Low leakage current working electrolyte for medium-voltage aluminum electrolytic capacitor and preparation method thereof

An aluminum electrolytic capacitor and electrolyte technology, applied in electrolytic capacitors, capacitors, circuits, etc., can solve the problems of large leakage current and low life, and achieve the effect of reducing freezing point, ensuring high life, and reducing the hydration of aluminum foil.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

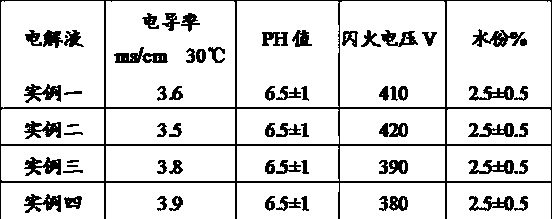

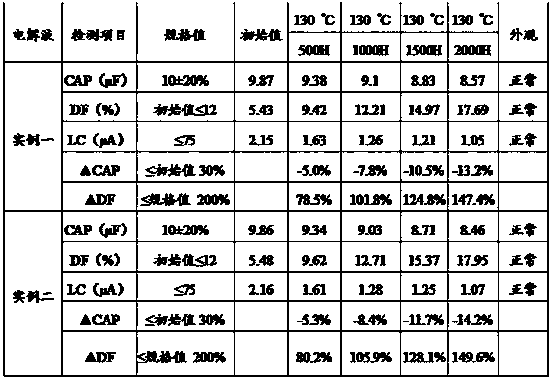

Embodiment 1

[0025] Name Proportion 1. Ethylene glycol (EG) 75 2. Pure water 3.5 3. Polyethylene glycol 6000 2 4. Mannitol 2 5. Ammonium Benzoate 12 6. Ammonium sebacate 5 7. Ethylenediaminetetraacetic acid 1 8. Ammonium hydrogen azelate 2 9. Azelaic Acid 1 10. Ammonium hypophosphite 1 11. p-nitrobenzyl alcohol 1 12. Dinitrobenzoic acid 0.8

Embodiment 2

[0027] Name Proportion 1. Ethylene glycol (EG) 70 2. Pure water 3 3. Polyethylene glycol 6000 1.6 4. Mannitol 1.6 5. Ammonium Benzoate 11 6. Ammonium sebacate 4.5 7. 8-carboxyquinoline 0.9 8. Ammonium hydrogen azelate 1.8 9. Azelaic Acid 0.9 10. Ammonium hypophosphite 0.9 11. p-nitrobenzyl alcohol 0.9 12. Dinitrobenzoic acid 0.7

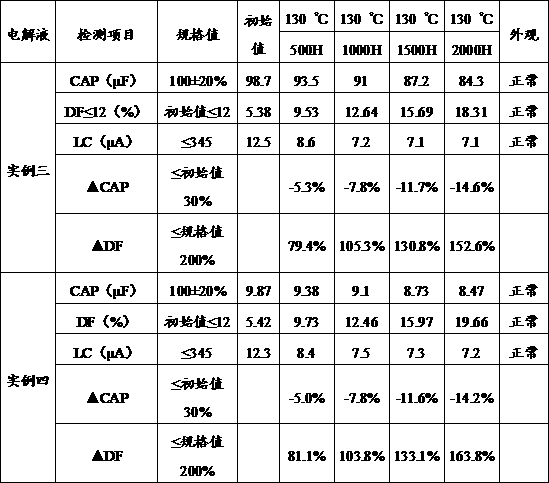

Embodiment 3

[0029] Name Proportion 1. Ethylene glycol (EG) 65 2. Pure water 3 3. Polyethylene glycol 6000 1.8 4. Mannitol 1.8 5. Ammonium Benzoate 10 6. Ammonium sebacate 4 7. Pentaerythritol 0.8 8. Ammonium hydrogen azelate 1.8 9. Azelaic Acid 0.8 10. Ammonium hypophosphite 0.8 11. p-nitrobenzyl alcohol 0.8 12. Dinitrobenzoic acid 0.7

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com