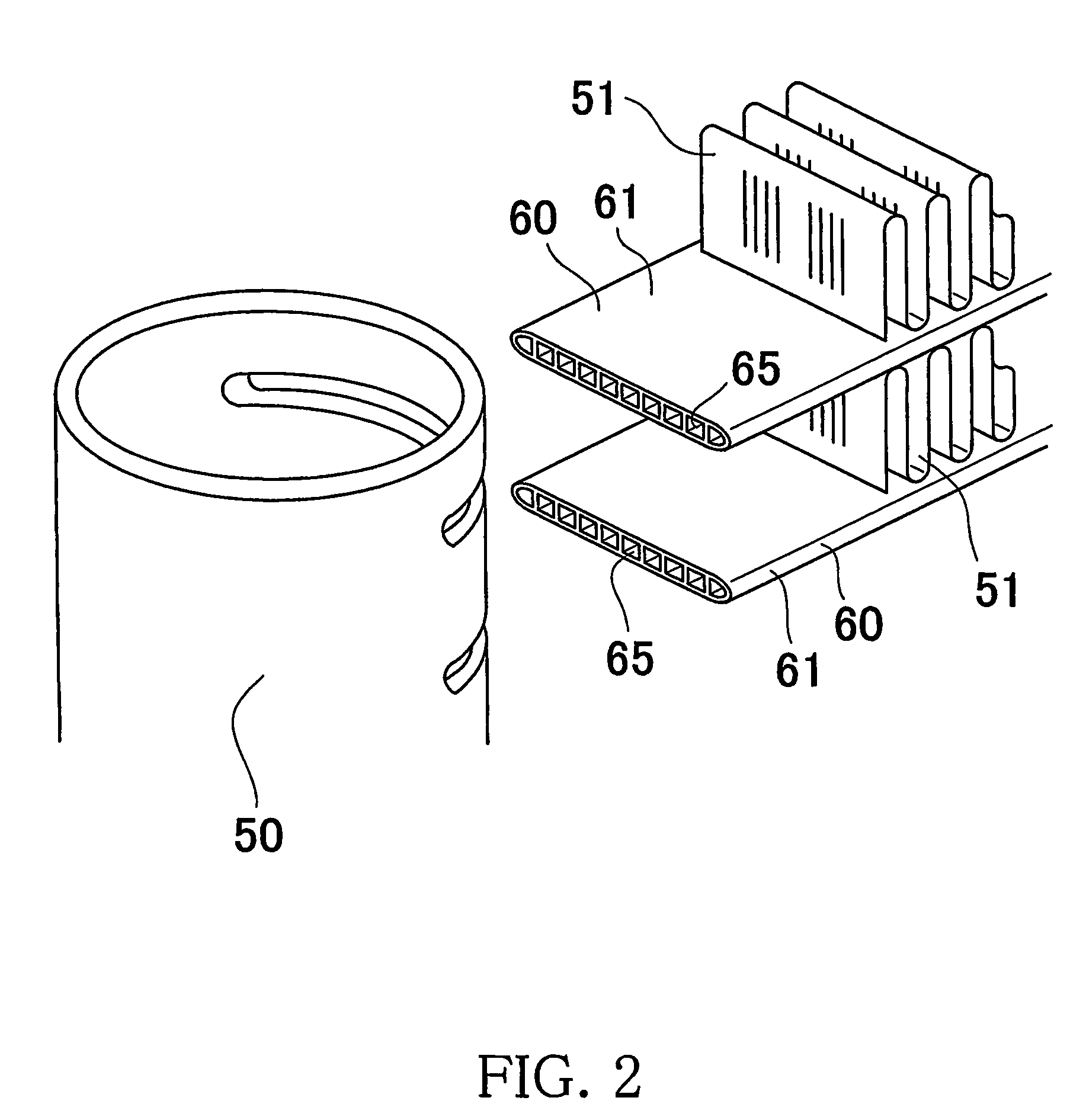

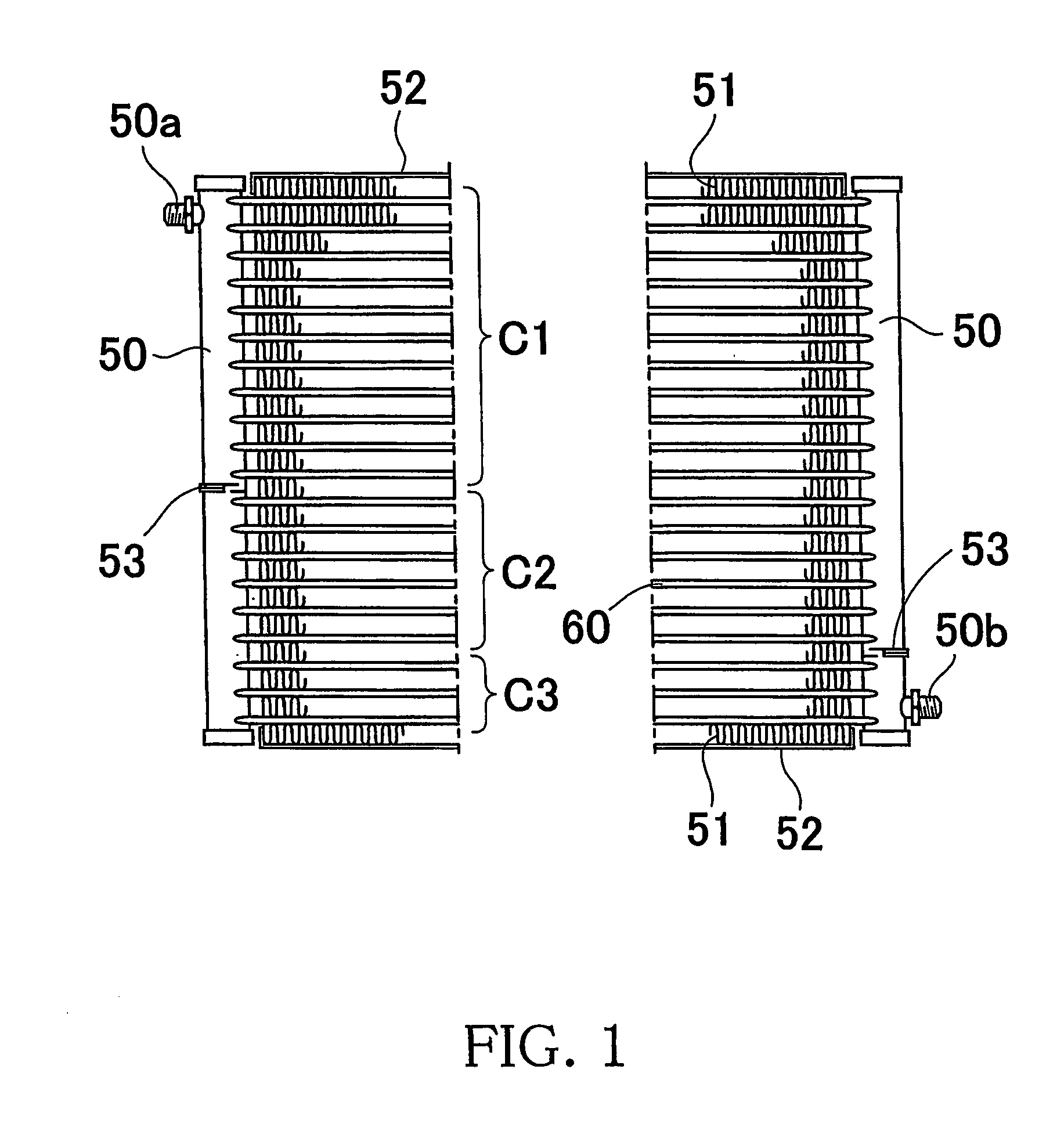

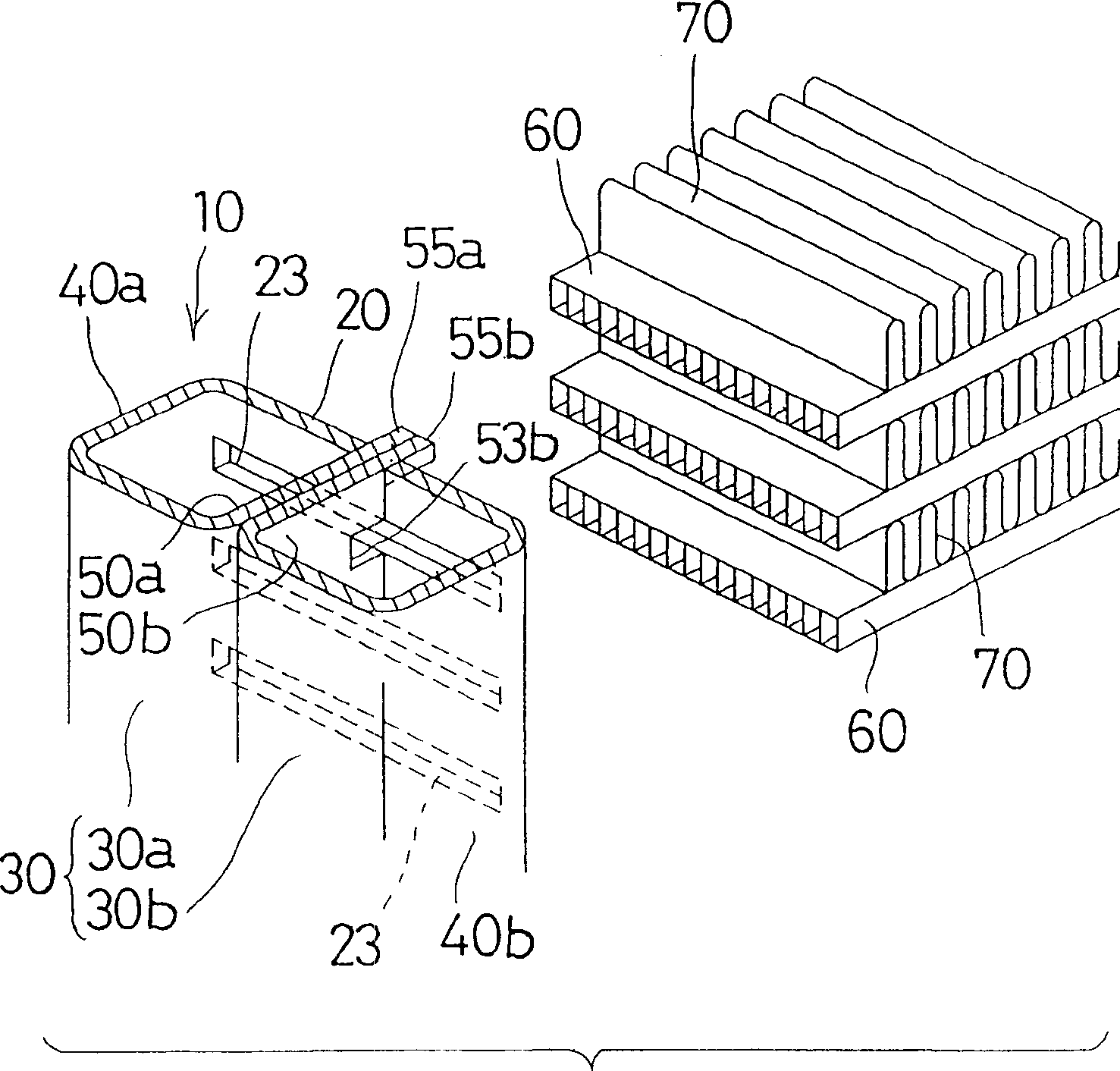

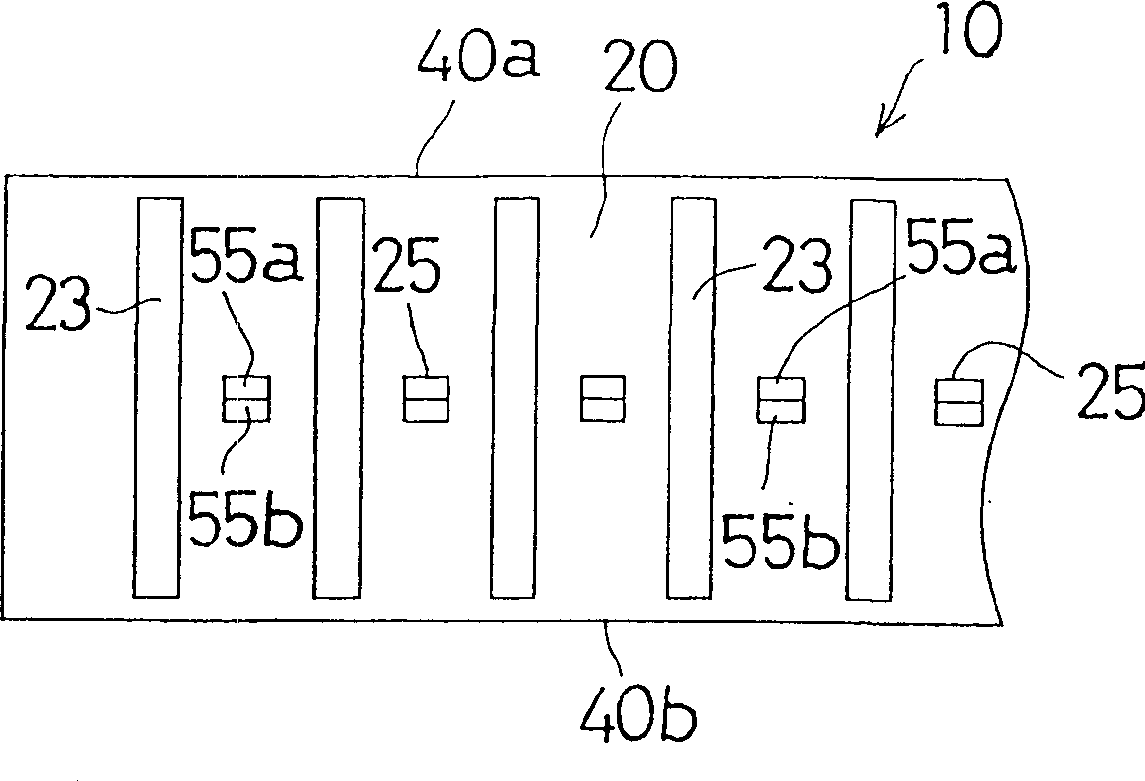

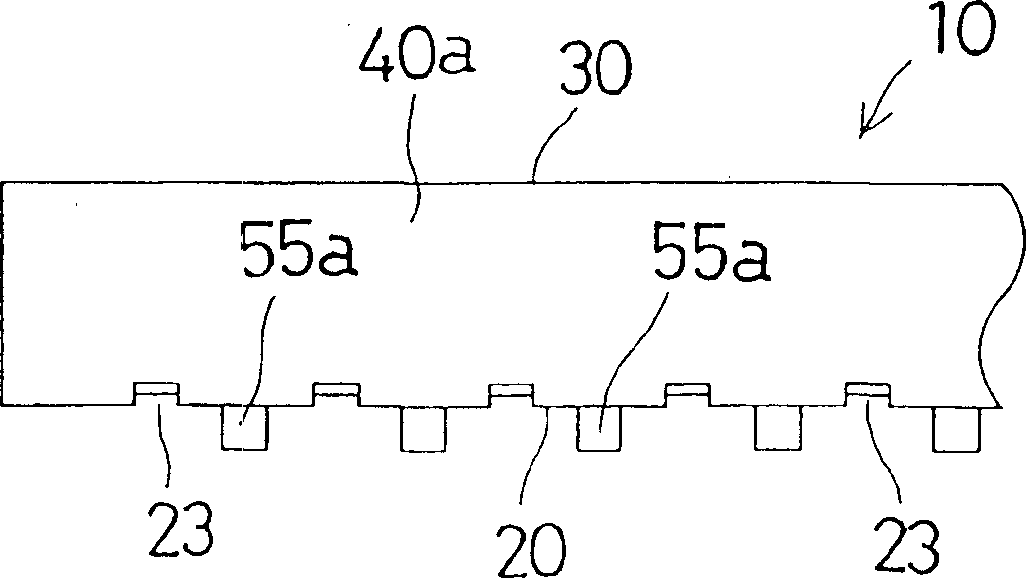

Header for use in heat exchangers, heat exchanger and method for manufacturing the same

InactiveCN1599859AReduce the numberReduce manufacturing costReinforcing meansStationary conduit assembliesStructural engineeringHigh pressure

A header for use in heat exchanger includes a base wall (20) with a plurality of tube insertion apertures (23), an opposite wall (30) opposed to the base wall (20), a pair of side walls (40a and 40b) disposed at both lateral sides of the base wall (20) and the opposite wall (30) and connecting the lateral sides and are inforcing walls (50a and 50b) disposed betwwen the base wall (20) and the opposite wall (30) along a longitudinal direction thereof and connecting the base wall (20) with the opposite wall (30). The side walls (40a and 40b) are integrally formed at both lateral sides of the base wall (20) be bending processing. A first half (30a) of the opposite wall (30) is integrally formed at a side of one of the side walls (40a) by bending processing, and a second half (30b) of the opposite wall (30) is integrally formed at a side of the other of the side walls (40b) by bending processing. Reinforcing walls (50a and 50b) are integrally formed at sides of the first half (30a) and the second half (30b) of the opposite wall (30) by bending processing. With this header for use in heat exchanger, high pressure resistance can be obtained, and the number of parts and the manufacturing cost can be decreased.

Owner:SHOWA DENKO KK

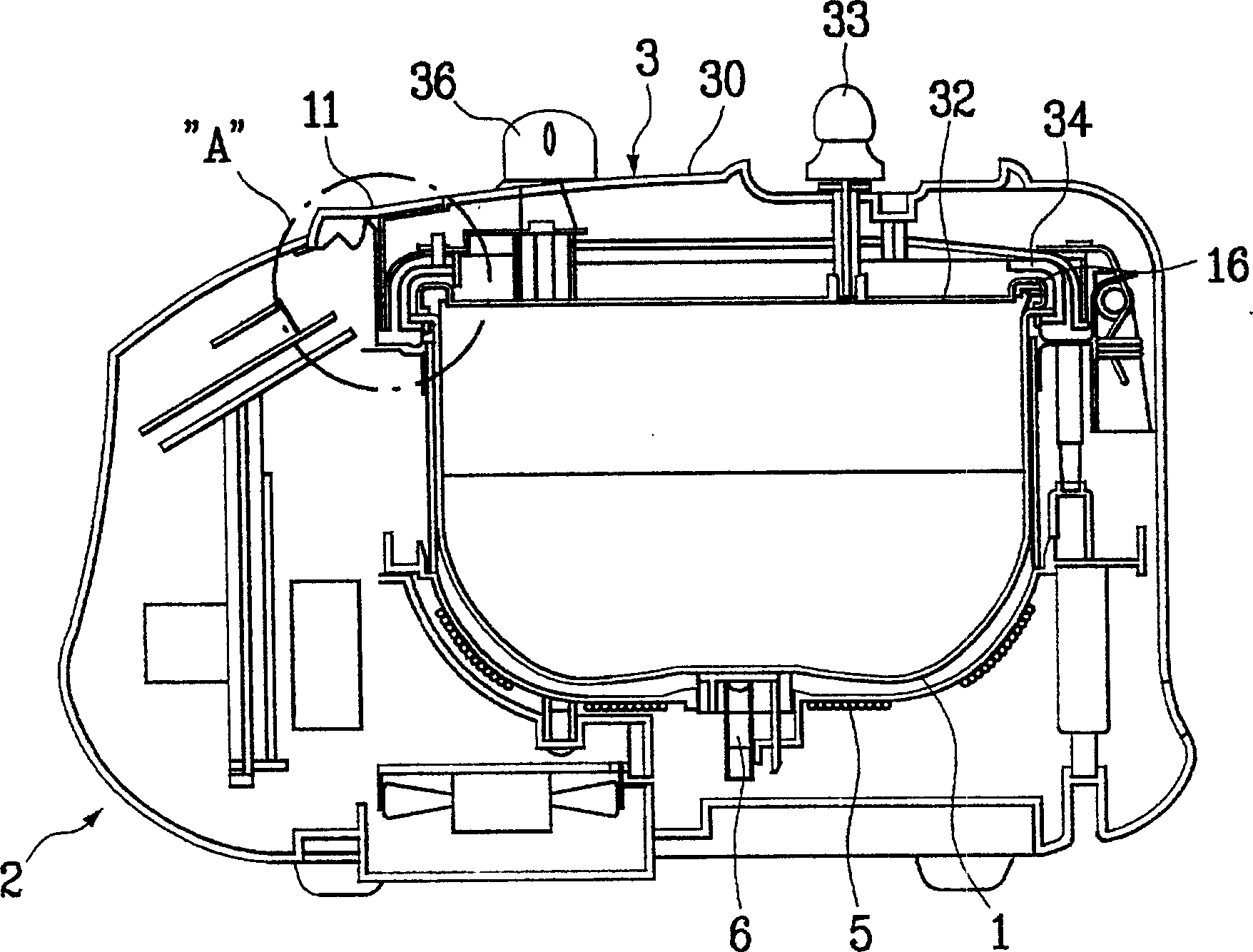

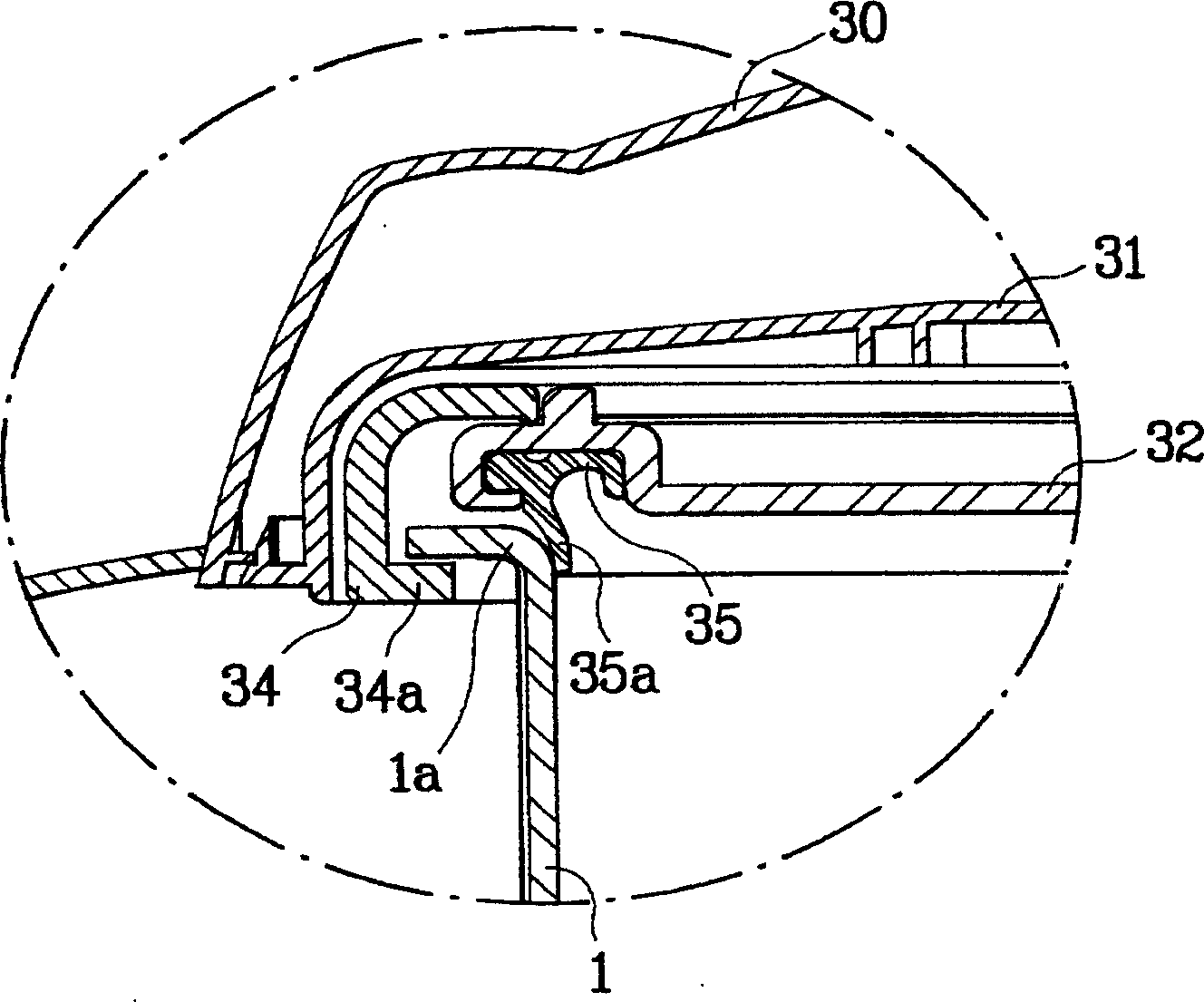

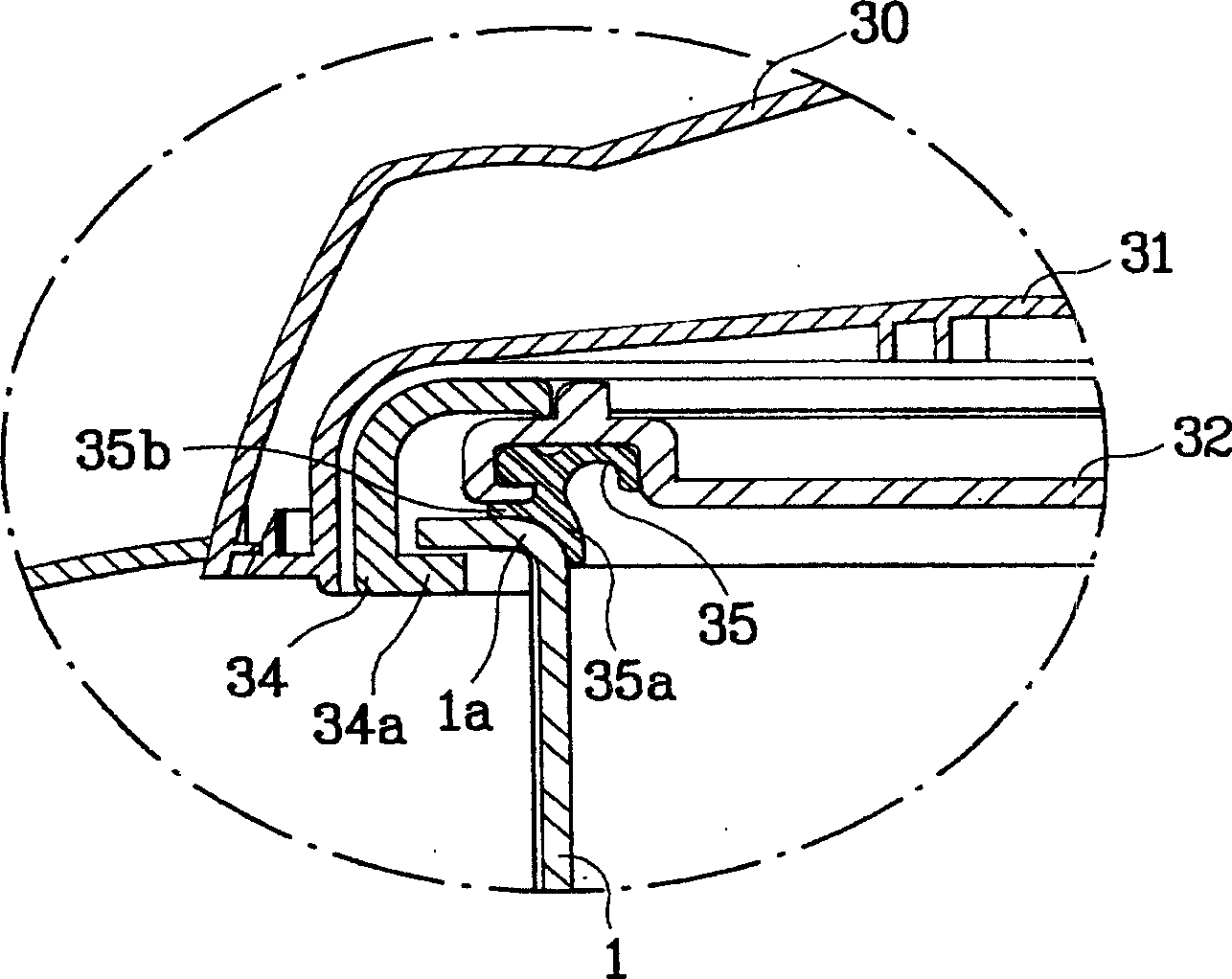

Pressure electric cooker lid gasket structure

The present invention discloses a cover gasket of pressure electric cooker. Said pressure electric cooker includes self-body portion and cooker cover portion. The cooker is inserted into the interior of self-body portion, and the cooker cover portion includes exterior cover, interior cover, inner cooker cover, lock ring and gasket. Said gasket is mounted at the interior edge of inner cooker cover, and is equipped with a horizontal reinforcement portion. Said invention also provides the connection relationship of the above-mentioned components. The reinforcement portion proimote the wearability of gasket, and can prolong its service life.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

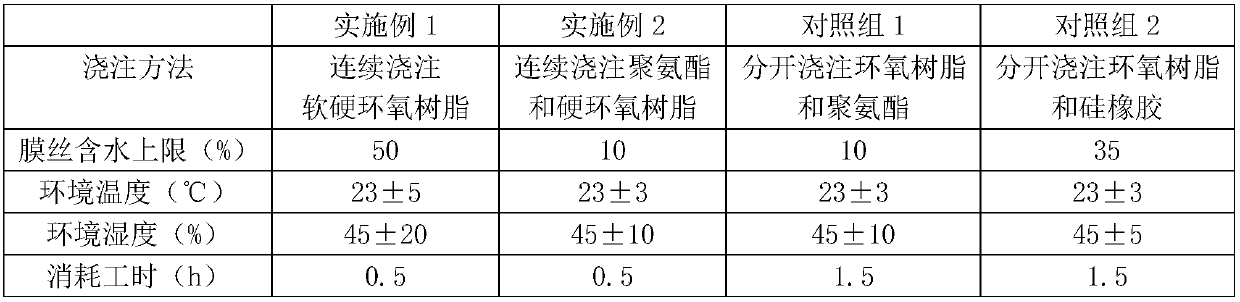

Continuous casting production molding method of hollow fiber membrane module

InactiveCN109647209ASimple processReduce labor costsSemi-permeable membranesFiberHollow fibre membrane

The invention discloses a continuous casting production molding method of a hollow fiber membrane module. The method comprises the following steps: filling the membrane shell of a hollow fiber membrane module with a bundle of membrane silks to be cast, and sealing the ends, to be cast, of the membrane silks with a sealant; and mounting a casting tool, performing continuous casting through successively casting flexible epoxy resin or polyurethane and then casting hard epoxy resin by a process for casting the flexible epoxy resin and the hard epoxy resin from the bottom of the hollow fiber membrane module, and curing the resins to form a sealed structure with a flexible top and a hard bottom on the dependence of the inherent density difference between the two resins. The flexible epoxy resinis adopted to substitute the polyurethane to carry out root protection, so the requirement for the dryness of the membrane silks is significantly reduced, and the requirements for the temperature andthe humidity of the casting environment are reduced, thereby the cost investment of casting hardware is reduced, and the production cost is reduced.

Owner:TIANJIN MOTIMO MEMBRANE TECH

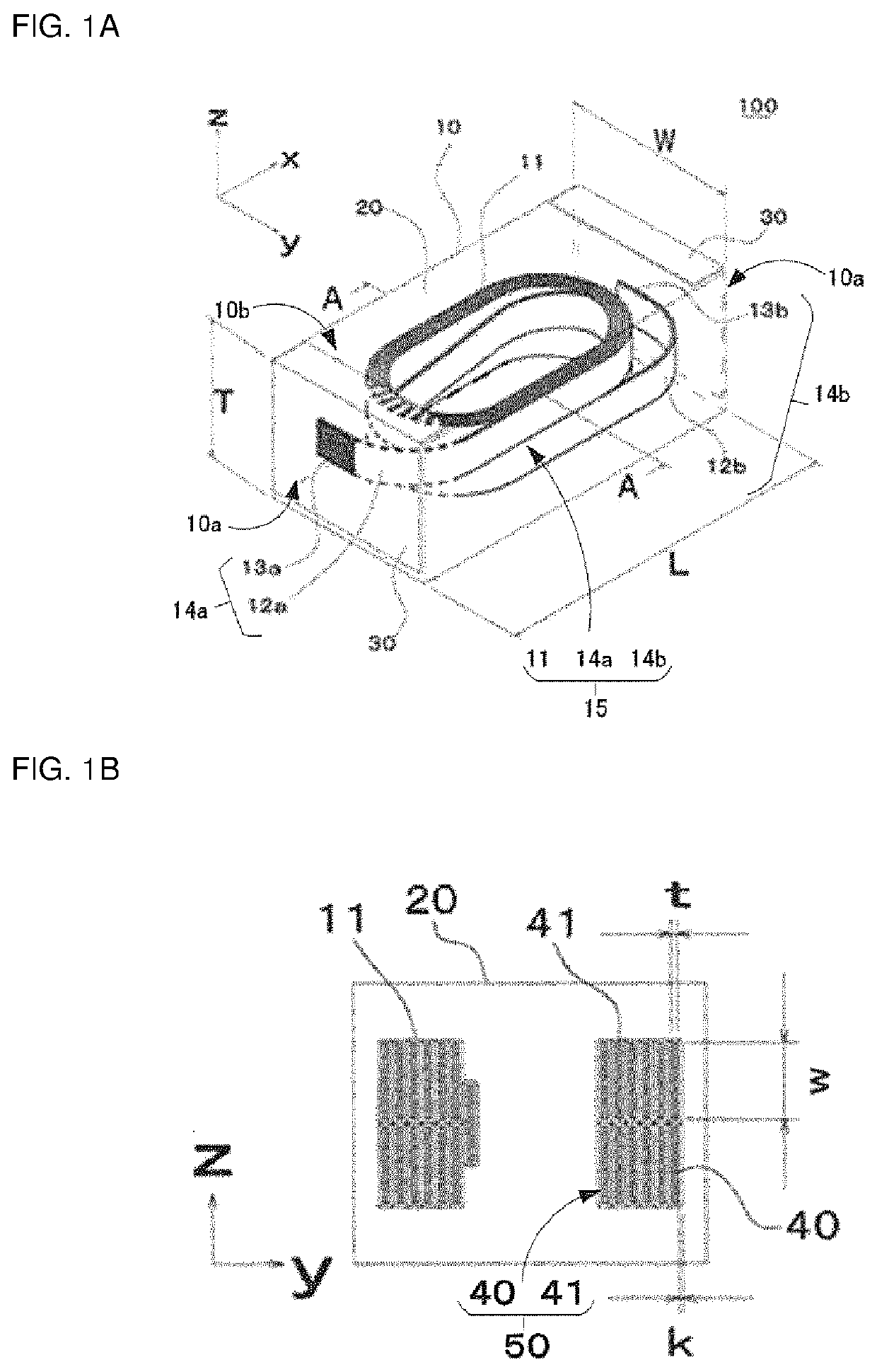

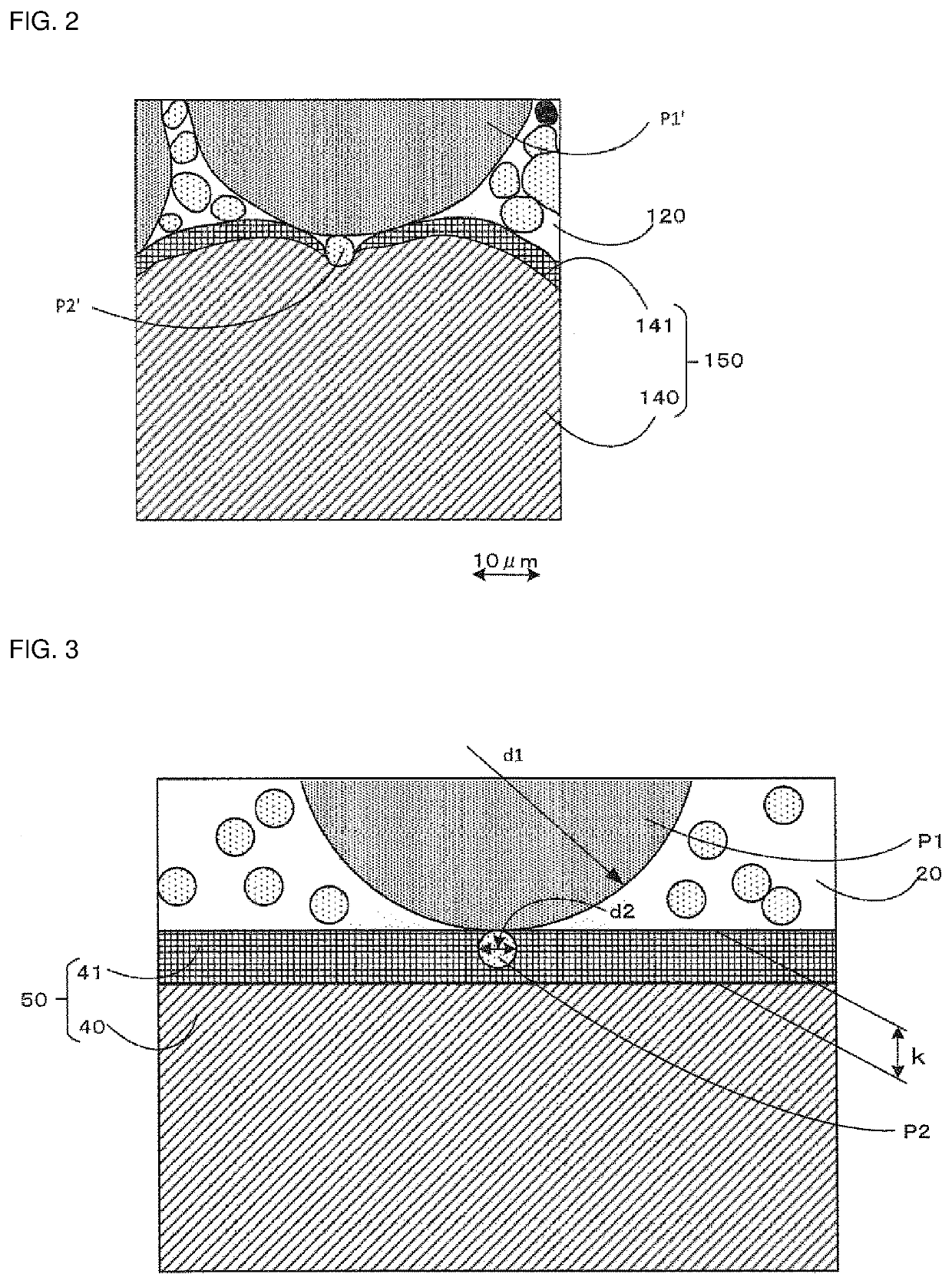

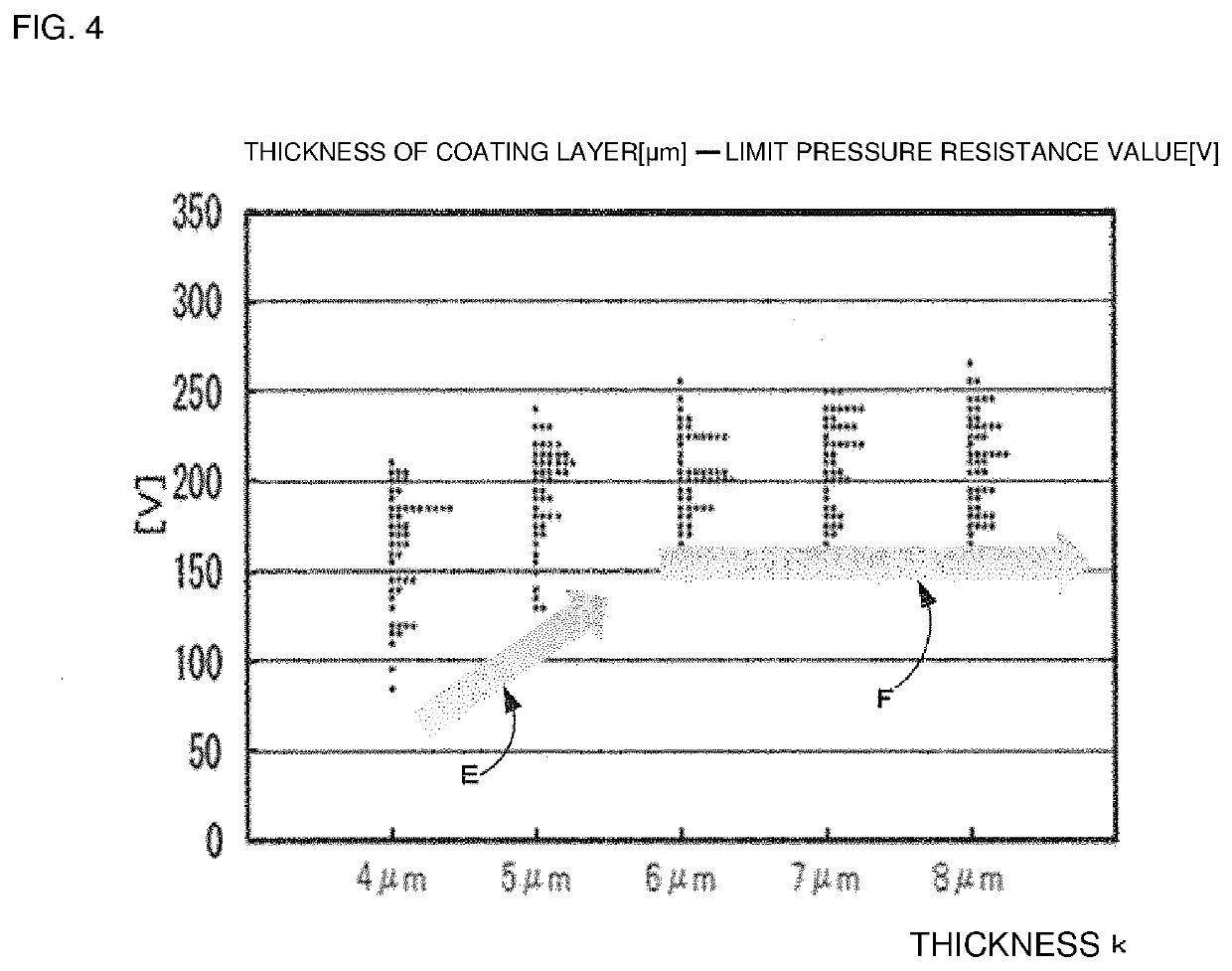

Inductor

InactiveUS20210043362A1High yieldSolve the lack of pressure resistanceTransformers/inductances coils/windings/connectionsInductances/transformers/magnets manufactureElectrical conductorEngineering

An inductor that includes a coil having a winding portion in which a conductor having a coating layer is wound, and a pair of lead-out portions formed by leading out the conductor from the winding portion; and a magnetic portion including magnetic powder and resin and configured to seal the coil. The magnetic powder includes first particles having a first average particle diameter, and second particles having a second average particle diameter smaller than the first average particle diameter, and a thickness of the coating layer has a value larger than the second average particle diameter.

Owner:MURATA MFG CO LTD

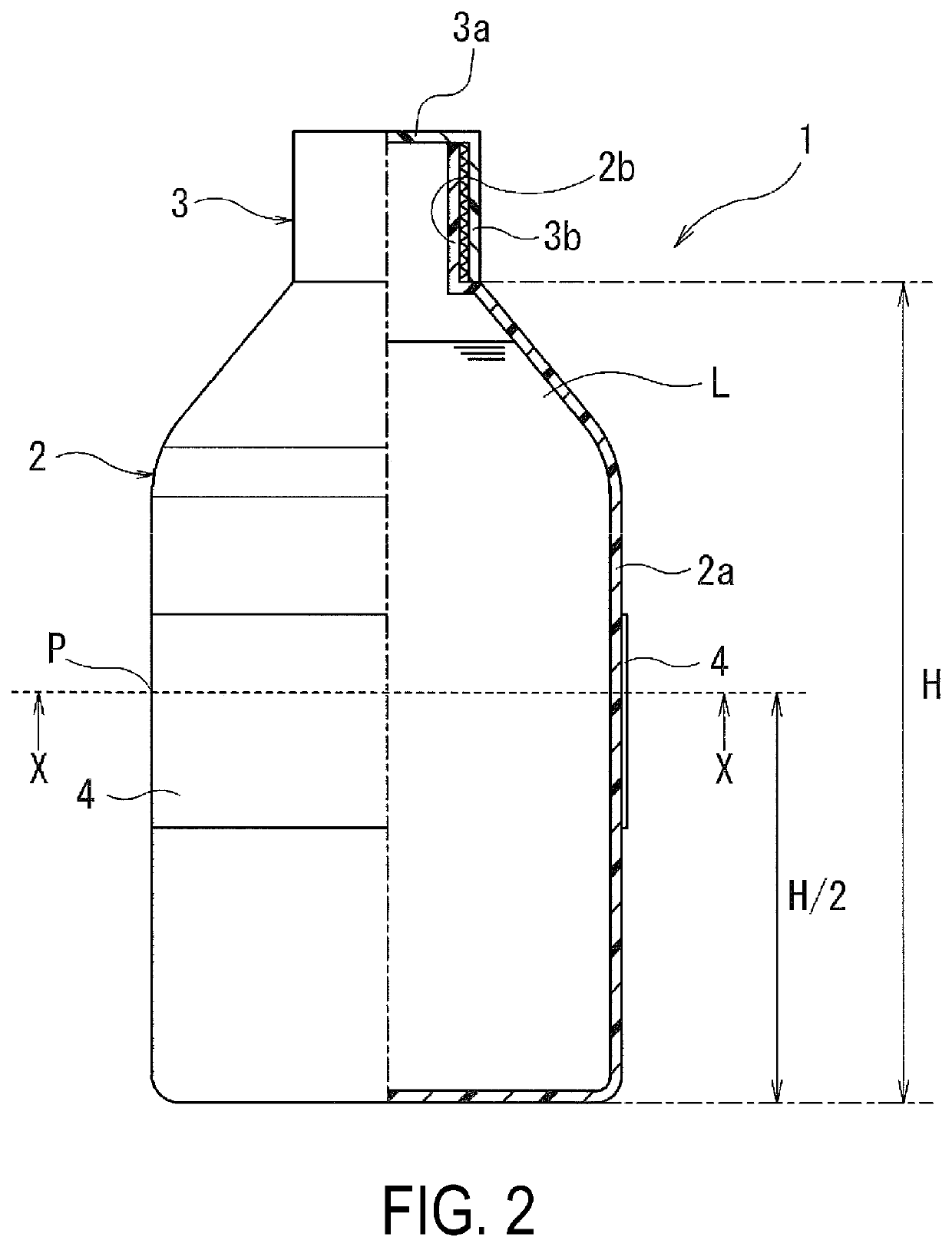

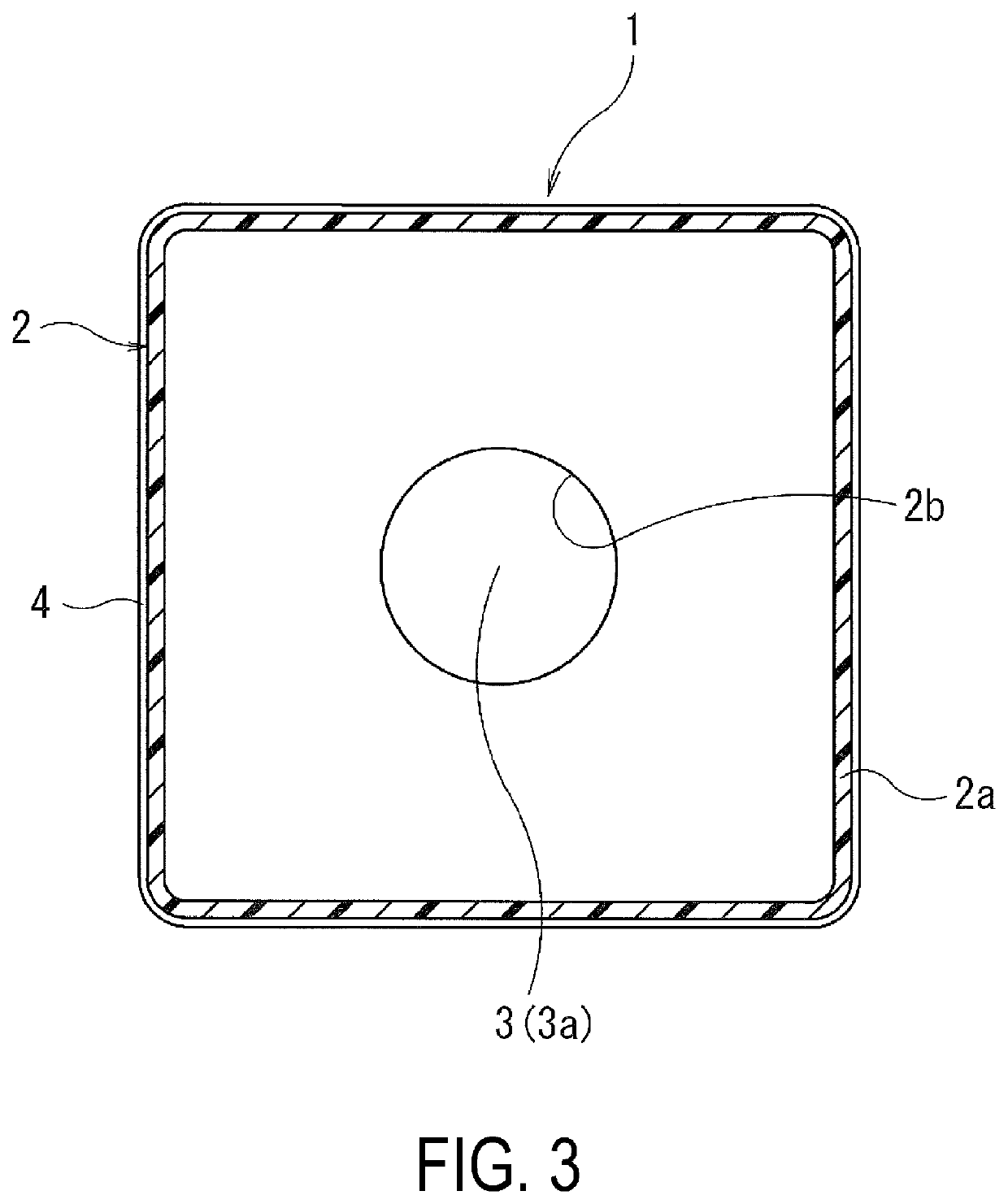

Puncture repair liquid holding container and puncture repair kit

A puncture repair liquid holding container includes: a container main body provided with and opening portion and a holding portion where puncture repair liquid is held; and a cap attached to the opening portion; wherein a cross-sectional shape of the holding portion is non-true circular, and a metal reinforcing member provided around an entire circumference of the holding portion is provided on at least a portion of the holding portion in a height direction.

Owner:THE YOKOHAMA RUBBER CO LTD

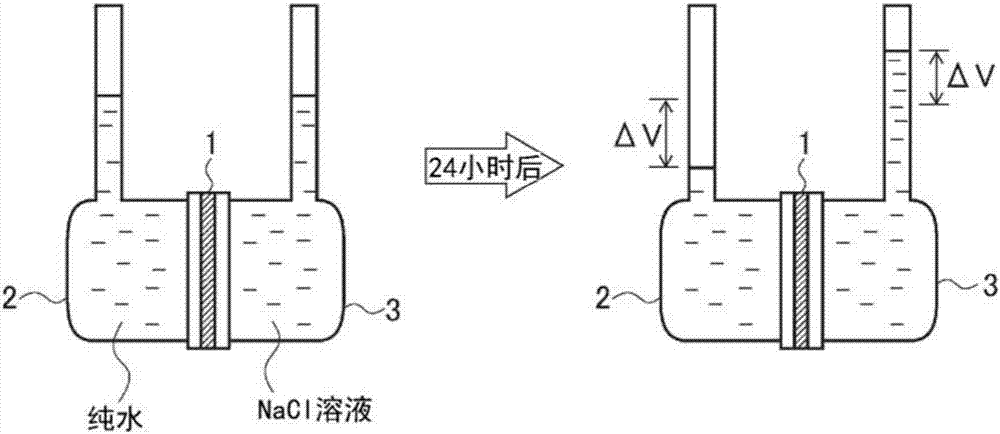

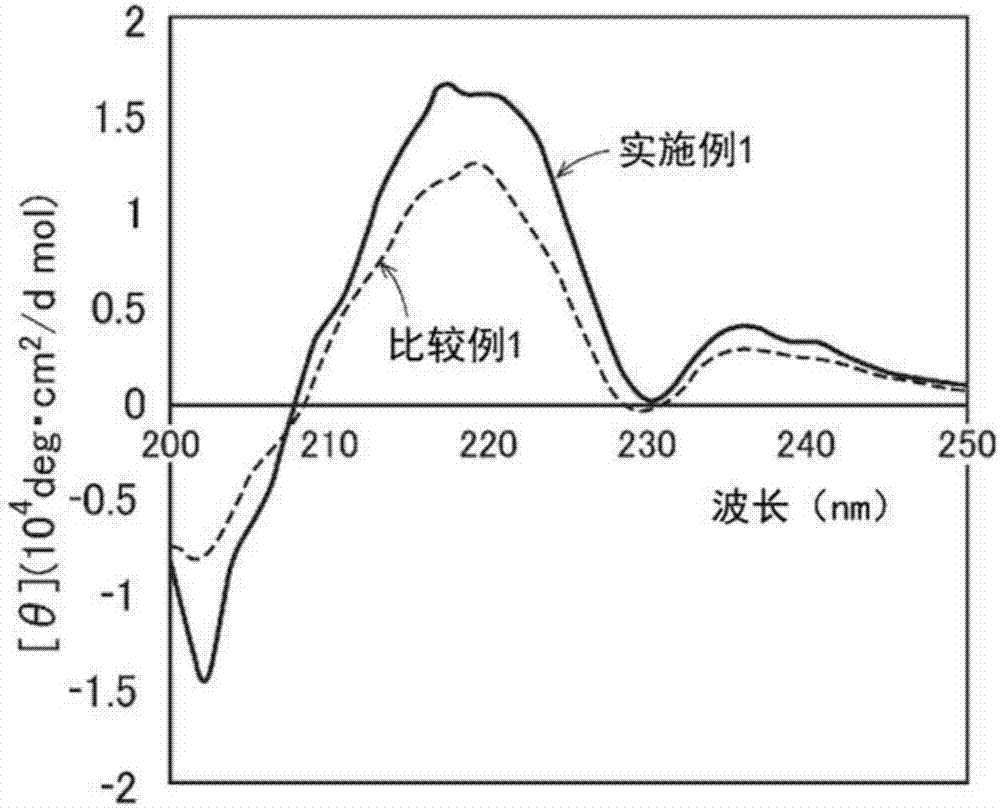

Selective-permeability membrane and method for manufacturing same

ActiveCN107206331AImprove pressure resistanceReduce liquidityMembranesSemi-permeable membranesCarbon numberMembrane bodies

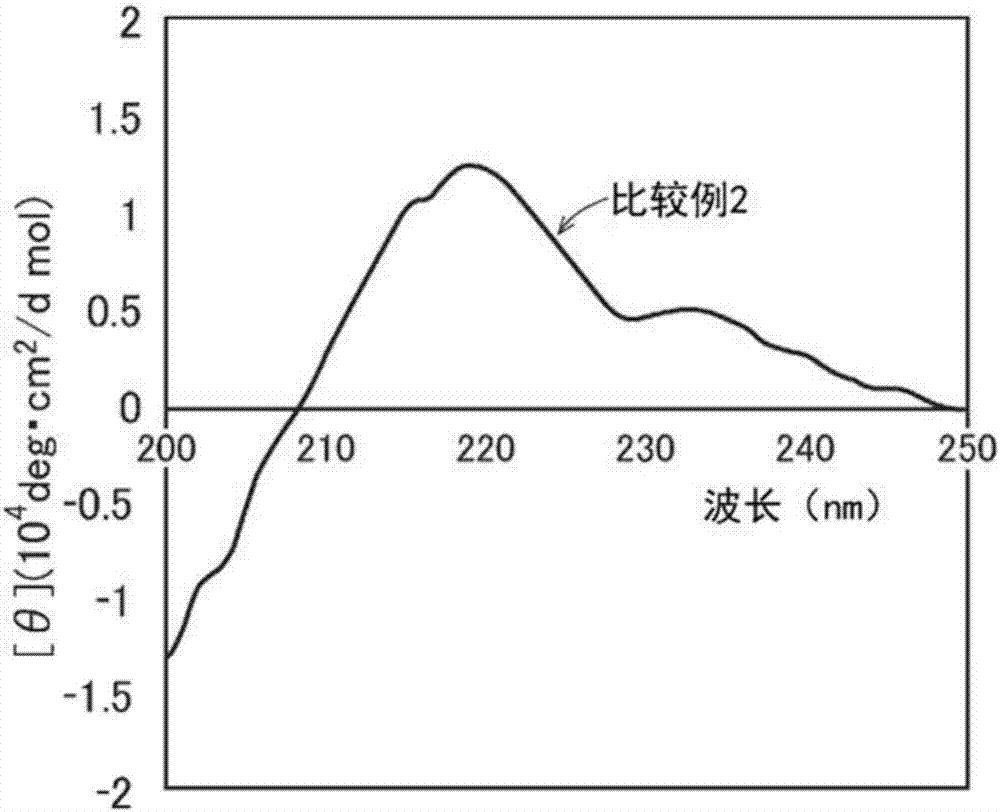

The present invention provides: a selective-permeability membrane which has a coating layer composed of a phospholipid double membrane, the coating layer enduring the pressure applied during water treatment and not detaching; and a method for manufacturing the same. Provided is a selective-permeability membrane that has a membrane body having selective permeability and a coating layer that is formed on a surface of the membrane body and that is composed of a phospholipid double membrane containing a channel material. The selective-permeability membrane is characterized in that the phospholipid double membrane contains, as the phospholipid, a first phospholipid containing an unsaturated fatty acid in an acyl group and a second phospholipid in which two acyl groups comprise a saturated fatty acid with a carbon number of 16-24.

Owner:KURITA WATER INDUSTRIES LTD +1

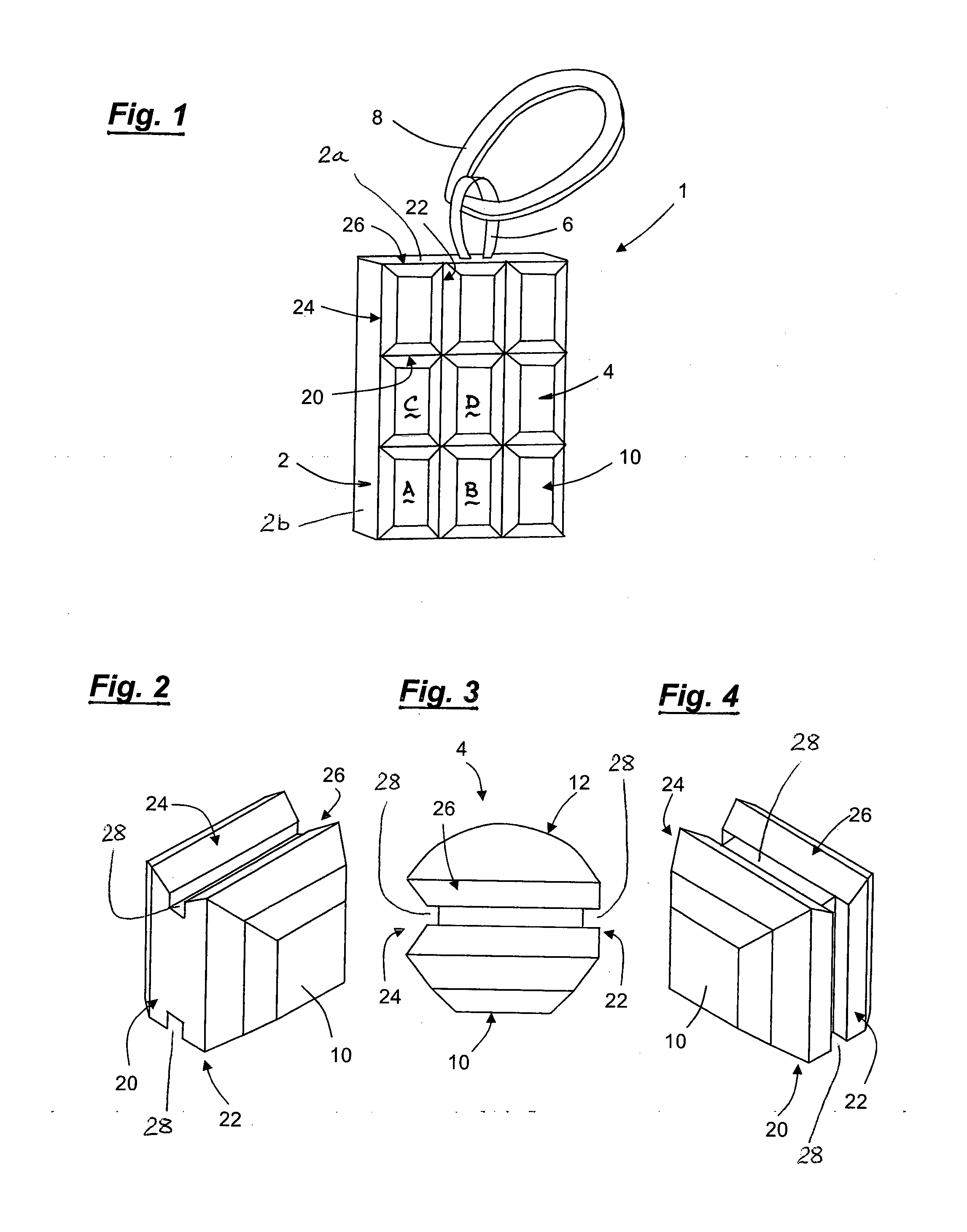

Decorative element comprising a number of stones which are assembled within a closed frame, comprising two decorative faces

ActiveUS20150367675A1Improve presentationSimple and efficientLayered productsOrnamental structuresEngineering

Owner:VAN CLEEF & ARPELS SA

Hydrogen filling hose

ActiveCN114222878AHigh trafficEasy to flow outSynthetic resin layered productsFlexible pipesGrandioso FlowMechanical engineering

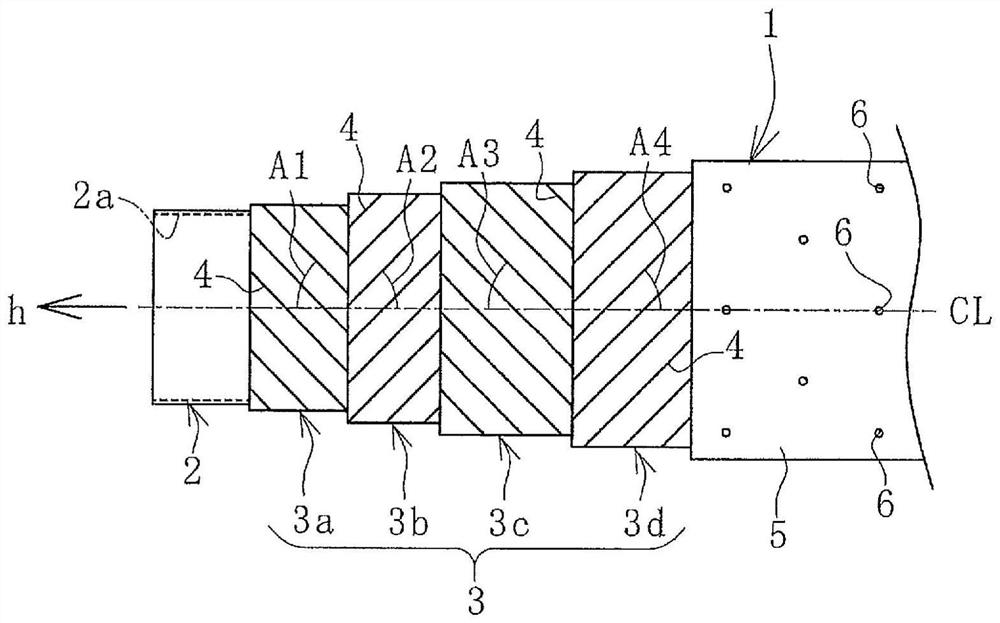

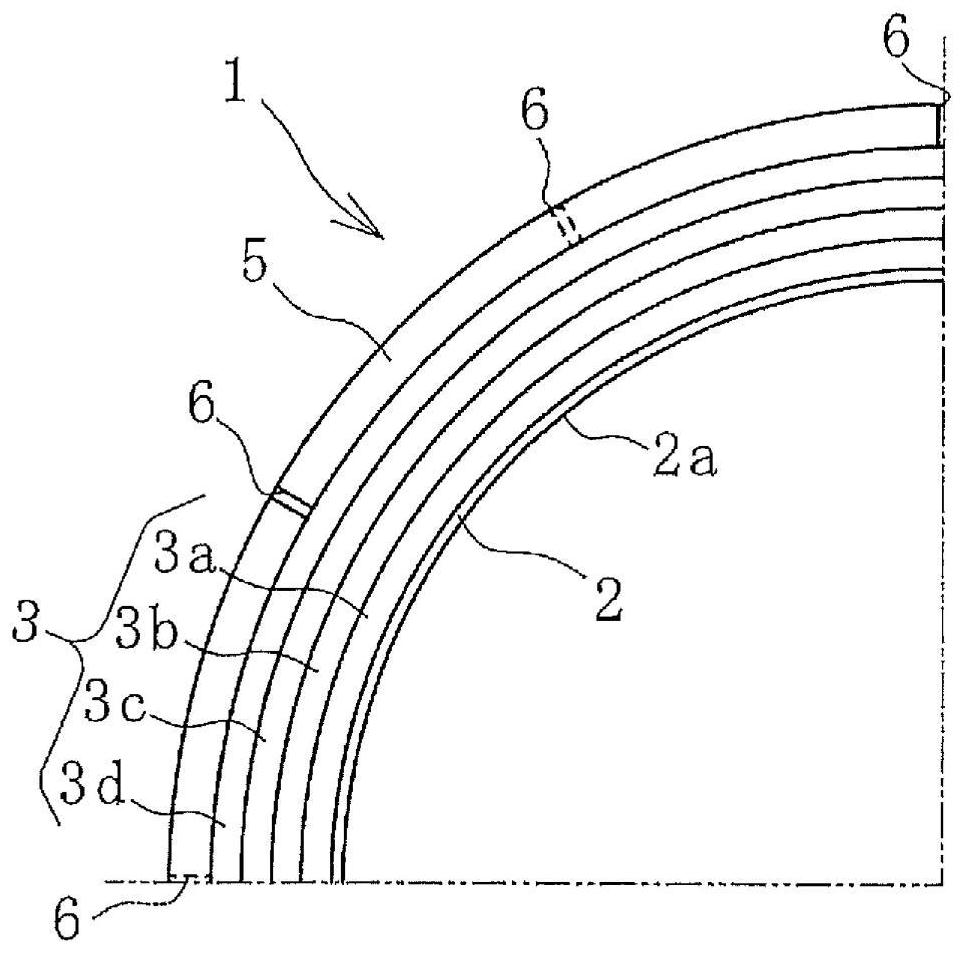

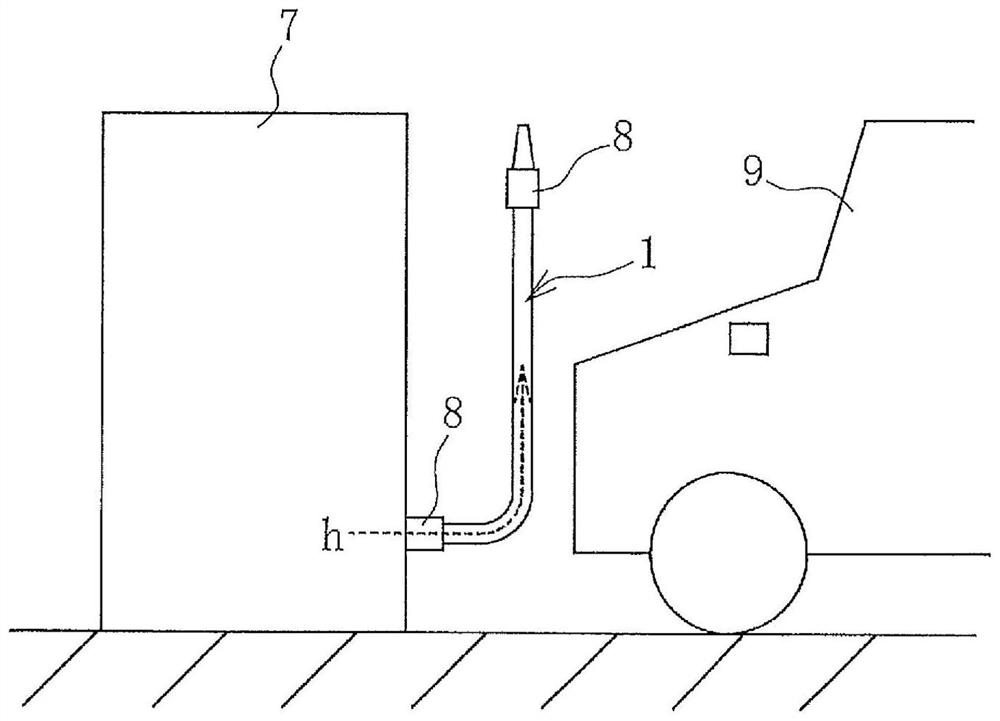

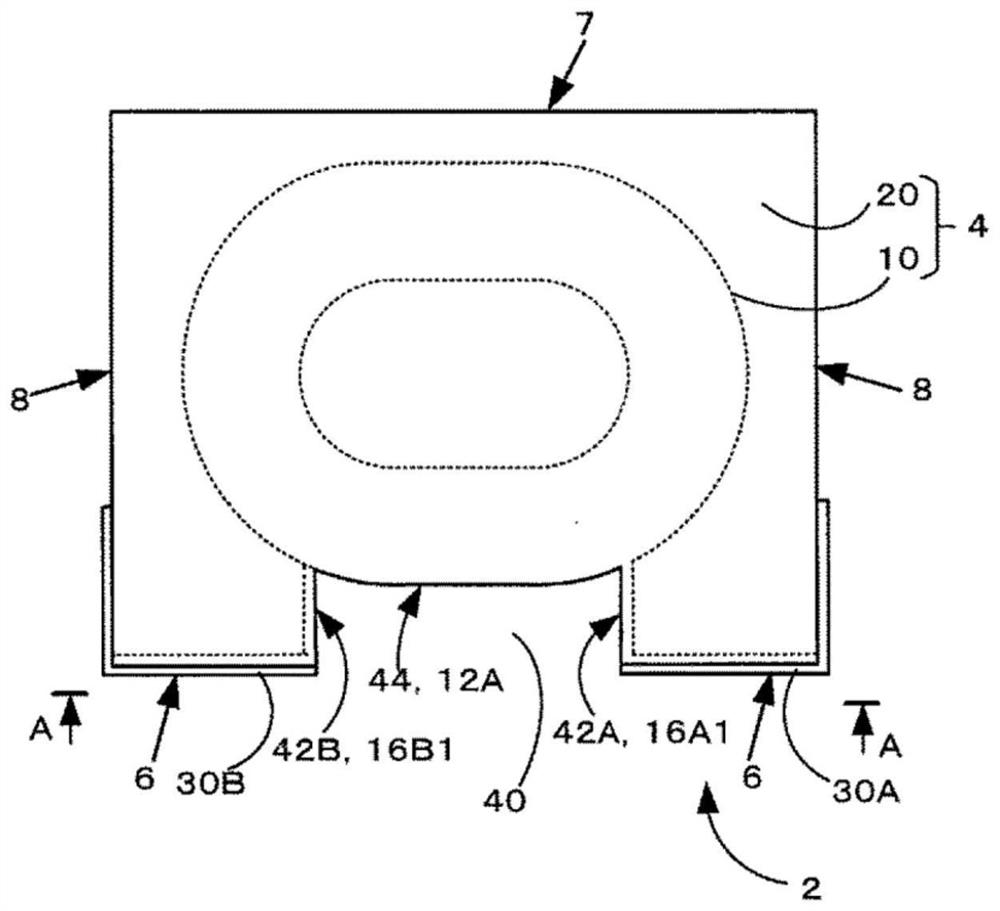

Provided is a hydrogen-filled hose (1) capable of allowing high-pressure hydrogen gas to flow at a greater flow rate. The present invention is characterized by being provided with a reinforcing layer (3) coaxially laminated between an inner surface layer (2) and an outer surface layer (5), the inner surface layer (2) being formed from a thermoplastic resin having a dry hydrogen gas permeation coefficient of 1 * 10-8 cc * cm / cm2 * sec * cmHg or less at 90 DEG C, and the outer surface layer (5) being formed from a thermoplastic resin having a dry hydrogen gas permeation coefficient of 1 * 10-8 cc * cm / cm2 * sec * cmHg or less at 90 DEG C, the reinforcing layer (3) being laminated coaxially between the inner surface layer (2) and the outer surface layer (5). The diameter of a flow path (2a) formed by the inner surface layer (2) is 10-25 mm (inclusive), the number of the reinforcing layers (3) is 4-8 (inclusive), each reinforcing layer (3) has a spiral structure formed by helically winding a metal wire (4), and puncture holes (6) penetrating in the thickness direction are distributed in the outer surface layer (5), so that hydrogen gas h penetrating through the inner surface layer (2) can easily and smoothly flow out to the outside of the hose (1).

Owner:THE YOKOHAMA RUBBER CO LTD

Inductor

ActiveCN112242223ASolve the lack of pressure resistanceTransformers/inductances coils/windings/connectionsTransformers/inductances magnetic coresInductorMechanical engineering

The invention relates to an inductor. The inductor includes an element assembly and a pair of outer electrodes. The element assembly includes a coil and a magnetic body. The coil includes a winding portion in which conductive wires each having a coating layer are spirally wound in two stages connected at their innermost segments and a pair of extension portions extended from their outermost segments in the stages of the winding portion. The magnetic body has a mounting surface, is made of magnetic powder and resin, and seals the coil such that the mounting surface is approximately parallel with a winding axis of the winding portion. The outer electrodes are disposed on the mounting surface. Each of the extension portions includes a first region and a second region. The element assembly hasa recess portion allowing the first regions and an outer surface of the winding portion positioned between the first regions to be exposed.

Owner:MURATA MFG CO LTD

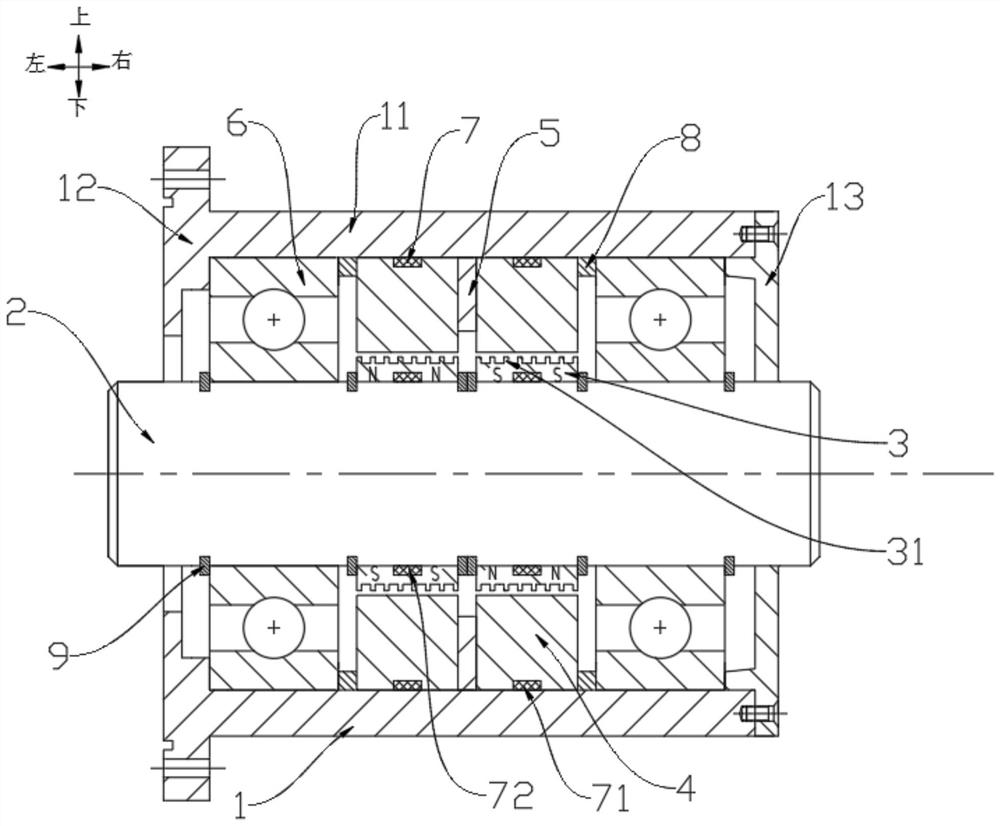

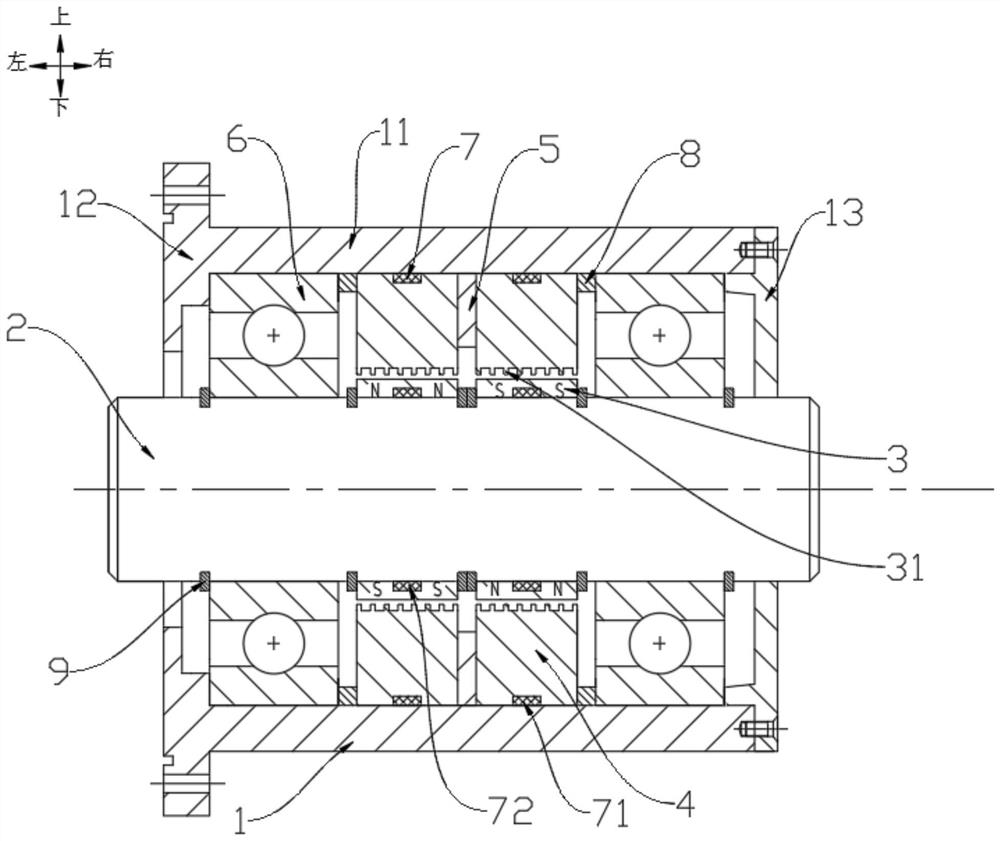

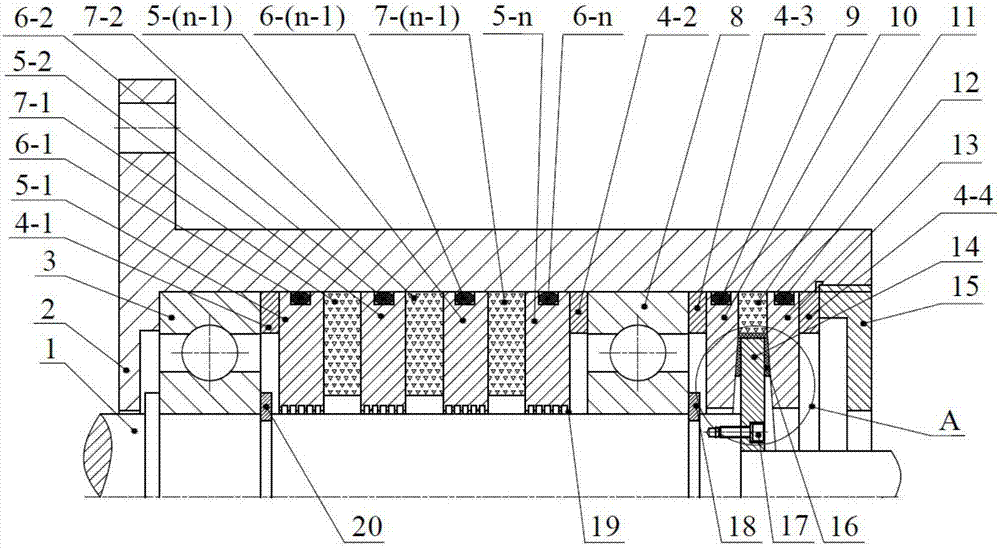

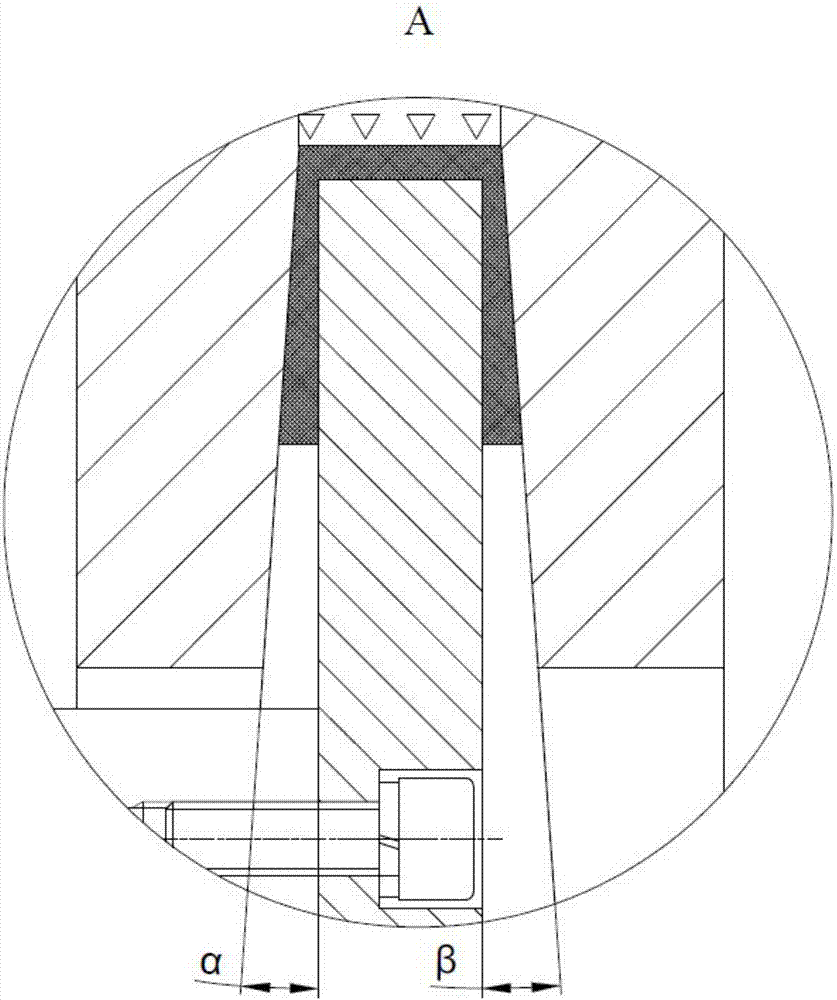

A magnetic liquid sealing device suitable for high linear speed rotating conditions

InactiveCN106594290BIncrease the number of sealing teethSolve the lack of pressure resistanceEngine sealsEngineeringMagnetic liquids

The invention discloses a magnetic liquid sealing device suitable for high-linear-speed rotating working conditions, belongs to the field of sealing of mechanical engineering, in particular, is suitable for sealing under high-linear-speed rotating working conditions, and can solve the problems of weak pressure resistance and lower reliability when the linear speed in the rotating shaft starting process of a traditional magnetic liquid centrifugal sealing structure is lower. The device consists of a rotating shaft (1), a shell (2), a left bearing (3), a first separation magnetic ring (4-1), a first pole shoe (5-1), a first sealing ring (6-1), a first permanent magnet (7-1) and the like. When the rotating shaft (1) rotates at low linear speed, an axial magnetic liquid sealing module achieves a sealing effect; and under the condition of sufficient axial space, the number of axial magnetic liquid sealing teeth can be increased, so that the pressure resistance is improved, the sealing reliability is improved, and the problem of weak pressure resistance in the rotating shaft starting process of the traditional magnetic liquid centrifugal sealing structure is solved.

Owner:BEIJING JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com