Hollow turbine blade ceramic core removal device based on heat convection principle

A technology of turbine blades and convective heat transfer, applied in the direction of cores, molds, mold components, etc., can solve the problems of no core-off equipment, high environmental isolation requirements, and high equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

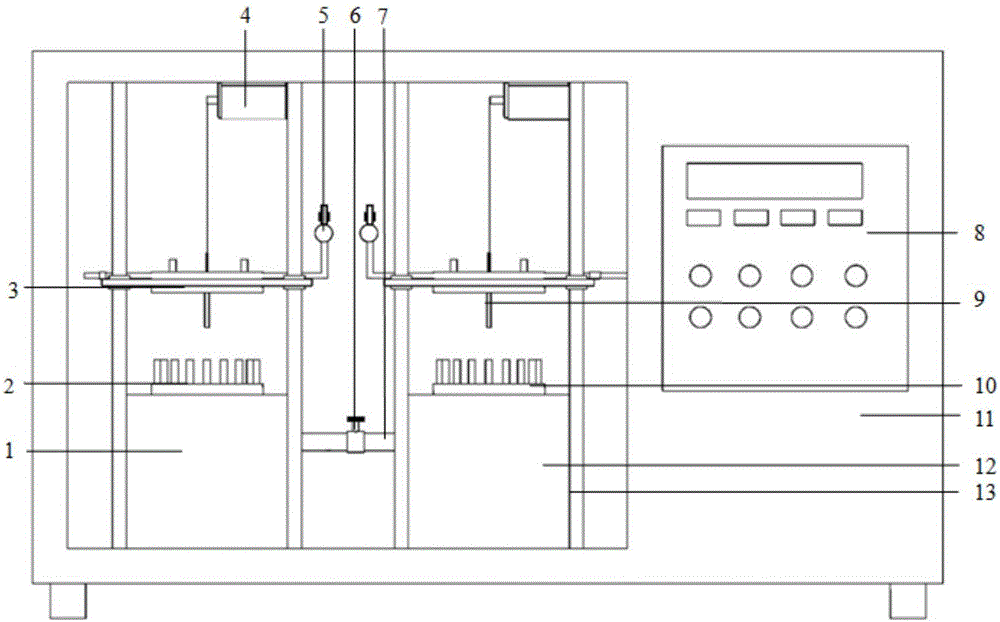

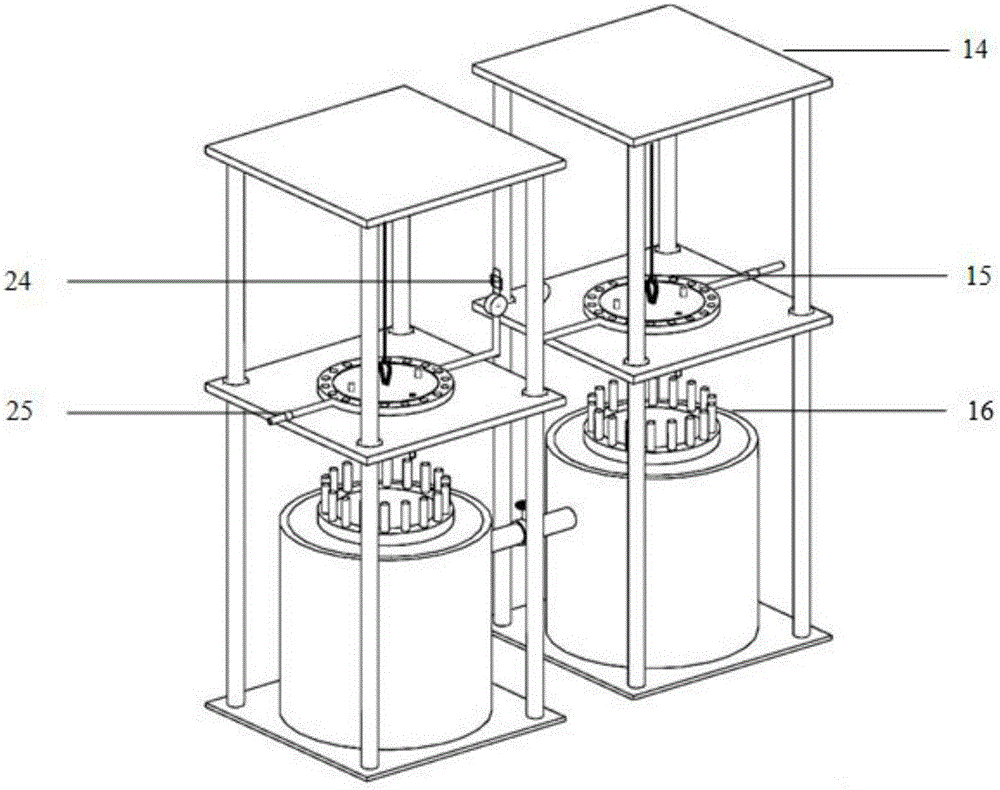

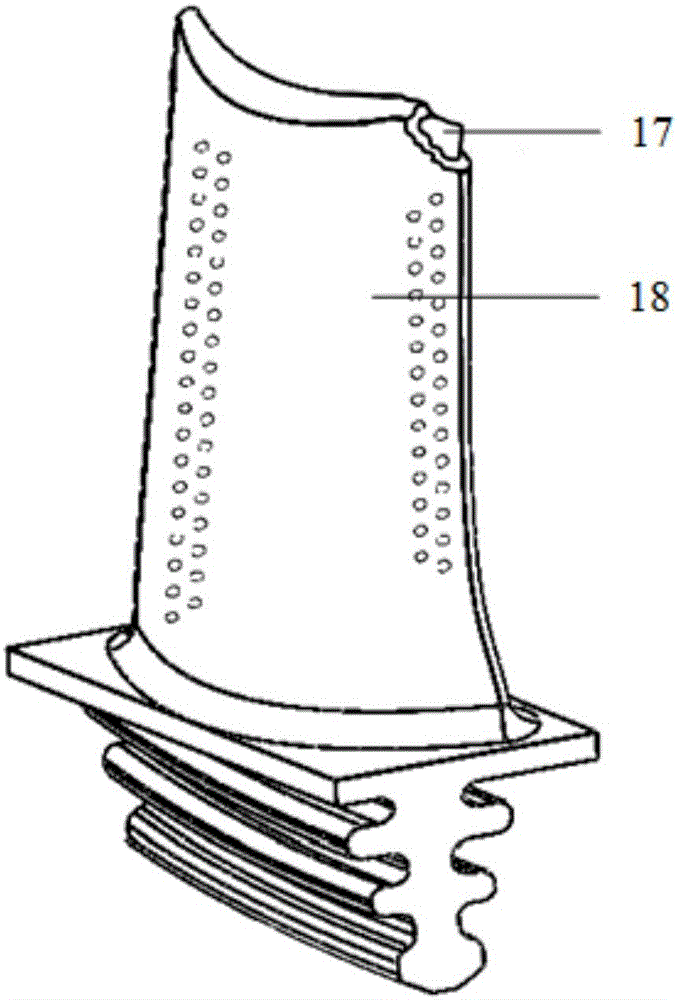

[0031] The invention provides a device for removing the ceramic core of a metal hollow turbine blade. Under high temperature and high pressure conditions, the chemical corrosion method is used to remove the core. The chemical corrosion method uses chemical substances to react with the ceramic core to make the core Dissolution and removal, the external conditions of the chemical corrosion method are formed by the high-temperature and high-pressure environment produced by the coring kettle. The coring kettle can produce a convective effect, causing the corrosive liquid to boil, thereby speeding up the stripping speed. The device consists of two tanks, a pressure tank and a buffer tank, and the inside of the tank forms a closed system. The autoclave and buffer autoclave are filled with leaching ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com