A kind of working electrolyte of lead wire aluminum electrolytic capacitor and preparation method thereof

An aluminum electrolytic capacitor and electrolyte technology, applied in the direction of electrolytic capacitors, capacitors, circuits, etc., can solve the problems of insufficient power supply, inability to perform normally, and a large voltage fluctuation range, and achieve freedom from hydration reaction, high withstand voltage, Increase the effect of flash voltage

Active Publication Date: 2022-02-15

南通新三能电容器有限公司

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] Under normal circumstances, there are several kinds of civil voltages in the world: 100V, 110V~130V, and 220V~240V. Under normal circumstances, if the power supply line is stable, 200V or 250V electrolysis is enough for 100V~130V line input filter, and 220V~240V The power line of 350V or 400V can be satisfied, but in some countries and regions, due to insufficient power supply, the voltage fluctuation range is particularly large, and the maximum fluctuation of the 220V power supply line even reaches 380V or above. At this time, the electrolysis below 500V cannot work normally. When it is effective, it is necessary to use 550V or even 600V electrolysis to ensure the normal operation of equipment and lighting and to achieve the designed service life

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0025] Ethylene glycol 44 γ-butyl 15 1,5-dodecanate 8.5 1-methyl-1,7 heptane dicarboxylate 3.5 additive 15 Nano-silicaethylene glycol solution 12 Sulfonate 2

Embodiment 2

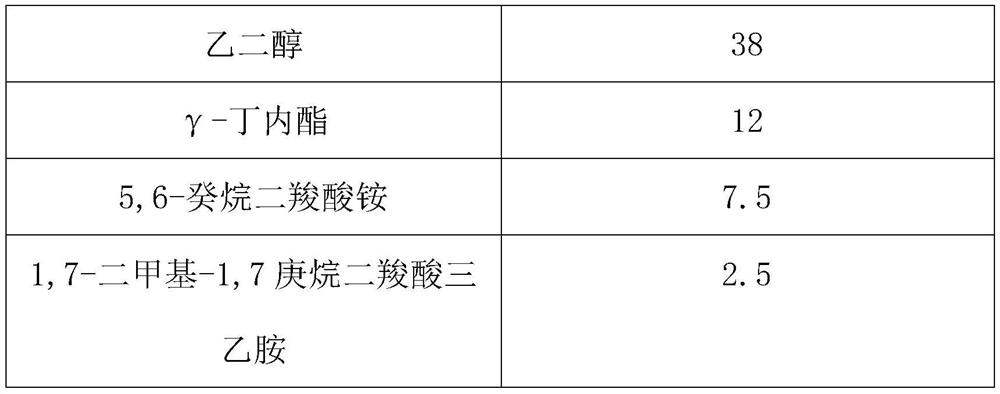

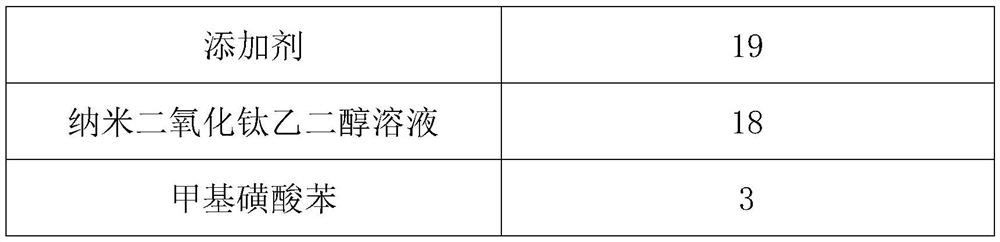

[0027]

[0028]

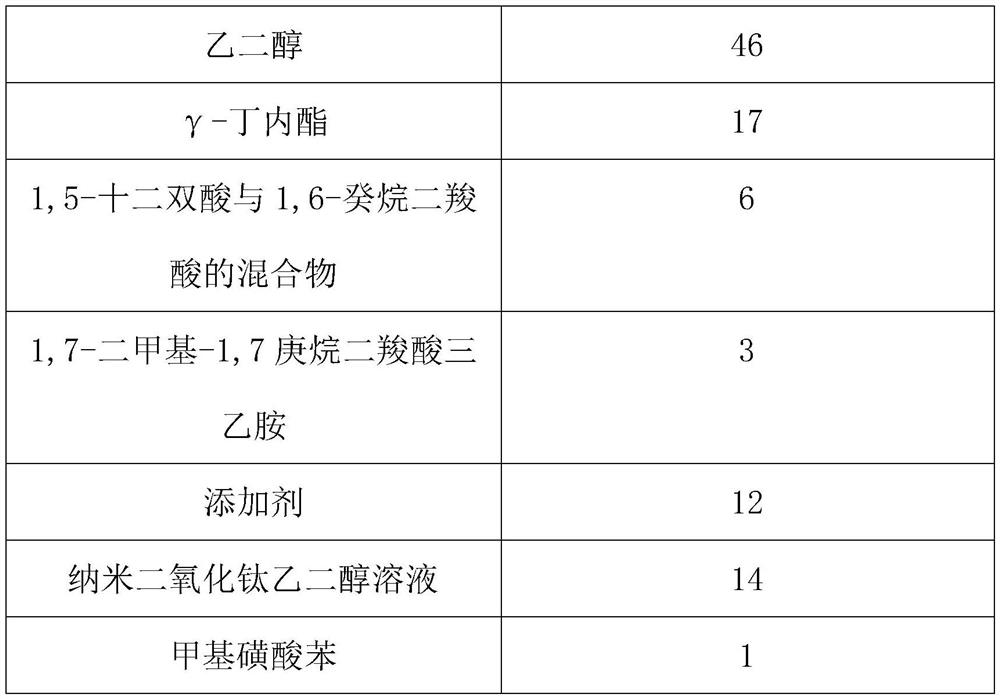

Embodiment 3

[0030] Ethylene glycol 35 γ-butyl 15 1,6-decane dicarboxylic acid 7 1-methyl-1,7 heptane dicarboxylate 2 additive 20 Nano-silicaethylene glycol solution 20 Sulfonate 1

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a working electrolyte for a leaded aluminum electrolytic capacitor, which is composed of the following raw materials in mass percentage: solvent one 30-50%, solvent two 10-20%, solute one 6-9%, solute two 2-4%, Antifouling agent 1-3%, additive 5-20%, pressure-resistant enhancer 8-20%. The preparation method is as follows: add solvent 1 and solvent 2 into the reaction kettle, heat while stirring, add additives when the temperature rises to 120ºC, and continue heating to 140ºC; then add solute 1 and solute 2, and keep at 140ºC for 45 minutes , then lower the temperature of the kettle to 130ºC, add a pressure-resistant enhancer and stir for 30 minutes; finally lower the temperature of the kettle to 110ºC, add an antifouling agent, stir well, and cool naturally to room temperature after 45 minutes to obtain the finished electrolyte. The invention can ensure sufficient pressure resistance in the case of high electrical conductivity, and prevents the aluminum foil from hydration reaction, thus prolonging the service life of the product.

Description

Technical field: [0001] The present invention belongs to the field of capacitor preparation, particularly a 550V to 600V special high pressure long life lead aluminum electrolytic capacitor working electrolyte and its preparation method thereof. Background technique: [0002] At present, the basic effects of aluminum electrolytic capacitors in electronic circuits generally summarize: communication, blocking stream, filter, bypass, coupling, and rapid charge and discharge, and has a small size, high storage capacity, and high cost performance. [0003] Aluminum electrolytic capacitors can be divided into liquid aluminum electrolyte capacitors and solid aluminum electrolytic capacitors depending on the electrolyte morphology; five kinds of lead type, solder needle, solder sheet, bolt, and patch type, and five areas can be divided into line. [0004] According to different aluminum electrolytic capacitors in the application, industrial and special application of aluminum electrolyti...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): H01G9/035

CPCH01G9/035

Inventor 陈建华

Owner 南通新三能电容器有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com