Flat tube making platelike body, flat tube, heat exchanger and process for fabricating heat exchanger

A technology for flat tubes and plate-shaped objects, which is applied to the manufacture of flat tubes and plate-shaped objects to achieve the effects of improving pressure resistance, brazing joint strength, and improving pressure resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] Embodiments of the present invention will be described below with reference to the drawings. In the following description, the upper part, the lower part, the left-hand side and the right-hand side of FIG. 1 will be referred to as "upper", "lower", "left" and "right", respectively. In the drawings, the same parts will be indicated by the same reference numerals.

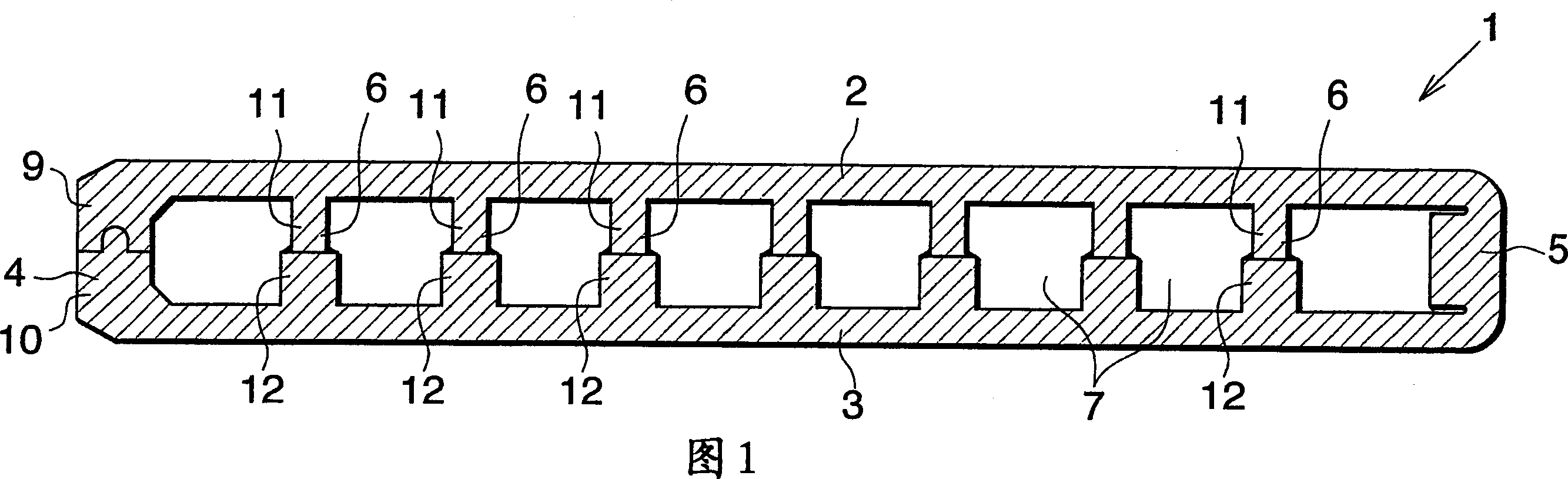

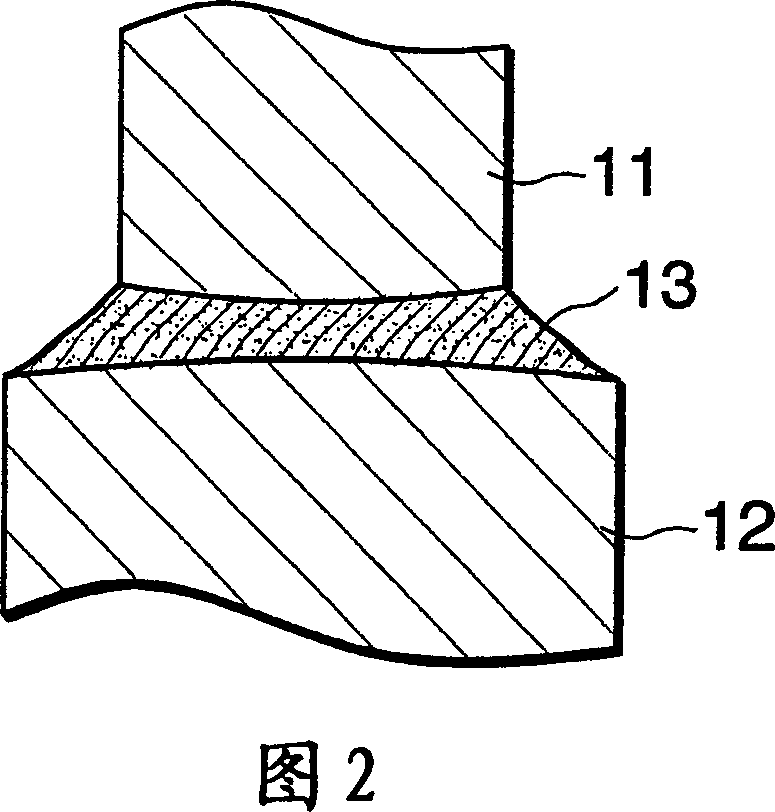

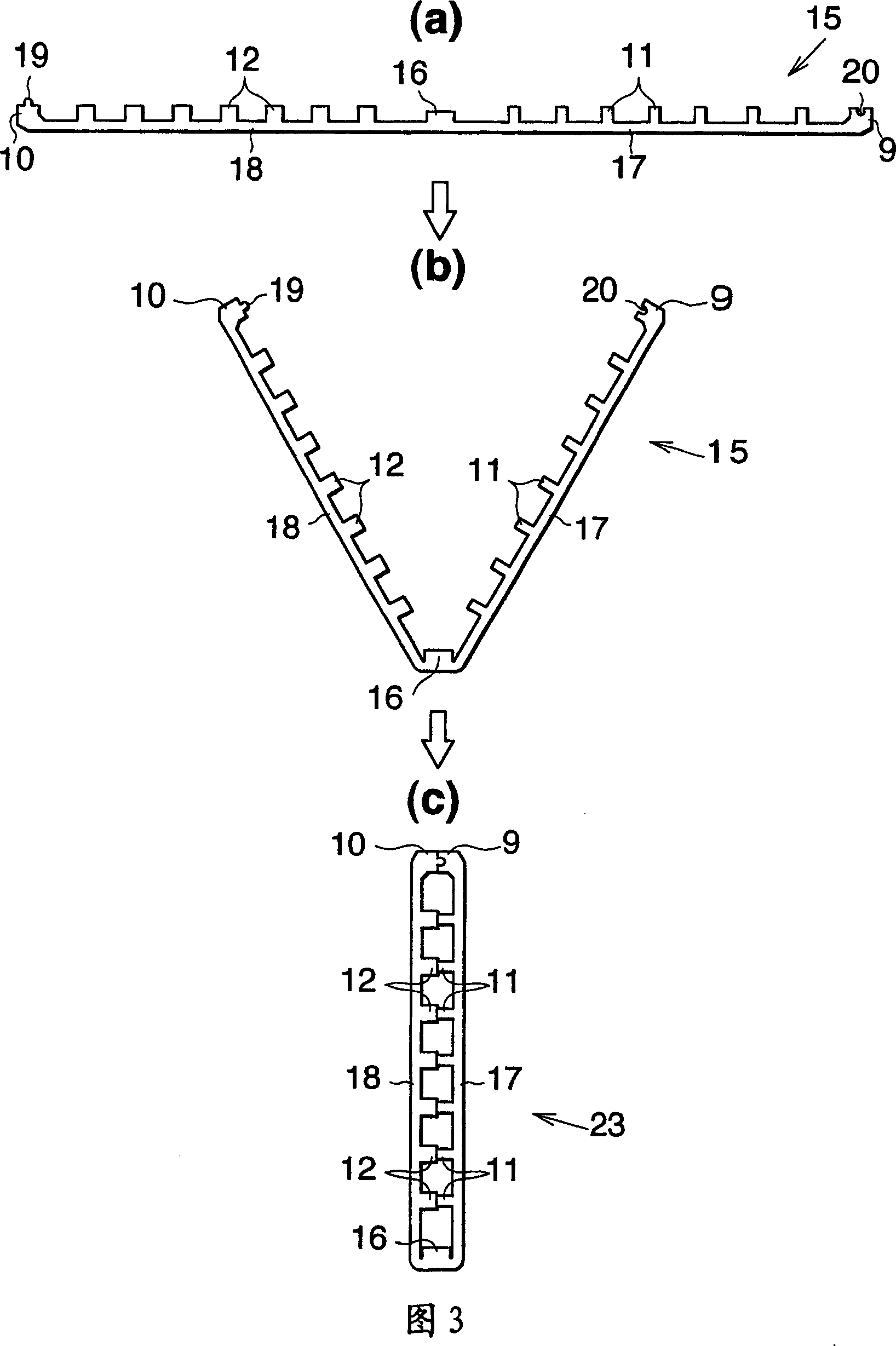

[0067] Fig. 1 shows a flat tube, Fig. 2 is a partial view of the flat tube, Fig. 3 shows steps of a method of manufacturing the flat tube using a plate-shaped body, and Fig. 4 is a partial view of Fig. 3(c).

[0068] Referring to FIG. 1, a flat tube 1 is made of aluminum and includes upper and lower flat walls 2, 3 (a pair of flat walls) opposed to each other so that the upper and lower flat walls 2, 3 are interconnected at their left and right opposite sides. The left and right opposite side walls 4, 5, and a plurality of reinforcing walls 6 interconnecting the upper and lower flat walls 2, 3, the reinforcin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com