Medium-voltage working electrolyte of aluminum electrolytic capacitor and preparation method of medium-voltage working electrolyte

A technology of aluminum electrolytic capacitors and electrolytes, applied in electrolytic capacitors, capacitors, circuits, etc., can solve problems such as high leakage, affecting device life, and large capacity changes, and achieve the effect of ensuring product life and reducing corrosion probability

Inactive Publication Date: 2018-03-30

NANTONG SUNION ELECTRONICS

View PDF8 Cites 9 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] At present, the development of miniaturization of electronic technology also puts forward higher requirements for the miniaturization of components, and the root of the miniaturization of aluminum electrolytic capacitors is that the positive electrode foil has a higher specific surface capacity, which requires more performance of the electrolyte. High, otherwise it will easily cause large capacity changes and high leakage, which will affect the life of the entire device

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

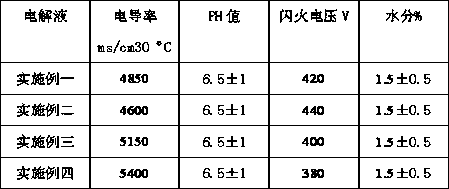

Embodiment 1

[0023]

Embodiment 2

[0025]

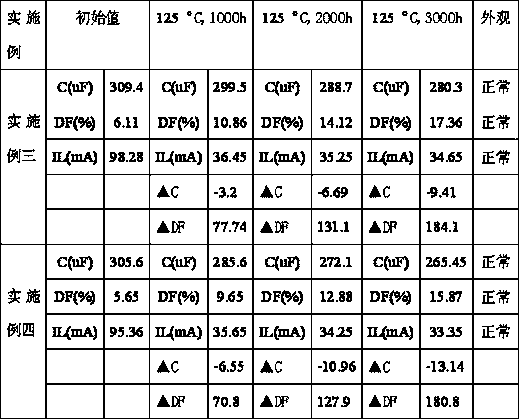

Embodiment 3

[0027]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a medium-voltage working electrolyte of an aluminum electrolytic capacitor. The electrolyte comprises constituents based on ratio by mass: 36.5-78% of main solvent, 3-20% of auxiliary solvent, 8-15% of main solute, 6-17% of auxiliary solute, 0.05-0.3% of waterproof mixture, 2-7% of voltage-resistant promoter, 1.5-3% of formation special modifier and 0.6-1.5% of hydrogen elimination agent, wherein the main solvent is ethylene glycol. A mixed solvent system is employed, high-temperature characteristic is ensured, and low-temperature characteristic is also compatible; theboiling point (245 DEG C) of diethylene glycol is high, the condensation point (-44 DEG C) of Gamma-butyrolactone is low, an appropriate amount of voltage resistant promoter is added, U<flash>=alg Rho+b (V), Rho is resistivity (ohm. cm) of the electrolyte, a and b are relevant constants of the electrolyte, thus, the electrical conductivity of the medium-voltage electrolyte is high to cause that the flash voltage is low, and enough voltage resistant capability can be ensured under the condition of high electrical conductivity by the introduction of the voltage resistant promoter; and moreover,with the addition of a corrosion resistant agent, the corrosion probability during long-term working is reduced, and the lifetime of a product is ensured.

Description

technical field [0001] The invention belongs to the field of capacitor preparation, in particular to a working electrolyte for a 120V-250V long-life medium-voltage aluminum electrolytic capacitor and a preparation method thereof. Background technique [0002] Aluminum electrolytic capacitors are the most widely used basic components in electronic products. With the rapid development of science and technology and the electronic industry, the requirements for various components are further improved, especially for the performance requirements of aluminum electrolytic capacitors. challenge. [0003] The electrolyte is the core component of the aluminum electrolytic capacitor and the actual cathode of the aluminum electrolytic capacitor. The service life, reliability and electrification parameters of the capacitor are closely related to it, and its performance directly affects the quality. [0004] At present, the development of miniaturization of electronic technology also put...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): H01G9/035

CPCH01G9/035

Inventor 陈建华

Owner NANTONG SUNION ELECTRONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com