Heat exchanger

一种换热器、换热管的技术,应用在间接换热器、换热器类型、换热器外壳等方向,能够解决增加集管重量、很难减小集管重量等问题,达到减小集管重量、重量轻、减小内部容积的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

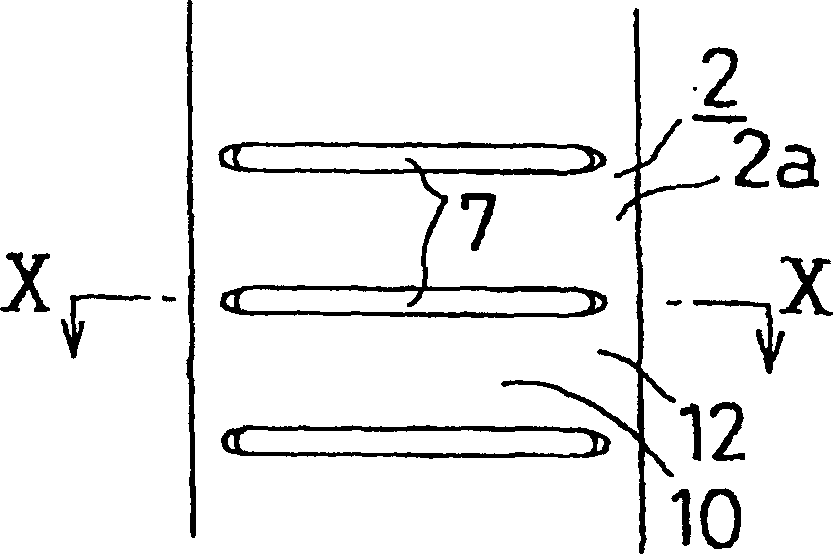

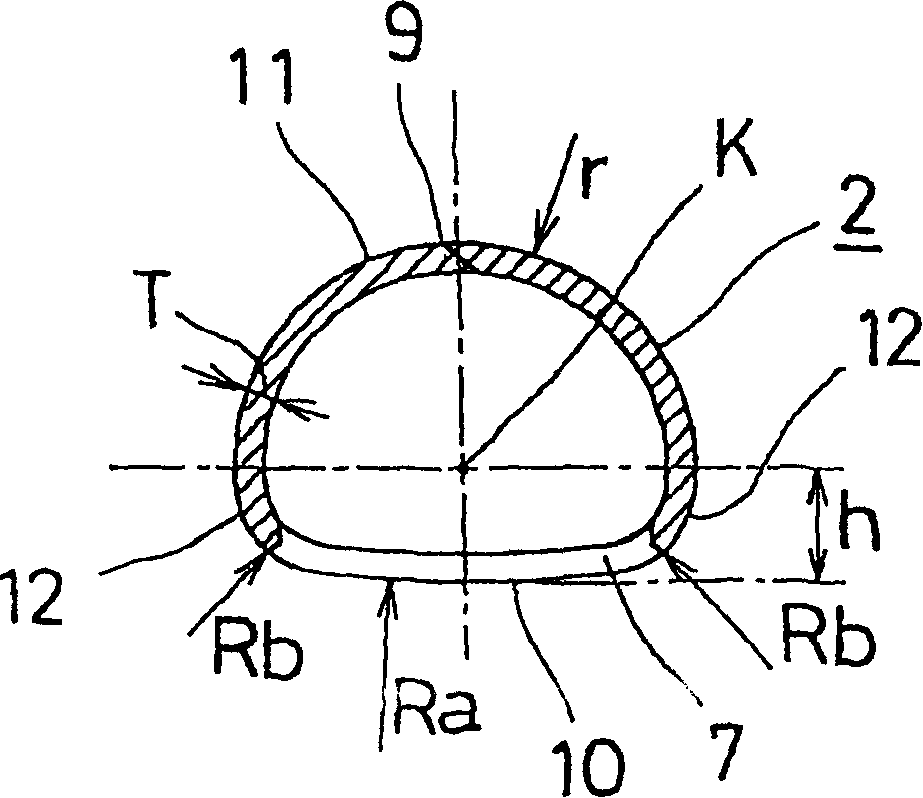

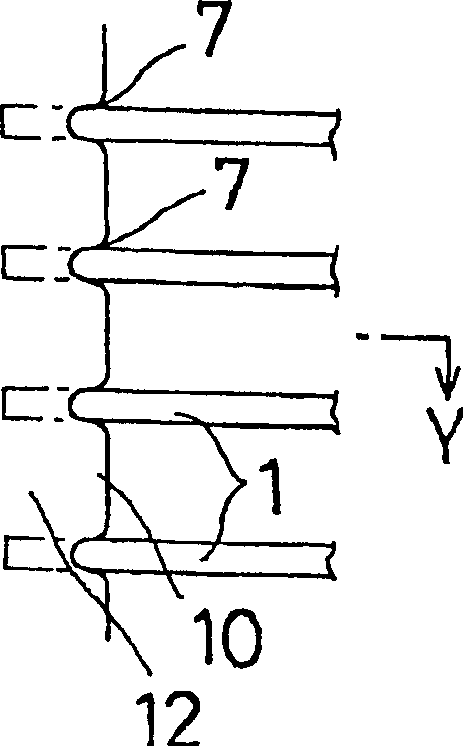

[0058] Prepare hollow headers. The manifold comprises: an inner peripheral wall portion 10 having a substantially flattened arcuate cross-sectional shape to which pipes are connected; an outer peripheral wall portion 11 having a substantially semicircular cross-section shape, and facing the inner peripheral wall portion 10; and connecting curved peripheral wall portions 12 and 12, the connecting curved peripheral wall portions 12 and 12 are connected with the inner peripheral wall portion 10 and the outer peripheral wall portion 11, and the header satisfies the following conditions.

[0059] Then, the condenser shown in Fig. 3 was fabricated using the aforementioned hollow headers.

[0060] Condition A: r=10mm;

[0061] Condition B: Ra=60mm;

[0062] Condition C: Rb=4mm;

[0063] Condition D: h=5mm; and

[0064] Condition E: T=1.3mm

[0065] Assuming a stress of 100% developed in a normal circular header, the stress developed in this header is 163%. Therefore, in this ex...

example 2

[0068] In Example 2, the same structure as Example 1 is used, but the conditions are set as follows:

[0069] Condition A: r=7.94mm;

[0070] Condition B: Ra=50mm;

[0071] Condition C: Rb=4mm;

[0072] Condition D: h=4mm; and

[0073] Condition E: T=1.1mm

[0074] Assuming a stress of 100% developed in a normal circular header, the stress developed in this header is 146%. Therefore, in this example, it was proved that the generated stress can be suppressed to be small and sufficient pressure resistance can be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com